Thermal shock resistance plays a critical role in the service life of Quartz Tubes for Analytical Applications. High-temperature analytical methods often expose these tubes to rapid heating and cooling, which can cause sudden stress and lead to cracking or failure. Effective management of thermal shock ensures reliable tube performance and extends their lifespan in demanding laboratory environments.

Key Takeaways

Thermal shock resistance is crucial for quartz tubes, as it prevents cracking during rapid temperature changes.

Selecting high-purity quartz with uniform wall thickness enhances durability and reduces failure risk.

Implementing controlled heating and cooling rates minimizes internal stress and extends tube lifespan.

Regular visual inspections help detect early signs of devitrification, allowing for timely replacements.

Using multi-stage annealing processes during manufacturing significantly improves thermal shock resistance.

What Temperature Differential Causes Thermal Shock Failure in Analytical Quartz Tubes?

Thermal shock resistance determines how well Quartz Tubes for Analytical Applications withstand rapid temperature changes. Laboratories often push these tubes to their limits during high-temperature analysis, making it essential to understand the factors that lead to failure. Knowing the causes and thresholds of thermal shock helps laboratories prevent costly downtime and extend tube life.

Understanding Thermal Expansion Coefficient Differences Between Glass Materials

Thermal shock occurs when different parts of a tube expand or contract at different rates. Fused quartz has a very low thermal expansion coefficient (α = 0.5 × 10⁻⁶ K⁻¹), which allows it to survive temperature gradients that would quickly shatter borosilicate glass (α = 3.3 × 10⁻⁶ K⁻¹). This property means Quartz Tubes for Analytical Applications can withstand rapid heating and cooling cycles that would cause other materials to crack.

Material purity and wall thickness also play a role in thermal shock resistance. High-purity quartz with uniform wall thickness resists cracking better than impure or uneven tubes, and heating or cooling rates above 1000°C/minute can still cause failure even in high-quality quartz. Laboratories must select the right material and control temperature changes to prevent internal stresses.

Quartz tubes resist thermal shock better than most glass materials, but extreme temperature differentials can still cause cracking, warping, or complete failure.

Key Points:

Low thermal expansion coefficient gives quartz superior shock resistance.

Material purity and wall thickness affect tube durability.

Controlled heating/cooling rates are essential for tube longevity.

How Geometric Discontinuities Concentrate Thermal Stress

Geometric discontinuities, such as welded joints or diameter transitions, create weak points in quartz tubes. These areas concentrate thermal stress during rapid temperature changes, making them more likely to crack or fail. Stress often exceeds 50 MPa at these points, especially when temperature differentials are high.

Design modifications can reduce stress concentrations and improve tube longevity. Gradual transitions, relief notches, and fillet radii help distribute stress more evenly, while avoiding sharp corners prevents crack initiation. Analytical tube manufacturers use these strategies to minimize failure risk in demanding applications.

Quartz Tubes for Analytical Applications with optimized geometry survive more thermal cycles and experience fewer failures in laboratory settings.

Design Modification | Effect on Stress Concentration |

|---|---|

Gradual transitions | Reduces abrupt stress increases |

Relief notches | Alleviates localized stress |

Fillet radii | Prevents sharp corner cracks |

Multiple small notches | Smooths out stress distribution |

ASTM C1525 Water Quenching Test Methods for Thermal Shock Validation

The ASTM C1525 water quenching test evaluates how well quartz tubes resist thermal shock. In this test, technicians heat ceramic specimens to a high temperature, then rapidly cool them in water to create thermal stress. They inspect the specimens for visible damage and calculate flexural strength to determine if the material retains its properties.

Quartz glass can withstand temperatures above 1000°C in this test, often showing no visible failure or loss of strength. This method helps laboratories and manufacturers confirm that Quartz Tubes for Analytical Applications meet strict durability standards before use in high-temperature analysis.

The ASTM C1525 test provides a reliable benchmark for predicting tube performance under extreme thermal cycling.

Procedure | Description |

|---|---|

Heating | Specimens heated to predetermined high temperature |

Quenching | Rapid cooling in water bath to induce thermal stress |

Inspection | Visual and non-destructive checks for damage |

Flexural Strength | Calculation based on specimen dimensions and fracture load |

Why Do Some Quartz Tubes Survive Thousands of Thermal Cycles While Others Fail Prematurely?

Quartz tubes show different lifespans in high-temperature analytical settings. Some tubes withstand thousands of thermal cycles, while others crack or degrade after only a few hundred uses. Several factors, including devitrification, annealing, and hydroxyl content, explain these differences.

Devitrification Mechanisms in High-Temperature Quartz Glass

Devitrification begins when quartz glass faces repeated high temperatures. Nucleated liquid droplets slowly form inside the amorphous matrix, and over time, these droplets merge into fronts that grow more rapidly. Contamination from alkali elements such as sodium, potassium, or lithium, combined with exposure to oxygen-rich atmospheres above 1000°C, accelerates this process and leads to visible changes in the tube.

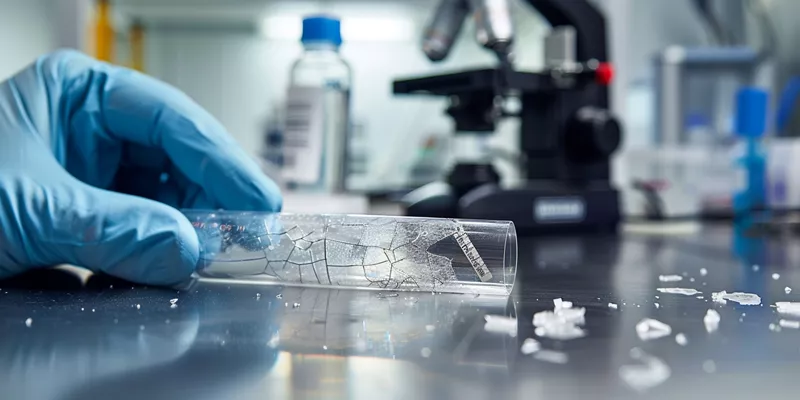

Laboratory technicians often notice milky zones or rough surfaces on Quartz Tubes for Analytical Applications after extended use. These visual indicators signal that crystal structures have started to form, which weakens the tube and increases the risk of thermal shock failure. Holding glass in the devitrification zone or cooling too slowly allows crystals to grow, reducing tube longevity.

Devitrification explains why some tubes fail early, especially when contamination or improper cooling occurs.

Key Points:

Contamination and high temperature drive devitrification.

Visual signs include milky appearance and roughness.

Slow cooling increases crystal growth risk.

Annealing Point Specifications and Their Impact on Stress Relief

Annealing removes internal stresses from quartz tubes. Manufacturers heat tubes to the annealing point, typically around 1120°C, and hold them for several hours before cooling at a controlled rate. This process prevents residual stress accumulation, which can reduce thermal shock resistance by up to 50% if not performed correctly.

Properly annealed tubes survive over 5,000 thermal cycles between ambient and 1100°C, while inadequately processed tubes may fail after only 500-1,000 cycles. Data from production batches show that programmed cooling at 50°C per hour after annealing ensures stress relief and maximizes tube durability. Tubes with residual stress are more likely to deform or crack under repeated thermal cycling.

Manufacturers use precise annealing protocols to ensure consistent tube performance.

Annealing Factor | Impact on Tube Longevity |

|---|---|

Correct annealing point | Maximizes stress relief |

Programmed cooling rate | Prevents residual stress |

Inadequate annealing | Reduces cycle endurance |

OH Content Influence on High-Temperature Phase Stability

Hydroxyl (OH) groups disrupt the stable structure of quartz glass. These groups break Si-O bonds in the network, increasing porosity and reducing chemical stability, density, and viscosity. The presence of hydroxyl groups also lowers the softening temperature and promotes crystallization, making tubes more vulnerable to high-temperature degradation.

Quartz tubes with high OH content show reduced structural strength, heat resistance, and optical uniformity. These changes decrease phase stability and increase the likelihood of failure during thermal cycling. Laboratories prefer tubes with OH content below 30 ppm to maintain durability and performance.

Low OH content is essential for reliable Quartz Tubes for Analytical Applications in demanding environments.

Key Points:

High OH content reduces chemical and structural stability.

Low OH content improves phase stability and tube longevity.

OH groups promote crystallization and lower heat resistance.

How Do Operational Parameters Optimize Quartz Tube Longevity in Analytical Furnace Systems?

Operational parameters play a decisive role in determining the lifespan of quartz tubes in analytical furnace systems. These parameters include temperature ramp rates, furnace design features, and the handling of mechanical stress during sample introduction and removal. Understanding why these factors matter helps laboratories maximize tube longevity and maintain reliable analytical results.

Temperature Ramp Rate Optimization for Different Analytical Methods

Temperature ramp rates directly affect the stress experienced by quartz tubes. Laboratories that use rapid heating or cooling expose tubes to sudden expansion or contraction, which increases the risk of cracking and shortens service life. By optimizing ramp rates, technicians can reduce thermal gradients and prevent premature tube failure.

Recommended ramp rates vary by temperature range, and following these guidelines helps maintain tube integrity. For example, heating from 25°C to 200°C should not exceed 80–100°C per hour, while higher ranges like 800°C to 1100°C allow up to 200–250°C per hour. Analytical methods that require frequent cycling benefit from slower ramp rates, as these minimize the buildup of internal stress.

A visual summary of these recommendations appears in the chart below:

Key Points:

Slower ramp rates reduce thermal stress and extend tube life.

Different analytical methods require tailored ramp rate settings.

Consistent ramp rate control prevents sudden tube failure.

Furnace Design Features That Enhance Quartz Tube Longevity

Furnace design features significantly influence the durability of quartz tubes. Engineers design modern furnaces with evenly distributed heating elements and low thermal mass insulation to ensure uniform temperature across the tube. These features prevent hot spots and thermal gradients that can cause localized stress and eventual tube failure.

Strategic placement of ceramic and alumina plugs helps maintain balanced temperatures, especially at the tube ends where sealing O-rings are vulnerable to heat. Three-zone furnace models provide extra power at the ends, further improving temperature uniformity and reducing the risk of thermal shock. Radiation shields and insulation plugs also minimize heat loss, supporting stable operating conditions.

The following table summarizes key furnace design features and their benefits:

Design Feature | Benefit |

|---|---|

Even heating elements | Prevents hot spots |

Low thermal mass insulation | Enhances efficiency |

Ceramic/alumina plug placement | Maintains balanced temperature |

3-zone power boosting | Improves end temperature uniformity |

Radiation shields/insulation plugs | Reduces thermal losses |

Mechanical Stress Factors During Sample Introduction and Removal

Mechanical stress during sample handling can shorten the life of quartz tubes. Sudden impacts, improper insertion, or removal of samples introduce localized forces that create microcracks or weaken the tube structure. Over time, these small defects grow and make the tube more susceptible to thermal shock.

Technicians can minimize mechanical stress by using smooth, controlled motions and ensuring samples are preheated before introduction. Regular maintenance and training help staff recognize and avoid risky handling practices. Consistent procedures reduce the chance of accidental damage and support longer tube service life.

Key Points:

Gentle sample handling prevents microcracks.

Preheating samples reduces thermal and mechanical shock.

Routine training and maintenance promote best practices.

What Manufacturing Advances Improve Thermal Shock Resistance in Analytical Quartz Tubes?

Manufacturing advances have transformed the durability of quartz tubes in analytical laboratories. These improvements help tubes withstand more thermal cycles and reduce the risk of sudden failure. Understanding why these advances matter can help laboratories choose the best products for demanding applications.

Multi-Stage Annealing Protocol Development and Optimization

Multi-stage annealing protocols increase the thermal shock resistance of quartz tubes. Manufacturers use controlled heating and cooling cycles at specific temperatures to remove internal stresses and improve tube strength. This process allows tubes to survive over 5,000 thermal cycles between room temperature and 1100°C, which is a significant improvement over older methods.

The use of temperature holds at both the strain point and annealing point ensures that stress relief is complete. Data from production batches show that tubes annealed with these protocols have 30-50% higher resistance to thermal shock compared to those processed with single-stage methods. Laboratories benefit from fewer tube replacements and more reliable analytical results.

Multi-stage annealing explains why modern tubes last longer in high-temperature environments.

Key Points:

Reduces internal stress

Increases cycle endurance

Improves reliability

Surface Finish Impact on Thermal Cycling Performance

Surface finish quality plays a crucial role in the performance of quartz tubes during thermal cycling. A smooth surface prevents particle adhesion and ensures uniform gas flow, which is vital for processes like plasma-enhanced chemical vapor deposition. Advanced manufacturing techniques create high-quality finishes that help tubes maintain their properties through repeated heating and cooling.

Tubes with rough surfaces develop microcracks more easily, which can lead to early failure. Studies show that tubes with a surface roughness below 0.4 μm have up to 25% lower failure rates during thermal cycling than those with rougher finishes. Laboratories that select tubes with superior surface quality experience fewer disruptions and longer tube lifespans.

A summary of the impact of surface finish appears in the table below:

Surface Finish Quality | Thermal Cycling Performance |

|---|---|

Smooth (<0.4 μm Ra) | Lower failure rate, better gas flow |

Rough (>0.4 μm Ra) | Higher risk of microcracks, failures |

Statistical Process Control for Thermal Expansion Consistency

Statistical process control (SPC) ensures that every batch of quartz tubes meets strict thermal expansion standards. Manufacturers monitor the thermal expansion coefficient during production to maintain consistency and prevent weak spots. This approach leads to tubes with predictable performance and fewer unexpected failures.

SPC uses real-time data and automated inspection systems to detect any deviations from the target coefficient of 0.5 × 10⁻⁶ K⁻¹. When manufacturers apply SPC, they achieve a ±5% variation across production lots, which reduces the risk of tubes failing under rapid temperature changes. Laboratories that use Quartz Tubes for Analytical Applications with verified SPC benefit from greater confidence in tube longevity.

Manufacturing advances like SPC explain why modern tubes offer improved reliability and performance.

Key Points:

Ensures consistent material properties

Reduces failure risk

Supports reliable analytical results

How Can Analytical Laboratories Implement Preventive Maintenance to Extend Quartz Tube Service Life?

Preventive maintenance plays a vital role in extending the service life of quartz tubes in analytical laboratories. Laboratories that implement structured inspection and replacement protocols reduce unexpected failures and maintain consistent analytical performance. Understanding why these practices matter helps laboratories maximize the value of Quartz Tubes for Analytical Applications.

Visual Inspection Criteria for Devitrification Detection

Visual inspection allows laboratory staff to detect early signs of devitrification before catastrophic tube failure occurs. Technicians look for milky or cloudy zones, surface roughness, and changes in tube transparency, which indicate the onset of crystallization. These visual cues often appear after repeated high-temperature cycles or exposure to contaminants, signaling that the tube’s structure has started to degrade.

Regular inspections every 500 analytical cycles help laboratories identify tubes at risk, as data shows that devitrification zones exceeding 10% of the heated length predict imminent failure. Technicians also measure tube diameter, since an increase of more than 0.2 mm suggests structural weakening from accumulated thermal stress. Early detection through visual inspection allows laboratories to replace tubes before they compromise analytical results.

Routine visual checks form the foundation of a proactive maintenance program.

Key Points:

Milky zones and roughness signal devitrification.

Diameter changes indicate structural stress.

Regular inspections prevent unexpected failures.

Developing Laboratory-Specific Tube Replacement Protocols

Each laboratory develops its own tube replacement protocol based on usage patterns and analytical demands. Staff track the number of thermal cycles, maximum operating temperatures, and any incidents of rapid cooling or power loss. These records help laboratories predict when a tube will reach the end of its reliable service life.

Data from over 600 installations show that proactive replacement, triggered by visual signs or dimensional changes, reduces emergency downtime by 40%. Laboratories also follow best practices for cleaning and handling, such as allowing the furnace to cool before cleaning, using soft brushes, and avoiding harsh chemicals. These steps prevent scratches and chemical reactions that could weaken the tube.

A summary table highlights key protocol elements:

Protocol Element | Purpose |

|---|---|

Cycle count tracking | Predicts tube lifespan |

Visual and dimensional checks | Detects early signs of failure |

Scheduled cleaning | Maintains tube integrity |

Proactive replacement | Reduces emergency downtime |

Lifetime Prediction Models Based on Thermal Cycling History

Lifetime prediction models use historical data to estimate when a quartz tube will fail. Laboratories collect information on the number of cycles, temperature ranges, and any thermal shock events to build accurate models. These models help staff schedule replacements before tubes reach critical failure points.

Statistical analysis shows that tubes with controlled ramp rates and low OH content last over 5,000 cycles, while those exposed to rapid temperature changes or contamination may fail after 500–1,000 cycles. By combining cycle history with inspection results, laboratories can optimize maintenance schedules and minimize costs. Predictive models ensure that analytical operations remain uninterrupted and compliant with quality standards.

Effective lifetime prediction relies on accurate record-keeping and regular data analysis.

Key Points:

Historical data improves prediction accuracy.

Controlled conditions extend tube life.

Predictive models support uninterrupted operations.

Thermal shock resistance directly determines how long Quartz Tubes for Analytical Applications last in high-temperature laboratory settings. Laboratories that follow technical best practices and preventive maintenance routines see fewer failures and more reliable results.

Poor sealing between the flange and tube allows oxygen or moisture to enter, which can react with silicon at high temperatures and form a defective layer that shortens tube life.

Quartz tubes show less resistance to repeated heat-cool cycles than some other materials, so frequent cycling can cause cracks or fatigue.

Applying the strategies and monitoring techniques discussed helps laboratories achieve optimal tube performance and extend service life.

FAQ

Why does thermal shock resistance matter for quartz tubes in analytical labs?

Thermal shock resistance prevents tubes from cracking during rapid temperature changes.

Quartz tubes with high resistance last longer and reduce replacement costs.

Laboratories rely on durable tubes for consistent results.

Tip: Choose tubes with low thermal expansion coefficients for best performance.

Why do geometric discontinuities increase failure risk in quartz tubes?

Geometric discontinuities create stress points during heating and cooling.

Stress concentrates at welded joints or diameter changes, causing cracks.

Manufacturers design tubes with smooth transitions to minimize this risk.

Feature | Impact |

|---|---|

Welded joints | High stress |

Smooth transitions | Lower failure risk |

Why should laboratories monitor OH content in quartz tubes?

High OH content weakens quartz structure at elevated temperatures.

Tubes with low OH content resist devitrification and last longer.

Laboratories use infrared spectroscopy to verify OH levels.

Key Points:

Low OH content increases tube longevity.

High OH content accelerates failure.

Why is preventive maintenance important for quartz tube longevity?

Preventive maintenance detects early signs of tube degradation.

Regular inspections and scheduled replacements prevent unexpected failures.

Laboratories maintain reliable operations by following maintenance protocols.

🛠️ Note: Inspect tubes every 500 cycles for best results.

Why do controlled temperature ramp rates extend quartz tube life?

Controlled ramp rates reduce thermal stress during heating and cooling.

Tubes exposed to slow temperature changes survive more cycles.

Technicians set ramp rates based on analytical method requirements.

Ramp Rate | Tube Longevity |

|---|---|

Fast | Shorter |

Controlled | Longer |