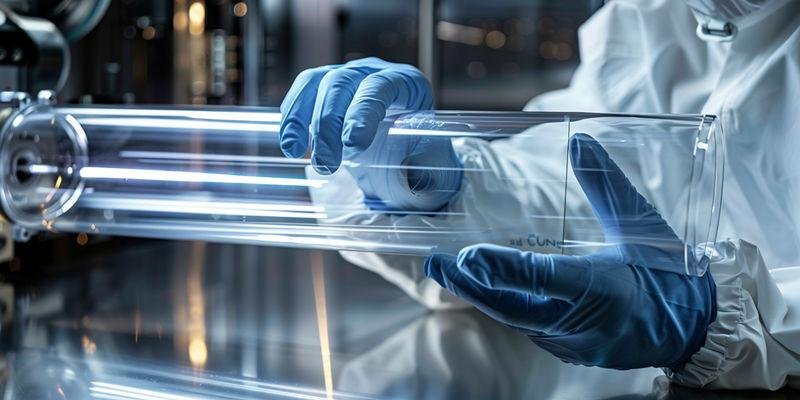

Only heat-resistant quartz glass tubing applications deliver unmatched performance in the most demanding environments. Engineers trust quartz glass when purity, temperature stability, optical clarity, and chemical resistance are critical. Quartz glass consistently outperforms alternatives in settings where precision and reliability matter most, such as:

Furnace or reactor parts exposed to temperatures above 800°C

Optical windows that must maintain transmission at high heat

Environments with oxidative, reducing, or plasma conditions

Processes where outgassing or molecular contamination is unacceptable

Every major industry operating beyond the limits of standard glass depends on quartz glass tubing for safety, productivity, and process yield.

Key Takeaways

Heat-resistant quartz glass tubing excels in high-temperature environments, maintaining purity and dimensional stability critical for semiconductor manufacturing.

Engineers trust quartz glass for its unmatched chemical resistance, preventing contamination in processes exposed to aggressive gases and reactive atmospheres.

Quartz glass provides excellent optical transparency, allowing real-time monitoring in applications like CVD and spectroscopy, which enhances process control.

Using quartz glass tubing extends the lifespan of heating elements by protecting them from oxidation and contamination, leading to lower maintenance costs.

A structured decision matrix helps engineers select the right material for high-temperature applications, balancing performance needs with cost considerations.

Why Do Semiconductor Diffusion Furnaces Specifically Require Heat-Resistant Quartz Glass Tubing?

Semiconductor diffusion furnaces operate in environments where every material choice impacts yield and reliability. Engineers select high-temperature quartz glass for these furnaces because only this material meets the strict demands for purity, dimensional stability, and chemical compatibility. The combination of high-temperature operation and contamination sensitivity makes heat-resistant quartz glass tubing applications indispensable in modern chip manufacturing.

Purity Requirements: Why <1 ppb Contamination Eliminates Alternative Materials

Semiconductor fabrication demands ultra-high purity. As chip architectures shrink, even a single contaminant molecule can cause defects. Manufacturers now require less than 1 part per billion contamination, a standard that only high-temperature quartz glass can consistently meet. Alternative materials, such as alumina ceramics or metal alloys, introduce impurities that exceed these limits and threaten device performance.

The industry’s shift to ultra-pure materials is driven by the need to maintain chip performance at resolutions as fine as 7 nanometers. Detection limits for impurities have moved from parts per million to parts per trillion. This evolution highlights why only high-temperature quartz glass tubing applications can prevent yield loss and costly production errors.

Material | Typical Contamination Level | Suitability for <1 ppb Purity |

|---|---|---|

Quartz Glass Tubing | <1 ppb | Ideal |

Alumina Ceramic | 100-500 ppm | Not suitable |

Metal Alloy | 10-100 ppb | Not suitable |

Engineers rely on high-temperature quartz glass to eliminate contamination risks. This choice protects wafer surfaces and ensures consistent, defect-free production.

Temperature Stability Needs: Maintaining Dimensional Accuracy at 1000-1200°C

Diffusion furnaces routinely operate at temperatures between 1,000°C and 1,200°C. High-temperature quartz glass maintains dimensional accuracy under these extreme conditions, thanks to its low thermal expansion coefficient and superior thermal shock resistance. Other materials, such as borosilicate glass, cannot withstand rapid temperature changes and often crack or deform.

Quartz glass tubing preserves its shape and integrity during continuous high-temperature operation. This stability is critical for maintaining precise wafer alignment and uniform diffusion profiles. Engineers trust high-temperature quartz glass because it resists warping and maintains tight tolerances over months of use.

Key advantages of quartz glass tubing:

Maintains dimensional accuracy at 1,050°C to 1,200°C

Withstands rapid temperature changes without cracking

Provides long-term reliability in thermal applications

The ability to endure high-temperature cycles without failure makes quartz glass the preferred choice for semiconductor diffusion furnaces. This reliability directly supports higher yields and lower maintenance costs.

Oxidation Atmosphere Compatibility: Processing in O₂/H₂O at High Temperature

Semiconductor diffusion processes often require oxidation atmospheres, such as oxygen and steam, at elevated temperatures. High-temperature quartz glass offers unmatched chemical resistance, allowing safe operation in these reactive environments. Alternative materials, including alumina ceramics and metal alloys, react with oxygen or release impurities, compromising wafer quality.

Quartz glass tubing remains inert during oxidation, preventing unwanted chemical interactions. This property ensures that wafers receive uniform treatment and that process gases do not introduce contaminants. The chemical stability of high-temperature quartz glass supports consistent results in demanding furnace conditions.

Atmosphere Type | Required Material Stability | Quartz Glass Performance | Alternative Performance |

|---|---|---|---|

O₂/H₂O at 1,100°C | High | Excellent | Poor |

Engineers choose high-temperature quartz glass for its proven compatibility with oxidation atmospheres. This decision safeguards process integrity and maximizes production efficiency.

What Makes Heat-Resistant Quartz Glass Tubing Essential for High-Temperature Laboratory CVD Processes?

High-temperature laboratory CVD processes demand materials that can withstand extreme conditions. Engineers select high-temperature quartz glass for these applications because it offers unmatched chemical compatibility, purity, and transparency. Only heat-resistant quartz glass tubing applications deliver the reliability and performance required for advanced research and production.

Chemical Compatibility: Resisting Corrosive CVD Precursor Gases at High Temperature

CVD processes expose tubing to aggressive gases at temperatures reaching 1,100°C. High-temperature quartz glass remains chemically inert, even when challenged by silane, ammonia, or organometallic compounds. This resistance prevents unwanted reactions that could compromise the process.

Quartz glass endures repeated exposure to acids, bases, and solvents without degradation. Its ability to withstand rapid temperature changes without cracking demonstrates superior thermal shock resistance. These properties ensure that the tubing maintains integrity throughout demanding thermal applications.

Key reasons for choosing quartz glass in CVD:

Withstands up to 1,100°C in continuous operation

Remains unaffected by most chemicals at high temperature

Resists cracking during rapid temperature cycling

Engineers trust high-temperature quartz glass because it protects both equipment and process outcomes. This chemical compatibility directly supports consistent, high-quality film deposition.

Contamination Control: Preventing Film Quality Degradation from Tube Impurities

Film quality in CVD depends on the purity of every component. High-temperature quartz glass tubing, with ultra-high purity levels (≥99.995% SiO₂), ensures no leaching of metal ions or impurities. This purity prevents contamination that could degrade thin film performance.

Smooth surfaces and tight dimensional tolerances further reduce the risk of particulate generation. Quartz glass resists chemical attack, maintaining a clean environment for sensitive deposition processes. Its thermal shock resistance allows for rapid heating and cooling, supporting efficient cleaning cycles.

Feature | Quartz Glass Tubing | Alternatives |

|---|---|---|

Purity (SiO₂ %) | ≥99.995 | 95-99 |

Metal Ion Leaching | None | Possible |

Surface Smoothness | High | Moderate |

High-temperature quartz glass enables laboratories to achieve superior film quality and process repeatability. This advantage leads to higher yields and fewer costly defects.

Optical Transparency: Enabling Visual Process Monitoring During Deposition

Visual monitoring is vital in laboratory CVD. High-temperature quartz glass provides excellent optical transparency, allowing researchers to observe deposition in real time. This visibility helps optimize process parameters and detect issues early.

Quartz glass maintains its transparency even after prolonged exposure to high temperatures and reactive gases. Engineers can quickly identify color changes, gas flow patterns, or substrate misalignment through the clear tube walls. This capability is not possible with opaque alternatives.

Benefits of optical transparency in CVD:

Enables real-time process adjustments

Supports rapid troubleshooting

Improves overall process control

The unique combination of high-temperature tolerance and optical clarity makes high-temperature quartz glass the material of choice for CVD process monitoring.

How Do High-Temperature Furnace Heating Elements Benefit from Heat-Resistant Quartz Glass Tubing Protection?

High-temperature furnace heating elements face extreme operational challenges. Engineers must protect these elements to ensure long service life, consistent performance, and energy efficiency. Heat-resistant quartz glass tubing applications deliver unmatched benefits in these demanding environments.

Oxidation Protection: Extending Heating Element Life Through Atmospheric Isolation

High-temperature quartz glass shields heating elements from direct exposure to air, which prevents rapid oxidation. This protection becomes critical as temperatures rise above 900°C, where unprotected elements can fail quickly due to oxidation. Quartz glass tubing creates a stable barrier, reducing the risk of oxidation-related damage.

Engineers see a dramatic increase in heating element lifespan when using high-temperature quartz glass. The tubing isolates the element, preventing the formation of volatile oxides that can thin and crack metal sheaths. Proper maintenance and correct usage patterns further maximize the life expectancy of quartz heater elements.

Failure Mode | Cause |

|---|---|

All three legs of element open, short lifespan | Operation above rated voltage or out of solution |

All three legs open, long lifespan | Overheating from low liquid level or buildup |

Holes/melting of metal sheath | Operation in viscous solution at high temperature |

Tube cracked at interface | Severe thermal shock from localized overheating |

Tube etched/porous | Operation in highly alkaline or fluoride solution |

This table highlights how quartz glass tubing prevents many common failure modes by providing atmospheric isolation. As a result, heating elements last longer and require less frequent replacement.

Contamination Prevention: Isolating Elements from Reactive Process Materials

High-temperature quartz glass tubing acts as a barrier between heating elements and reactive process materials. This isolation prevents contamination that can lead to short circuits, corrosion, or reduced heating efficiency. Engineers rely on this protection to maintain clean and stable furnace environments.

Quartz glass resists attack from aggressive chemicals, even at temperatures above 1000°C. The tubing’s superior thermal shock resistance ensures it remains intact during rapid heating and cooling cycles, reducing maintenance needs. This durability supports continuous operation in demanding thermal applications.

Key benefits of quartz glass tubing for contamination prevention:

Maintains element integrity in corrosive atmospheres

Reduces risk of electrical failure from contamination

Supports long-term, stable furnace operation

By choosing high-temperature quartz glass, engineers avoid costly downtime and equipment failures. This decision ensures reliable performance in critical high-temperature processes.

Radiant Heat Transmission: Enabling Efficient Infrared Energy Transfer

High-temperature quartz glass enables efficient radiant heat transfer from heating elements to furnace chambers. The material’s high infrared transmission allows nearly all generated energy to reach the target, minimizing heat loss and maximizing process efficiency. This advantage is especially important for applications requiring fast, even heating.

Quartz glass outperforms ceramic alternatives in infrared heating due to its rapid heating capabilities and superior energy efficiency. Furnaces equipped with quartz heaters experience lower energy consumption and faster heating cycles. The long operational life and low maintenance needs of quartz heaters further enhance their value.

Advantages of quartz glass in radiant heat transmission:

Superior energy efficiency with minimal heat loss

Fast, uniform heat distribution across surfaces

Durable performance with reduced maintenance

Engineers select high-temperature quartz glass for its unmatched ability to deliver efficient, reliable heat in demanding furnace environments. This choice supports productivity and cost savings over the long term.

Why Do UV Lamp and Optical Heating Applications Demand Heat-Resistant Quartz Glass Tubing?

UV lamp and optical heating systems operate in environments where both high-temperature and optical performance are critical. Engineers choose heat-resistant quartz glass tubing applications because only this material meets the demanding requirements for UV and infrared transmission, thermal stability, and purity. Understanding why quartz is essential helps ensure reliable, efficient, and safe operation in these advanced thermal applications.

UV Transmission Requirements: >80% at 254 nm for Germicidal Applications

Germicidal UV lamps must deliver strong UV-C output at 253.7 nm to achieve effective sterilization. High-temperature quartz glass provides the necessary transmission, with TOQUARTZ tubes offering at least 70% transmittance at this wavelength, which meets the strict standards for germicidal performance. This high level of UV transmission ensures that disinfection processes remain effective and consistent.

Engineers select quartz glass because alternative materials, such as borosilicate glass, block most UV-C radiation and cannot support high-temperature operation. The unique composition of quartz, including titanium oxide doping, allows it to block harmful radiation below 220 nm while maximizing germicidal output. This combination of properties makes quartz the only viable choice for critical sterilization systems.

Key reasons for quartz selection in UV applications:

Delivers ≥70% transmittance at 253.7 nm

Maintains performance at elevated temperatures

Blocks unwanted radiation below 220 nm

These advantages explain why high-temperature quartz glass remains the industry standard for germicidal UV lamps, ensuring both safety and efficacy.

Infrared Transmission: Enabling Efficient Radiant Heating at 900-1100°C

Infrared heating systems require materials that can transmit radiant energy efficiently at high temperatures. High-temperature quartz glass achieves over 95% direct radiation in clear quartz tubes, supporting rapid heat-up and cool-down cycles. This performance enables precise temperature control and energy efficiency in demanding industrial settings.

Quartz glass tubing supports continuous operation at temperatures up to 1100°C, with peak capability reaching 1450°C. This thermal stability ensures that heating elements deliver consistent output without degradation or loss of efficiency. The ability to maintain high infrared transmission under these conditions sets quartz apart from other materials.

Temperature Range | Quartz Type | Infrared Energy Production | Heat Up/Cool Down Time |

|---|---|---|---|

1000°F to 2000°F | Clear Quartz | 95% direct radiation | Full output in 30s, cool in 15s |

1000°F to 2000°F | Satin Quartz | 35% absorption | Similar times |

This table highlights how quartz glass enables efficient, reliable heating in high-temperature environments, making it the preferred material for optical heating systems.

Temperature-Optical Performance Balance: Maintaining Transmission at Operating Temperature

Maintaining optical clarity at high temperatures is essential for both UV and infrared applications. High-temperature quartz glass retains over 93% transmission in the visible range and more than 80% in the UV range, even during continuous use at elevated temperatures. This stability ensures that lamps and heaters perform reliably over long service lives.

Quartz glass exhibits outstanding thermal shock resistance, allowing it to withstand rapid temperature changes without cracking or losing optical quality. This property supports frequent cycling and demanding operational schedules. The combination of optical and thermal performance makes quartz glass indispensable for advanced lighting and heating systems.

Performance Factor | Quartz Glass | Alternatives |

|---|---|---|

UV/IR Transmission | >80% at 254 nm, >93% visible | Low/Variable |

High-Temperature Stability | Up to 1100°C continuous | Limited |

Thermal Shock Resistance | Excellent | Moderate/Poor |

These features explain why engineers consistently specify high-temperature quartz glass for applications where both optical and thermal demands are high.

What Analytical Instrumentation High-Temperature Applications Require Quartz Glass Tubing?

Analytical instrumentation often operates in environments where precision, purity, and durability are non-negotiable. High-temperature applications in laboratories and industry demand materials that can withstand extreme conditions without compromising results. Quartz glass tubing stands out as the essential choice for these demanding scenarios.

Optical Transparency for UV/Visible Light Transmission in Spectroscopy

Spectroscopy instruments rely on clear, unobstructed light paths to deliver accurate measurements. Quartz glass tubing provides exceptional optical transparency, transmitting over 90% of visible light and at least 80% of UV light above 300 nm. This high level of transmission ensures that analytical instruments capture even the faintest signals, which is critical for sensitive detection.

Engineers choose quartz glass because alternative materials cannot match its performance in the UV and visible ranges. For example, borosilicate glass blocks most UV light, while ceramics remain opaque. Quartz glass tubing enables laboratories to perform advanced analyses, such as trace element detection and fluorescence studies, with confidence.

Key reasons for quartz glass in spectroscopy:

Maintains ≥90% transmittance in the visible range

Delivers ≥80% transmittance in the UV range above 300 nm

Supports high-precision, high-temperature measurements

This unique optical clarity directly supports reliable, reproducible results in high-temperature analytical environments.

Ultra-High Purity for ppb-Level Contamination-Free Analysis

Analytical instruments must avoid even the smallest contamination to ensure accurate results. High-temperature quartz glass tubing offers ultra-high purity, with at least 99.98% SiO₂ and less than 20 ppm metallic impurities. This purity prevents interference in trace analysis, which often requires detection at parts-per-billion levels.

Laboratories depend on quartz glass tubing to maintain calibration stability and prevent contamination. Certified quartz tubes help ensure that results remain consistent over time, reducing the risk of costly errors. Strict dimensional tolerances also guarantee leak-free seals, which are vital for maintaining sample integrity.

Feature | Quartz Glass Tubing | Benefit |

|---|---|---|

Purity Level | ≥99.98% SiO₂ | Prevents contamination |

Metallic Impurities | <20 ppm | Enables ppb-level analysis |

Calibration Stability | Certified tubes | Reliable, repeatable measurements |

Dimensional Tolerance | Strict | Leak-free, accurate results |

This combination of purity and precision makes high-temperature quartz glass the clear choice for contamination-free analytical work.

Extreme Thermal Gradient Tolerance in ICP Torch Applications

Inductively Coupled Plasma (ICP) instruments operate under intense thermal gradients, with plasma centers reaching thousands of degrees while tube exteriors remain much cooler. Quartz glass tubing withstands these high-temperature extremes without cracking or deforming, ensuring uninterrupted operation.

Engineers select quartz glass for ICP torches because it resists rapid temperature changes and mechanical stress. This durability allows for repeated sample introduction and high-throughput analysis, which are essential in modern laboratories. Quartz glass tubing also supports high-purity sample handling, further enhancing analytical accuracy.

Summary of quartz glass advantages in ICP applications:

Tolerates extreme thermal gradients and rapid cycling

Maintains structural integrity at high temperature

Supports high-purity, high-throughput analysis

These properties explain why high-temperature analytical instrumentation depends on quartz glass tubing for reliable, long-term performance.

How Should Engineers Select Between Quartz and Alternative Materials for Specific High-Temperature Applications?

Engineers face critical decisions when choosing materials for high-temperature environments. The right choice impacts safety, efficiency, and long-term costs. Understanding why quartz or alternatives fit specific needs ensures reliable performance and avoids costly mistakes.

Decision Matrix: Temperature, Purity, Optical, and Chemical Requirements

Engineers must evaluate several factors before selecting a material for high-temperature use. Temperature limits, purity levels, optical properties, and chemical resistance all play a role in determining suitability. Opaque quartz tubes, for example, offer uniform heating and superior thermal shock tolerance, which is essential for applications with rapid temperature changes.

A structured decision matrix helps engineers weigh these requirements. By considering operational temperature, required purity (such as ≥99.9% SiO₂), optical transmission, and chemical compatibility, they can match the right material to the task. The Transmission–Thickness–Temperature Matrix and SEMI/ASTM standards provide quantifiable benchmarks, while control of OH⁻ and bubble class reduces defects in quartz products.

Factor | Description |

|---|---|

Temperature Limits | Establishes operational temperature ranges for materials. |

Purity Levels | Specifies the required purity of materials, e.g., ≥99.9% SiO₂. |

Optical Properties | Correlates optical transmission with wall thickness and operational temperature. |

Chemical Requirements | Addresses the need for materials to withstand specific chemical environments. |

This approach ensures engineers select materials that meet all high-temperature application demands, reducing the risk of failure and maximizing process reliability.

Cost-Performance Analysis: When Alternative Materials Suffice

Cost often influences material selection, but performance must remain the top priority in high-temperature settings. Quartz glass tubing excels in temperature resistance, UV transmission, and chemical inertness, making it the preferred choice for demanding applications. However, ordinary glass may suffice for moderate-performance needs, offering a more budget-friendly option.

Engineers should consider total cost of ownership, not just initial price. Fused quartz proves cost-effective for standard UV applications, while synthetic quartz, though more expensive, justifies its use in high-performance scenarios. Replacement frequency, maintenance, and downtime all factor into the real cost of material choices.

Key points for cost-performance analysis:

Quartz delivers unmatched durability in high-temperature environments.

Ordinary glass suits less demanding, lower-cost applications.

Total cost includes replacement and maintenance, not just purchase price.

By balancing budget constraints with performance needs, engineers ensure the selected material supports both operational goals and financial targets.

Application-Specific Selection: Matching Requirements to Material Capabilities

Every high-temperature application presents unique challenges. Engineers must gather detailed criteria for each task, including thermal shock resistance, chemical inertness, and optical performance. Superior thermal shock resistance and enhanced heat transfer make quartz ideal for rapid cycling and confined spaces.

Customization options also influence material selection. Flexible routing and specialized designs may require quartz tubing, especially when handling reactive substances or maintaining high clarity. A structured framework prevents common pitfalls, such as overlooking alternatives or misjudging trade-offs between properties.

Requirement | Description |

|---|---|

Thermal Shock Resistance | Superior performance for rapid cycling applications. |

Chemical Inertness | Essential for applications involving reactive substances. |

Optical Performance | Critical for applications requiring high clarity and precision. |

Customization Options | Important for specialized designs and configurations. |

Engineers who match application requirements to material capabilities achieve optimal results, ensuring safety, efficiency, and long-term value in high-temperature environments.

Quartz glass tubing stands out in high-temperature environments because it combines durability, chemical inertness, and optical clarity. Engineers rely on quartz for semiconductor fabrication, CVD, laboratory heating, and UV disinfection. The table below highlights why quartz remains the top choice:

Property | Description |

|---|---|

High Thermal Stability | Withstands up to 1,050°C |

Chemical Inertness | Resists acids, bases, and solvents |

High Transparency | Transmits UV and visible light |

A structured decision framework helps engineers match material capabilities to application needs, reducing costly errors and maximizing performance.

FAQ

Why do engineers prefer quartz glass tubing for high-temperature applications?

Quartz glass tubing offers unmatched purity, thermal stability, and chemical resistance. Engineers choose quartz because it prevents contamination, maintains shape at extreme temperatures, and supports reliable, long-term operation.

Key reasons:

Ultra-high purity

Superior thermal shock resistance

Chemical inertness

Why does quartz glass outperform alternatives in UV lamp systems?

Quartz glass transmits over 80% of UV-C light at 254 nm, enabling effective sterilization. Alternatives block UV or degrade at high temperatures. Quartz maintains optical clarity and performance, ensuring consistent disinfection.

Material | UV Transmission | High-Temp Stability |

|---|---|---|

Quartz Glass | >80% | Excellent |

Borosilicate | <10% | Poor |

Why is quartz glass tubing essential for semiconductor diffusion furnaces?

Semiconductor diffusion furnaces require less than 1 ppb contamination. Quartz glass tubing meets this strict standard, preventing yield loss and costly defects. Alternatives introduce impurities that compromise chip quality.

Engineers trust quartz for purity and reliability in advanced manufacturing.

Why do analytical instruments rely on quartz glass tubing?

Quartz glass provides high optical transparency and ultra-low contamination. Analytical instruments need clear light paths and precise measurements. Quartz ensures accurate results and withstands rapid temperature changes.

Why should engineers use a decision matrix when selecting tubing materials?

A decision matrix helps engineers match temperature, purity, optical, and chemical needs to material capabilities. This approach prevents costly errors and ensures optimal performance in high-temperature environments.

Benefits:

Reduces risk of failure

Maximizes process reliability

Supports informed material selection