- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz UV Cuvette

- /

- Broadband UV-Visible Fused Quartz...

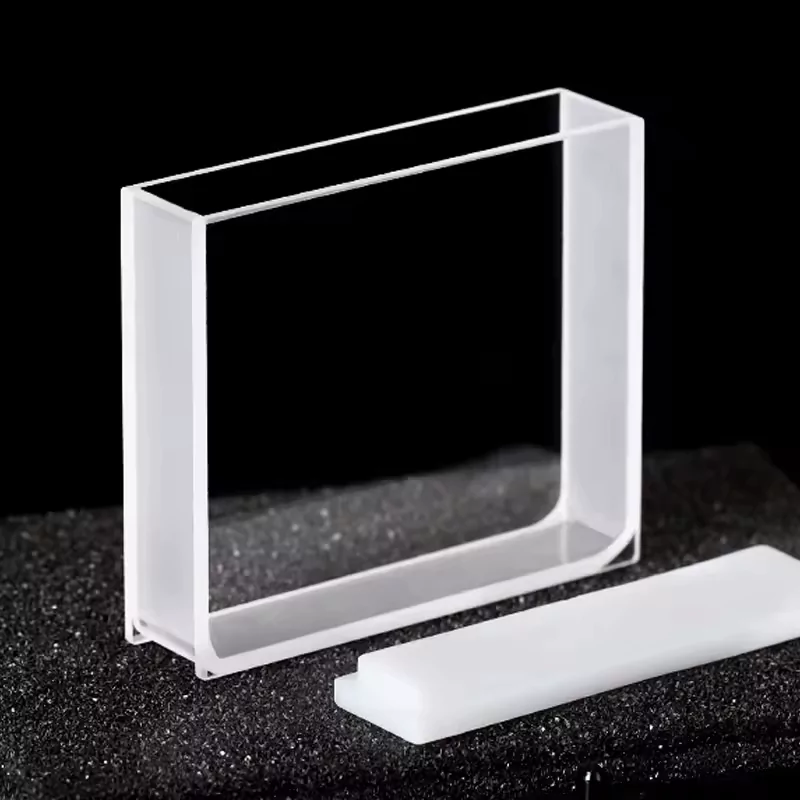

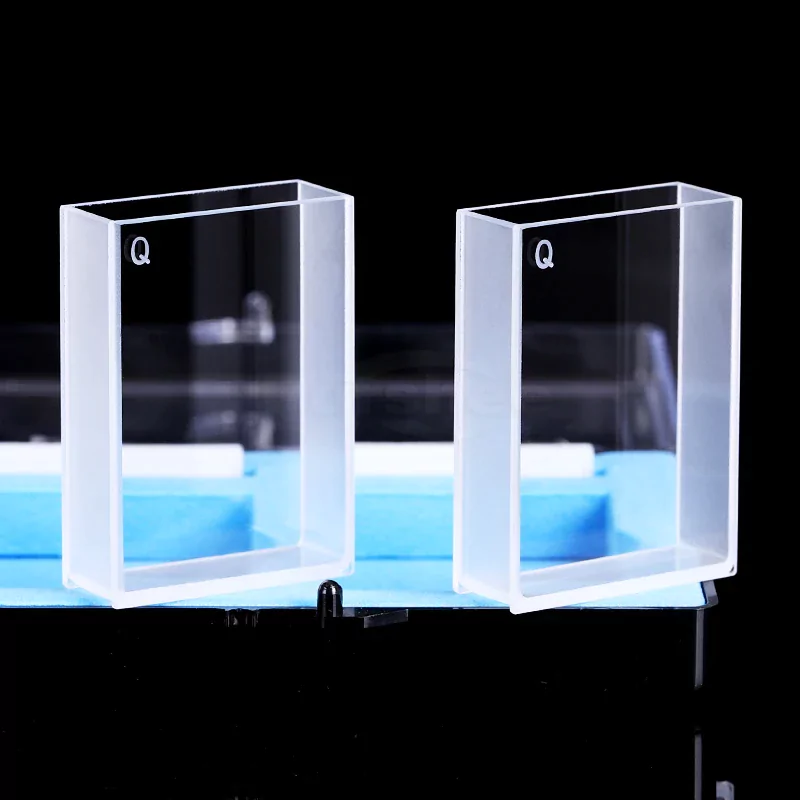

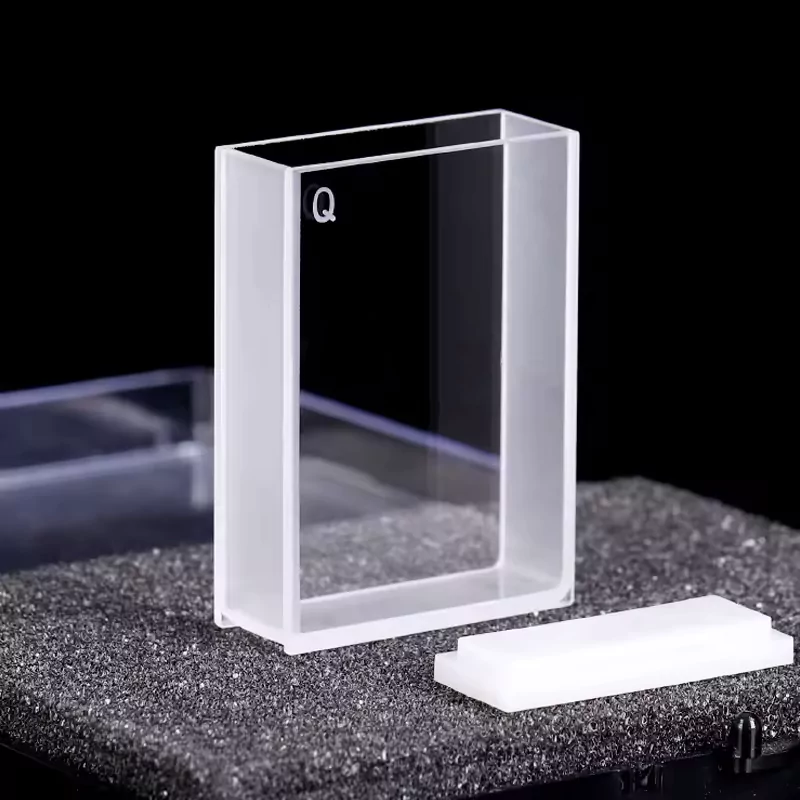

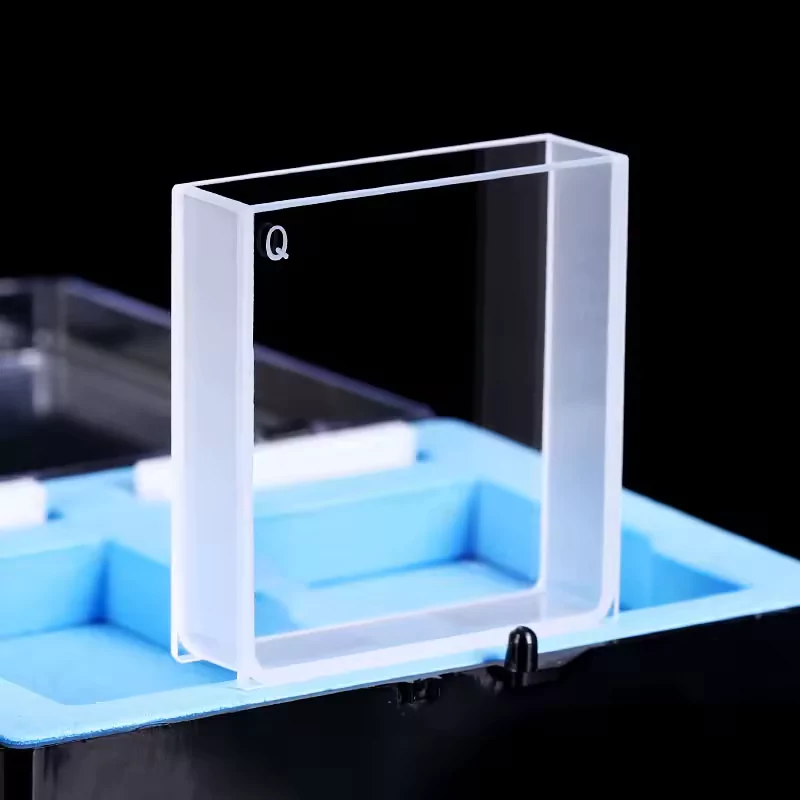

Broadband UV-Visible Fused Quartz Macro Cuvette for Spectrophotometric Analysis-TOQUARTZ®

Features of Fused Quartz Macro Cuvette

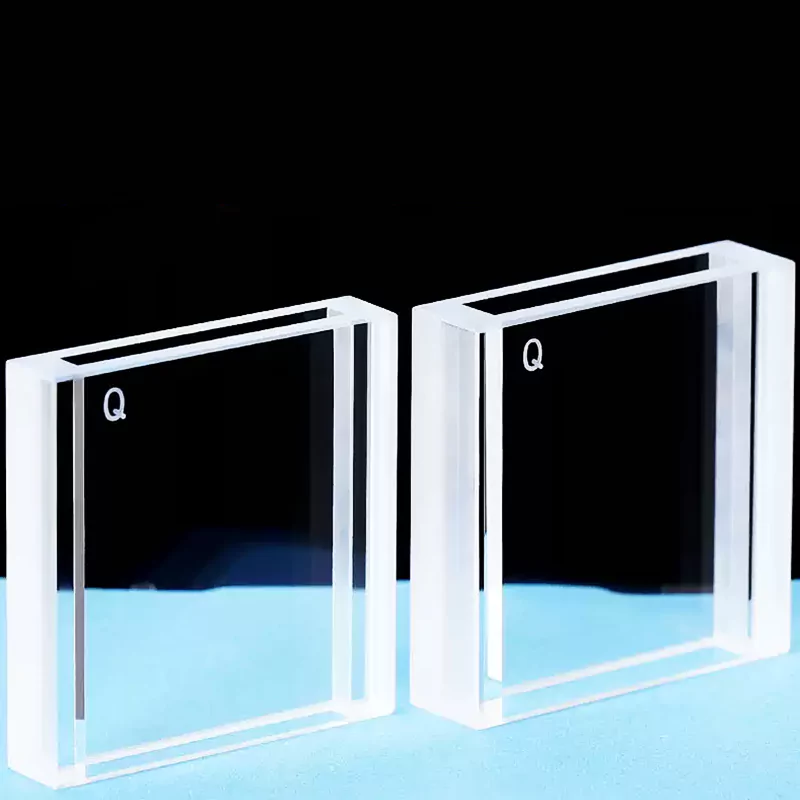

TOQUARTZ® Fused Quartz Macro Cuvettes are engineered for precision analytical applications in UV-VIS spectrophotometry. Each cuvette is crafted from high-purity materials with careful attention to optical and physical properties crucial for accurate laboratory measurements.

Optical Properties

- Exceptional UV transparency (200nm-2500nm range)

- No absorption peaks across the full spectrum

- Precision polished surfaces for optimal light transmission

- Optical transparency ≥80% (200-800nm)

Material Excellence

- High-purity fused quartz (≥99.98% SiO₂)

- Excellent chemical resistance to acids, bases, and salts

- Thermal stability up to 600°C

- Low thermal expansion coefficient: 5.5×10⁻⁷ /°C

Design Advantages

- Large optical windows for enhanced light path

- Precision manufacturing with ±0.1mm dimensional tolerance

- Available with PTFE or quartz lids

- Large Path Length

- High UV Transparency

- Custom Sizes Available

Technical Specifications & Dimensions of Fused Quartz Macro Cuvette

Technical Specifications

| Property | Value |

| 1. Physical Properties | |

| Material | Fused Quartz (≥99.99% SiO₂) |

| Density | 2.2 g/cm³ |

| Hardness | 5.5-6.5 Mohs |

| Wall Thickness | 1.25mm ±0.1mm |

| Surface Finish | Optical polish, fire polished edges |

| Dimensional Tolerance | ±0.1mm |

| 2. Chemical Properties | |

| Purity | ≥99.99% SiO₂ |

| Acid Resistance | Excellent (except HF) |

| Alkali Resistance | Good up to pH 12 |

| Solvent Resistance | Excellent |

| Water Absorption | 0% |

| OH Content | < 30 ppm |

| 3. Optical Properties | |

| Wavelength Range | 190nm-2500nm |

| Transparency | ≥80% (200-800nm) |

| Refractive Index | 1.458 (at 587.6nm) |

| Thermal Expansion | 5.5×10⁻⁷ /°C |

| Max Operating Temp | 600°C |

| Absorption Peaks | None in UV-VIS range |

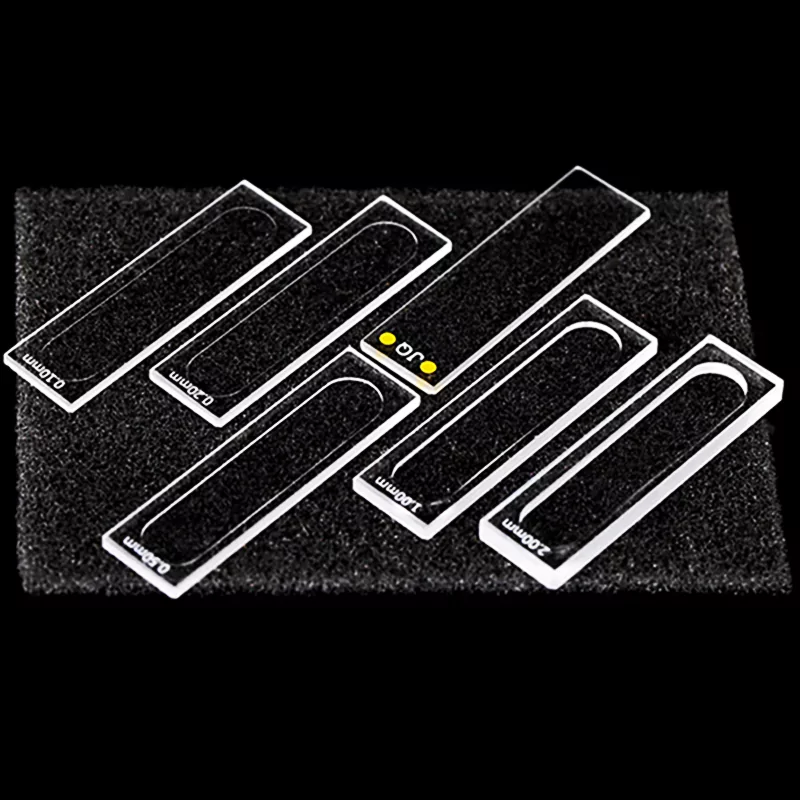

Size Chart

| Model | Description | Wavelength | Path Length | Volume | Thermostability | Outline Dimension |

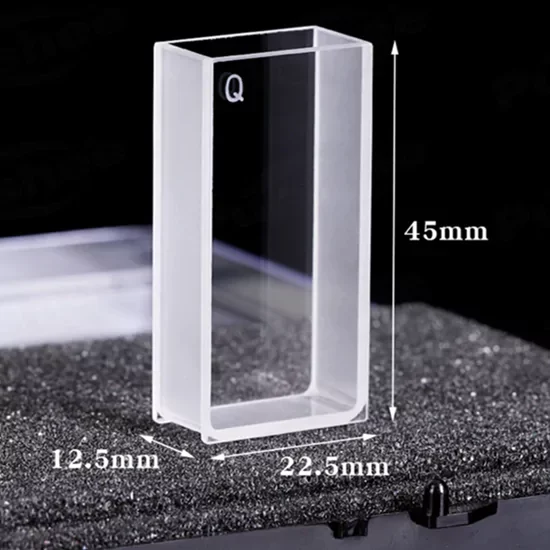

| AT-BSM-040 | 7ml Fused Quartz Macro Cuvette | 200nm-2500nm | 10mm | 7ml | 600℃ | 12.5×22.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Thermostability | Outline Dimension |

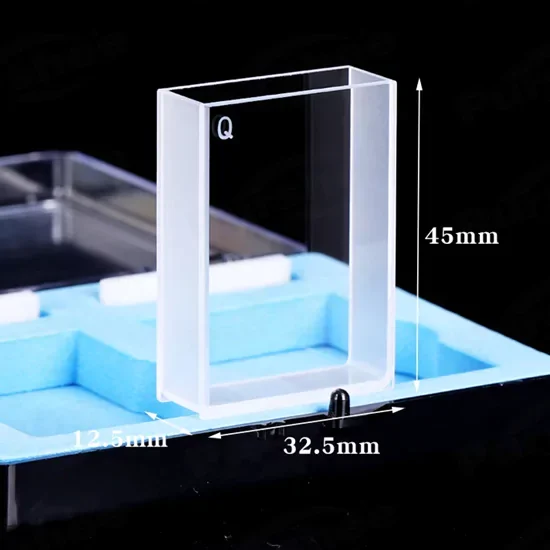

| AT-BSM-003 | 10.5ml Fused Quartz Macro Cuvette | 200nm-2500nm | 10mm | 10.5ml | 600℃ | 12.5×32.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Thermostability | Outline Dimension |

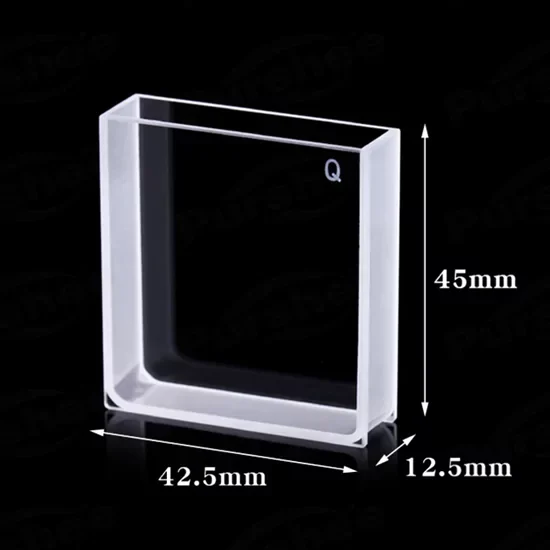

| AT-BSM-002 | 14ml Fused Quartz Macro Cuvette | 200nm-2500nm | 10mm | 14ml | 600℃ | 12.5×42.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Thermostability | Outline Dimension |

| AT-BSM-007 | 17.5ml Fused Quartz Macro Cuvette | 200nm-2500nm | 50mm | 17.5ml | 600℃ | 12.5×52.5x45mm |

TOQUARTZ® Solving Challenges with Fused Quartz Macro Cuvette

Fused Quartz Macro Cuvette for Protein Analysis

Key Advantages

-

Extended Path Length for Low-Concentration Detection

50mm path length increases absorbance signal by up to 5× for samples below 0.1 mg/mL. -

Large Volume Capacity for Sample Homogeneity

17.5ml capacity reduces pipetting error and improves reproducibility in triplicate assays. -

No UV Absorption Interference in 190–220nm Range

Zero absorption peaks ensure accurate readings for peptide bonds and aromatic residues.

TOQUARTZ® solution

A German university lab conducting BCA protein assays at 562nm reported inconsistent readings using standard 10mm cuvettes. After switching to TOQUARTZ 50mm macro cuvettes, signal-to-noise ratio improved by 4.8×, enabling detection down to 0.03 mg/mL. Assay repeatability increased by 22%, reducing retest frequency and reagent waste.

Fused Quartz Macro Cuvette for Instrument Manufacturing

Key Advantages

-

±0.1mm Dimensional Tolerance for Calibration Consistency

Ensures <1% deviation in absorbance across instrument batches during factory QA. -

Batch-Matched Optical Uniformity

Refractive index variation <0.0002 across production lots verified by interferometry. -

Custom Fit for Spectrophotometer Holders

Outer dimensions tailored to ±0.05mm to eliminate alignment drift during calibration.

TOQUARTZ® solution

A Japanese spectrophotometer OEM faced a 9.6% calibration failure rate due to cuvette dimensional drift from previous suppliers. After adopting TOQUARTZ macro cuvettes with certified ±0.1mm tolerance and batch-matched optical specs, calibration pass rate rose to 99.2%, and warranty claims dropped by 87% over two quarters.

Fused Quartz Macro Cuvette for Reaction Monitoring

Key Advantages

-

Thermal Stability Maintained up to 600°C

Supports continuous monitoring of exothermic reactions without optical distortion. -

Low Thermal Expansion (5.5×10⁻⁷ /°C)

Prevents path length shift during temperature ramping in kinetic assays. -

High Volume Enables Long-Term Sampling

17.5ml capacity supports 72-hour reaction tracking without sample depletion.

TOQUARTZ® solution

A U.S. biochemical lab monitoring enzyme kinetics at 45–90°C observed 0.2 nm baseline drift per hour using standard cuvettes. Switching to TOQUARTZ macro cuvettes eliminated thermal-induced distortion, maintaining baseline stability within ±0.03 nm over 48 hours. This improved data integrity and reduced experiment reruns by 35%.

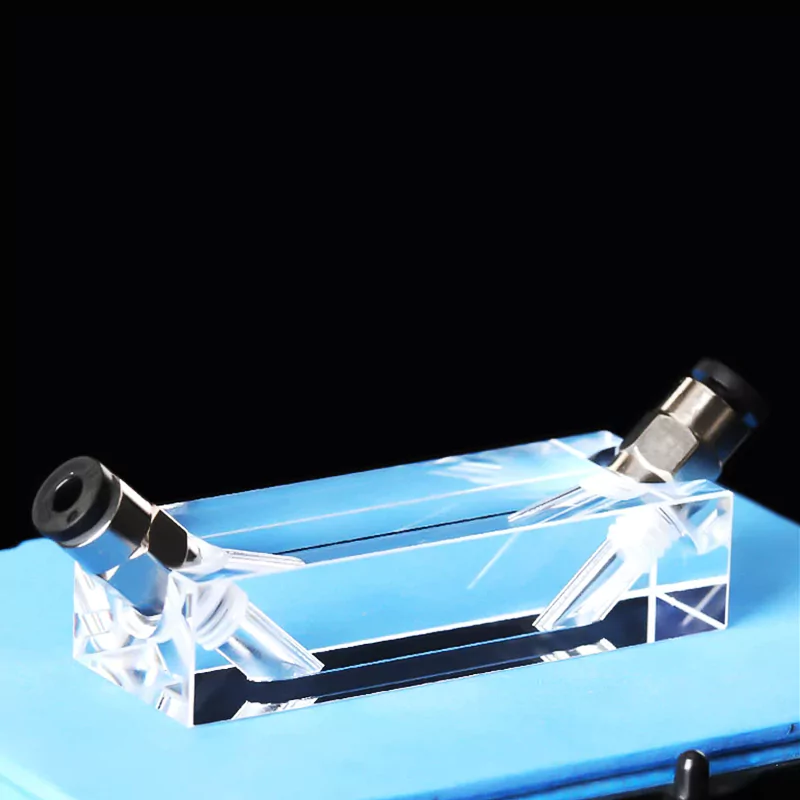

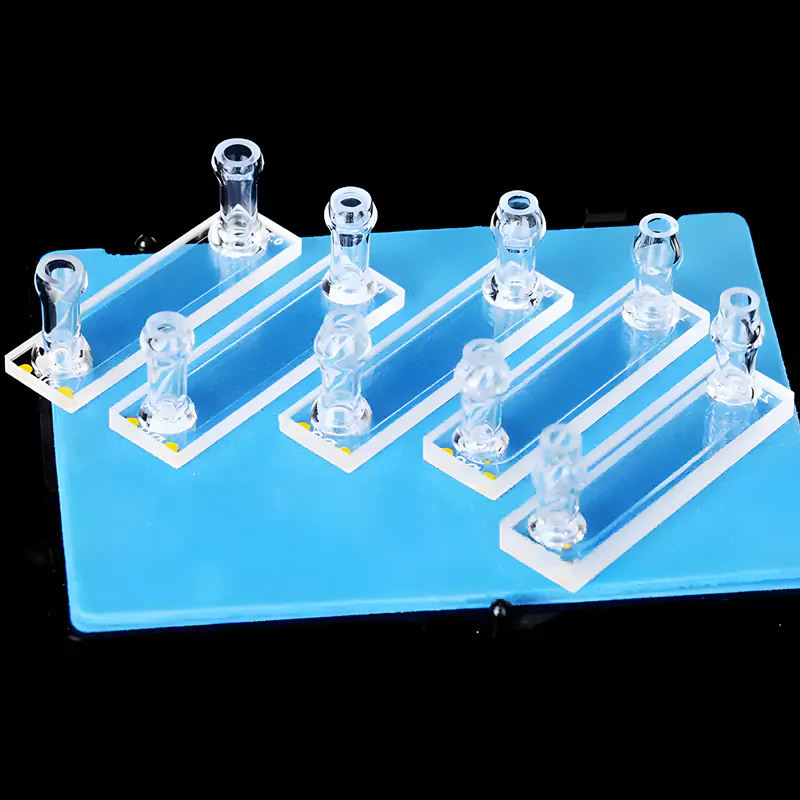

Customization Services for TOQUARTZ® Fused Quartz Macro Cuvette

Custom Dimensions

- Custom wall thickness options

- Modified height and width dimensions

- Instrument-specific designs for direct compatibility

Specialized Features

- Custom flow-through ports for continuous monitoring

- Specialized lid designs (screw caps, snap-on, etc.)

- Multiple optical windows for 90° measurements

TOQUARTZ® Customization Process

Consultation

TOQUARTZ® engineers discuss your specific requirements and application needs to understand the optimal solution.

Prototype & Testing

We develop a custom prototype based on your specifications and provide samples for testing and validation.

Production

After approval, we manufacture your custom cuvettes with rigorous quality control and deliver within agreed timeframes.

Usage Guide of Fused Quartz Macro Cuvette

Handling & Operation

- Always handle cuvettes by the non-optical sides to prevent fingerprints and contamination on measurement windows.

- Fill cuvettes to the recommended volume level, typically 80-90% of total capacity for best results.

- When using lids, ensure proper seating to prevent leakage or evaporation during extended measurements.

- For temperature-controlled applications, allow gradual temperature changes (max 5°C/minute) to prevent thermal shock.

- When inserting into spectrophotometers, ensure proper orientation with optical windows aligned with the light path.

Cleaning & Storage

- Clean immediately after use to prevent sample residue from drying and becoming difficult to remove.

- Use mild laboratory detergent (pH 7-8) in distilled water for initial cleaning, followed by thorough rinsing.

- For stubborn residues, soak in 10% HCl or ethanol solution (avoid HF which damages quartz). Rinse thoroughly afterward.

- Dry with lint-free optical tissue or allow to air dry in a dust-free environment.

- Store in original packaging or dedicated cuvette holders in a clean, dry environment away from potential impacts.

Important Precautions

- Avoid rapid temperature changes that can cause thermal shock and potential fractures.

- Never use hydrofluoric acid (HF) for cleaning as it etches and damages quartz surfaces.

- Avoid mechanical stress or pressure that could cause fractures or affect optical alignment.

- Do not use abrasive cleaning materials that could scratch optical surfaces and affect measurements.

Need Technical Guidance for Your Application?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: How does the material purity affect spectrophotometric measurements?

A: Material purity directly impacts UV transparency and baseline stability. Our ≥99.98% SiO₂ fused quartz minimizes absorption and scattering effects, providing more accurate measurements, especially in the deep UV range (190-220nm). Lower purity materials may introduce absorption peaks or background interference.

Q: What is the maximum path length available for macro cuvettes?

A: TOQUARTZ® standard macro cuvettes offer path lengths up to 100mm. For custom requirements beyond this range, please contact our engineering team. Extended path lengths may require special handling and design considerations to maintain optical performance.

Q: Can these cuvettes be used for fluorescence spectroscopy?

A: Yes, TOQUARTZ® Fused Quartz Macro Cuvettes are suitable for fluorescence applications. For optimal fluorescence measurements, we recommend models with four clear optical windows. We also offer specialized black-walled cuvettes that reduce light scattering and improve signal-to-noise ratios for sensitive fluorescence measurements.

Q: How do I clean macro cuvettes without damaging the optical surfaces?

A: For routine cleaning, rinse with distilled water followed by acetone or ethanol, and air dry or use lint-free optical tissue. For stubborn residues, soak in dilute laboratory detergent, then rinse thoroughly. Always avoid abrasive materials and hydrofluoric acid (HF), which attacks quartz. Refer to our detailed cleaning guide for specific sample residue recommendations.

Q: Are calibration certificates available with the cuvettes?

A: Yes, we offer optional traceable calibration certificates for path length verification and material certification. These certificates include measurements performed on traceable instruments with NIST-traceable standards. Many instrument manufacturers and regulated laboratories require these certificates for validation and quality assurance purposes.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.