- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz UV Cuvette

- /

- Spectral-Flat Custom UV-Grade Dual-Path...

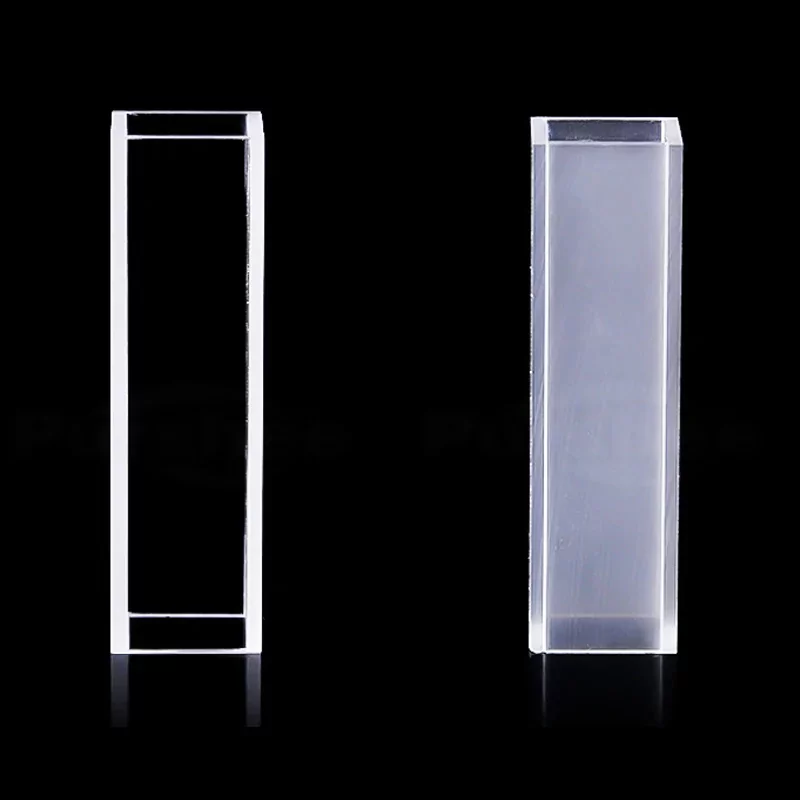

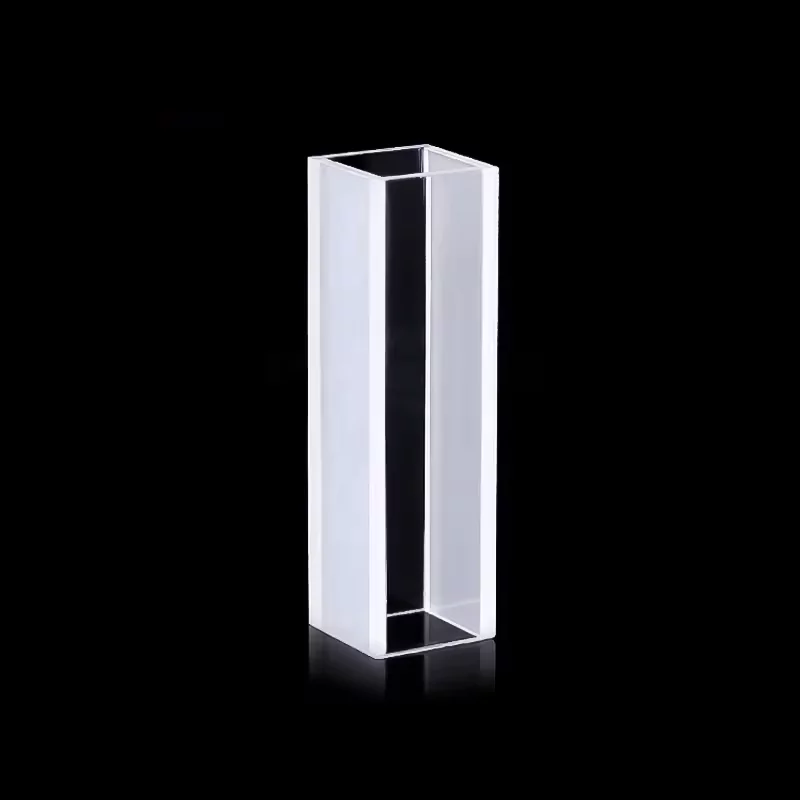

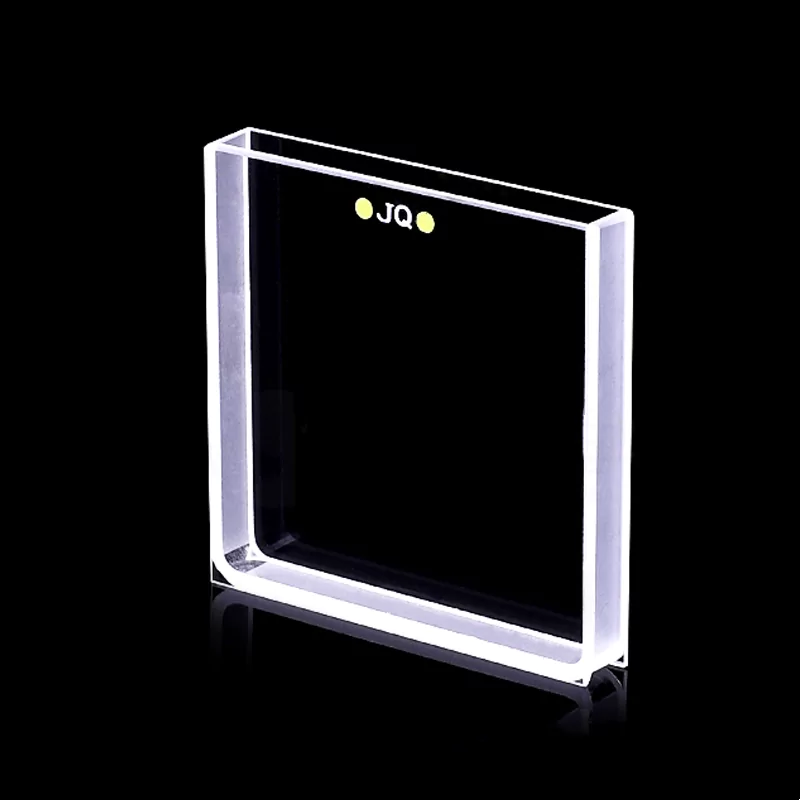

Spectral-Flat Custom UV-Grade Dual-Path Quartz Cuvette for UV-Vis Applications -TOQUARTZ®

Features of UV-Grade Dual-Path Quartz Cuvette

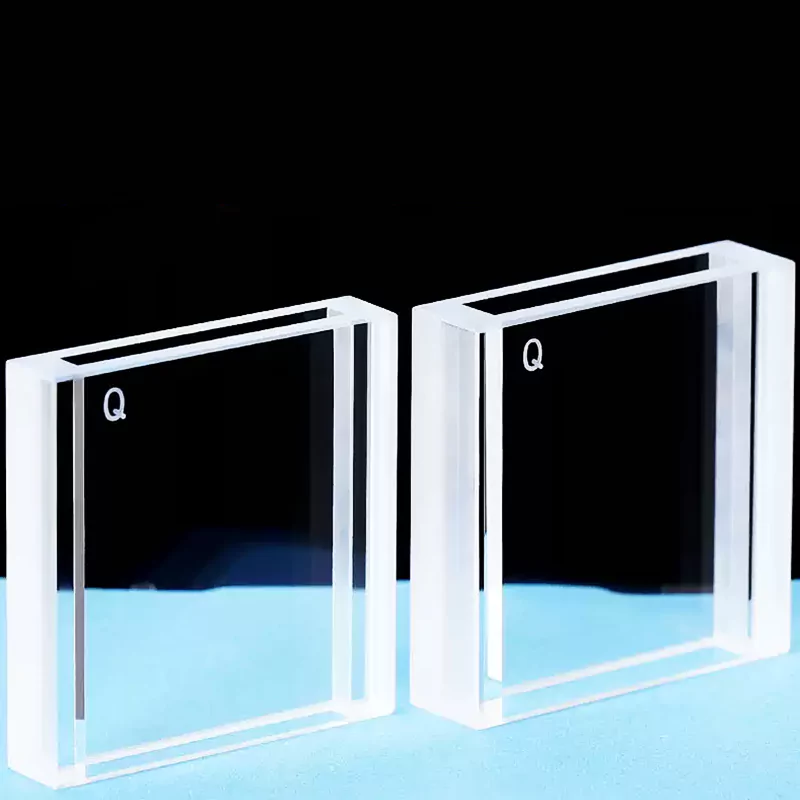

TOQUARTZ® UV-Grade Dual-Path Quartz Cuvettes are manufactured using premium-grade fused quartz, ensuring excellent optical performance and durability for your spectroscopic applications. Each cuvette is carefully crafted to meet precise specifications and undergoes rigorous quality control testing.

Material Composition

- High-purity fused quartz (≥99.98% SiO₂)

- High thermal stability (up to 1100°C)

- Excellent chemical resistance to acids, bases, and salt solutions

- Low thermal expansion coefficient (5.5×10⁻⁷ /°C)

Optical Performance

- High UV transmission (>80% at 190-250nm)

- No absorption peaks in 200-2500nm range

- Optical surface flatness ≤λ/4

- Dual-path design ensures consistent light path alignment

Precision Manufacturing

- Tight dimensional tolerances (±0.1mm)

- Optical-grade polishing for clear, bubble-free surfaces

- Scratch-free surfaces for optimal light transmission

- Consistent wall thickness for uniform optical properties

- Customizable chamber volumes

- Various geometric configurations available

- Multiple path length options

Technical Specifications & Dimensions of UV-Grade Dual-Path Quartz Cuvette

Technical Specifications

| Property | Specification | Testing Method |

| 1. Physical Properties | ||

| Material | Fused Quartz (≥99.98% SiO₂) | XRF Analysis |

| Density | 2.2 g/cm³ | ASTM C693 |

| Dimensional Tolerance | ±0.1mm | Digital Micrometer |

| Wall Thickness Uniformity | ±0.1mm | Digital Micrometer |

| Surface Finish | Optical Polish | Visual Inspection |

| Maximum Operating Temperature | 1100°C | Thermal Testing |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ /°C | ASTM E228 |

| 2. Optical Properties | ||

| Transmission Range | 200-2500nm | UV-Vis-NIR Spectrophotometer |

| UV Transmittance (200-250nm) | >80% (Paired Testing) | UV-Vis Spectrophotometer |

| Optical Surface Flatness | ≤λ/4 | Interferometer |

| Refractive Index (589.3nm) | 1.4585 | Refractometer |

| Surface Quality | Scratch-Free, Bubble-Free | Visual Inspection (10X) |

| Path Length Accuracy | ±0.01mm | Digital Micrometer |

| 3. Chemical Properties | ||

| Chemical Composition | ≥99.98% SiO₂ | XRF Analysis |

| Acid Resistance | Excellent (except HF) | Chemical Exposure Testing |

| Alkali Resistance | Very Good | Chemical Exposure Testing |

| Solvent Resistance | Excellent | Chemical Exposure Testing |

| Water Absorption | Nil | ASTM C1285 |

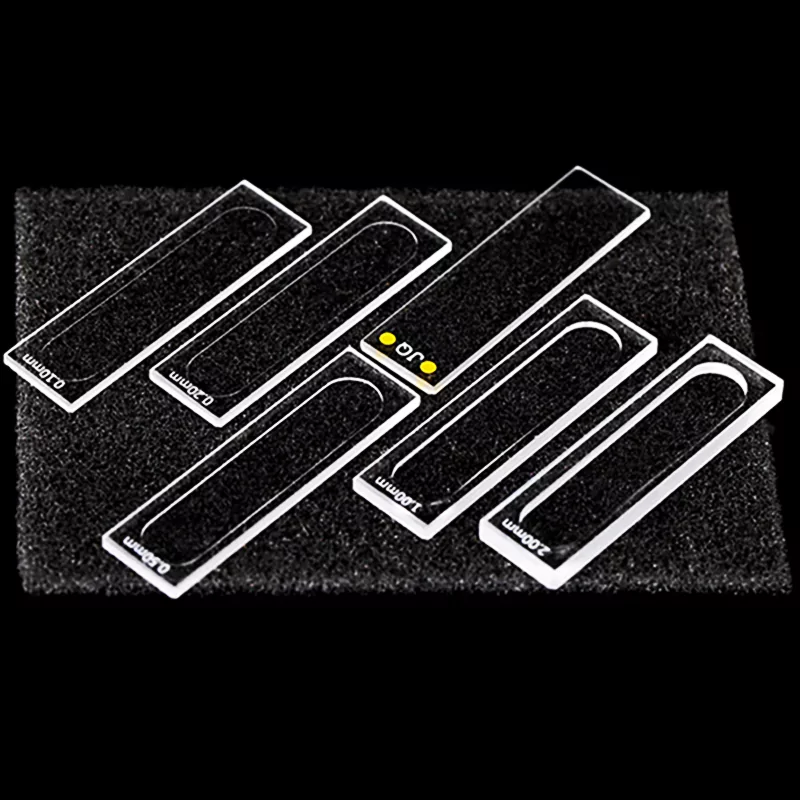

Size Chart

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

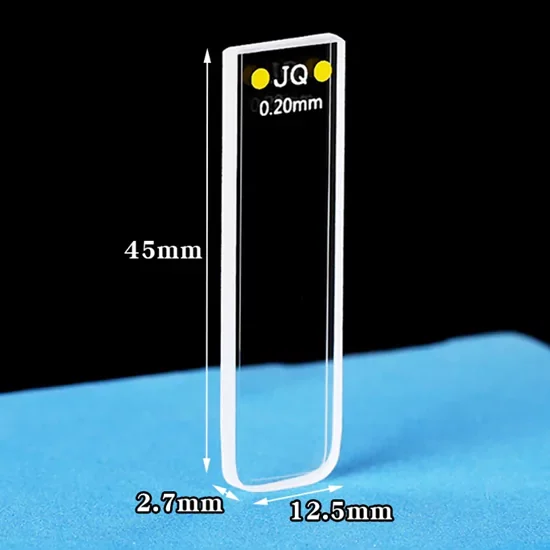

| AT-BSM-025 | 70μl UV Quartz Cuvette Sample Cell with Path Length 0.2mm | 200nm-2500nm | 0.2mm | 70μl | >80% (Paired Testing) | 12.5×2.7×45 mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-043 | 250μl UV-Grade Dual-Path Quartz Cuvette | 200nm-2500nm | 5mm | 250μl | >80% (Paired Testing) | 7x7x15mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-036 | 7ml UV-Grade Dual-Path Quartz Cuvette | 200nm-2500nm | 5mm | 7ml | >80% (Paired Testing) | 45x7x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-060 | Standard UV-Grade Dual-Path Quartz Cuvette | 200nm-2500nm | 10mm | / | >80% (Paired Testing) | 12.5×12.5x44mm |

TOQUARTZ® Solving Challenges with UV-Grade Dual-Path Quartz Cuvette

UV-Grade Dual-Path Quartz Cuvettes in Analytical Instrumentation

Key Advantages

-

Sub-millimeter Path Length Accuracy

Each cuvette maintains ±0.01mm path length tolerance across batches, verified by laser interferometry. -

Batch-to-Batch Optical Consistency

Transmission deviation between batches is controlled within ±0.5% at 200–250nm. -

Instrument-Specific Dimensional Matching

Outer dimensions are calibrated to ±0.05mm to ensure seamless fit with OEM spectrophotometer holders.

TOQUARTZ® solution

A German spectrophotometer OEM reported a 12% calibration failure rate due to inconsistent cuvette dimensions from a previous supplier. After switching to TOQUARTZ® Custom UV-Grade Dual-Path Quartz Cuvettes with certified ±0.01mm path length and ±0.05mm outer tolerance, the failure rate dropped below 1.2%, saving over €38,000 annually in recalibration and support costs.

UV-Grade Dual-Path Fused Quartz Cuvettes in Medical Diagnostics

Key Advantages

-

UV Transmission Stability in Protein Range

82% transmission at 200–220nm ensures accurate protein quantification in clinical assays. -

Biofluid-Compatible Surface Finish

Optical surfaces are polished to ≤λ/4 flatness and tested for zero protein adsorption in 24h exposure. -

Micro-Volume Precision Chambers

Custom chambers down to 250μl with ±0.01ml volume tolerance for enzyme-limited diagnostics.

TOQUARTZ® solution

A Japanese IVD device manufacturer faced inconsistent absorbance readings in protein assays due to cuvette surface variability. TOQUARTZ® supplied matched-pair UV-Grade Dual-Path Quartz Cuvettes with certified UV transmission and non-adsorptive surfaces, improving assay repeatability by 19% and reducing false positives by 22% across 3,000 test cycles.

UV-Grade Dual-Path Quartz Cuvettes in Environmental Analysis

Key Advantages

-

Acid-Resistant Optical Integrity

No surface degradation after 1,500h exposure to pH 2.0 HCl solution at 25°C. -

Low Background Absorption for Trace Detection

<0.2% baseline absorbance at 220nm enables detection of pollutants at ppb levels. -

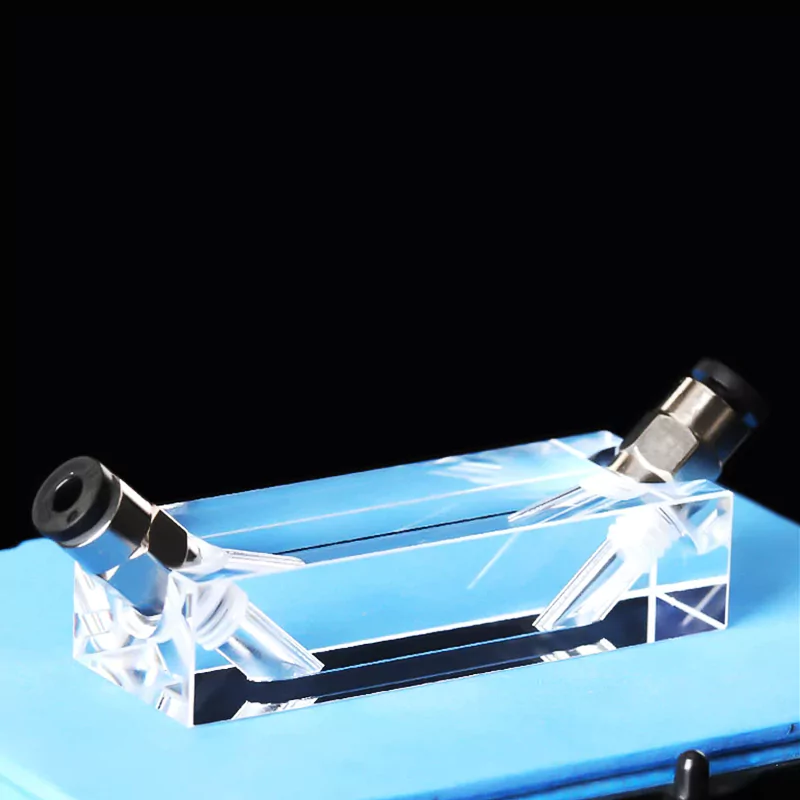

Flow-Through Ready Customization

Supports integrated inlet/outlet ports with 1.6mm ID tubing for real-time water monitoring.

TOQUARTZ® solution

A Canadian water quality lab experienced cuvette etching and signal drift after 3 weeks of acidic sample exposure. TOQUARTZ® delivered acid-resistant UV-Grade Dual-Path Quartz Cuvettes with <0.2% baseline absorbance and no surface wear after 1,500h testing, extending cuvette life by 3.7x and reducing replacement costs by 68%.

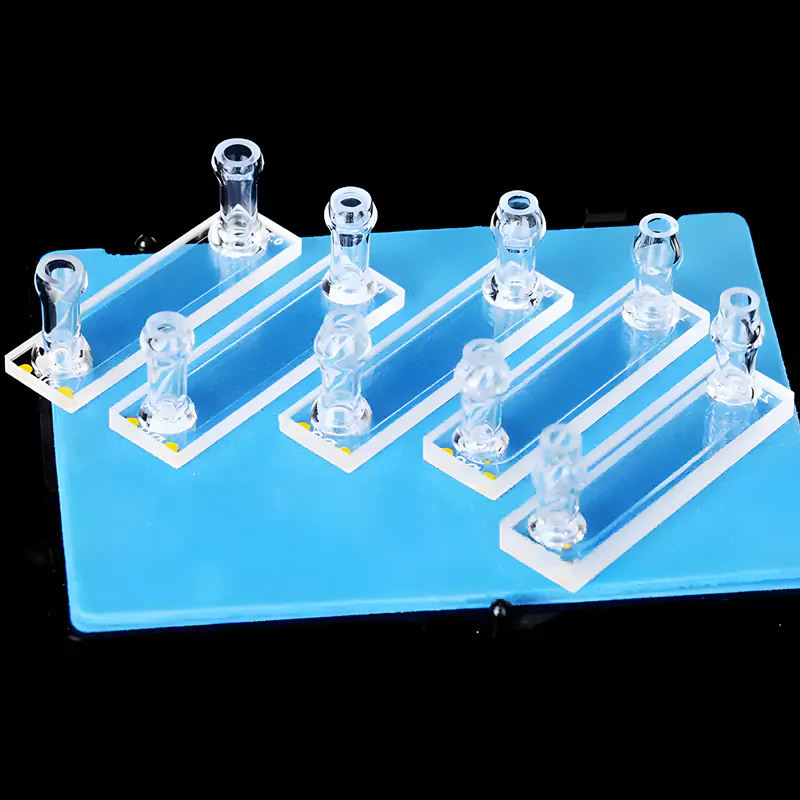

Customization Services for TOQUARTZ® UV-Grade Dual-Path

Quartz Cuvette

Custom Dimensions

- Non-standard path lengths

- Custom chamber volumes and geometries

- Special wall thickness requirements

- Instrument-specific exterior dimensions

Custom Testing

- Specific wavelength transmission testing

- Enhanced dimensional verification reports

- Chemical compatibility validation

- Matched set certification

Custom Design Process

- Consultation: Discuss requirements and technical specifications

- Design Proposal: Detailed drawings and specifications review

- Prototype: Sample production and testing

- Validation: Quality verification and approval

- Production: Full-scale manufacturing and delivery

Usage Guide of UV-Grade Dual-Path Quartz Cuvette

Handling & Cleaning

- Always handle cuvettes with clean gloves to prevent fingerprints on optical surfaces.

- Clean with mild detergent (pH 7-8) followed by thorough rinsing with distilled water.

- For organic residues, use spectroscopic-grade solvents (acetone, ethanol) followed by water rinse.

- Avoid abrasive materials or brushes that could scratch optical surfaces.

- Dry with clean, compressed air or nitrogen rather than wiping.

Storage & Maintenance

- Store in the original protective case or in a dust-free environment.

- Avoid rapid temperature changes that could cause thermal stress.

- Inspect regularly for chips, cracks, or surface contamination.

- For long-term storage, ensure cuvettes are thoroughly clean and dry.

- Maintain an inventory record including usage history and cleaning cycles.

Sample Loading & Measurement

- Fill to the recommended volume to ensure proper light path alignment.

- Avoid air bubbles by tilting the cuvette slightly during filling.

- Clean optical windows with lens tissue before placement in instrument.

- Ensure correct orientation with light path perpendicular to the beam.

- For paired cuvettes, maintain consistent orientation between reference and sample.

Chemical Compatibility

- Compatible with most acids, bases, and organic solvents (except HF).

- Avoid prolonged exposure to concentrated alkaline solutions above pH 12.

- Rinse immediately after use with corrosive or reactive samples.

- For samples containing fluoride compounds, limit exposure time and rinse thoroughly.

- For unusual or highly reactive samples, test compatibility on a spare cuvette first.

Need Expert Assistance with Your UV-Grade Dual-Path Quartz Cuvette?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What are the standard path lengths available for UV-Grade Dual-Path Quartz Cuvettes?

A: TOQUARTZ® standard path lengths include 1mm, 2mm, 5mm, 10mm, 20mm, 50mm, and 100mm. The most commonly used path length is 10mm, which is compatible with most spectrophotometers. We also offer custom path lengths between 0.5mm and 100mm to meet specific application requirements. All path lengths are manufactured with a tolerance of ±0.01mm to ensure measurement accuracy.

Q: How should I clean UV-Grade Dual-Path Quartz Cuvettes to maintain optical performance?

A: For routine cleaning, we recommend using a mild detergent solution (pH 7-8) followed by thorough rinsing with distilled or deionized water. For more stubborn residues, spectroscopic-grade solvents like acetone or ethanol can be used, followed by water rinsing. Always avoid abrasive materials or brushes that could scratch the optical surfaces. Dry with clean, compressed air or nitrogen rather than wiping. For detailed cleaning protocols for specific sample types, please refer to our complete usage guide.

Q: What is the temperature resistance of your UV-Grade Dual-Path Quartz Cuvettes?

A: TOQUARTZ® UV-Grade Dual-Path Quartz Cuvettes can withstand temperatures up to 1100°C, making them suitable for high-temperature applications. However, we recommend not exceeding 600°C for standard designs to avoid potential stress on seams or joints. For rapid temperature changes, we suggest limiting the rate to 10°C/minute to prevent thermal shock. For applications requiring extreme temperature cycling or exposure above 600°C, please consult with our engineering team for specially designed high-temperature versions.

Q: Can TOQUARTZ® provide UV-Grade Dual-Path Quartz Cuvette with certified optical flatness?

A: Yes, we offer optical surface flatness certification up to ≤λ/4, verified using Zygo interferometers for high-precision applications.

Q: Are your UV-Grade Dual-Path Quartz Cuvette tested for birefringence or internal stress?

A: Yes, we conduct birefringence testing using polarized light to ensure internal stress is below 10nm/cm, critical for high-precision optical systems.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.