Key Differences in High-Temperature Performance

Explore how quartz tubes outperform standard glass tubes.

Features | Fused Quartz Glass Tubes | Standard Glass Tubes |

|---|---|---|

Thermal Stability | Exceptional thermal stability at high temperatures. | Lower thermal stability, prone to deformation. |

SiO₂ Purity | >99.98% SiO₂ for high performance. | ~80% SiO₂ with additives. |

Max Operating Temp | Up to 1200°C for short periods. | Limited to around 500°C. |

Thermal Expansion | Low thermal expansion coefficient. | Higher expansion, leading to stress. |

Cycle Life | Over 5,000 thermal cycles. | Only 50-100 cycles. |

Chemical Resistance | Highly resistant to acids and bases. | Less resistant, prone to degradation. |

Softening Point | Softening point at 1665°C. | Softening point around 820°C. |

Devitrification Resistance | 8,000-15,000 hours before devitrification. | 1,000-2,000 hours before devitrification. |

Heating Rate Capability | Can withstand 500°C/min heating rates. | Limited to 30-150°C/min. |

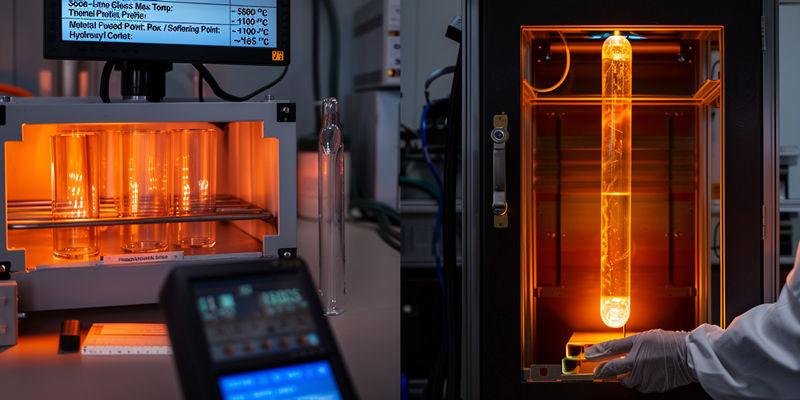

Material choice plays a critical role in high-temperature environments. Quartz Tubes deliver superior thermal stability, resisting deformation and failure when exposed to intense heat. Standard glass tubes often show higher failure rates, especially in demanding laboratory and industrial settings. The table below illustrates the difference in reliability:

Tube Type | Failure Rate |

|---|---|

Standard Glass Tubes | ~10% rejection |

Quartz Tubes | Significantly lower |

Selecting the right tube material enhances performance, increases durability, and ensures safer operation at elevated temperatures.

Key Takeaways

Quartz tubes can withstand temperatures up to 1200°C, making them ideal for high-heat applications.

High-purity quartz glass resists deformation and maintains its shape, unlike standard glass which can crack or soften at lower temperatures.

Quartz tubes have a much longer service life, lasting 18-36 months compared to just 3-8 months for standard glass in high-temperature settings.

Quartz glass is highly resistant to chemical attacks, ensuring reliability in harsh environments where standard glass may degrade.

Choosing quartz tubes enhances performance and safety in demanding applications, making them a smart investment despite higher initial costs.

What Material Composition Distinguishes Quartz Tubes from Glass Tubes in High-Temperature Performance?

Material composition plays a crucial role in determining how tubes perform under extreme heat. The unique structure and purity of quartz glass set it apart from standard glass, especially in demanding environments. Understanding these differences helps users select the right material for reliable, long-lasting high-temperature applications.

99.98% SiO₂ Purity Enabling 1200°C Operation Versus 80% SiO₂ + Additives Limited to 500°C

Quartz tubes contain over 99.98% silicon dioxide, which gives them remarkable resistance to heat. This high purity allows fused quartz tubes to operate at temperatures up to 1200°C for short periods and maintain continuous use near 1100°C. In contrast, standard glass tubes typically have about 80% SiO₂, with the rest made up of additives that lower their maximum safe temperature to around 500°C.

The difference in purity between quartz glass and standard glass directly impacts their performance. Fused quartz, made from high-purity synthetic silica, resists deformation and maintains its shape even during rapid heating and cooling cycles. Standard glass, with its lower SiO₂ content and added modifiers, cannot withstand such extremes and may crack or deform under thermal stress.

Material Type | SiO₂ Purity (%) | Max Operating Temp (°C) | Continuous Use Temp (°C) |

|---|---|---|---|

Quartz Tubes | >99.98 | 1200 | 1100 |

Standard Glass Tubes | ~80 | 500 | 400 |

Key Takeaway:

High-purity quartz glass enables safe operation at much higher temperatures than standard glass.

Fused quartz tubes are ideal for applications that demand both purity and heat resistance.

Network Modifier Ions (Na₂O, CaO) Creating Viscous Flow Above 600-700°C in Glass

Standard glass tubes contain network modifier ions such as sodium oxide (Na₂O) and calcium oxide (CaO). These ions disrupt the silica network, making the glass less stable at high temperatures. When heated above 600-700°C, these modifiers cause the glass to soften and flow, leading to deformation and loss of dimensional accuracy.

The presence of these network modifiers changes the viscosity of the glass. As temperature rises, the glass becomes less rigid and more prone to sagging or warping. This effect limits the use of standard glass in high-temperature environments, especially where precise shapes and dimensions are critical.

Summary of Effects:

Network modifiers lower the viscosity of glass at high temperatures.

Standard glass tubes may deform or fail above 600-700°C.

Quartz glass, free from these modifiers, maintains its shape and strength.

Si-O-Si Covalent Network in Quartz Maintaining Structural Integrity at High Temperature

Quartz glass features a continuous network of strong silicon-oxygen-silicon (Si-O-Si) covalent bonds. This structure provides exceptional thermal stability and allows quartz to retain its integrity even above 1000°C. The absence of weak points, such as grain boundaries or cleavage planes, means that fused quartz can withstand repeated heating and cooling without breaking down.

High-purity quartz glass resists devitrification and chemical attack, making it suitable for harsh laboratory and industrial settings. The robust Si-O-Si network ensures that quartz labware and fused quartz capillaries remain reliable, even when exposed to rapid temperature changes or aggressive chemicals.

Feature | Quartz Glass | Standard Glass |

|---|---|---|

Bond Structure | Si-O-Si Covalent Network | Disrupted by Modifiers |

Structural Integrity >1000°C | Maintained | Lost |

Resistance to Devitrification | High | Low |

In summary:

The Si-O-Si network in fused-quartz provides unmatched structural stability.

High-purity quartz glass maintains optical transparency and mechanical strength at elevated temperatures.

This makes quartz the preferred choice for demanding applications in science and industry.

How Does Thermal Expansion Difference Impact High-Temperature Cycling Between Quartz and Glass Tubes?

Thermal expansion plays a crucial role in determining how tubes perform during repeated heating and cooling. Quartz glass and standard glass respond differently to temperature changes, which affects their durability and reliability. Understanding these differences helps users choose the right material for demanding high-temperature cycling.

Thermal Stress at 1000°C: 3.5 MPa in Quartz Versus 23-64 MPa in Glass

Quartz glass exhibits a very low thermal expansion coefficient, which means it resists cracking and maintains its shape even at high temperatures. Standard glass, on the other hand, expands much more when heated, leading to higher internal stresses. This difference becomes critical at 1000°C, where quartz experiences only about 3.5 MPa of thermal stress, while glass can reach 23-64 MPa.

The low thermal expansion of quartz tubes ensures dimensional stability and prevents warping or failure during rapid temperature changes. This property supports repeated cycling in high-temperature furnaces and precision applications. Fused quartz capillaries and quartz labware benefit from this stability, making them reliable for laboratory and industrial use.

Property | Quartz Glass | Standard Glass |

|---|---|---|

Thermal Stress at 1000°C | 3.5 MPa | 23-64 MPa |

Expansion Coefficient | 5 × 10⁻⁷ K⁻¹ | 3-9 × 10⁻⁶ K⁻¹ |

Key Points:

Quartz glass resists thermal stress and maintains integrity at high temperatures.

Standard glass is more likely to crack or deform due to higher expansion and stress.

Heating Rate Capability: 500°C/min for Quartz Versus 30-150°C/min for Glass

Quartz tubes can withstand rapid heating rates up to 500°C per minute, far surpassing the 30-150°C per minute range typical for standard glass. This capability allows quartz to perform in processes that require fast temperature changes, such as thermal shock testing or rapid thermal processing. The low expansion and high purity of fused quartz prevent sudden failure, even under extreme conditions.

In contrast, standard glass tubes often fail when subjected to quick temperature shifts. Their higher expansion coefficient causes internal stresses to build up rapidly, leading to cracks or breakage. This limitation restricts their use in high-speed or high-temperature cycling environments.

Summary of Heating Rate Advantages:

Quartz tubes handle rapid heating without cracking.

Fused quartz supports advanced applications needing fast thermal cycling.

Standard glass is limited by lower heating rate tolerance.

5,000+ Cycle Life in Quartz Versus 50-100 Cycles in Borosilicate at High Temperature

Quartz glass stands out for its exceptional cycle life in high-temperature environments. Users can expect over 5,000 thermal cycles from quartz tubes before any signs of degradation appear. In comparison, borosilicate glass tubes typically last only 50 to 100 cycles under similar conditions, making them less suitable for repeated use.

The long cycle life of fused quartz results from its low thermal expansion, high purity, and resistance to chemical attack. These properties ensure that quartz maintains its optical transparency and structural integrity, even after thousands of heating and cooling cycles. This durability makes quartz the preferred choice for applications where reliability and longevity are essential.

Material | Typical Cycle Life at High Temp |

|---|---|

Quartz Glass | 5,000+ cycles |

Borosilicate Glass | 50-100 cycles |

Corrosion Resistance and Chemical Stability

Quartz glass offers superior resistance to corrosion, especially in chemically aggressive environments. Its high purity and strong Si-O-Si network make it highly resistant to most acids, bases, and solvents. This chemical durability ensures that quartz labware and fused quartz capillaries remain uncontaminated and reliable during repeated use.

Standard glass tubes, by contrast, are more vulnerable to chemical attack and contamination. Additives in standard glass can react with harsh chemicals, leading to surface degradation and reduced service life. This vulnerability limits their use in laboratories and industries that require high chemical resistance.

Material | Chemical Resistance |

|---|---|

Quartz Tubes | Highly resistant to most acids, bases, and solvents |

Glass Tubes | Less resistant, especially to strong acids and bases |

Summary:

Quartz glass maintains purity and resists contamination.

Standard glass is less reliable in harsh chemical environments.

Quality Standards and Assurance

Manufacturers of quartz tubes, such as TOQUARTZ, adhere to strict international standards to ensure consistent quality and chemical resistance. Compliance with ISO 9001 guarantees that each batch meets rigorous quality management requirements. Standards like ASTM C100 further specify dimensional and purity requirements for quartz glass products.

These certifications provide confidence to users in critical applications, where reliability and safety are paramount. High-quality fused quartz products undergo thorough testing for dimensional accuracy, thermal stability, and chemical resistance. This attention to quality ensures that quartz tubes deliver long-term performance in demanding environments.

Standard | Purpose |

|---|---|

ISO 9001 | Quality management for consistent manufacturing |

ASTM C100 | Dimensional and purity requirements |

In summary:

Certified quartz glass products offer proven reliability and safety.

Quality assurance supports consistent performance in high-temperature and chemically aggressive settings.

Why Does Softening Point Difference Determine High-Temperature Service Life Between Quartz and Glass Tubes?

The softening point of a material determines how long it can withstand high temperatures before losing its shape and function. When tubes operate near their softening point, they risk deformation and reduced reliability. Choosing the right material for high-temperature applications ensures longer service life and consistent performance.

1665°C Softening Point in Quartz Enabling 1200°C Service Versus 820°C Limiting Borosilicate to 500°C

Quartz glass has a softening point of about 1665°C, which allows quartz tubes to operate safely at temperatures up to 1200°C for extended periods. Borosilicate glass, with a much lower softening point near 820°C, cannot match this performance. This difference means fused quartz can handle more demanding environments without losing its shape.

Engineers rely on fused quartz for processes that require continuous exposure to high heat. Quartz labware and fused quartz capillaries maintain their structure and optical transparency even during short-term exposure up to 1450°C. Borosilicate glass tubes, however, begin to deform and lose their properties well below these temperatures.

Material | Softening Point | Continuous Operation | Short-term Exposure |

|---|---|---|---|

Quartz Tubes | 1270°C | Up to 1200°C | Up to 1450°C |

Borosilicate Glass | Lower than Quartz | Lower thermal resistance | Not specified |

Viscous Flow Above 700°C in Borosilicate Creating Dimensional Deformation

Borosilicate glass starts to soften and flow when heated above 700°C. This viscous flow causes tubes to lose their shape, which can lead to leaks or failures in critical applications. Quartz glass, with its higher purity and strong Si-O-Si bonds, resists this effect and maintains its dimensions.

Manufacturers choose quartz for high-temperature processes because it does not deform easily. Fused quartz capillaries and quartz labware remain stable, even after repeated heating cycles. This stability supports applications that demand precise measurements and reliable containment.

Key points to remember:

Quartz glass resists viscous flow at temperatures where borosilicate glass fails.

Dimensional stability ensures safe operation in laboratory and industrial settings.

High purity and strong bonds give quartz tubes their superior properties.

18-36 Month Service Life in Quartz Versus 3-8 Months in Glass at High Temperature

Quartz tubes offer a much longer service life in high-temperature environments compared to standard glass tubes. Users can expect quartz glass to last between 18 and 36 months, while borosilicate glass often needs replacement after just 3 to 8 months. This difference results from the superior thermal resistance and purity of fused quartz.

Longer service life reduces maintenance costs and downtime. Quartz labware and fused quartz capillaries provide reliable performance, even in harsh conditions. Their ability to maintain optical transparency and structural integrity makes them the preferred choice for demanding applications.

Material | Typical Service Life at High Temp |

|---|---|

Quartz Tubes | 18-36 months |

Glass Tubes | 3-8 months |

Quartz glass stands out for its durability and reliability. Engineers and researchers select quartz tubes for applications where longevity and consistent properties are essential.

How Does Devitrification Resistance Differ Between Quartz and Glass at Elevated Temperatures?

Devitrification resistance describes how well a material avoids turning from glassy to crystalline form when exposed to high heat. This property matters for tubes used in demanding environments, where loss of transparency or strength can cause failure. Quartz glass and standard glass show major differences in devitrification resistance, affecting their performance in high-temperature applications.

Devitrification Onset: 8,000-15,000 Hours in Pure Quartz Versus 1,000-2,000 Hours in Glass

Quartz glass resists devitrification for much longer periods than standard glass. Pure quartz can withstand 8,000 to 15,000 hours at elevated temperatures before devitrification begins. Standard glass, however, often shows signs of crystallization after only 1,000 to 2,000 hours.

This difference results from the unique structure of fused quartz, which lacks the network modifiers found in ordinary glass. The strong Si-O-Si bonds in quartz glass prevent the formation of crystalline regions, even during long-term heating. Standard glass, with its additives, forms crystals more quickly, leading to cloudiness and loss of strength.

Material | Devitrification Onset (hours) | Structural Integrity |

|---|---|---|

Quartz Glass | 8,000–15,000 | Maintained |

Standard Glass | 1,000–2,000 | Compromised |

Impurity Content (<20 ppm in Quartz vs >5,000 ppm Additives in Glass) Affecting Crystallization

The purity of quartz glass plays a key role in its resistance to devitrification. Fused quartz contains less than 20 parts per million (ppm) of impurities, while standard glass may have over 5,000 ppm of additives. These impurities, such as alkali metals and hydroxyl groups, speed up crystallization and reduce the thermal stability of glass.

Alkali metals and transition metals in glass act as catalysts for devitrification, causing the material to become brittle and lose transparency. In contrast, the low impurity content in fused quartz ensures that the glass remains stable and strong, even at high temperatures. Fused-silica tubes maintain their properties because they avoid the chemical reactions that lead to crystallization.

Key points to remember:

Low impurity levels in quartz glass slow down devitrification.

Additives in standard glass increase the risk of crystallization.

High purity supports long-term use in demanding applications.

Maintaining Transparency and Strength at 1100°C: Quartz Success Versus Glass Failure

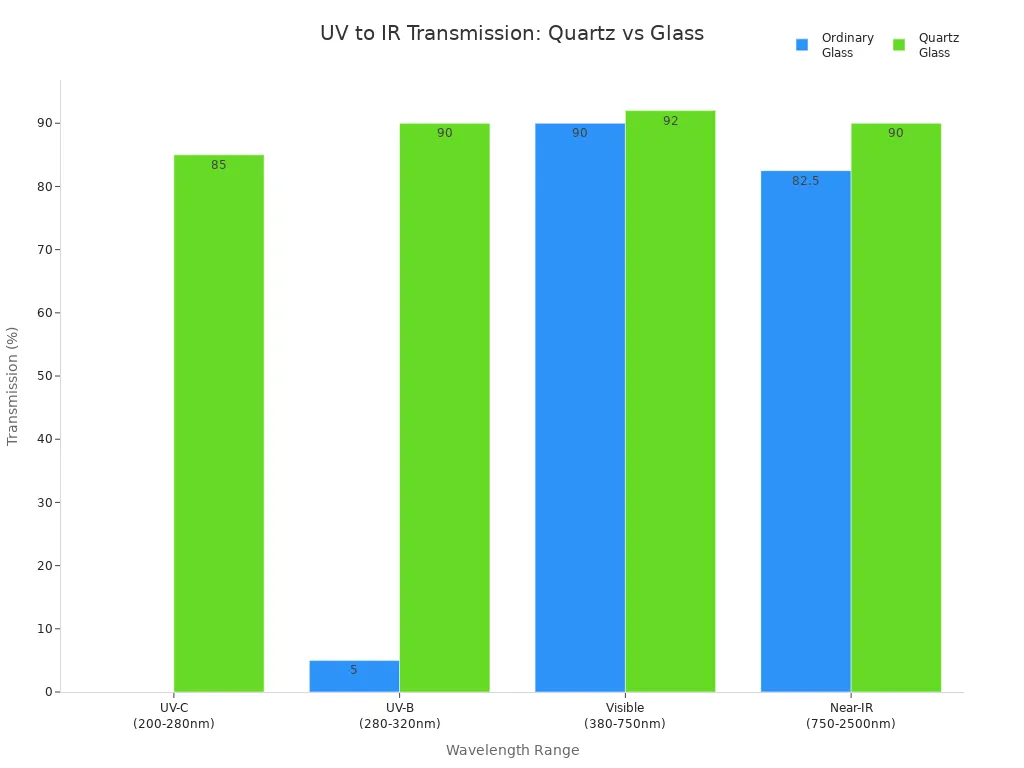

Quartz tubes maintain both transparency and mechanical strength at temperatures up to 1100°C. Fused quartz capillaries and tubes can operate continuously at these temperatures, with over 93% light transmission in the visible range and more than 80% in the UV range. Standard glass tubes lose clarity and become weak when exposed to similar conditions.

The superior optical properties of quartz glass come from its pure, uninterrupted structure. This allows quartz to transmit UV, visible, and IR light efficiently, making it ideal for scientific and industrial uses. The chart below compares the light transmission of quartz and ordinary glass across different wavelengths:

Summary of advantages:

Quartz glass keeps its strength and clarity at high temperatures.

Fused quartz supports applications needing UV-to-IR transparency.

Standard glass fails to maintain these properties under heat.

Which High-Temperature Application Requirements Mandate Quartz Over Glass Tube Selection?

Engineers and researchers often face demanding conditions that require materials with exceptional thermal stability and reliability. Quartz glass stands out in high-temperature applications where standard glass tubes cannot maintain performance or safety. Selecting quartz tubes ensures consistent results, longer service life, and compliance with strict industry standards.

Temperature Thresholds: >700°C Continuous or >900°C Cycling Requiring Quartz

Quartz tubes excel in environments where temperatures exceed 700°C for continuous operation or 900°C during cycling. Fused quartz maintains its structure and clarity under these conditions, while standard glass tubes lose mechanical strength and durability. Industries such as semiconductor manufacturing and chemical processing rely on quartz glass for processes that demand high thermal resistance.

Key temperature thresholds for quartz glass:

Withstands up to 1100°C for long-term use

Handles up to 1200°C for short-term exposure

Maintains performance in rapid cycling above 900°C

Quartz glass provides chemical resistance and chemical inertness, making it suitable for aggressive environments. Fused quartz supports applications that require both purity and resilience, ensuring safety and reliability.

Service Life Comparison: 18-24 Months for Quartz Versus Days-to-Weeks for Glass Above 700°C

Service life becomes a critical factor when tubes operate above 700°C. Fused quartz typically lasts 18 to 24 months in these conditions, while standard glass tubes may only survive for days or weeks. This difference results from the superior mechanical strength and durability of quartz glass, which resists deformation and devitrification.

Tube Type | Typical Service Life Above 700°C | Mechanical Strength and Durability |

|---|---|---|

Quartz Tubes | 18–24 months | High |

Standard Glass Tubes | Days to weeks | Low |

Quartz glass offers long-term reliability, reducing maintenance and replacement costs. Fused-silica tubes maintain their properties throughout extended use, supporting critical laboratory and industrial operations.

High-Temperature Certification Requirements Validating Quartz Performance

Certifications validate the quality and performance of quartz glass in high-temperature applications. Manufacturers like TOQUARTZ meet ISO 9001 and ISO 12123 standards, ensuring strict quality control and consistency. ASTM and SEMI standards set benchmarks for testing, contamination control, and batch-specific purity certificates.

Summary of certification requirements:

ISO 9001 and ISO 12123 for quality management

ASTM and SEMI standards for performance and contamination control

Batch-specific purity certificates for consistent results

Quartz tubes meet rigorous certification requirements, making them the preferred choice for industries that demand reliability and safety. TOQUARTZ offers competitive wholesale pricing and no minimum order quantity, providing access to high-quality fused quartz for any project.

Quartz tubes and standard glass tubes show clear differences in high-temperature performance. Quartz offers higher thermal resistance, better chemical stability, and longer service life. Standard glass tubes cost less but cannot match quartz in demanding environments.

Quartz tubes excel in:

Extreme heat tolerance

Chemical resistance

Mechanical strength

Optical clarity

For critical applications, engineers should select quartz tubes. Those with budget constraints or lower temperature needs may consider standard glass. TOQUARTZ provides expert advice and custom solutions for every requirement.

FAQ

What makes quartz tubes better for high-temperature use than standard glass tubes?

Quartz tubes withstand higher temperatures and resist deformation. Standard glass tubes soften and lose shape at lower temperatures. Quartz offers longer service life and better reliability for demanding environments.

Can quartz tubes be used for optical applications?

Quartz tubes provide excellent clarity and transmit UV to IR light. They support optical applications that require high transparency and minimal distortion. Standard glass tubes often block UV and show less clarity.

How does chemical resistance compare between quartz and glass tubes?

Quartz tubes resist most acids and bases. Standard glass tubes react with harsh chemicals and may degrade. Quartz maintains purity and prevents contamination during scientific analysis.

Are quartz tubes more expensive than standard glass tubes?

Quartz tubes cost more initially. They last longer and reduce replacement frequency. Standard glass tubes offer lower upfront costs but require frequent replacement in high-temperature settings.

What sizes and tolerances are available for quartz tubes?

Manufacturers offer quartz tubes in diameters from 1.5mm to 450mm and lengths up to 2000mm. Tolerances can reach ±0.03mm for diameter and ±0.2mm for length. Custom sizes are available for specialized needs.