Customization Services For Quartz Glass Products by TOQUARTZ® Quartz Experts

We offer customized quartz glass products and full-spectrum customization services at TOQUARTZ®,

including engineering design, prototyping, precision manufacturing, and global delivery.

What Customization Services TOQUARTZ® Can Offer

Custom Design Services

TOQUARTZ® engineering team works directly with you to develop customized quartz glass products from concept to completion.

We can work from your existing drawings or collaborate to design components that meet your exact requirements for laboratory equipment, industrial applications, or specialized research needs.

- Engineering support for customizable quartz material selection

- Prototype development and testing

- CAD assistance and technical drawings

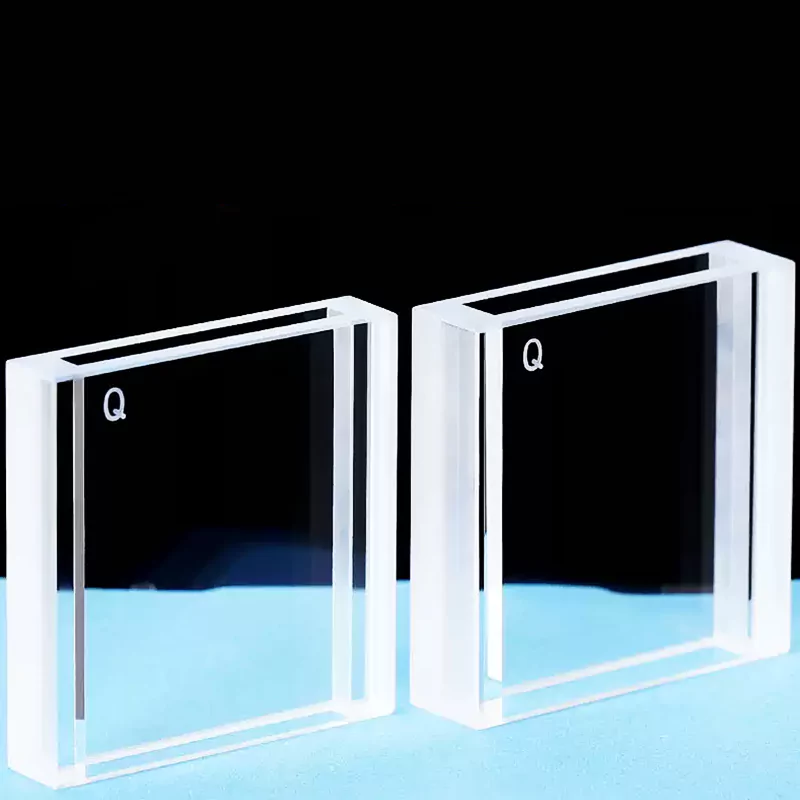

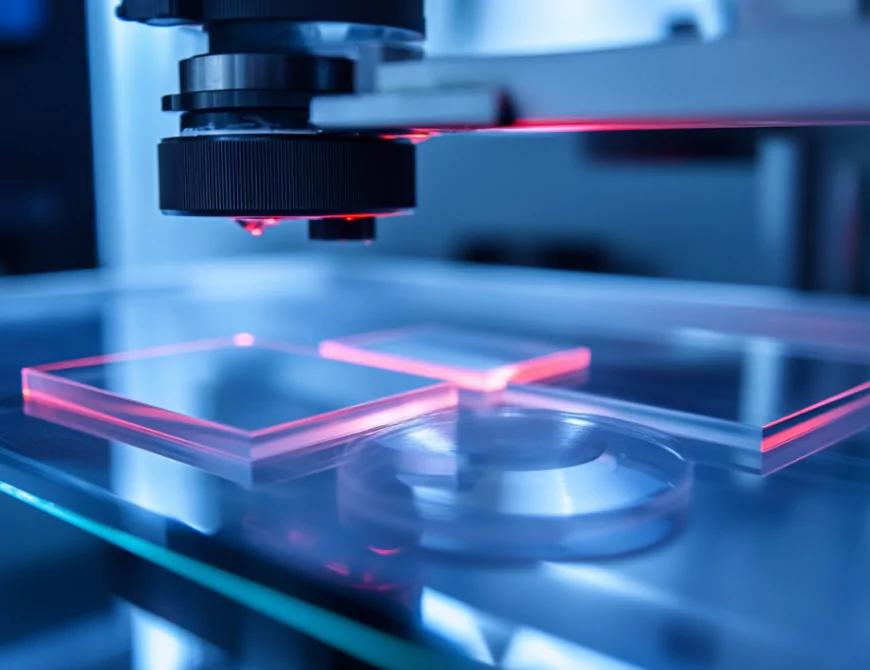

Custom Specification Service

The advanced CNC machining capabilities allow us to customize complex quartz glass products with tight tolerances.

TOQUARTZ® specializes in creating precision components for laboratory equipment, semiconductor processing, and optical applications where dimensional accuracy is critical.

- Tolerance control to ±0.1mm for most applications

- Complex geometries and features

- Surface finish customization

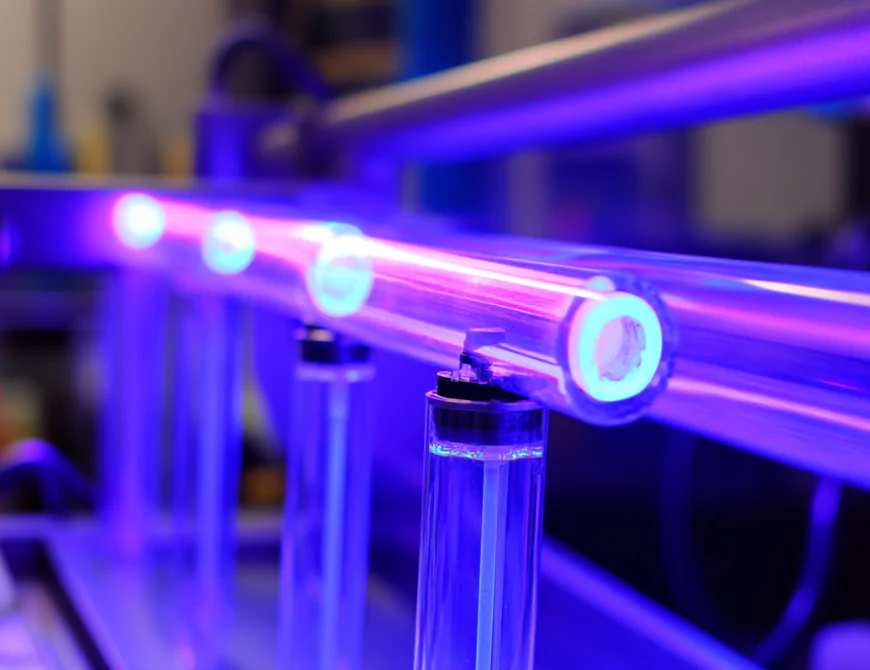

Customized Application Services

- UV-transparent quartz for sterilization

- Opaque quartz for IR applications

- High-purity quartz for semiconductor processes

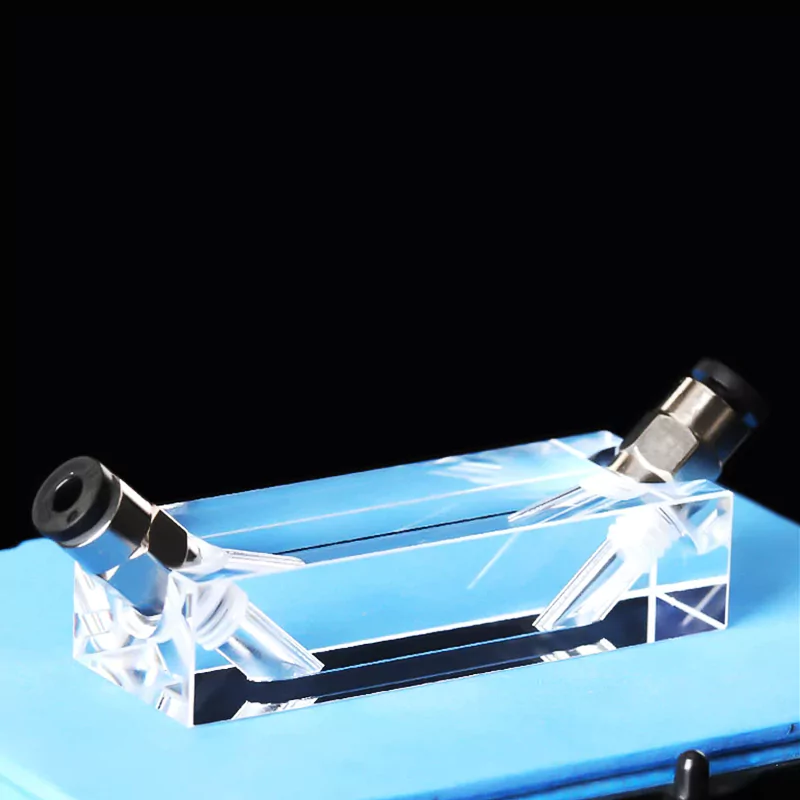

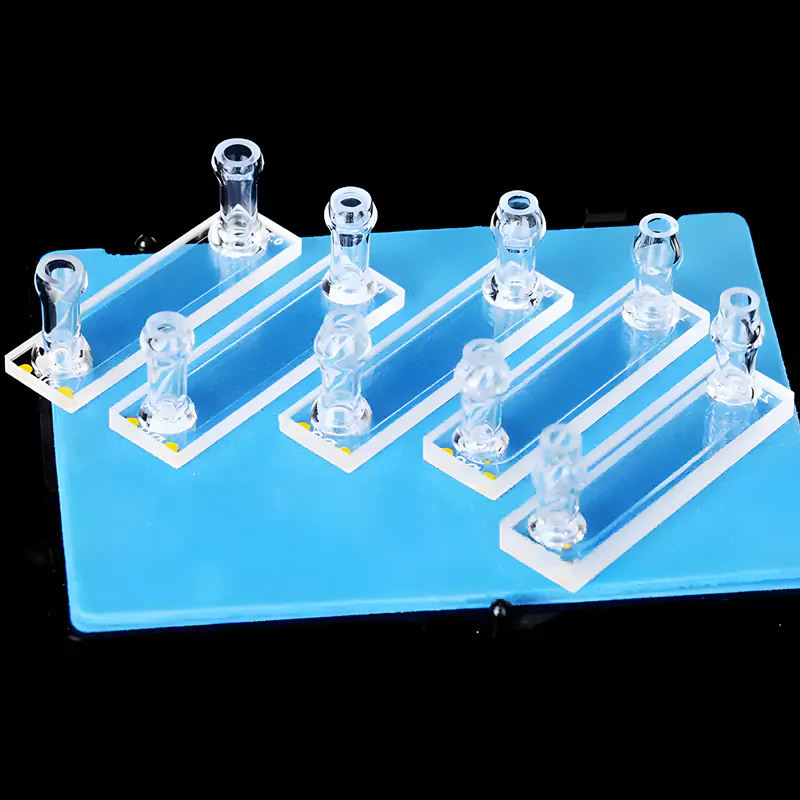

Custom Complex Assemblies

- Multi-component quartz systems

- Integrated flange and connection systems

- Custom reaction chambers and vessels

The TOQUARTZ® Customization Service Process

At TOQUARTZ®, we follow a structured, four-step process to turn your specifications into precision-engineered quartz glass products. This ensures speed, accuracy, and complete alignment with your application needs.

Requirement Assessment & Technical Review

We clarify specifications, material requirements, tolerances, and feasibility before moving to production planning.

Design Optimization & Quotation

A formal quotation is shared along with lead time estimates and recommendations for sampling or prototyping when appropriate.

Precision Manufacturing & In-Process QC

Every batch is monitored via in-process quality control to ensure dimensional accuracy and visual inspection compliance.

Final Inspection, Secure Packaging & Logistics

We then package using export-grade materials—foam inserts, vacuum sealing, or wooden crates—and coordinate air or sea shipment per your Incoterms or freight instructions.

Why Choose TOQUARTZ®

We deliver custom quartz solutions with speed, precision, and engineering support.

Fast Lead Times

Most stocked items ship within 24 hours; custom parts are efficiently scheduled.

Engineering Support

Our technical experts assist with drawings, tolerances, and material recommendations.

Flexible Order Quantities

From prototypes to bulk orders, we support small batch without MOQ limitation.

End-to-End Quality

Each order undergoes full inspection, from raw quartz to custom fabrication and packaging.

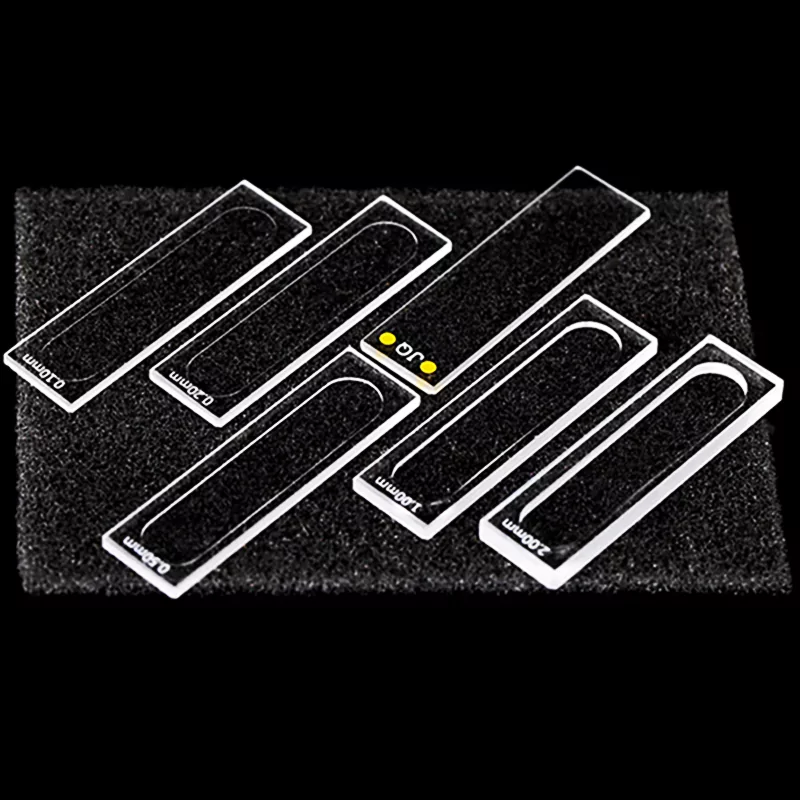

Quartz Glass Products Under TOQUARTZ® Customization Services

We maintain consistent quality standards and can accommodate both small batch production and large-scale manufacturing needs.

Start Your Quartz Project with TOQUARTZ® Customization Services

Contact our engineering team today to discuss your custom quartz glass requirements. We’ll help you develop the perfect solution for your application.