- Home

- /

- Types

- /

- Custom Quartz Parts

- /

- Custom Seal-optimized Quartz Vacuum...

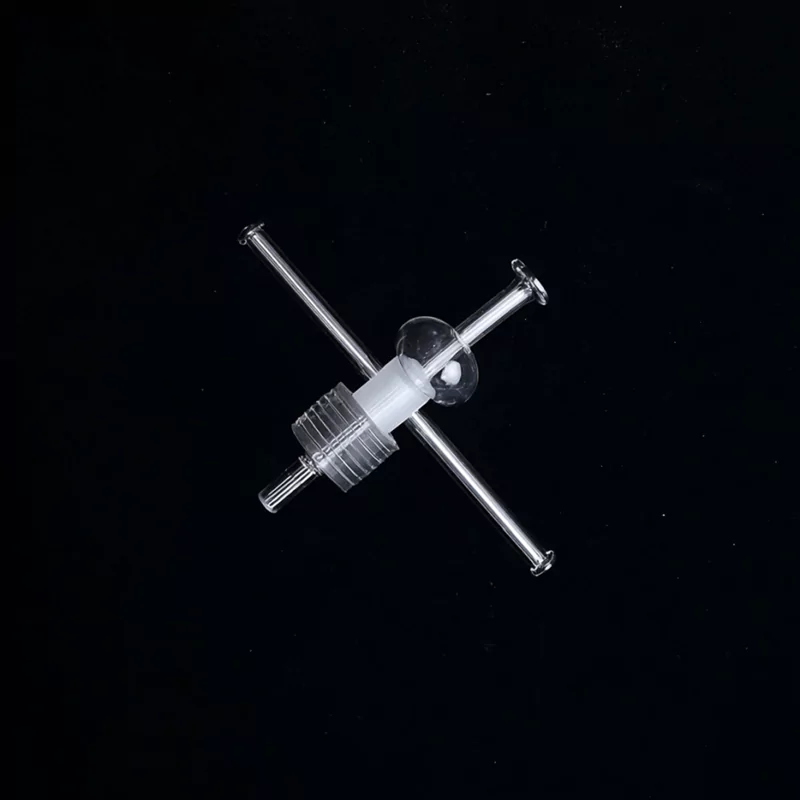

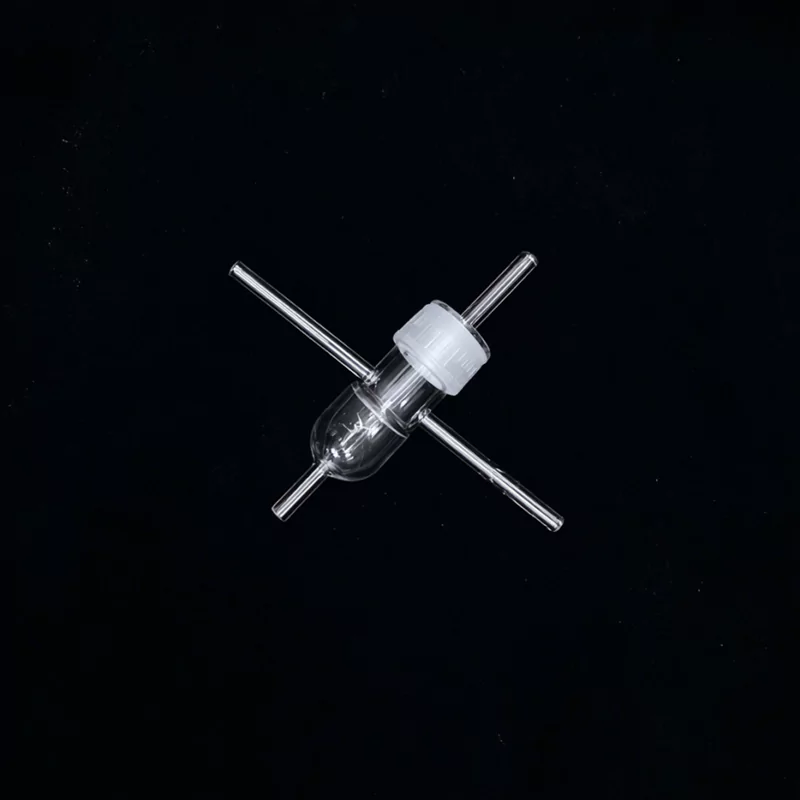

Custom Seal-optimized Quartz Vacuum Stopcocks for Vacuum Flow Systems -TOQUARTZ®

Features of Quartz Vacuum Stopcocks

TOQUARTZ® quartz vacuum stopcocks combine precision engineering with exceptional material properties, offering reliable performance for vacuum systems, gas flow control, and chemical processing applications.

High Material Purity

Manufactured from 99.99% SiO₂ quartz glass, ensuring minimal contamination in sensitive applications.

Thermal Stability

Withstands temperatures up to 1600°C with minimal thermal expansion (0.5×10⁻⁶/K coefficient).

Chemical Resistance

Resists acids, bases, molten salts, and fluorinated gases, ideal for corrosive environments.

- Precision-Ground Surfaces

- Low Friction Coefficient

- Customizable Dimensions

Specifications of Quartz Vacuum Stopcocks

TOQUARTZ® quartz vacuum stopcocks meet rigorous quality standards and provide consistent performance across various industrial and laboratory applications.

| Property | Specification | Notes |

| Material | High Purity Quartz Glass | 99.995% SiO₂ |

| Maximum Operating Temperature | 1600°C | Continuous operation |

| Thermal Expansion Coefficient | 0.5×10⁻⁶/K | 20-300°C range |

| Chemical Resistance | Excellent | Resistant to acids, bases, and corrosive gases |

| Dimensional Tolerance | ±0.1mm | Higher precision available on request |

| Surface Finish | Precision Ground | Bubble-free, scratch-free |

TOQUARTZ® Solving Industry Challenges with Quartz Vacuum Stopcocks

Quartz Vacuum Stopcock for Research Laboratory Applications

Key Advantages

-

Ultra-low contamination risk in plasma-sensitive setups

TOQUARTZ stopcocks maintain <0.001 ppm metal ion leaching under 1000°C plasma conditions. -

Stable sealing under high-vacuum cycling (10⁻⁶ Torr)

Leak rate tested at <1×10⁻⁹ mbar·L/s after 500 thermal cycles between 25°C and 800°C. -

No surface degradation in HF vapor exposure (≤60°C)

Surface roughness Ra < 0.02μm maintained after 72h HF vapor exposure in lab tests.

TOQUARTZ® solution

A German university lab conducting plasma etching experiments reported 3% data deviation due to valve contamination. After switching to TOQUARTZ® stopcocks, contamination dropped below detection limits, and vacuum integrity improved by 98% over 6 months of continuous use.

Fused Quartz Vacuum Stopcock for Chemical Processing Industry

Key Advantages

-

Zero corrosion in 40% HCl + 20% HF mixed acid at 80°C

No mass loss detected after 168h immersion; surface integrity fully retained. -

Maintains seal integrity in pH 1–14 dynamic flow systems

No seal failure observed in 1000h continuous flow test with alternating acid/alkali. -

No extractables in pharmaceutical-grade solvent contact

TOC < 10 ppb and no detectable heavy metals after 24h exposure to DMSO and IPA.

TOQUARTZ® solution

A Polish specialty chemical plant faced monthly valve failures in HF acid lines, costing €12,000 per incident. TOQUARTZ® stopcocks extended replacement cycles to 14 months, reducing downtime by 87% and eliminating contamination-related batch rejections.

Quartz Vacuum Stopcock for High-Temperature Processing Equipment

Key Advantages

-

Dimensional stability up to 1150°C under vacuum

Length variation <0.05mm after 200h at 1150°C in vacuum furnace simulation. -

No microcracking after 300 thermal shock cycles (25°C ↔ 900°C)

100% structural integrity retained; no visible or microscopic defects observed. -

Zero gas leakage at 1000°C under 2 bar pressure

Helium leak rate <1×10⁻⁹ mbar·L/s confirmed in high-temp pressure test.

TOQUARTZ® solution

A US-based CVD equipment OEM reported valve warping and leakage every 6 weeks at 950°C. After integrating TOQUARTZ® stopcocks, service intervals extended to 9 months, reducing maintenance costs by 72% and improving system uptime by 41%.

TOQUARTZ® Customization Services for Fused Silica Vacuum Stopcocks

Technical Drawing Support

TOQUARTZ® engineering team assists with technical drawings and designs to match your exact specifications. We provide CAD assistance and material recommendations based on your application requirements.

Dimensional Customization

We customize bore diameter, connection type, overall length, and other critical dimensions to match your specific system requirements. Tolerances as precise as ±0.1mm ensure perfect fit.

Prototype to Production

From small batch sampling to full-scale production runs, we support your project lifecycle. Rapid prototyping with 2-3 week delivery for custom designs, and scaling to meet ongoing demand.

Usage & Maintenance Guidelines of Quartz Vacuum Stopcocks

Proper handling, installation, and maintenance of quartz vacuum stopcocks ensures optimal performance and extended service life in your applications.

Installation Guidelines

- Inspect the stopcock for any damage or defects before installation.

- Handle with clean gloves to avoid surface contamination.

- Use appropriate vacuum grease sparingly on ground glass surfaces.

- Ensure connections are properly aligned to avoid stress points.

- Use appropriate support clamps to prevent mechanical stress.

Maintenance Recommendations

- Clean with appropriate solvents (acetone, isopropyl alcohol) followed by thorough rinsing.

- Inspect regularly for signs of wear, etching, or damage.

- Replace vacuum grease as needed to maintain proper sealing.

- Avoid thermal shock by heating and cooling gradually.

- Store in a clean, dry environment to prevent contamination.

Need Custom Quartz Vacuum Stopcocks for Your Project?

Share your requirements and we'll develop a tailored solution.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a quartz stopcock used for?

A: Quartz stopcocks are used for controlling gas or liquid flow in vacuum systems, chemical processing equipment, and laboratory apparatus where high temperature resistance, chemical inertness, and contamination prevention are critical. They provide reliable sealing and flow control in environments where conventional materials would deteriorate.

Q: What are the advantages of quartz glass stopcocks?

A: Quartz glass stopcocks offer several advantages over metal or conventional glass alternatives: exceptional chemical resistance to acids, bases, and corrosive gases; stability at temperatures up to 1600°C; minimal thermal expansion; ultra-high purity (99.995% SiO₂) for contamination-sensitive applications; excellent transparency for visual flow monitoring; and long service life in harsh environments.

Q: Can quartz stopcocks be used for high temperature applications?

A: Yes, quartz stopcocks can withstand continuous operating temperatures up to 1600°C, making them ideal for high-temperature applications where conventional valves would fail. Their low thermal expansion coefficient (0.5×10⁻⁶/K) ensures dimensional stability during thermal cycling, maintaining seal integrity. However, when used at elevated temperatures, special high-temperature vacuum grease or dry operation may be required.

Q: What is the chemical resistance of quartz vacuum valves?

A: Quartz vacuum valves exhibit exceptional chemical resistance to most acids (including hydrofluoric acid at room temperature), bases, organic solvents, and corrosive gases. They remain stable in contact with molten salts and fluorinated compounds that would attack most metals and other glass types. The only significant exceptions are concentrated phosphoric acid at high temperatures and strong alkaline solutions above 300°C.

Q: How to clean and maintain quartz glass stopcocks?

A: To clean quartz glass stopcocks:

(1) Carefully disassemble the components;

(2) Remove old vacuum grease using appropriate solvents like acetone or isopropyl alcohol;

(3) For stubborn residues, soak in a cleaning solution appropriate for your contaminants;

(4) Rinse thoroughly with distilled water;

(5) Allow to dry completely in a dust-free environment;

(6) Inspect for any damage or wear;

(7) Apply fresh vacuum grease sparingly before reassembly.

Avoid abrasive cleaners that could damage the precision-ground surfaces.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.