Industries rely on large diameter quartz tubes for demanding applications in semiconductor manufacturing, photovoltaics, chemical processing, and advanced optics.

The semiconductor sector leads, accounting for over 40% of the market in 2024, with strong demand from microelectronics, chip fabrication, and automotive electronics.

Chemical, optical, and solar energy applications also require these tubes for high-purity and safety standards.

Property | Description |

|---|---|

High temperature resistance | Handles up to 1100 °C for extended periods |

Corrosion resistance | Withstands harsh chemicals in industrial environments |

Good thermal stability | Maintains structure during rapid temperature changes |

Good light transmission | Supports optical and UV-based applications |

Good electrical insulation | Provides safety in high-voltage and high-frequency settings |

Large-diameter quartz tubes remain indispensable where thermal stability, purity, and safety are critical for consistent results.

Key Takeaways

Large diameter quartz tubes are essential in semiconductor manufacturing, supporting high temperatures and strict purity standards.

Selecting the right tube diameter based on wafer size enhances batch capacity and improves production efficiency.

High purity quartz tubes with low hydroxyl content prevent contamination, ensuring high-quality silicon for photovoltaic applications.

Engineers must match tube dimensions and material grades to specific industrial processes for optimal performance and safety.

Larger quartz tubes provide better thermal stability, reducing energy costs and increasing reliability in demanding environments.

Why Do Semiconductor Wafer Processing Systems Require 250-600mm Diameter Quartz Tubes?

Semiconductor manufacturing relies on large diameter quartz tubes to process silicon wafers at high temperatures. These tubes support advanced applications such as chemical vapor deposition, diffusion, and oxidation. Engineers select tube diameters based on wafer size, batch capacity, and strict purity requirements to ensure safety and maximize production yields.

Wafer Size to Tube Diameter Scaling Requirements

Wafer size directly determines the minimum diameter needed for quartz tubes in semiconductor processing. As wafer dimensions increase from 200mm to 300mm, tube diameters must scale from 250mm up to 600mm to accommodate multiple wafer boats and maintain uniform gas flow. This scaling ensures that each wafer receives consistent thermal treatment, which is essential for device quality.

Larger tube diameters allow manufacturers to process more wafers in each batch, improving throughput and reducing cost per wafer. For example, a 300mm wafer batch may require a 450-500mm tube, supporting up to 150 wafers per cycle. The increased space also helps maintain temperature uniformity within ±3°C, meeting ASTM C1279 standards for advanced semiconductor nodes.

Key Points:

Tube diameter must match wafer size for optimal processing.

Larger tubes enable higher batch capacity and better temperature control.

Proper scaling supports uniformity and high device yields.

Batch Capacity Economics for High-Volume Manufacturing

Manufacturers choose large diameter quartz tubes to boost batch capacity and lower production costs. A tube sized for 300mm wafers can process 2.5 times more wafers per cycle than one sized for 200mm wafers, reducing cost-per-wafer from $28-35 to $12-15. This economic advantage drives the adoption of larger tubes in high-volume facilities.

The relationship between tube diameter and batch size is critical for maximizing efficiency. Facilities transitioning to larger wafers experience a fourfold increase in tube diameter requirements, but the investment pays off through higher throughput and reduced energy consumption. Engineers must balance tube size with gas flow dynamics to avoid process uniformity issues.

Tube Diameter (mm) | Wafer Size (mm) | Batch Capacity | Cost per Wafer ($) |

|---|---|---|---|

300 | 200 | 50-100 | 28-35 |

450-500 | 300 | 75-150 | 12-15 |

Process-Specific Purity and OH Content Requirements

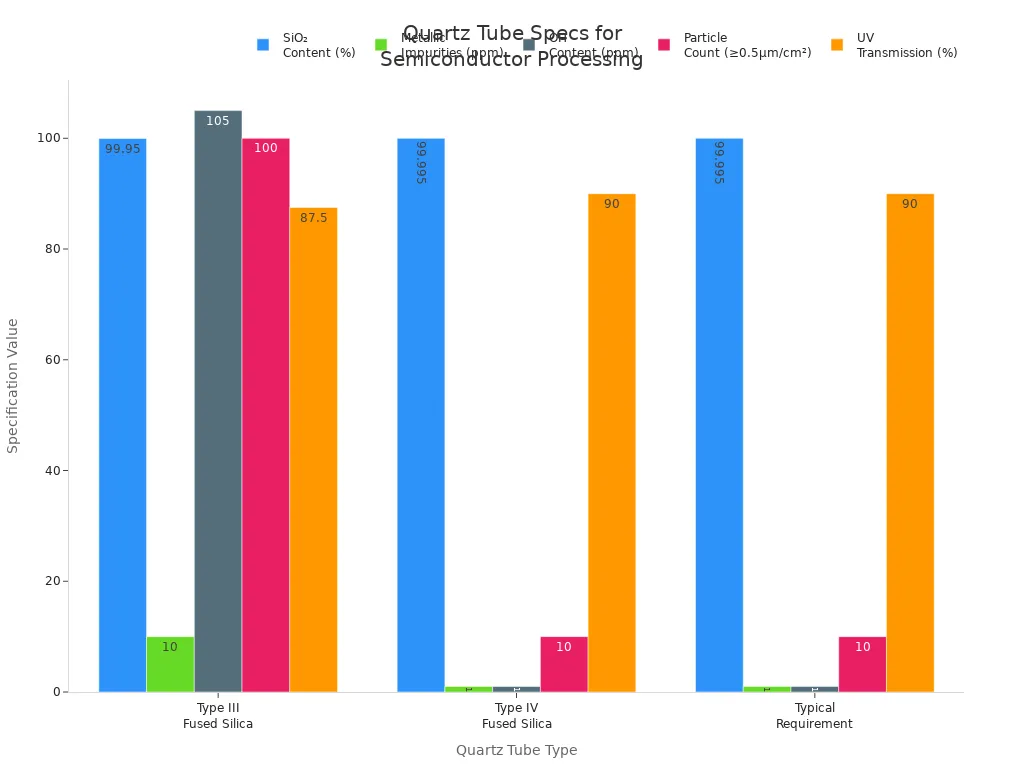

Semiconductor applications demand large-diameter quartz tubes with high purity and controlled OH content. Advanced processes require tubes with SiO₂ content above 99.995% and metallic impurities below 1 ppm to prevent contamination and ensure high wafer yields. Low OH content (<1 ppm) is crucial for sub-10nm device nodes, minimizing devitrification and extending tube service life.

Quartz tubes offer high temperature resistance, corrosion resistance, and chemical stability, making them ideal for harsh processing environments. Their low thermal expansion and high melting point allow them to withstand rapid heating cycles and aggressive chemicals without compromising safety or performance.

Which Photovoltaic Manufacturing Processes Depend on 300-500mm Quartz Tube Dimensions?

Photovoltaic manufacturing uses large diameter quartz tubes to improve efficiency and product quality. These tubes play a vital role in both polysilicon production and monocrystalline silicon growth. Their unique properties support demanding applications that require high temperature resistance, purity, and safety.

Siemens Reactor Throughput Scaling with Tube Diameter

Polysilicon production relies on large diameter quartz tubes to increase reactor throughput. A 400mm tube can process up to 100kg of polysilicon in a single cycle, while a 300mm tube handles only 60kg. This difference reduces energy consumption per kilogram and boosts overall output for facilities producing thousands of tons each year.

Quartz tubes offer high transparency, which allows operators to monitor the process in real time. Thick walls provide mechanical strength, preventing failures under pressure and maintaining safety. The chemical stability of quartz ensures corrosion resistance, extending service life in harsh environments.

Problem Description | Solution Provided |

|---|---|

Opaque materials block observation | High transparency of quartz enables real-time monitoring |

Ordinary tubes fail at high temperatures | Quartz resists up to 1270 °C and maintains purity |

Thin walls risk failure | Thickened walls improve mechanical strength and safety |

Corrosion in harsh environments | Quartz’s chemical stability extends service life |

Czochralski Process Dimensional Requirements for Atmosphere Control

Monocrystalline silicon growth uses large diameter quartz tubes to create a controlled atmosphere around the crucible. The tube diameter must exceed the crucible size by 100-150mm to maintain an inert argon environment. This gap prevents oxygen contamination, which can lower solar cell efficiency below industry standards.

High purity quartz is essential for these applications. Metal impurities must remain below 1 ppm, and ultra-high-purity quartz requires less than 0.1 ppm. Low hydroxyl content, typically under 5 ppm, helps prevent unwanted energy absorption and supports optimal photo-generated carrier generation.

Key Points:

Large diameter quartz tubes maintain atmosphere control for crystal growth.

Purity and low hydroxyl content protect silicon quality.

Proper sizing prevents contamination and supports high efficiency.

Service Life Correlation with Tube Diameter and Material Grade

The service life of large diameter quartz tubes depends on both tube size and material grade. Tubes with diameters above 400mm and electrically fused construction last 45% longer than smaller or flame-fused alternatives. Controlled hydroxyl content minimizes devitrification, reducing the growth rate of cristobalite layers and extending operational periods.

Quartz tubes with high temperature resistance and corrosion resistance withstand continuous use in photovoltaic manufacturing. Facilities report service lives of 24-30 months for large diameter tubes, compared to 16-20 months for smaller ones. This improvement lowers maintenance costs and increases production reliability.

Summary of Key Points:

Larger tube diameters and high-grade quartz extend service life.

Controlled hydroxyl content reduces material degradation.

Longer service life improves reliability and lowers costs.

What Large-Scale Industrial Thermal Processing Systems Utilize 200-400mm Quartz Tubes?

Industrial furnaces use large diameter quartz tubes to process glass, ceramics, and metals at high temperatures. These tubes provide reliable performance in demanding environments where thermal stability and safety matter most. Engineers select tube dimensions and material grades to optimize efficiency and durability for each application.

Rapid Thermal Processing Requirements for Production Efficiency

Large diameter quartz tubes play a vital role in rapid thermal processing systems. These tubes withstand fast temperature changes, which allows manufacturers to heat materials quickly and reduce production time. The ability to reach 900-1100°C in less than 25 minutes improves throughput and lowers energy costs.

Quartz offers high temperature resistance and good thermal stability, making it ideal for repeated heating cycles. Data from industrial furnace installations shows that quartz tubes can reduce annual energy expenses by $8,000-$15,000 per furnace compared to other materials. The tubes also maintain structural integrity during rapid heating, which supports consistent product quality.

Key Points:

Large diameter quartz tubes enable fast heating and cooling cycles.

High temperature resistance and thermal stability improve efficiency.

Manufacturers benefit from lower energy costs and reliable performance.

Heating Zone Length and Diameter Selection for Workpiece Dimensions

Engineers match tube diameter and heating zone length to the size of the workpiece. A tube with a diameter of 250-350mm and a length over 2000mm can accommodate large items and ensure uniform temperature distribution. This design supports consistent results in glass annealing and ceramics sintering.

The wall thickness of large diameter quartz tubes ranges from 1mm to 20mm, depending on pressure and temperature requirements. Tubes with optimized thickness provide stability and minimize weight, which helps maintain safety and process control. The coefficient of thermal expansion remains minimal, allowing tubes to handle drastic temperature fluctuations without cracking.

Specification | Details |

|---|---|

Diameter | 200-400mm |

Wall Thickness | 1mm~20mm, optimized for stability |

Thermal Stability | Up to 1100°C continuous, 1450°C brief |

Thermal Expansion | Minimal, prevents cracking |

Hydrogen Atmosphere Processing Structural Requirements

Hydrogen atmosphere processing demands tubes with high temperature resistance and corrosion resistance. Large diameter quartz tubes provide the necessary protection for the treatment of high temperature acid resistant gases. Engineers select wall thicknesses of 10-12mm with tight tolerances to prevent structural failure under vacuum and pressure loads.

Quartz resists chemical attack and maintains safety in harsh environments. The tubes support continuous operation at temperatures up to 1200°C, which is essential for metal heat treatment and reduction processes. Good thermal stability ensures that tubes endure prolonged use without warping or cracking.

Summary of Key Points:

Large diameter quartz tubes protect against chemical and thermal stress.

Wall thickness and material grade support safety and durability.

Tubes enable reliable processing of high temperature acid resistant gases.

Why Do Optical Manufacturing and Laboratory Systems Specify Large Quartz Tube Dimensions?

Optical manufacturing and laboratory systems rely on large diameter quartz tubes for precision, purity, and performance. These tubes support critical applications such as UV sterilization and crystal growth. Their unique properties ensure defect-free results and long-term reliability in demanding environments.

UV Lamp Diameter Requirements for Sterilization Output

Engineers select large diameter quartz tubes for UV lamps to maximize sterilization output. The diameter of the tube influences how UV light disperses, affecting the irradiation strength on the target area. Larger tubes allow for higher throughput in industrial water treatment and surface sterilization, but they also require careful design to maintain effective disinfection.

Studies show that UV lamps emit light from a point source, which spreads in all directions. This scattering means that increasing the tube diameter can reduce the actual irradiation strength, making it important to balance size with output efficiency. Facilities often choose tube diameters between 150mm and 300mm to optimize both coverage and intensity for sterilization applications.

Key Points:

Larger tube diameters increase sterilization throughput.

Light scattering requires careful diameter selection for effective output.

Tube size impacts both coverage and efficiency in UV lamp applications.

Crystal Growth Chamber Sizing for Crucible Accommodation

Large diameter quartz tubes serve as growth chambers for synthetic crystals and optical materials. The tube must accommodate the crucible size, providing enough space for atmosphere control and temperature uniformity. Manufacturers often specify diameters from 200mm to 350mm, ensuring the chamber exceeds the crucible by 100-150mm for optimal results.

The following table summarizes important features for crystal growth chambers:

Feature | Description |

|---|---|

Purity | >99.98% |

Dimensional Accuracy | Exceptional accuracy for precise crystal growth |

Length | Customizable from 50mm to over 5 meters |

Extreme resistance to chemicals and thermal shock | |

Applications | Ideal for lab analysis, optical fiber systems, and cleanroom use |

Manufacturers achieve higher yields and better crystal quality by matching tube dimensions to process requirements. The right chamber size supports contamination-free environments and consistent temperature control.

Optical Quality Material Requirements for Defect-Free Processing

Optical manufacturing demands large diameter quartz tubes with exceptional purity and transparency. These tubes must meet strict standards for SiO₂ content, light transmission, and thermal stability. High optical quality ensures defect-free processing for laboratory analysis and advanced optical equipment.

Data shows that tubes with SiO₂ content above 99.99% and ultra-high transmittance over 92% in the UV to IR band deliver superior results. Chemical inertness and low thermal expansion protect against acid and alkali exposure, except for hydrofluoric acid. These properties guarantee reliable performance in optical fiber systems and chromatography.

Key Points:

High purity and transparency support defect-free processing.

Strict standards for SiO₂ content and light transmission ensure quality.

Chemical inertness and thermal stability protect against harsh conditions.

How Should Engineers Match Tube Diameter to Specific Industrial Application Requirements?

Engineers must select large diameter quartz tubes based on the specific needs of each industrial process. The right tube diameter, wall thickness, and material grade ensure optimal performance, enhanced safety, and long service life. Careful matching of these parameters supports reliable operation in environments with high temperatures, pressure, and corrosive gases.

Application-Specific Diameter Calculation Methods

Process temperature, pressure, and chemical exposure play a critical role in determining the appropriate diameter for quartz tubes. High temperatures can cause deformation, so engineers must consider both the operating environment and the required electrical insulation performance. For example, semiconductor furnaces processing wafers at 1100°C need tubes with diameters scaled to batch size and gas flow requirements.

Engineers use formulas and industry standards to calculate the minimum diameter. They factor in workpiece dimensions, clearance for uniform heating, and the need for high voltage and high frequency insulation tube properties. Tubes with inner diameters ranging from 10mm to 190mm allow for tailored solutions, supporting a wide range of furnace designs and high-temperature acid-resistant gas combustion applications.

Key Points:

Diameter selection depends on process temperature, pressure, and chemical exposure.

Calculations must include workpiece size and insulation requirements.

Tailored diameters support diverse industrial applications.

Wall Thickness Structural Design Guidelines

Wall thickness directly affects the mechanical strength and service life of quartz tubes. Thicker walls provide greater structural integrity and pressure resistance, which is essential for processes involving high voltage and high frequency insulation tube performance. Thinner walls handle rapid temperature changes better, improving thermal shock resistance and heat transfer.

Engineers balance these factors by selecting wall thicknesses that match the demands of each application. For example, tubes used in hydrogen atmosphere processing often require 10-12mm thickness with tight tolerances to prevent failure under vacuum or pressure. The choice of thickness also impacts optical properties, as thicker walls may slightly reduce UV transmission.

Aspect | Impact of Wall Thickness |

|---|---|

Mechanical strength | Greater integrity and pressure resistance |

Thermal shock resistance | Thinner walls handle rapid changes better |

Optical properties | Thicker walls may reduce UV transmission |

Heat transfer | Thinner walls allow faster heat transfer |

Material Grade Selection by Operating Temperature Range

Material grade selection ensures quartz tubes perform reliably under extreme conditions. Standard fused quartz suits general industrial use up to 1050°C, while low-OH fused and extreme purity grades excel in high-temperature and corrosive environments. High-purity quartz with low hydroxyl content provides superior electrical insulation performance and resists devitrification.

Engineers evaluate operating temperature, thermal cycling frequency, and chemical compatibility when choosing material grades. Certified test data, such as ASTM C1525, guides decisions for applications requiring enhanced safety and durability. High-purity and low-hydroxyl grades support semiconductor fabrication and aerospace, where service life and performance are critical.

Summary Table: Material Grades for Quartz Tubes

Grade Type | Recommended Temp (°C) | Max Cycle ΔT (°C) | OH- Content (ppm) | Application Focus |

|---|---|---|---|---|

Standard Fused | 900–1050 | 700–800 | >100 | General industrial |

Low-OH Fused | 1050–1200 | >1000 | <10 | High temp/optical |

Extreme Purity | 1150–1250 | >1200 | <1 | UHV, semiconductor |

Large diameter quartz tubes play a vital role in semiconductor manufacturing, thermal processing, pharmaceuticals, optics, and electronics. Each application depends on the right tube size, purity, and material grade to achieve high product quality and safety. Proper tube selection reduces material waste, improves flow efficiency, and lowers replacement costs. When engineers match tube specifications to process needs, they help companies increase reliability and maintain consistent results across demanding environments.

FAQ

What industries use large-diameter quartz tubes above 200mm?

Semiconductor, photovoltaic, glass, ceramics, and optical manufacturing industries use large-diameter quartz tubes. These sectors require tubes for high-temperature processing, purity, and batch efficiency. In 2024, semiconductor applications account for over 40% of total demand.

What determines the correct tube diameter for an application?

Engineers select tube diameter based on workpiece size, batch capacity, and process temperature. For example, a 300mm wafer batch needs a 450-500mm tube. Proper sizing improves throughput and maintains temperature uniformity within ±3°C.

What purity levels do advanced applications require?

Semiconductor and optical processes require quartz tubes with SiO₂ purity above 99.995%. Metallic impurities must remain below 1 ppm. Low hydroxyl content, often under 5 ppm, extends tube service life and prevents contamination.

What is the typical service life of large-diameter quartz tubes?

Facilities report service lives of 24-30 months for tubes above 400mm diameter. Electrically fused quartz tubes last 45% longer than flame-fused alternatives. Controlled hydroxyl content reduces devitrification, supporting longer operational periods.

What safety features do large-diameter quartz tubes provide?

Quartz tubes offer high temperature resistance, corrosion protection, and electrical insulation. Wall thicknesses of 10-12mm prevent structural failure under vacuum or pressure. These features ensure safe operation in hydrogen atmosphere and high-voltage environments.