Keeping quartz glass clean is essential for maintaining its optical clarity and functional performance in demanding environments.

To clean quartz glass effectively, use approved chemicals, follow step-by-step procedures, and verify results with quality checks. Always prioritize safety and adapt methods to your specific application.

Quartz glass cleaning is more than a routine task—it's a critical process that impacts product lifespan, measurement accuracy, and operational safety. This guide provides actionable steps and expert insights for laboratory, industrial, and commercial users.

What Safety Protocols Are Required for Cleaning Quartz Glass?

Safety is the foundation of any quartz glass cleaning operation.

Always wear appropriate PPE, ensure proper ventilation, and prepare for chemical emergencies before starting any cleaning procedure.

Strict adherence to safety protocols protects both personnel and equipment from chemical exposure and accidents. Consider this: even a minor spill of concentrated acid can cause severe injury or equipment damage.

Quartz Glass Cleaning Safety Requirements

| Safety Aspect | Key Requirement | Application Context |

|---|---|---|

| PPE | Nitrile gloves, goggles, lab coat | All cleaning operations |

| Ventilation | Fume hood or exhaust system | Acid/base cleaning |

| Emergency Response | Eyewash station, spill kit, neutralizer | All chemical handling |

Personal Protective Equipment (PPE) Requirements

PPE1 is non-negotiable. Always use chemical-resistant gloves, safety goggles, and a lab coat. For industrial-scale cleaning, consider face shields and chemical aprons.

Chemical Handling & Ventilation Standards

Work in a well-ventilated area or under a fume hood. Store chemicals in labeled containers and never mix incompatible substances. Ensure all staff are trained in chemical handling protocols.

Emergency Response Procedures

Know the location of eyewash stations and emergency showers. In case of a spill, use neutralizing agents and follow your facility's emergency plan. Immediate action can prevent escalation.

What Is the Step-by-Step Methodology for Cleaning Quartz Glass?

A structured cleaning process ensures consistent results and minimizes contamination risk.

Start with routine maintenance, escalate to deep cleaning as needed, and tailor treatments to specific contaminants.

Following a standardized methodology reduces errors and extends the service life of quartz glass components.

Quartz Glass Cleaning Procedures Overview

| Step | Purpose | Frequency/Trigger |

|---|---|---|

| Routine Maintenance | Remove light residues | Daily/Weekly |

| Deep Cleaning | Eliminate stubborn deposits | Monthly or as needed |

| Contaminant-Specific | Targeted removal (e.g., organics) | After specific exposures |

Routine Maintenance (Daily/Weekly)

Routine cleaning involves rinsing with deionized water, wiping with lint-free cloths, and drying with filtered air. This prevents buildup and maintains surface integrity.

Comprehensive Deep Cleaning

Deep cleaning uses chemical baths (e.g., nitric acid, hydrogen peroxide) and ultrasonic agitation to remove embedded contaminants. Always follow manufacturer guidelines for concentration and exposure time.

Contaminant-Specific Treatment

For organic residues, use oxidizing agents. For inorganic deposits, apply acid soaks. For particulates, ultrasonic cleaning2 is most effective. Always verify compatibility before applying any treatment.

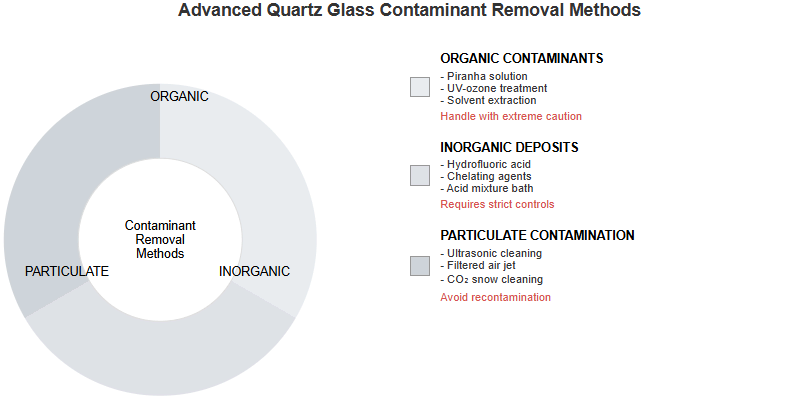

How Can Advanced Contaminant Removal Be Achieved for Quartz Glass?

Some contaminants require specialized removal techniques beyond standard cleaning.

Organic, inorganic, and particulate contaminants each demand tailored approaches for effective elimination.

Advanced removal ensures that even trace residues do not compromise performance in sensitive applications.

Advanced Contaminant Removal Techniques

| Contaminant Type | Recommended Method | Notes |

|---|---|---|

| Organic | Piranha solution, UV-ozone | Handle with extreme caution |

| Inorganic | Hydrofluoric acid, chelating agents | Requires strict controls |

| Particulate | Ultrasonic cleaning, filtered air | Avoid recontamination |

Organic Residue Removal

Use piranha solution (sulfuric acid + hydrogen peroxide) or UV-ozone treatment3 for stubborn organic films. Always follow strict safety protocols due to the reactive nature of these methods.

Inorganic Deposit Treatment

Hydrofluoric acid is effective for silicate and mineral deposits but poses significant health risks. Only trained personnel should use it, and always in a controlled environment.

Particulate Contamination Solutions

Ultrasonic cleaning dislodges fine particles from surfaces and crevices. Use filtered air or nitrogen to dry and prevent new contamination.

What Chemicals Are Compatible with Quartz Glass Cleaning?

Chemical compatibility is crucial to prevent damage and ensure effective cleaning.

Only use chemicals approved for quartz glass, and be aware of substances that can cause etching or clouding.

Consult manufacturer databases and industry standards before introducing new chemicals into your cleaning process.

Approved Chemicals for Quartz Glass Cleaning

| Chemical | Application | Notes |

|---|---|---|

| Nitric Acid (HNO₃) | General cleaning | Avoid prolonged exposure |

| Hydrogen Peroxide | Organic removal | Use in combination with acid |

| Hydrochloric Acid | Metal ion removal | Rinse thoroughly afterward |

| Deionized Water | Rinsing | Always final rinse |

Approved Chemicals Database

Maintain a list of chemicals tested and approved for quartz glass. Update regularly based on supplier recommendations and new research.

Prohibited Substances List

Avoid strong alkalis (e.g., sodium hydroxide), fluorides (unless specifically required), and abrasive powders. These can etch or scratch the glass surface.

Temperature-Dependent Reactions

Some chemicals react differently at elevated temperatures. For example, acid etching rates increase with heat. Always monitor temperature and adjust exposure times accordingly.

How Can Equipment Be Optimized for Quartz Glass Cleaning?

The right equipment enhances cleaning efficiency and consistency.

Select ultrasonic cleaners, racks, and drying systems tailored to your quartz glass geometry and contamination profile.

Equipment optimization reduces manual handling, minimizes breakage, and ensures uniform results.

Equipment Optimization for Quartz Glass Cleaning

| Equipment Type | Key Feature/Spec | Application Context |

|---|---|---|

| Ultrasonic Cleaner | Frequency (40–80 kHz), power | Particle removal |

| Custom Racks | Material compatibility, design | Secure holding, drainage |

| Drying System | HEPA filtration, temp control | Prevents recontamination |

Ultrasonic Cleaner Selection

Choose a cleaner with adjustable frequency and sufficient power for your load size. Higher frequencies are better for delicate items.

Custom Rack Design Principles

Use racks made from PTFE or quartz to avoid cross-contamination. Design for easy drainage and minimal contact points.

Drying System Configuration

HEPA-filtered drying cabinets or nitrogen blow-off systems4 prevent airborne particulates from settling on clean surfaces.

What Quality Assurance Protocols Ensure Cleanliness of Quartz Glass?

Quality assurance validates the effectiveness of your cleaning process.

Implement surface inspection, contamination testing, and thorough documentation for traceability.

A robust QA protocol reduces the risk of product failure and supports compliance with industry standards.

Quality Assurance Steps for Quartz Glass Cleaning

| QA Step | Method/Tool | Acceptance Criteria |

|---|---|---|

| Surface Inspection | Visual, UV light, microscopy | No visible residues |

| Trace Contamination | TOC, ICP-MS, FTIR | Below application limits |

| Documentation | Cleaning logs, batch records | Full traceability |

Surface Inspection Methodology

Inspect surfaces under bright light and, if possible, UV illumination. Use microscopes for critical applications to detect micro-residues.

Trace Contamination Testing

Total Organic Carbon (TOC) analysis5, Inductively Coupled Plasma Mass Spectrometry (ICP-MS)6, and Fourier Transform Infrared Spectroscopy (FTIR)7 are standard methods for detecting trace contaminants.

Documentation & Traceability

Maintain detailed cleaning logs, batch records, and QA reports. This supports audits and helps identify sources of contamination if issues arise.

How Can Quartz Glass Cleaning Be Adapted for Different Scenarios?

Cleaning requirements vary across laboratory, industrial, and educational settings.

Adapt procedures to match the scale, contamination risk, and regulatory requirements of each scenario.

Scenario-specific adaptation ensures both efficiency and compliance.

Scenario-Based Quartz Glass Cleaning Approaches

| Scenario | Key Adaptation | Special Considerations |

|---|---|---|

| Laboratory | Precision, trace analysis | Avoid cross-contamination |

| Industrial | High throughput, automation | Equipment durability |

| Educational | Simplicity, safety, cost | Student training, oversight |

Laboratory Precision Cleaning

Use the highest purity chemicals, strict protocols, and advanced QA methods. Document every step for traceability.

Industrial Scale Processing

Automate cleaning steps where possible. Use robust equipment and design for high throughput. Regularly audit processes for efficiency.

Educational Institution Adaptation

Simplify procedures, prioritize safety, and use cost-effective materials. Provide clear instructions and supervision for students.

Conclusion

Effective quartz glass cleaning combines safety, precision, and scenario-specific adaptation.

Achieving flawless quartz glass cleanliness is a technical challenge. Leverage TOQUARTZ’s engineering support, direct factory supply, and rapid delivery to ensure your laboratory or industrial project meets the highest standards—contact us for expert guidance and custom solutions.

FAQ (Frequently Asked Questions)

How does quartz glass cleaning differ from cleaning other laboratory glassware?

Quartz glass requires stricter chemical compatibility and higher purity standards than borosilicate or soda-lime glass. Avoid alkalis and abrasives.

What are the key cost factors in quartz glass cleaning for industrial users?

Major costs include high-purity chemicals, specialized equipment (e.g., ultrasonic cleaners), and QA testing. Investing in proper cleaning reduces long-term replacement costs.

What should buyers consider when sourcing quartz glass cleaning services or supplies?

Evaluate supplier certifications, chemical compatibility data, and ability to provide documentation. Request sample cleaning protocols and QA results.

How does ultrasonic cleaning compare to manual cleaning for quartz glass?

Ultrasonic cleaning is more effective for removing fine particulates and reduces manual handling risks, but requires investment in equipment and proper rack design.

References:

-

Learn why PPE is essential for protecting yourself from chemical hazards and how to choose the right equipment for maximum safety. ↩

-

Learn about ultrasonic cleaning techniques and their effectiveness in removing particulates for a thorough cleaning solution. ↩

-

Learn about UV-ozone treatment and its advantages in cleaning processes, especially for organic films. ↩

-

Discover the functionality of nitrogen blow-off systems and their role in maintaining contamination-free surfaces. ↩

-

Understanding TOC analysis is crucial for assessing water quality and environmental health, making this resource invaluable. ↩

-

Exploring ICP-MS will enhance your knowledge of advanced analytical techniques used in various scientific fields. ↩

-

Learn how FTIR works and why it's a trusted method for identifying trace contaminants in various samples, enhancing your understanding of analytical techniques. ↩