- Home

- /

- Types

- /

- Quartz Tube

- /

- High Purity Cylindrical Clear...

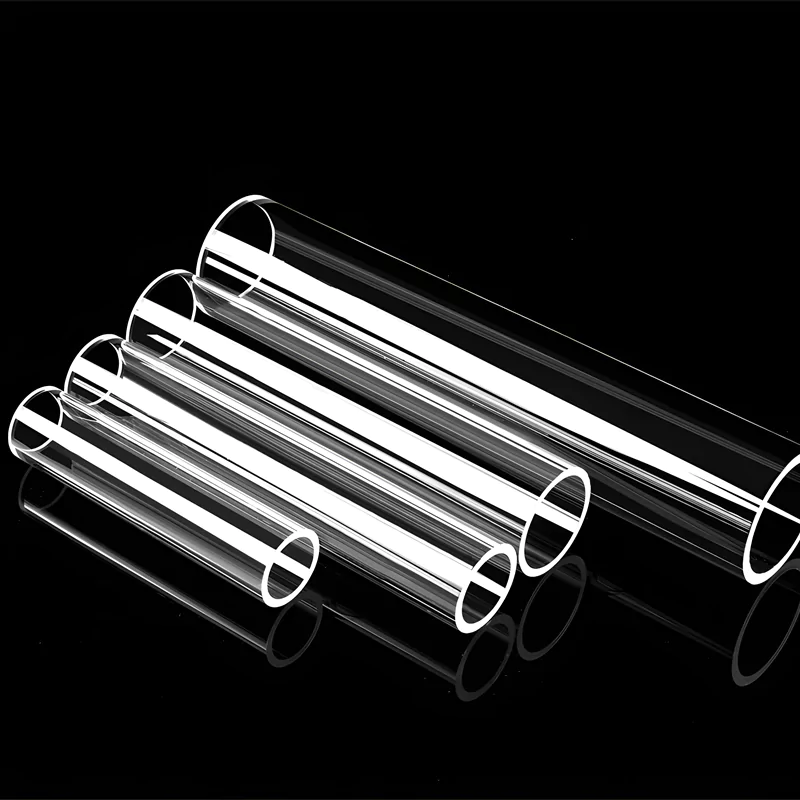

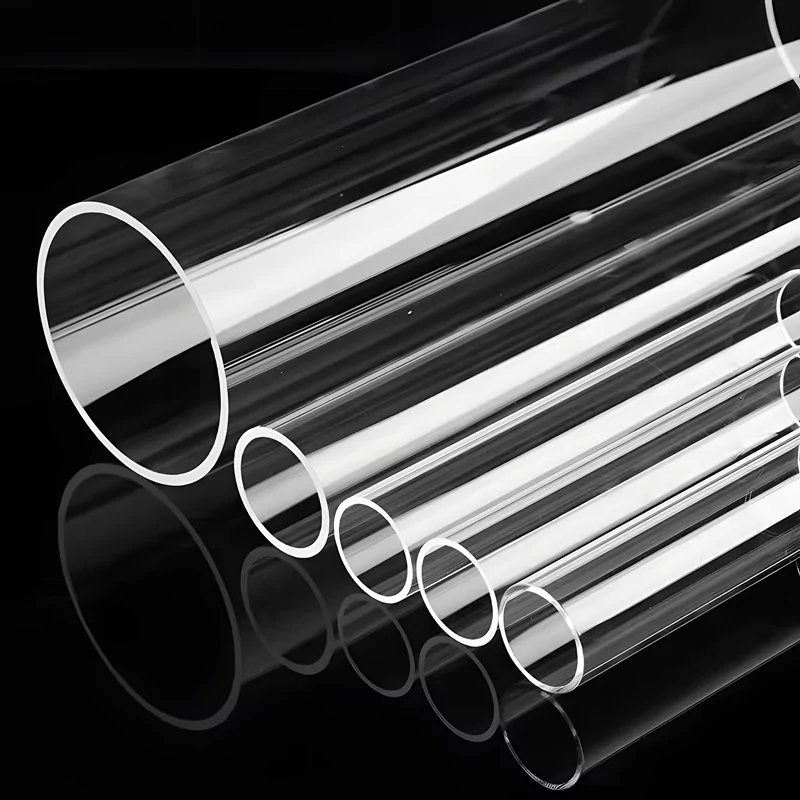

High Purity Cylindrical Clear Fused Quartz Tubing -TOQUARTZ®

Ideal for laboratory equipment, UV systems, industrial heating applications, and scientific research.

Key Features of Cylindrical Clear Fused Quartz Tubing

TOQUARTZ® cylindrical clear fused quartz tube cylinders are manufactured with high-purity silica (≥99.98%, max. purity up to 99.995%), delivering exceptional performance characteristics for demanding laboratory, industrial, and scientific applications.

Exceptional Thermal Stability

TOQUARTZ® cylindrical clear fused quartz tubing withstands continuous use at 1100°C (peaks to 1450°C), with 5.5×10⁻⁷/°C thermal stability for crack-resistant thermal cycling in high-temperature lab and industrial applications.

Superior Optical Properties

With excellent light transmission across the UV to IR spectrum, TOQUARTZ® cylindrical clear fused quartz tubings offer >93% transmission in the visible range and >80% in the UV range.

Superior Corrosion Resistance

Highly resistant to most chemicals except hydrofluoric acid, TOQUARTZ® cylindrical clear fused quartz tubings maintain their chemical stability even at elevated temperatures.

- Extreme Heat Resistance

- Optimal UV Transmission

- Strong Chemical Resistance

Dimension of Cylindrical Clear Fused Quartz Tubing

| Model | Outer Diameter (mm) | Wall Thickness (mm) | Length (mm) | Purity |

| AT-QTZ-G2001 | 0.8 | 0.3 | 20 | 99.98% |

| AT-QTZ-G2002 | 1.5 | 0.5 | 30 | 99.98% |

| AT-QTZ-G2003 | 2.4 | 0.4 | 50 | 99.98% |

| AT-QTZ-G2004 | 3 | 0.8 | 50 | 99.98% |

| AT-QTZ-G2005 | 3 | 0.09 | 80 | 99.98% |

| AT-QTZ-G2006 | 3.6 | 0.6 | 80 | 99.98% |

| AT-QTZ-G2007 | 3.65 | 0.65 | 100 | 99.98% |

| AT-QTZ-G2008 | 4.35 | 1 | 150 | 99.98% |

| AT-QTZ-G2009 | 6 | 1 | 150 | 99.98% |

| AT-QTZ-G2010 | 10 | 2.2 | 200 | 99.98% |

| AT-QTZ-G2011 | 15 | 5 | 300 | 99.98% |

| AT-QTZ-G2012 | 20 | 8 | 500 | 99.98% |

| AT-QTZ-G2013 | 27 | 6 | 350 | 99.98% |

| AT-QTZ-G2014 | 32 | 4 | 500 | 99.98% |

| AT-QTZ-G2015 | 40 | 3 | 800 | 99.98% |

| AT-QTZ-G2016 | 40 | 3 | 1000 | 99.98% |

| AT-QTZ-G2017 | 50 | 3 | 450 | 99.98% |

| AT-QTZ-G2018 | 50 | 3 | 500 | 99.98% |

| AT-QTZ-G2019 | 50 | 3 | 600 | 99.98% |

| AT-QTZ-G2020 | 50 | 3 | 700 | 99.98% |

| AT-QTZ-G2021 | 50 | 3 | 800 | 99.98% |

| AT-QTZ-G2022 | 50 | 3 | 1000 | 99.98% |

| AT-QTZ-G2023 | 50 | 4 | 600 | 99.98% |

| AT-QTZ-G2024 | 50 | 4 | 1000 | 99.98% |

| AT-QTZ-G2025 | 60 | 3 | 800 | 99.98% |

| AT-QTZ-G2026 | 60 | 3 | 1000 | 99.98% |

| AT-QTZ-G2027 | 60 | 3 | 1400 | 99.98% |

| AT-QTZ-G2028 | 60 | 4 | 1000 | 99.98% |

| AT-QTZ-G2029 | 60 | 5 | 1000 | 99.98% |

| AT-QTZ-G2030 | 80 | 3 | 1000 | 99.98% |

| AT-QTZ-G2031 | 80 | 3 | 1200 | 99.98% |

| AT-QTZ-G2032 | 80 | 4 | 1000 | 99.98% |

| AT-QTZ-G2033 | 80 | 5 | 1000 | 99.98% |

| AT-QTZ-G2034 | 100 | 3 | 1000 | 99.98% |

| AT-QTZ-G2035 | 100 | 3 | 1200 | 99.98% |

| AT-QTZ-G2036 | 100 | 4 | 1000 | 99.98% |

| AT-QTZ-G2037 | 100 | 5 | 1000 | 99.98% |

| AT-QTZ-G2038 | 1.5-450 | 0.09-10 | 20-2000 | 99.98% |

Properties of Cylindrical Transparent Quartz Glass Tube

| Property | Value Range |

| Chemical Composition(ppm) | Cr: 0.1, Ge: 0.4, Fe: 1.5, Mg: 0.4, Ti: 0.1, Ga: 0.8; Al: 16, Na: 2.3, Li: 0.5, K: 2.0 |

| Spectral Transmission | ≧93% transmittance (280-780nm), 93.4% peak at 780nm, UV cutoff ≤220nm |

| Thermal Properties | Working temperature: Operate continuously at 1100°C (2012°F), and withstand short-term temperature bursts of 1450°C (2642°F) Thermal expansion: 5.5~6.7×10⁻⁷/cm·°C |

| Mechanical Strength | Compressive: >1.1×10⁹ Pa, Young’s modulus: 7.0~7.5×10¹⁰ Pa |

| Optical Performance | Refractive index: 1.456~1.485, dielectric constant: 3.75~6.0 @1MHz |

Solving Critical Challenges with Cylindrical Clear Fused Quartz Tubing

UV Quartz Tube for Water Treatment Systems

TOQUARTZ® cylindrical clear quartz tubes serve as reaction chambers, sample holders, and observation windows in critical experimental setups where contamination control and thermal stability are paramount.

Key Advantages

- Ultra-low contamination for analytical sample integrity

- Material inertia in strong acid and base exposure conditions

- Optical-grade clarity for in-situ reaction monitoring

TOQUARTZ® solution

A materials research institute faced persistent contamination issues with their high-temperature reaction chambers, resulting in compromised experimental results.

TOQUARTZ provided custom-dimensioned cylindrical quartz tubes with ±0.15mm tolerance that maintained their integrity at 1050°C, eliminating contamination concerns and improving experimental reproducibility by 40%.

Cylindrical Clear Fused Quartz Tubing for UV Light Systems

TOQUARTZ® cylindrical clear quartz tubes deliver superior UV transparency and longevity in these critical applications.

Key Advantages

- Protects UV lamp from temperature-related flux decay

- Maintains UV optical window clarity after prolonged exposure

- Shock-resistant envelope design for fragile quartz lamp tubes

TOQUARTZ® solution

A water treatment equipment manufacturer experienced frequent sleeve failures in their UV disinfection systems, causing costly maintenance cycles and system downtime.

TOQUARTZ supplied cylindrical transparent quartz tubes with optimized UV transmission properties and precise dimensional control, reducing sleeve replacement frequency by 65% and improving system efficiency by 15%.

Cylindrical Clear Fused Quartz Tubing for Industrial Heating Applications

TOQUARTZ® cylindrical clear quartz tubing excels in furnaces, heating elements, and thermal processing equipment where conventional materials fail.

Key Advantages

- Resists warping during extended furnace cycling

- Transparent for direct observation of heated zones

- Withstands radiative and convective thermal stress

TOQUARTZ® solution

A thermal processing equipment manufacturer struggled with frequent tube failures in their high-temperature annealing furnaces, causing production delays and quality issues.

TOQUARTZ provided custom cylindrical clear quartz tubes with optimized wall thickness that withstood rapid temperature cycling, reducing tube failures by 80% and extending maintenance intervals from 6 weeks to 6 months.

Customization Services for

TOQUARTZ® Cylindrical Clear Fused Quartz Tubing

Our engineering team works closely with you to develop the perfect quartz components for your application.

- Custom Dimensions

- Precision OD/ID sizing

- Custom wall thickness

- Specific length requirements

- End Finishing Options

- Fire polished ends

- Ground finish

- Sealed/closed ends

- Material Options

- JGS-1 grade (standard)

- JGS-2 (high purity)

- JGS-2 (high purity)

- Custom Design Process

Requirement Analysis

We begin by thoroughly understanding your application requirements, including dimensions, material specifications, and performance criteria.

Design & Engineering

Our engineers develop a detailed design specification, including technical drawings and material requirements.

Prototype Development

We produce sample tubes for your evaluation and testing, with rapid turnaround times for urgent projects.

Production & Quality Control

Following approval, we manufacture your cylindrical clear fused quartz tubing with rigorous quality control at every step.

Usage Guide for Cylindrical Clear Fused Quartz Tubing

Follow these guidelines to ensure optimal results and prevent premature failure.

Handling & Installation

Handle it with care to prevent impacts or drops. Even minor surface damage can significantly reduce mechanical strength and thermal shock resistance. Use clean gloves when handling tubes for high-temperature applications to prevent contamination from skin oils.

Temperature Limits

Do not exceed the maximum operating temperature (1100°C for continuous use, 1450°C for short-term exposure). Exceeding these limits can cause softening and deformation of the quartz material.

Cleaning

Clean tubes thoroughly before high-temperature use. For precision applications, use ultrasonic cleaning with appropriate solvents followed by deionized water rinse. Always wear fine-thread gloves during handling to prevent fingerprints and contamination.

Chemical Compatibility

Quartz is an acidic material and should not contact alkaline substances (such as sodium silicate, asbestos, potassium/sodium compounds) at high temperatures, as this will significantly degrade performance. Avoid hydrofluoric acid contact at all temperatures.

Thermal Cycling

While quartz has excellent thermal shock resistance, gradual heating and cooling are recommended for thick-walled tubes to minimize stress. Avoid direct flame contact that creates extreme localized heating.

Need Expert Guidance for Your Cylindrical Clear Fused Quartz Tubing Project?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: How does UV transmission differ between standard glass and TOQUARTZ® cylindrical clear fused quartz tubing?

A: Standard borosilicate glass typically blocks most UV radiation below 300nm, while our cylindrical clear fused quartz tubing offers excellent transmission across the UV spectrum, including the critical germicidal range (200-280nm). Our quartz tubes provide ≥85% transmission in the 200-250nm range, making them ideal for UV disinfection systems, photochemical reactors, and analytical instruments.

Q: What is the difference between JGS-1, JGS-2, and JGS-3 quartz materials?

A: These designations refer to different grades of quartz purity and optical properties. JGS-1 is standard grade (≥99.95% SiO₂) suitable for general applications. JGS-2 is high-purity grade (≥99.98% SiO₂) with improved UV transmission and fewer bubbles/inclusions, ideal for optical and UV applications. JGS-3 is ultra-high purity grade (≥99.995% SiO₂) with exceptional optical homogeneity and UV transmission, used in semiconductor and advanced optical applications.

Q: Can cylindrical clear fused quartz tubing be sealed to other materials?

A: Quartz can be directly sealed to certain materials with compatible thermal expansion coefficients. For most applications, mechanical sealing methods using O-rings, gaskets, or specialized fittings are recommended. We can provide tubes with ground ends or special preparations to facilitate specific sealing requirements. For complex assemblies, we offer technical guidance on appropriate sealing methods based on your application parameters.

Q: How does wall thickness affect the performance of cylindrical clear fused quartz tubing?

A: Wall thickness significantly impacts several performance aspects: 1) Mechanical strength – thicker walls provide greater structural integrity and pressure resistance; 2) Thermal shock resistance – thinner walls generally handle rapid temperature changes better; 3) Optical properties – thicker walls may slightly reduce UV transmission; 4) Heat transfer – thinner walls allow faster heat transfer. Our engineers can help you determine the optimal wall thickness for your specific application requirements.

Q: What is the maximum temperature cylindrical clear fused quartz tubing can withstand?

A: TOQUARTZ® cylindrical clear fused quartz tubing can withstand continuous operating temperatures up to 1100°C and short-term exposure up to 1450°C. The actual temperature limit may vary depending on the specific application, duration of exposure, and mechanical stresses involved.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.