Corrosion Defense in Laboratory Innovation

Aggressive Chemistry? Quartz Labware Handles It All.

TOQUARTZ® quartz lab equipment resists acids, alkalis, and solvents that degrade conventional glass:

Quartz Boat Crucibles

Boiling nitric and hydrochloric acid mixtures (1:3 ratio) in sample digestion leave zero marks on 99.99% SiO₂ surfaces.

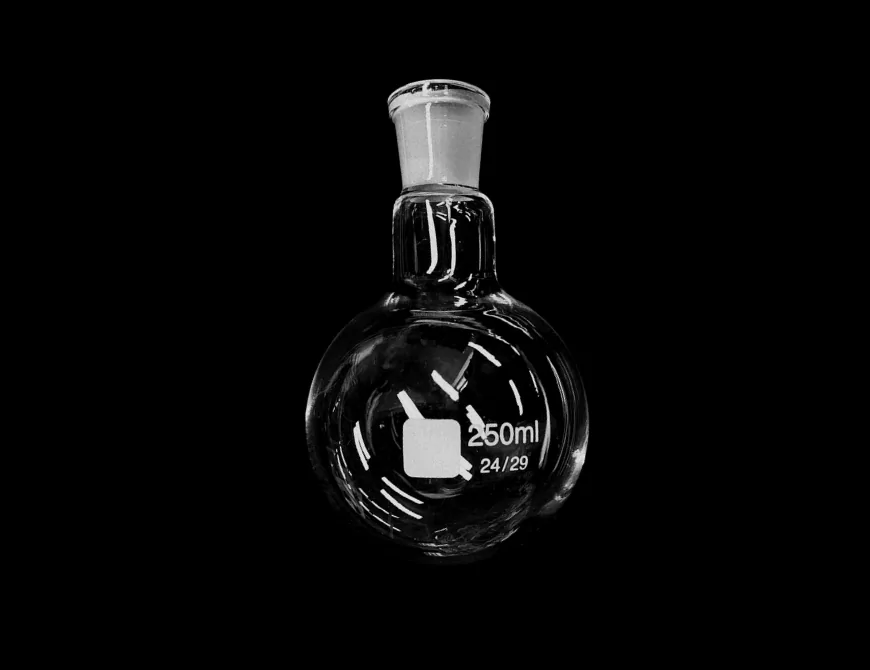

Quartz Flasks

Store hydrofluoric acid-free corrosive solvents (e.g., H₂SO₄, HNO₃) with minimal risk of ionic leaching.

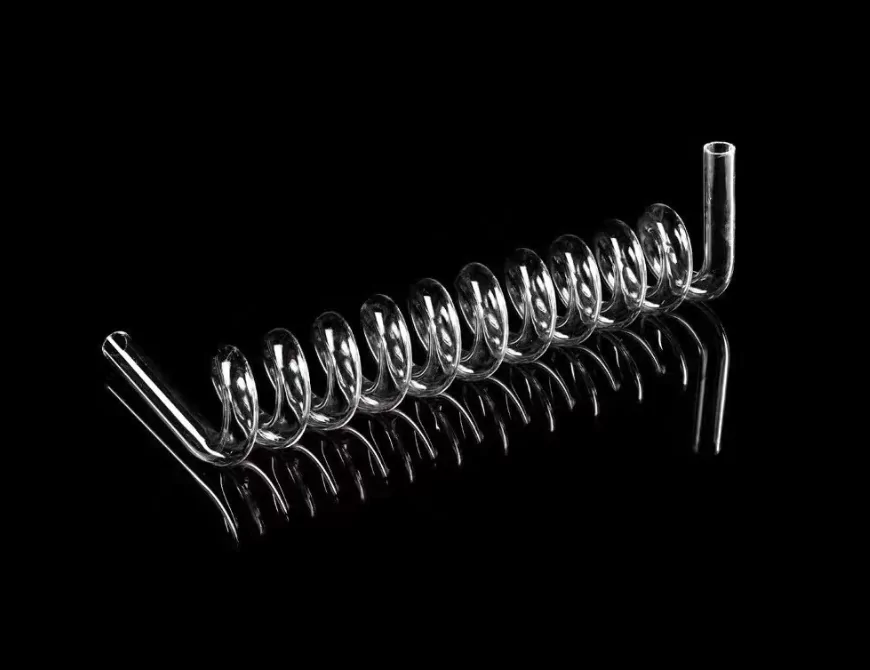

Spiral Tubes

Condense volatile organic compounds (VOCs) in distillation setups—no surface crazing after 200+ cycles (tested at ≤400°C).

Laboratory Impact: Labs report 30% longer equipment lifespans compared to borosilicate alternatives, reducing replacement costs and downtime.

Optical Prowess Across the Spectrum

From UV Lasers to IR Sensors: Clarity Redefined.

Applications demanding spectral precision rely on TOQUARTZ® optical-grade quartz:

Multi-Well Plates

Enable UV-Vis/IR cross-validation in drug discovery, with ≤1% inter-well transmission variance (190–2,500nm).

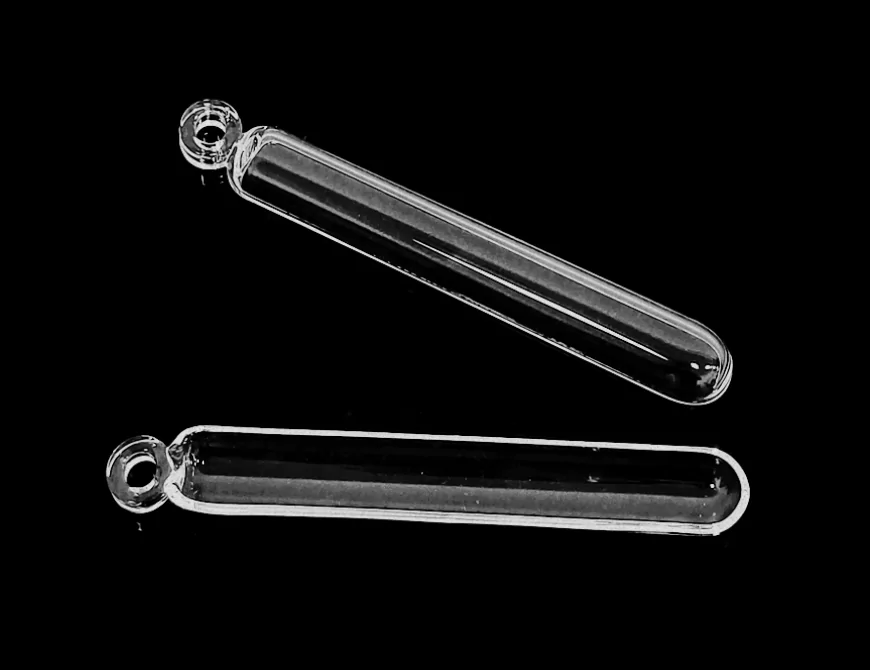

Quartz Cuvettes

Deliver >95% transmittance for spectroscopy—critical for detecting nano-molar analyte concentrations.

Quartz Rods

Transmit CO₂ laser light (10.6µm) with <0.01% signal loss per meter, ideal for surgical and industrial laser systems.

Certified Performance: Surface roughness ≤5nm (AFM-tested) ensures minimal light scattering.

Industrial Resilience Under Fire

Where Metals Fail, Quartz Endures.

TOQUARTZ® components withstand punishing industrial conditions:

Quartz Flanges

Seal 1,200°C chlorine gas lines in titanium refining—zero deformation over 3 years (vs. alumina’s 18-month average).

Quartz Blowtorches

Direct 1,400°C flame exposure tested for 500+ hours without thermal fatigue.

Etching Rings

Resist plasma etching in semiconductor-adjacent applications (e.g., optical coating), with 2x the lifespan of competitors.

Proven ROI: Clients report 40% maintenance cost reductions by switching to quartz-based industrial parts.

TOQUARTZ® thrives at this intersection—combining ≥99.99% SiO₂ purity(max. up to 99.995%), precision engineering, and flexible order terms (no MOQ, rapid prototyping).

Whether you’re refining corrosive chemicals, aligning optical systems, or scaling extreme-temperature processes, our solutions are engineered to elevate your operational limits.