Quartz Tubes for Analytical Applications must meet a minimum SiO₂ purity of 99.98% and keep total metallic impurities below 20 ppm to prevent contamination in trace analysis. Laboratories report that even small amounts of trace metals can distort calibration and lower detection accuracy. A recent study compared two-step pretreatment and advanced detection techniques, showing improved accuracy and lower detection limits when using high-purity quartz tubes:

Methodology | Findings |

|---|---|

Two-step pretreatment for high-purity quartz | Lowered detection limits and improved trace element accuracy by removing silicon matrix effects. |

Analysis Techniques | ICP-OES and ICP-MS required only 100-fold dilution for precise results. |

Results Consistency | RSD% values ranged from 0.62% to 9.73% for certified materials. |

Certified purity remains essential for laboratories targeting sub-ppb detection.

Key Takeaways

Quartz tubes must have at least 99.98% SiO₂ purity and less than 20 ppm metallic impurities to ensure accurate trace analysis.

Using certified quartz tubes helps maintain calibration stability and prevents contamination, leading to reliable analytical results.

Low hydroxyl (OH) content in quartz tubes enhances durability and performance, especially in high-temperature applications.

Strict dimensional tolerances are essential for leak-free seals in analytical instruments, ensuring consistent and accurate measurements.

Laboratories should validate quartz tube performance through thorough testing and documentation to minimize contamination risks.

What SiO₂ Purity Specification Ensures Contamination-Free Results in Trace Element Analysis?

Selecting the right purity level for quartz tubes is essential for reliable trace element analysis. Laboratories depend on strict SiO₂ purity and minimal metallic impurities to achieve accurate results. Quartz Tubes for Analytical Applications must meet these standards to prevent contamination and ensure consistent performance.

How Metallic Impurities Below 20 ppm Impact Spectroscopic Detection Limits

Even metallic impurities below 20 ppm can influence the accuracy of spectroscopic detection.

Trace metals such as iron (Fe), aluminum (Al), and titanium (Ti) can introduce background signals that interfere with the measurement of analytes at very low concentrations. These interferences may cause calibration drift and raise the limit of detection, especially for elements like aluminum, which has a detection limit as low as 0.03 ppm.

Element | Limit of Detection (LOD) (ppm) |

|---|---|

Cu | 3.27 |

Zn | 4.5 |

Sn | 2.98 |

Si | 4.46 |

Al | 0.03 |

Pb | 3.06 |

Small residual interferences can affect trace-level measurements, so laboratories often use reactive cell gases and different measurement modes to reduce these effects.

The use of Quartz Tubes for Analytical Applications with certified low impurity levels helps maintain stable calibration and low detection limits.

Key Points:

Trace metals below 20 ppm can still impact detection limits.

Aluminum has a particularly low detection threshold, making purity critical.

Certified quartz tubes help maintain calibration stability.

This summary highlights why impurity control is vital for trace analysis.

Understanding Type I vs Type III Quartz Classifications for Analytical Chemistry

Quartz tubes come in different types, each with unique purity and production methods.

Type I quartz is naturally occurring and has lower purity, while Type III quartz is synthetic and offers higher purity, making it more suitable for trace analytical chemistry. Laboratories seeking sub-ppb detection often choose Type III quartz to minimize contamination risks.

Purity Level | Production Method | Suitability for Trace Analysis | |

|---|---|---|---|

Type I | Lower purity | Naturally occurring | Less suitable |

Type III | Higher purity | Synthetic | More suitable |

Synthetic and plasma-fused quartz tubes provide ultra-high purity, which is essential for applications that require the lowest possible detection limits.

Quartz Tubes for Analytical Applications made from Type III quartz ensure that even the most sensitive analyses remain free from contamination.

Verification Testing Protocols per ISO 12123 Optical Material Standards

Verification protocols confirm that quartz tubes meet strict purity and optical standards.

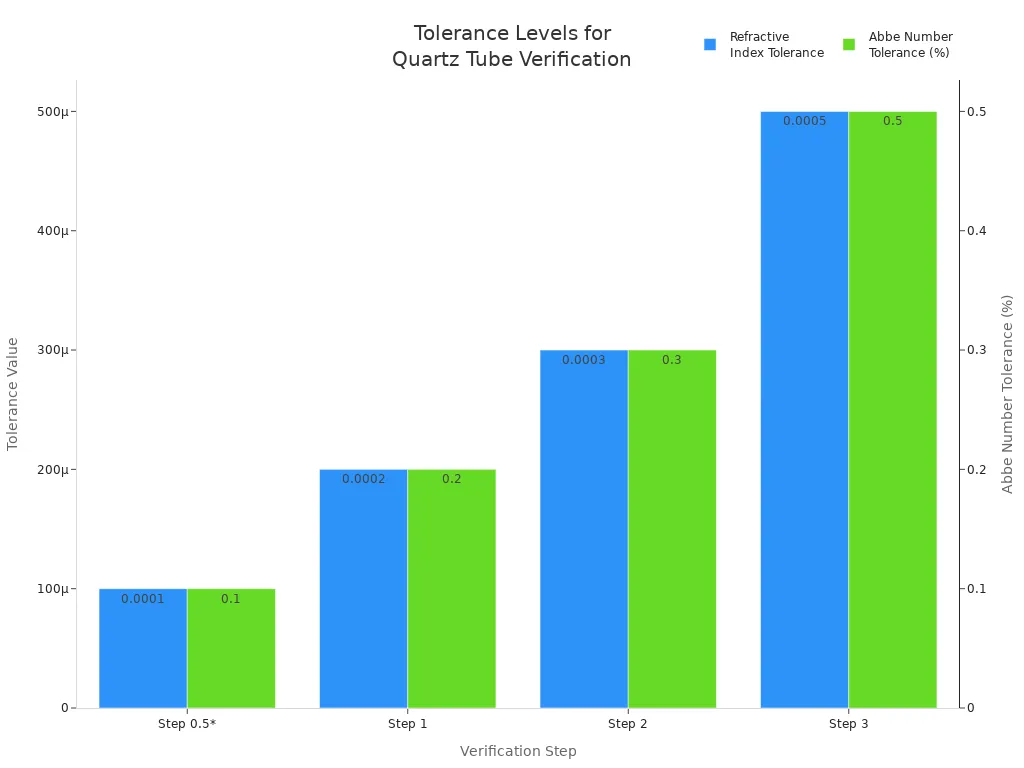

ISO 12123 specifies tests for refractive index variation and Abbe number tolerance, ensuring that only high-quality tubes are used in analytical instruments. These tests allow laboratories to compare products from different suppliers and select those with the most reliable performance.

Standardized optical tests and rigorous tolerances help maintain both transmission quality and cleanliness, which are critical for trace analysis.

Quartz Tubes for Analytical Applications that pass ISO 12123 protocols provide confidence in both purity and performance.

Key Points:

ISO 12123 sets strict standards for optical and purity testing.

Refractive index and Abbe number tolerances ensure quality.

Certified tubes support reliable trace analysis.

These protocols help laboratories achieve consistent and contamination-free results.

Why Does OH Content Affect Performance in High-Temperature Analytical Techniques?

Quartz tubes play a critical role in high-temperature analytical techniques. The hydroxyl (OH) content in these tubes directly affects their durability, purity, and performance. Laboratories must understand how manufacturing methods and OH levels influence analytical outcomes.

Comparing Electrical Fusion vs Flame Fusion Manufacturing Methods

Manufacturers use electrical fusion and flame fusion to produce quartz tubes with different OH contents. Electrical fusion typically results in lower OH levels, which improves sag resistance and reduces the risk of devitrification during high-temperature use. Flame fusion often produces tubes with higher OH content, increasing the likelihood of structural changes and contamination.

GE adjusts the OH content in quartz to meet specific customer needs, demonstrating that manufacturing methods can be tailored for purity. Higher OH levels accelerate devitrification, which can compromise tube integrity and analytical accuracy. Laboratories select electrical fusion quartz for demanding applications that require stable performance under repeated heating cycles.

Key Points:

Electrical fusion produces quartz tubes with lower OH content.

Lower OH levels improve sag resistance and purity.

This comparison helps laboratories choose the right manufacturing method for their analytical requirements.

OH Absorption Bands and Their Impact on Mid-IR Spectroscopy

OH absorption bands in quartz tubes can interfere with mid-infrared (mid-IR) spectroscopy. Tubes with high OH content absorb more IR radiation, which reduces signal clarity and affects molecular fingerprinting. Low-OH quartz tubes, recommended at less than 10 ppm, minimize these absorption effects and support accurate spectral analysis.

Minimizing OH content also slows the sag rate at diffusion temperatures, preserving tube structure during extended use. This specification retards devitrification, maintaining the tube’s integrity and performance in high-temperature processes. Laboratories benefit from improved data quality and reliable results when using low-OH quartz tubes.

OH Content (ppm) | Mid-IR Absorption | Analytical Impact |

|---|---|---|

<10 | Minimal | High accuracy |

50-200 | Significant | Reduced clarity |

Selecting quartz tubes with low OH content ensures optimal performance in mid-IR spectroscopy and other sensitive analytical techniques.

Thermal Cycling Performance Data Across OH Content Ranges

Thermal cycling tests reveal how quartz tubes with varying OH content perform under repeated heating and cooling. Standard fused quartz operates reliably up to 1050°C, while high-purity, low-hydroxyl quartz excels above 1150°C and withstands aggressive thermal cycling. For every 10 ppm increase in OH content, the maximum long-term use temperature drops by about 20°C, which limits tube endurance.

Mechanical endurance, softening point, and price vary among thermal grades, reflecting their suitability for continuous operation or peak heat exposure. In vacuum conditions, quartz tubes can reach temperatures near 1700°C for short periods, but oxygen-rich environments above 1000°C accelerate silicon-oxygen bond breakage and reduce permeability. Laboratories rely on low-OH quartz for consistent performance in demanding thermal cycles.

Key Points:

Low-OH quartz excels in high-temperature and thermal cycling applications.

Higher OH content reduces maximum use temperature and endurance.

Environmental factors influence quartz tube performance.

Understanding thermal cycling data guides laboratories in selecting the best quartz tubes for mission-critical analytical work.

How Do Dimensional Tolerances Impact Seal Integrity in Analytical Instrument Integration?

Dimensional tolerances play a crucial role in the performance of quartz tubes within analytical instruments. Laboratories rely on precise measurements to maintain reliable seals and prevent contamination. Consistent tube dimensions help ensure that analytical results remain accurate and reproducible.

Standard Taper Joint Specifications for Laboratory Quartz Connections

Standard taper joints connect quartz tubes to laboratory equipment and must meet strict specifications. These joints require precise alignment and reliable sealing to prevent leaks during trace analysis. Laboratories often compare quartz glass ball and socket joints with standard taper joints to determine which offers better performance.

Feature | Quartz Glass Ball and Socket Joints | Standard Taper Joints |

|---|---|---|

Flexibility | Greater | Limited |

Alignment Tolerance | Higher | Lower |

Reliable Sealing | Yes | Varies |

Thermal Stability | Superior | Moderate |

Chemical Resistance | Excellent | Good |

Quartz glass ball and socket joints provide greater flexibility and superior thermal stability, which helps maintain seal integrity during temperature changes. Standard taper joints offer good chemical resistance but may vary in sealing reliability. Laboratories select joint types based on the demands of their analytical methods.

Compression Fitting Compatibility Across Temperature Ranges

Compression fittings must match the dimensions and thermal properties of quartz tubes to ensure leak-free operation. Fused quartz has a low coefficient of thermal expansion and high resistance to temperature, making it compatible with compression fittings in demanding environments. Stainless steel fittings also support hard tubing and maintain seals under various conditions.

Key Points:

Fused quartz supports high compatibility with compression fittings.

Low thermal expansion reduces leak risk during temperature changes.

Compression fittings maintain seal integrity in high-temperature applications.

Compression fittings paired with fused quartz tubes help laboratories achieve reliable performance across a wide temperature range. This compatibility minimizes failures and supports consistent analytical results.

Leak Testing Methods per ASTM C657 for Analytical Applications

Leak testing ensures that quartz tubes and their connections meet the required standards for analytical work. ASTM C657 outlines procedures for evaluating seal integrity, including pressure decay and helium leak detection. Laboratories use these methods to verify that dimensional tolerances prevent leaks and maintain sample purity.

Type of Quartz Tube | Tolerance |

|---|---|

Double Layer Quartz Glass Tube | ±0.1mm |

Cylindrical Clear Fused Quartz Tubing | ±0.15mm |

Precise tolerances reduce the risk of leaks and failures in high-temperature or chemically aggressive environments. Laboratories rely on these standards to confirm that their quartz tubes support contamination-free analysis. Reliable leak testing helps maintain the integrity of analytical instruments and ensures accurate results.

What Quality Standards Validate High-Purity Quartz Tube Performance for Analytical Instruments?

High-purity quartz tubes must meet strict quality standards to ensure reliable performance in analytical instruments. Laboratories depend on these standards to prevent contamination and maintain accurate results. Consistent quality validation supports confidence in every analytical workflow.

ISO 12123 Compliance Requirements for Optical-Grade Fused Silica

ISO 12123 sets the benchmark for optical-grade fused silica used in analytical applications. This standard requires quartz tubes to meet precise tolerances for refractive index and Abbe number, ensuring consistent optical clarity. Laboratories use these specifications to select tubes that deliver reliable transmission and minimal signal loss.

Manufacturers must also meet dimensional tolerances, such as ±0.1 mm for outer diameter and ±0.05 mm for wall thickness, to guarantee proper sealing and fit. These tolerances prevent leaks and reduce baseline noise, which can affect trace analysis. Dimensional accuracy supports stable instrument performance over repeated use.

Tolerance Type | Specification |

|---|---|

Outer Diameter | ±0.03 mm ID tolerance |

Wall Thickness | Sub-mm uniformity |

This table highlights how strict tolerances directly support contamination-free analysis.

Third-Party Certification Standards for Trace Analytical Applications

Third-party certification plays a vital role in validating quartz tube quality for trace analytical work. Independent laboratories verify SiO₂ purity and trace element levels through documented analysis, often using Certificates of Analysis (CoA). These certifications confirm that each batch meets industry standards and regulatory requirements.

Quality certifications, such as ISO 9001:2015, demonstrate a manufacturer’s commitment to consistent production and quality management. On-site audits and compliance with standards like SEMI F57 further ensure that manufacturing processes support high-purity outcomes. Laboratories gain assurance from these certifications, knowing their Quartz Tubes for Analytical Applications meet the highest standards.

Key Points:

Third-party certification confirms purity and trace element levels.

Quality certifications and audits validate manufacturing processes.

Certified tubes support regulatory compliance and analytical accuracy.

These points show how independent validation strengthens confidence in analytical results.

Comparing Manufacturer Quality Control Protocols and Documentation

Manufacturers use detailed quality control protocols to ensure consistent high-purity quartz tube production. Inspection methods include dimensional checks, visual inspections, and bubble or streak detection systems. Certificates of Analysis provide documented verification of SiO₂ purity and trace element content.

Industry standards compliance, such as adherence to SEMI F57 and ISO 10110, supports optical homogeneity and compatibility with analytical instruments. On-site audits allow laboratories to assess manufacturing capabilities firsthand, ensuring that quality processes meet expectations. Reliable documentation and transparent protocols help laboratories make informed purchasing decisions.

Evidence Type | Description |

|---|---|

Certificates of Analysis (CoA) | Verification of SiO₂ purity and trace element levels through documented analysis. |

Quality Certifications | Importance of certifications such as ISO 9001:2015 for quality management. |

Inspection Methods | Protocols for dimensional checks and visual inspections. |

This table summarizes how robust quality control and documentation support consistent tube performance.

How Should Analytical Laboratories Validate Quartz Tube Performance Before Critical Method Development?

Analytical laboratories must validate quartz tube performance before starting critical method development. This process ensures that contamination risks remain low and that analytical results stay reliable. Laboratories follow established standards and protocols to confirm the suitability of Quartz Tubes for Analytical Applications.

Developing Laboratory-Specific Acceptance Criteria for Quartz Tubes

Laboratories create acceptance criteria based on international standards such as ISO 12123, ISO 720, and ASTM C693. These criteria include dimensional checks, impurity profiling, and traceability through third-party certification. Laboratories use impurity profiling with ICP-MS to detect trace metals and confirm purity levels down to parts per trillion.

Contribution | Description |

|---|---|

Highest Purity Levels | ICP-MS analysis delivers precise data down to the ppt range, ensuring the highest purity of quartz tubes. |

Early Detection of Impurities | The method enables reliable detection of even the smallest amounts of inorganic impurities, particularly metals. |

Process Optimization | Supports quality assurance, process control, and research to improve product quality and minimize risks. |

These criteria help laboratories select quartz tubes that meet the demands of trace analysis and regulatory compliance.

Blank Analysis Protocols for Contamination Assessment

Blank analysis protocols help laboratories assess potential contamination from quartz tubes before method development. Technicians use FEP or quartz containers and avoid borosilicate glass to minimize contamination. They separate labware by concentration levels and metals, rinse volumetric vessels with deionized water, and use both field-based and lab-based blanks.

Key Points:

Segregate labware for specific metals and concentration levels.

Rinse and store vessels with deionized water and utilize blanks for evaluation.

These steps ensure that laboratories can identify and control contamination sources, supporting accurate trace analysis.

Thermal Cycling Qualification Tests for Mission-Critical Applications

Thermal cycling qualification tests verify the durability of quartz tubes under repeated heating and cooling. Laboratories cycle tubes between 200°C and 1000°C at rapid ramp rates, checking for visible crazing or devitrification. They compare new tubes against certified reference tubes using representative sample matrices to confirm stability.

Test Type | Purpose | Outcome |

|---|---|---|

Thermal Shock Testing | Assess resistance to rapid heating | No visible crazing after 10 cycles |

Chemical Resistance | Evaluate leachable contamination | ICP-MS confirms low impurity levels |

Analytical Comparison | Validate performance with samples | Stable results across cycles |

These qualification tests help laboratories ensure that Quartz Tubes for Analytical Applications perform reliably in mission-critical environments.

Quartz tubes for trace analytical applications must meet strict standards. Laboratories require purity levels above 99.99% SiO₂, low OH content, and tight dimensional tolerances. Certified quality and proper validation help prevent contamination and ensure reliable results. Laboratories should request documentation and perform in-house validation before starting method development.

Requirement | Specification |

|---|---|

Purity | ≥99.995% SiO₂ |

OH Content | Low |

Dimensional Tolerances | Tight tolerances required |

Laboratories that follow these guidelines achieve consistent and accurate trace analysis.

FAQ

What purity level of quartz tubes do laboratories need for trace analysis?

Laboratories need quartz tubes with at least 99.98% SiO₂ purity and less than 20 ppm total metallic impurities. This level prevents contamination and supports detection limits below 1 ppb in sensitive analytical methods.

What is the impact of high OH content in quartz tubes?

High OH content, above 30 ppm, increases devitrification risk and reduces tube durability during repeated heating. Low-OH quartz tubes maintain structure and performance through over 5,000 thermal cycles, based on ISO 7991 testing.

What standards verify quartz tube quality for analytical use?

ISO 12123, ISO 720, and ASTM C693 set the main standards. These standards require strict purity, dimensional accuracy, and chemical resistance. Third-party certification and ICP-MS impurity profiling confirm compliance.

What dimensional tolerances ensure leak-free seals in instruments?

Quartz tubes with outer diameter tolerances of ±0.1 mm and wall thickness tolerances of ±0.05 mm ensure reliable seals. Leak rates below 1×10⁻⁹ mbar·L/s support stable analytical results, as shown in laboratory testing.

What validation steps should laboratories take before using new quartz tubes?

Laboratories should check dimensions, inspect for defects, and run blank analysis for contamination. They should also perform thermal cycling tests between 200°C and 1000°C. These steps confirm tube suitability for trace analysis.