- Home

- /

- Types

- /

- Quartz Tube

- /

- Custom Multi-System Compatible Quartz...

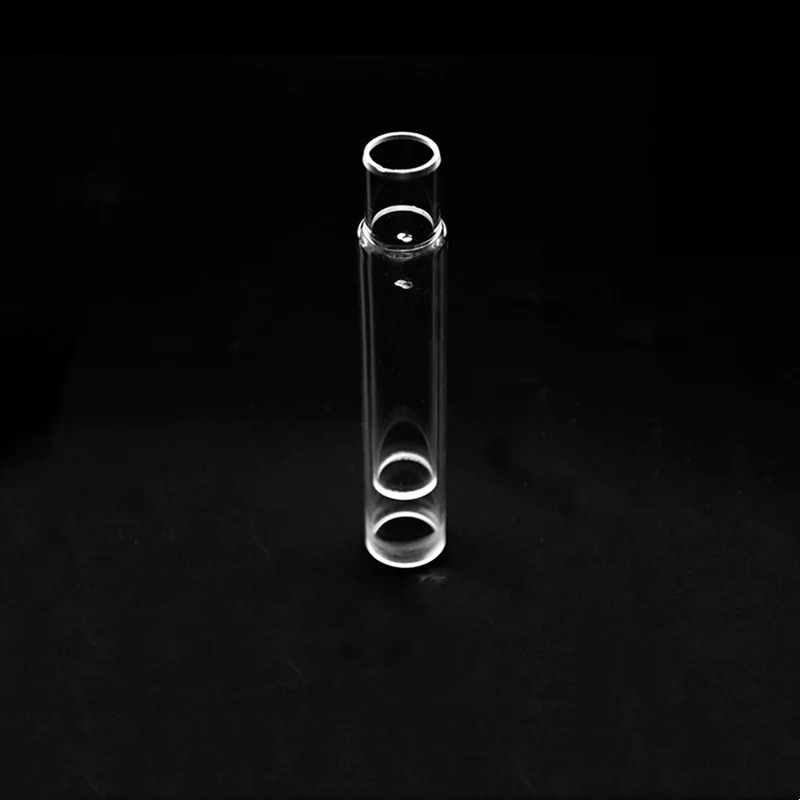

Custom Multi-System Compatible Quartz Glass Reducer Tube for Scientific & Industrial Applications-TOQUARTZ®

Key Features of Quartz Glass Reducer Tube

TOQUARTZ® Quartz reducer tubes offer reliable dimensional transitions between quartz components, ensuring system integrity across laboratory, optical, and industrial environments. Their material stability and design flexibility make them essential for precision-driven applications.

High Temperature Resistance

Maintains structural integrity and dimensional stability at temperatures up to 1200°C, ideal for furnace applications and high-temperature gas transport.

Chemical Compatibility

Exceptional resistance to acids, bases, salt solutions, and fluorine gases. Withstands corrosive environments where other materials fail.

Precision Dimensions

Manufactured to tight tolerances (±0.1mm) ensuring leak-tight connections and seamless integration with existing quartz systems.

- Thermal shock resistance ΔT > 1000°C

- Service life exceeds 300 thermal cycles

- Maintains vacuum integrity to 10⁻⁸ Torr

Technical Specifications of Quartz Glass Reducer Tube

TOQUARTZ® quartz glass reducer tubes are manufactured to precise technical specifications for reliable performance in demanding applications.

| Property | Specification |

| Material | High-purity fused quartz (up to 99.995% SiO₂) |

| Maximum Operating Temperature | 1200°C continuous |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷ /°C (20-1000°C) |

| Standard Dimensional Tolerance | ±0.1mm (±0.05mm available for select configurations) |

| Surface Finish Options | Fire-polished, Ground finish, Standard |

| Chemical Resistance | Resistant to most acids, bases, and corrosive chemicals (except HF, phosphoric acid at high temperatures) |

| Electrical Resistivity | 10¹⁰ Ω·cm at 500°C |

TOQUARTZ® Solving Challenges with Quartz Glass Reducer Tube

Quartz Glass Reducer Tube for Laboratory Vacuum Systems

Key Advantages

-

Leak rate below 1×10⁻⁹ mbar·L/s

Ensures ultra-tight seals in UHV systems under repeated thermal cycling. -

Dimensional deviation under ±0.08 mm

Maintains precise alignment in modular vacuum assemblies. -

No detectable outgassing at 10⁻⁸ Torr

Pre-cleaned quartz surface prevents contamination in sensitive experiments.

TOQUARTZ® solution

A German university lab reported 12% failure rate using borosilicate adapters in vacuum lines due to thermal cycling above 400°C. After switching to TOQUARTZ® quartz reducer tubes, vacuum integrity was maintained at 10⁻⁸ Torr for over 300 cycles. This reduced system downtime by 87% and eliminated contamination-related experiment failures.

Fused Quartz Glass Reducer Tube for Optical Fiber Production

Key Advantages

-

Metallic impurity content < 0.5 ppm

Prevents dopant interference during fiber preform synthesis. -

Inner surface roughness < 0.8 μm Ra

Minimizes light scattering and preserves optical clarity. -

Dimensional tapering tolerance ±0.05 mm

Enables precise alignment in MCVD and VAD systems.

TOQUARTZ® solution

A Japanese optical fiber manufacturer experienced 9% yield loss due to misaligned preform transitions and silica contamination from standard connectors. TOQUARTZ® quartz reduction tubes with <0.5 ppm metallic content and ±0.05 mm tapering tolerance improved alignment accuracy and purity, increasing fiber yield by 21% and reducing polishing rework by 35%.

Fused Silica Reducer Tube for Industrial Heating Applications

Key Advantages

-

Thermal shock resistance ΔT > 1000°C

Survives rapid heating from 25°C to 1100°C in <5 minutes. -

Wall thickness uniformity ±0.1 mm

Prevents stress concentration under cyclic thermal loads. -

Alkali vapor corrosion rate < 0.01 mm/year

Maintains structural integrity in corrosive furnace atmospheres.

TOQUARTZ® solution

A Polish furnace OEM faced frequent connector failures in high-temperature gas lines operating at 1150°C with alkali vapors. TOQUARTZ® quartz reducer tubes maintained dimensional stability over 280 thermal cycles and showed <0.01 mm/year corrosion rate.

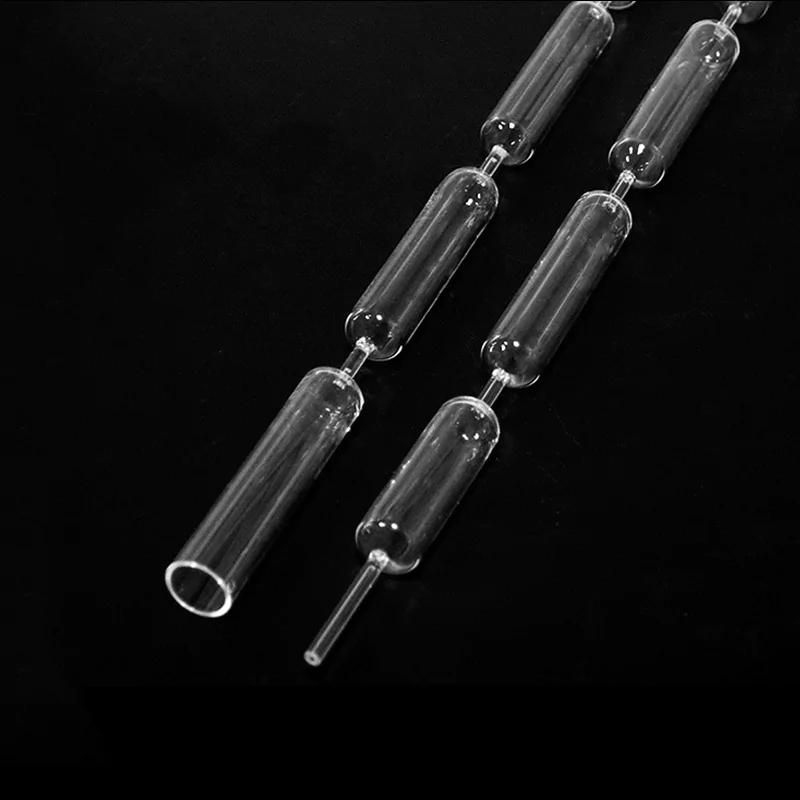

TOQUARTZ® Customized Services for Quartz Glass Reducer Tube

TOQUARTZ® offer comprehensive customization services for specialized quartz glass reducer tube requirements beyond standard specifications.

Custom Geometries

- Multi-diameter transitions

- Custom transition angles (15° to 90°)

- Stepped reduction profiles

- Offset reductions

- Y-shaped or T-shaped junctions

Specialized Finishes

- Ground glass joint ends

- Flange connections

- Fire-polished finishes

- Integrated O-ring grooves

- Custom end face treatments

Engineering Support

- CAD drawing assistance

- Thermal analysis

- Material recommendations

- System integration consulting

- Prototype development

Custom Quartz Reducer Tube Development Process

-

Initial Consultation

Our engineers discuss your specific requirements, including operating conditions, dimensional needs, and system integration requirements. -

Design & Engineering

We develop technical drawings and specifications for your custom quartz transition tube, including material selection and manufacturing approach. -

Prototype Production

For complex designs, we manufacture prototype quartz step-down tubes for verification before full production. -

Manufacturing & Quality Control

Production of your custom quartz reducer tube with rigorous quality testing to ensure dimensional accuracy and material integrity.

Usage Guidelines for Quartz Glass Reducer Tube

Proper handling, installation, and maintenance of quartz glass reducer tubes ensures optimal performance and extended service life.

Installation Recommendations

-

Gradual Temperature Changes:

When heating, allow for gradual temperature increases of approximately 10°C/minute to prevent thermal shock. -

Clean Contact Surfaces:

Ensure all connection surfaces are clean and free from particulates before assembly. -

Appropriate Sealing:

Use compatible gaskets or O-rings designed for high-temperature applications when creating sealed connections. -

Even Support:

Support quartz components evenly to prevent stress concentration and potential fracture. -

Avoid Mechanical Stress:

Do not overtighten fittings or clamps on quartz components.

Maintenance & Storage

-

Regular Inspection:

Periodically inspect for microcracks, especially after thermal cycling. -

Cleaning Protocol:

Clean with deionized water followed by reagent-grade acetone or isopropanol. For persistent contamination, use dilute aqueous solutions of HCl or HNO₃ (avoid HF). -

Storage:

Store in clean, dust-free environments away from potential mechanical impacts. -

Handling:

Always handle with clean gloves to prevent surface contamination and fingerprints. -

End-of-Life:

Quartz can be recycled; contact your local recycling facility for proper disposal procedures.

Need Expert Assistance with Quartz Glass Reducer Tubes?

help you select the right quartz reducer tube for your application or develop custom solutions for your specific requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the maximum temperature limit for quartz reducer tubes?

A: TOQUARTZ® standard quartz glass reducer tubes can withstand continuous operating temperatures up to 1200°C. For short-term exposure, they can tolerate up to 1400°C. However, we recommend considering the thermal gradients and expansion characteristics in your specific application. For temperatures approaching these limits, consult with our technical team for optimal design recommendations.

Q: Can quartz reducer tubes be used in vacuum systems?

A: Yes, TOQUARTZ® quartz reducer tubes are excellent for vacuum applications. They exhibit minimal outgassing, maintain dimensional stability under vacuum, and can achieve high vacuum levels (10⁻⁸ Torr). For ultra-high vacuum applications, we offer specially cleaned and processed quartz step-down tubes with enhanced surface treatment to minimize potential contaminants.

Q: What connection types are available for quartz reducer tubes?

A: TOQUARTZ® quartz glass reducer tubes are available with various end connections, including standard straight cut, ground glass joints (14/23, 19/38, 24/40, etc.), O-ring groove ends, flange connections, ball-and-socket joints, and custom configurations. For specialized systems, we can produce hybrid connections integrating with metal components or other materials.

Q: Are quartz reducer tubes resistant to all chemicals?

A: TOQUARTZ® Quartz reducer tubes offer excellent chemical resistance to most substances, including strong acids, bases, organic solvents, and salt solutions. However, they can be attacked by hydrofluoric acid (HF), concentrated phosphoric acid at high temperatures, and strong alkaline solutions above 600°C. For applications involving these chemicals, special coatings or alternative materials may be recommended.

Q: How do I specify dimensions for a custom quartz reducer tube?

A: For custom quartz tubes with different diameters, please provide the following specifications:

(1) Large end outer diameter (OD) and wall thickness,

(2) Small end outer diameter (OD) and wall thickness,

(3) Overall length,

(4) Transition angle or length of transition section,

(5) Any special end treatments or connections,

(6) Surface finish requirements.

Our technical team can assist with developing detailed specifications from your application requirements.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.