- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz UV Cuvette

- /

- Custom-configurable Flow-through Quartz Cuvette...

Custom-configurable Flow-through Quartz Cuvette with Tubes for Spectrophotometric Systems -TOQUARTZ®

Features of Flow-through Quartz Cuvette with Tubes

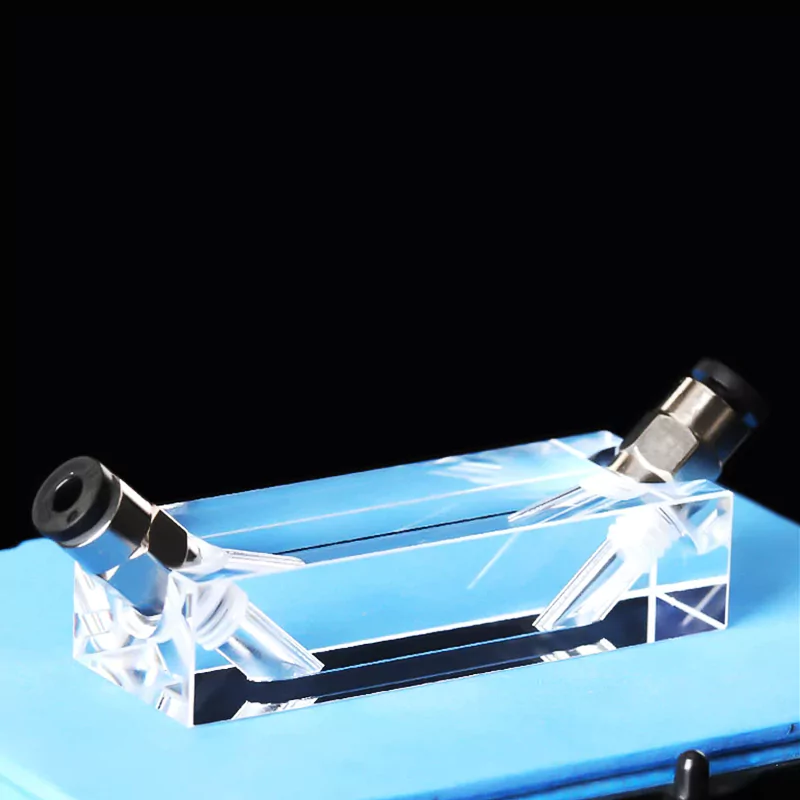

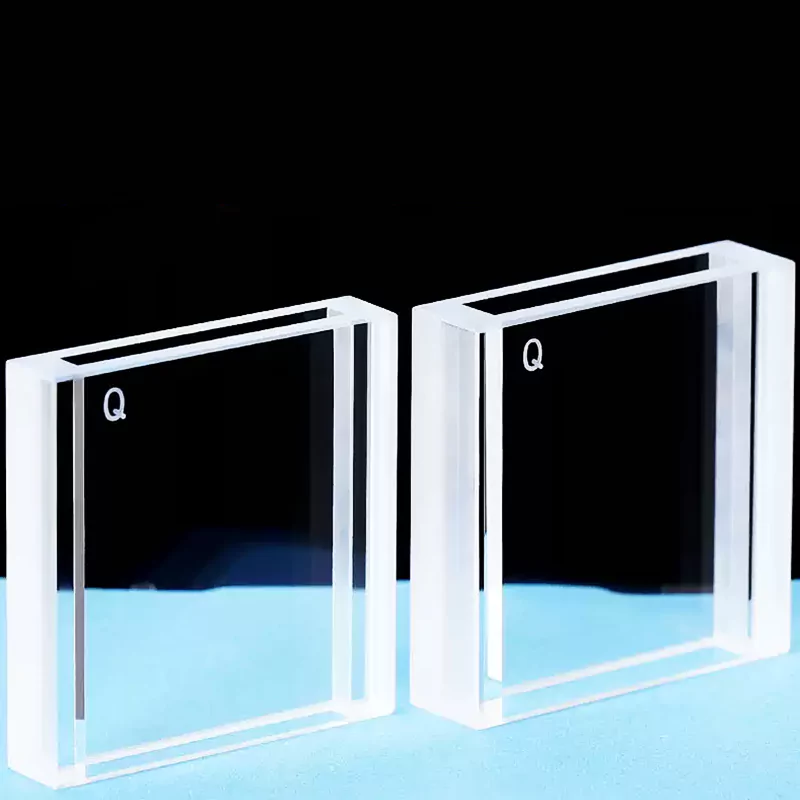

TOQUARTZ® Flow-through Quartz Cuvettes combine precision optical design with high-performance material properties to deliver reliable continuous flow analysis in spectrophotometric applications. Each cuvette is manufactured from high-purity fused quartz with exceptional material characteristics suitable for demanding analytical environments.

Optical Properties

Transparency in UV-Vis range (200-2500nm) with no absorption peaks, making these cuvettes ideal for precise spectrophotometric measurements across a wide wavelength range.

Chemical Resistance

Resistance to acids, bases, and corrosive chemicals (except HF and hot phosphoric acid), enabling use with aggressive reagents and samples in analytical applications.

Precision Flow Control

Carefully designed inlet and outlet tubes with consistent inner diameter enable stable flow rates and precise control of sample volume, essential for reproducible analytical results.

- High-purity fused quartz ≥99.98% SiO₂

- Temperature resist up to 1100°C

- Tolerance ±0.1mm for standard products

Technical Specifications & Dimensions of Flow-through Quartz Cuvette with Tubes

Technical Specifications

| Property | Value |

| Physical Properties | |

| Material | High-purity fused quartz (99.995% SiO₂) |

| Density | 2.2 g/cm³ |

| Mechanical Strength | Tensile Strength: 50 MPa |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷ /°C (20-300°C) |

| Max Operating Temperature | 1100°C |

| Dimensional Tolerance | ±0.1mm (standard), ±0.05mm (available for select models) |

| Chemical Properties | |

| Chemical Composition | SiO₂ > 99.995% |

| Chemical Resistance | Resistant to most acids, bases, and solvents (except HF and hot phosphoric acid) |

| Water Absorption | < 0.001% |

| Optical Properties | |

| Transmission Range | 200nm – 2500nm |

| UV Cutoff | ~170nm |

| Refractive Index | 1.458 (at 546nm) |

| Surface Quality | Polished optical windows, free from scratches and bubbles in optical path |

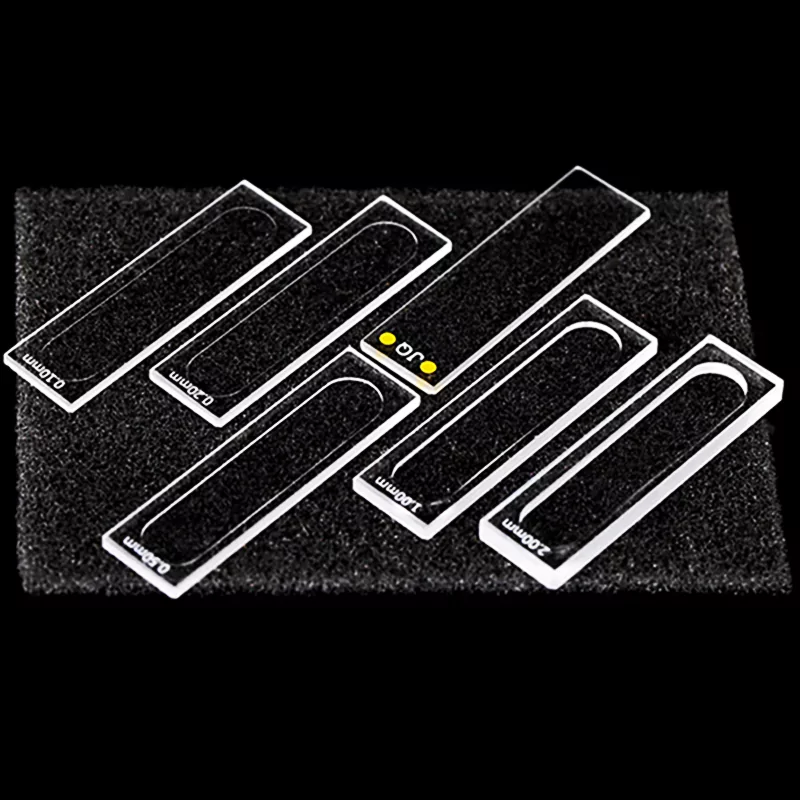

Size Chart

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-022 | 150μl Flow-through Quartz Cuvette with Tubes | 200nm-2500nm | 0.5mm | 150μl | >80% (Paired Testing) | 12.5x3x45mm |

TOQUARTZ® Solving Challenges with Flow-through Quartz Cuvette

with Tubes

Flow-through Quartz Cuvettes for Analytical Instrument Manufacturers

Key Advantages

-

Batch-to-batch optical path deviation < ±0.01mm

Ensures consistent absorbance readings across instruments in multi-unit production lines. -

3D-aligned tubing ports with ±0.1mm positional tolerance

Facilitates seamless integration into automated spectrophotometer assemblies without manual adjustment. -

150μl internal volume with 0.5mm path length for high-sensitivity detection

Optimized for compact instrument designs requiring low sample consumption and high signal-to-noise ratio.

TOQUARTZ® solution

A German UV-Vis instrument OEM faced ±0.03mm path length variation from their previous supplier, causing calibration drift across units. After switching to TOQUARTZ, path length deviation was reduced to <±0.01mm, improving inter-instrument consistency by 85% and reducing recalibration time by 40% across 200+ units annually.

Flow-through Quartz Cuvettes for Water Quality Monitoring Systems

Key Advantages

-

99.98% SiO₂ purity with <0.001% water absorption rate

Prevents signal drift in long-term monitoring of high-humidity or submerged environments. -

Acid-resistant tubing fusion tested in 10% HCl for 72 hours

Maintains structural integrity and optical clarity under continuous exposure to corrosive water samples. -

Thermal cycling durability: 500 cycles from 5°C to 80°C without microfracture

Validated for outdoor installations with fluctuating ambient temperatures.

TOQUARTZ® solution

A U.S. municipal water monitoring integrator reported 12% annual failure rate due to microcracks in flow cells exposed to acidic effluents. TOQUARTZ flow cells passed 500 thermal cycles and 72-hour acid soak tests, reducing failure rate to <1.5% and extending field replacement intervals from 6 to 18 months.

Flow-through Fused Quartz Cuvettes for Laboratory Automation

Key Advantages

-

70μl internal volume with <0.2% dead volume ratio

Enables precise quantification in microfluidic systems with limited sample availability. -

Flow rate stability at 0.1–10 ml/min with <±2% deviation

Supports rapid switching between samples in high-throughput screening workflows. -

Custom tube-to-window offset <0.05mm for robotic alignment

Ensures compatibility with automated pipetting and optical alignment systems.

TOQUARTZ® solution

A Japanese biotech lab using automated enzyme kinetics platforms experienced 18% sample loss due to dead volume in standard flow cells. TOQUARTZ delivered a 70μl low-dead-volume design with robotic-compatible alignment, reducing sample waste by 60% and increasing throughput by 25% in 96-well plate workflows.

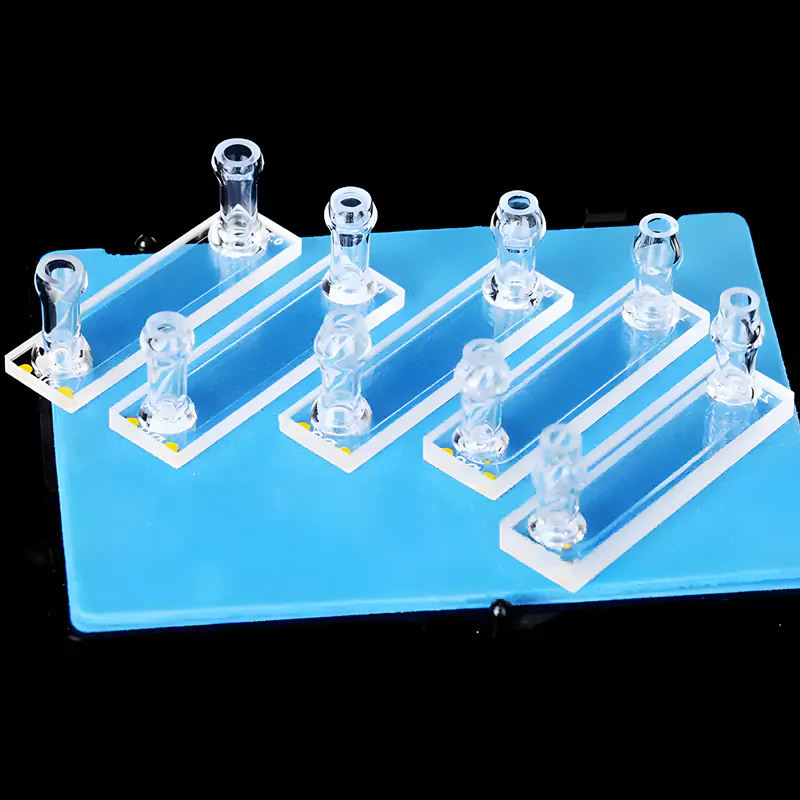

Customization Services for TOQUARTZ® Flow-through Quartz Cuvette

with Tubes

Dimensional Customization

Ideal for instrument designers requiring precise integration with existing hardware or specialized analytical methods demanding non-standard optical geometries.

- Custom path lengths

- Non-standard cell body dimensions

- Specialized optical window geometries

- Modified tube length, diameter, and positioning

- Custom internal flow path configurations

Connection Adaptations

Simplifies integration with existing laboratory systems and reduces the need for adapters that can introduce dead volume or potential leak points.

- Customized tube diameters for specific tubing compatibility

- Integration of specialized fittings directly onto cell body

- Multi-port designs for complex flow arrangements

- Angled tube configurations for space-constrained installations

- Compatible with HPLC, microfluidic, or proprietary connection systems

Performance Optimization

Tailored solutions for demanding analytical environments where standard flow cells may not deliver optimal performance or durability for specialized requirements.

- Enhanced pressure tolerance designs

- Temperature-optimized configurations

- Special surface treatments for specific applications

- Low-volume cell designs for precious samples

- Optimized internal geometry for specific flow characteristics

Customization Process

- Consultation: Initial discussion of requirements, application details, and performance specifications.

- Design Proposal: Our engineering team develops preliminary designs with 3D renderings and specifications.

- Refinement: Collaborative review and adjustment of design elements to meet exact requirements.

- Prototyping: Production of prototype units for testing and validation in your application.

- Production: Full-scale manufacturing with comprehensive quality control and documentation.

Usage Guide of Flow-through Quartz Cuvette with Tubes

Installation and Setup

- Inspect the flow cell upon receipt for any damage or defects in the optical windows or connecting tubes.

- Handle the flow cell only by the non-optical surfaces to prevent fingerprints or contamination on the optical windows.

- Connect tubing using appropriate fittings designed for the specific tube diameter. Avoid overtightening which may crack the quartz tubes.

- When mounting in an instrument, apply minimal pressure and use flexible connections where possible to prevent stress on the cell body.

- For initial setup, flush the flow cell with filtered, degassed solvent to remove any manufacturing residues or dust particles.

Operational Recommendations

- Maintain flow rates within recommended ranges (typically 0.1-10 ml/min) to prevent pressure buildup or air bubble formation.

- Filter all samples and mobile phases to 0.45μm or better to prevent particulate accumulation in the flow cell.

- When changing sample types, flush the cell thoroughly with an appropriate solvent to prevent cross-contamination.

- For high-sensitivity applications, establish a stable baseline by flowing the reference solution through the cell before introducing samples.

- Monitor backpressure during operation; sudden increases may indicate blockage requiring immediate attention.

Cleaning and Maintenance

- For routine cleaning, flush with appropriate solvents in increasing polarity (e.g., water → methanol → acetone) followed by the intended mobile phase.

- For persistent contamination, use a 10% nitric acid solution (avoid HF or hot phosphoric acid which can damage quartz), followed by thorough water rinsing.

- If optical windows show residue, prepare a cleaning solution of 2% laboratory detergent in water, flush slowly for 30 minutes, then rinse thoroughly with distilled water.

- For biological samples, a 5% sodium hypochlorite solution can be effective for removing protein deposits, followed by thorough water rinsing.

- Dry the flow cell completely before storage by flushing with acetone or methanol followed by dry nitrogen or air if available.

Storage and Handling

- Store clean, dry flow cells in their original packaging or in a dust-free container with optical windows protected.

- For long-term storage, seal the tube ends with appropriate caps to prevent dust contamination of the internal surfaces.

- Avoid thermal shock by allowing the flow cell to gradually reach operating temperature when transitioning between temperature extremes.

- Periodically inspect stored flow cells for signs of damage, contamination, or degradation before reuse.

- When transporting installed flow cells, fill with an appropriate solvent to prevent air bubble formation during movement.

Need Expert Guidance for Your Flow Analysis Application?

the ideal Flow-through Quartz Cuvette with Tube for your specific requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the maximum pressure a TOQUARTZ flow-through cuvette with tube can withstand?

A: Standard models are rated up to 5 bar; reinforced designs with thicker walls and fused joints can handle up to 10 bar, depending on geometry and tubing configuration.

Q: How does temperature affect quartz flow cell with tube performance?

A: Temperature affects quartz flow cell with tube performance in several ways:

1) Thermal expansion – quartz has a very low thermal expansion coefficient (5.5×10⁻⁷ /°C), making it dimensionally stable across a wide temperature range;

2) Optical properties – the refractive index of quartz varies slightly with temperature, which may impact precise optical measurements;

3) Mechanical stress – rapid temperature changes can induce thermal stress, so gradual temperature transitions are recommended;

4) Connection integrity – differential expansion between quartz and connection materials may affect sealing at extreme temperatures;

5) Maximum operating temperature is 1100°C, though most analytical applications operate between ambient and 95°C.

Q: Are TOQUARTZ® quartz flow UV cells with tube compatible with HPLC systems?e 6-sided quartz flow cuvette?

A: Yes, TOQUARTZ® Flow-through Quartz Cuvettes with Tube can be designed for compatibility with HPLC systems. Standard models can handle pressures up to 5 bar, while reinforced designs can withstand up to 20 bar pressure. For HPLC integration, we recommend:

1) Specifying the exact connection type required (1/16″ PEEK, etc.);

2) Considering low internal volume designs (70-150μl) to minimize band broadening;

3) Selecting appropriate path length based on expected analyte concentration;

4) Using our reinforced designs for high-pressure applications;

5) Specifying compatibility with specific mobile phases, especially for specialized chromatography methods using aggressive solvents.

Q: What flow rates can TOQUARTZ Flow-through Quartz UV Cuvettes with Tube handle? connection ports?

A: TOQUARTZ® Flow-through Quartz UV Cuvettes with Tubes are designed to handle flow rates from 0.1 ml/min to 10 ml/min for standard models. The optimal flow rate depends on several factors:

1) Cell geometry and internal volume;

2) Desired residence time for the analytical method;

3) Pressure limitations of the overall system;

4) Sample viscosity and temperature;

5) Connection tubing diameter.

Custom designs can accommodate higher flow rates up to 50 ml/min with appropriate reinforcement and connection adaptations. For high-precision analytical applications, maintaining a consistent flow rate is often more important than the absolute flow rate value.

Q: How does the internal volume of a flow-through cuvette affect analysis?

A: The internal volume of a flow-through cuvette impacts several analytical parameters:

1) Sample consumption – smaller volumes require less sample, critical for precious or limited samples;

2) Response time – smaller volumes enable faster detection of concentration changes in dynamic systems;

3) Dispersion – larger volumes can lead to band broadening in chromatographic applications;

4) Residence time – affects reaction monitoring and kinetic studies where time-resolved measurements are important;

5) Flow resistance – smaller volumes may create higher backpressure at equivalent flow rates.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.