The demand for reliable and efficient heating solutions in high-temperature applications is growing across industries. Compact spiral opaque quartz tubes provide a unique combination of space efficiency, high thermal resistance, and customization, making them an ideal choice for both laboratory and industrial heating systems.

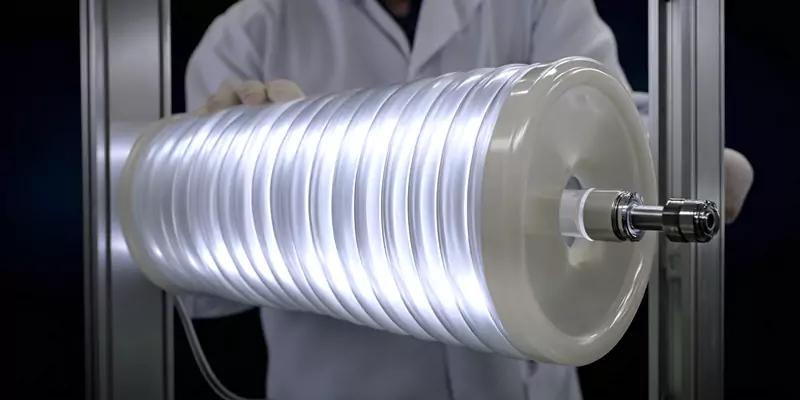

Opaque spiral quartz tubes are designed for high-efficiency heating solutions, with the compact spiral design ensuring optimal use of space in laboratories and industrial heating systems.

In this article, we explore the key advantages of compact spiral opaque quartz tubes for high-temperature applications and how their features benefit industries such as manufacturing, chemical processing, and laboratory research.

The Key Advantages of Compact Spiral Opaque Quartz Tubes for High-Temperature Applications

Compact spiral opaque quartz tubes are engineered to deliver superior thermal performance in high-temperature environments. Their unique design offers unmatched space efficiency, making them ideal for compact industrial and laboratory setups. The combination of high thermal resistance and durability ensures long-lasting performance under extreme conditions. This section explores the primary advantages these tubes offer in high-heat applications.

Superior Thermal Resistance and Stability at High Temperatures

Compact spiral opaque quartz tubes are built to withstand extreme temperatures, offering exceptional thermal resistance. This makes them ideal for use in high-temperature environments like industrial furnaces and laboratory heating systems.

How the Compact Spiral Design Enhances Space Efficiency

The spiral design not only ensures an even heat distribution but also makes efficient use of space. This is crucial in applications where equipment size and spatial limitations are a concern, such as in compact industrial systems or laboratory setups.

Unique Benefits of Opaque Quartz in High-Temperature Environments

Opaque quartz has a unique ability to reflect heat and minimize energy loss. This feature is essential in high-temperature applications, where maximizing thermal efficiency is critical. The opacity of the quartz also offers additional benefits, including protection from UV radiation and enhanced durability.

How Compact Spiral Opaque Quartz Tubes Maximize Thermal Shock Resistance

Thermal shock resistance is a critical factor for materials used in high-temperature environments. Compact spiral opaque quartz tubes excel in this area, effectively withstanding rapid temperature fluctuations without compromising structural integrity. The spiral design reduces thermal stress, contributing to the overall durability of the material. This section examines how these tubes handle extreme temperature changes and their resilience in demanding applications.

Thermal Shock Resistance in Extreme Environments

Thermal shock resistance is a critical property for materials exposed to extreme temperature variations. Compact spiral opaque quartz tubes excel in this aspect due to their ability to handle rapid temperature changes without cracking or degrading. Their unique spiral design helps evenly distribute heat across the tube, reducing localized stress and enhancing overall durability. These tubes maintain structural integrity even when exposed to thermal shock from sudden heating or cooling. This feature makes them indispensable in industrial and laboratory applications that require reliable performance under fluctuating temperatures.

In environments like chemical vapor deposition (CVD)1 or material processing, temperature fluctuations are common, and materials often fail under rapid changes. However, compact spiral opaque quartz tubes are designed specifically to withstand these fluctuations. Their resistance to thermal shock ensures that they perform consistently without requiring frequent replacements or maintenance. In high-temperature applications, the ability to maintain performance during thermal stress is essential to avoid costly downtime.

The material’s resilience to thermal shock is an essential advantage in industries where high-precision and reliability are paramount. Compact spiral opaque quartz tubes ensure that operations continue smoothly even in the face of extreme temperature fluctuations. This makes them ideal for processes involving quick thermal cycles or irregular heating patterns, such as semiconductor manufacturing or high-temperature laboratory testing.

How Compact Spiral Design Contributes to Durability

The compact spiral design of these quartz tubes enhances their overall durability in high-temperature environments. By distributing heat evenly along the tube’s surface, the spiral structure reduces thermal stress and prevents localized overheating. This design minimizes the chances of cracks or fractures that might occur when the material is subjected to intense temperature changes. Additionally, the compact structure makes the tubes more resistant to physical damage from external forces.

In high-temperature applications, durability is crucial to maintaining operational efficiency and safety. Compact spiral opaque quartz tubes have a longer lifespan compared to traditional quartz tubes because their design reduces stress points. This contributes to fewer breakdowns and longer intervals between replacements, making them a cost-effective solution for long-term use. The ability to endure extreme conditions without compromising structural integrity is a key feature of these tubes.

The added durability also makes these tubes ideal for use in industries with high wear and tear, such as glass manufacturing, metal processing, and chemical reactions. In such industries, reliability is vital to ensure continuous operations. Compact spiral quartz tubes are engineered to meet these demands, providing a dependable, long-lasting solution to high-temperature material processing challenges.

Applications in High-Temperature Processes that Require Rapid Temperature Fluctuations

Rapid temperature fluctuations are a common challenge in many high-temperature processes. Compact spiral opaque quartz tubes are specifically designed to perform in these dynamic conditions. Their excellent thermal shock resistance allows them to withstand sudden heating and cooling cycles without losing integrity or performance. This capability makes them ideal for applications like chemical vapor deposition (CVD), material processing, and other high-heat industrial processes.

In processes where temperature changes occur frequently, such as in chemical or industrial furnaces, the material’s ability to handle these shifts is paramount. These quartz tubes maintain consistent performance under fluctuating conditions, offering a stable and reliable solution for industries that demand precision. The spiral design ensures even heat distribution, which reduces the risks associated with rapid temperature changes, making them more durable than conventional materials.

Industries that rely on high-precision equipment require materials that can endure frequent temperature shifts without compromising on quality or safety. Compact spiral opaque quartz tubes provide this capability, ensuring that high-temperature processes continue smoothly. Their resistance to thermal shock is vital for industries such as electronics, aerospace, and pharmaceuticals, where rapid temperature cycling is common.

Improved Performance in High-Temperature Industrial and Laboratory Settings

Compact spiral opaque quartz tubes enhance performance in both industrial heating systems and laboratory environments. Their efficient heat distribution and space-saving design allow for more effective and precise temperature control. These tubes are specifically tailored for high-temperature processes where reliability and durability are essential. In this section, we will explore the benefits of using these tubes in such critical settings.

Role in Industrial Heating Systems and Furnaces

Compact spiral opaque quartz tubes are essential components in industrial heating systems and furnaces, where they play a key role in improving the efficiency of heating processes. Their ability to distribute heat evenly across the tube’s surface ensures uniform heating, which is crucial for industrial applications like glass manufacturing, metal processing, and ceramic production. This efficient heat distribution maximizes energy use and reduces waste, contributing to lower operational costs.

In environments like furnaces or kilns, where high temperatures are sustained over long periods, the high thermal stability of these tubes allows them to maintain consistent performance without degradation. This makes them an ideal material for long-term use in harsh, high-temperature environments. Their compact design also offers space-saving benefits, making them suitable for installations with limited space or complex configurations.

The durability and thermal efficiency of these tubes enable industries to optimize their heating processes. They ensure that heat is applied precisely where needed, leading to better control over the manufacturing process. The reduced need for replacements and maintenance further enhances operational efficiency, making compact spiral opaque quartz tubes a reliable and cost-effective choice for industrial heating systems.

Precision and Efficiency in Laboratory Heating Applications

In laboratory settings, where precise temperature control is critical, compact spiral opaque quartz tubes offer unparalleled performance. Their spiral design ensures even heat distribution, which is essential for experiments that require consistent heating over extended periods. This feature makes them a preferred choice for laboratory heating applications such as material testing, heat treatment, and chemical analysis.

In addition to thermal efficiency, these tubes offer high chemical resistance, which is essential in laboratories where harsh chemicals are often used. Their resistance to corrosion ensures that they remain stable and reliable, even in the most demanding laboratory conditions. The combination of precision, efficiency, and durability makes these quartz tubes a top choice for research and experimental applications.

The ability to maintain consistent performance in high-temperature laboratory settings is essential for accurate results. Compact spiral opaque quartz tubes provide the necessary thermal stability to achieve precise temperature control. This makes them indispensable in laboratories focused on high-heat experiments, where uniform heating is essential to obtaining reliable and repeatable results.

Case Studies of Successful Implementations

Real-world examples demonstrate the effectiveness of compact spiral opaque quartz tubes in various industrial and laboratory settings. In one instance, a high-temperature laboratory was able to significantly reduce downtime by using these tubes in their heat treatment processes. The tubes’ resistance to thermal shock and chemical degradation ensured smooth operations, even under challenging conditions.

Another case study highlights the use of these tubes in an industrial furnace where consistent temperature control was essential. By incorporating compact spiral opaque quartz tubes, the facility was able to enhance heat distribution, reduce energy consumption, and improve overall process efficiency. These improvements resulted in both cost savings and increased production throughput.

The versatility and reliability of compact spiral opaque quartz tubes make them suitable for a wide range of applications. These case studies illustrate how they contribute to enhanced performance and reliability in high-temperature processes, providing valuable insights into their real-world applications. Their ability to deliver consistent results in diverse environments has made them a preferred choice across multiple industries.

The Exceptional Chemical Resistance of Compact Spiral Opaque Quartz Tubes at Elevated Temperatures

At elevated temperatures, chemical resistance becomes a vital factor in material selection. Compact spiral opaque quartz tubes are designed to withstand aggressive chemical environments while maintaining structural integrity. Their resistance to corrosion and degradation makes them ideal for industries dealing with harsh chemicals and gases. This section delves into the chemical resistance properties of these tubes and their role in extreme conditions.

Resistance to Corrosive Gases and Harsh Environments

Compact spiral opaque quartz tubes offer exceptional resistance to corrosive gases and harsh chemical environments. This makes them ideal for applications in chemical processing industries where exposure to aggressive gases and substances is a regular occurrence. The material’s ability to withstand corrosion ensures long-lasting performance in environments where other materials might fail.

In industries like semiconductor manufacturing and petrochemical processing, exposure to harsh chemicals is common. The superior chemical resistance of compact spiral opaque quartz tubes ensures that they remain intact and functional, even when exposed to highly corrosive gases. This ability to resist degradation under extreme conditions makes them a reliable choice for processes that involve reactive or aggressive substances.

Their resilience to corrosive environments also enhances the overall safety of operations. By preventing material failure due to chemical exposure, compact spiral opaque quartz tubes help reduce the risk of accidents and ensure uninterrupted processes. This makes them a key component in industries that prioritize both efficiency and safety in their operations.

How Opaque Quartz Protects Against Chemical Degradation

Opaque quartz is highly effective at preventing chemical degradation, particularly in high-temperature applications. The opacity of the material helps protect it from UV radiation, while its strong chemical resistance ensures that it remains stable even when exposed to harsh chemicals. This protection is crucial for maintaining the integrity of the material in environments where aggressive chemicals are frequently used.

The chemical resistance of opaque quartz is particularly beneficial in processes like chemical vapor deposition (CVD) and gas-phase reactions, where the material must endure prolonged exposure to reactive gases. By maintaining its structural integrity, opaque quartz helps extend the lifespan of the equipment and reduce the frequency of replacements. This makes it an ideal choice for industries that require continuous, high-performance materials in aggressive environments.

Opaque quartz also helps prevent chemical reactions that could compromise the process or contaminate the materials being processed. Its ability to resist degradation ensures that the tubes remain reliable throughout their operational life. This makes opaque quartz tubes indispensable in applications where chemical stability and longevity are critical.

Importance of Chemical Resistance in Industrial Applications

Chemical resistance is one of the most important factors in selecting materials for industrial applications. Compact spiral opaque quartz tubes offer exceptional resistance to a wide range of chemicals, making them suitable for industries such as petrochemicals, pharmaceuticals, and electronics. Their ability to withstand exposure to aggressive chemicals ensures that they perform reliably in challenging environments.

In many industrial applications, the materials being processed or handled can be highly corrosive. The superior chemical resistance of compact spiral opaque quartz tubes ensures that they remain intact, even in the most demanding conditions. This capability not only improves the safety of operations but also contributes to the longevity of the equipment used in these processes.

The ability of these tubes to resist chemical degradation ensures that industrial processes continue smoothly without interruptions or failures. This makes them a key component in industries where reliability, safety, and efficiency are paramount. Their chemical stability guarantees that these tubes maintain their performance over time, even in harsh chemical environments.

Why Engineers Prefer Compact Spiral Opaque Quartz Tubes for Extreme Thermal Applications

Engineers frequently turn to compact spiral opaque quartz tubes for extreme thermal applications due to their consistent performance. These tubes combine exceptional heat resistance with a compact design that offers flexibility and space efficiency. The ability to tailor these tubes to specific requirements makes them highly desirable for demanding engineering projects. This section highlights the reasons why engineers favor these tubes in critical thermal environments.

Why Opaque Quartz Tubes Are Preferred Over Traditional Quartz Tubes

Opaque quartz tubes offer several advantages over traditional transparent quartz tubes. Their enhanced thermal performance and chemical resistance make them better suited for extreme high-temperature environments. The opaque material also provides additional protection against UV radiation, ensuring that the tubes remain stable even in high-radiation environments.

Traditional quartz tubes, while effective in many applications, often do not provide the same level of durability and thermal resistance as opaque quartz tubes. In industries that require high-performance materials, opaque quartz tubes are the preferred choice. Their ability to resist thermal shock, chemical degradation, and UV exposure makes them a more reliable solution for demanding applications.

The compact spiral design of opaque quartz tubes further enhances their versatility. This design allows for better heat distribution, reducing thermal stress and improving overall durability. This makes opaque quartz tubes a superior choice for applications where both space efficiency and performance are essential.

Performance Consistency in Long-Term High-Temperature Use

Compact spiral opaque quartz tubes offer consistent performance even in long-term high-temperature applications. Their ability to withstand prolonged exposure to heat without degradation ensures that they remain functional over extended periods. This makes them an ideal material for industries that rely on continuous, high-temperature operations, such as glass manufacturing and metal processing.

The consistent performance of these tubes is a result of their excellent thermal stability and resistance to thermal shock. Unlike many other materials, they do not experience a significant loss in performance over time. This ensures that operations remain efficient and reliable throughout the lifespan of the equipment.

In industries where uptime is critical, the long-term performance of compact spiral opaque quartz tubes is essential. Their ability to maintain stability and performance over extended periods reduces the need for frequent replacements, ensuring that high-temperature processes continue without interruption. This contributes to lower maintenance costs and improved operational efficiency.

Customization to Meet Specific Engineering Requirements

One of the main advantages of compact spiral opaque quartz tubes is their ability to be customized to meet specific engineering requirements. These tubes can be tailored in terms of size, material grade, and thermal properties to suit the needs of different applications. This flexibility allows engineers to optimize the tubes for use in various industries and processes.

Customization ensures that compact spiral opaque quartz tubes perform optimally in their designated high-temperature applications. Whether the requirement is for enhanced thermal conductivity, greater resistance to chemicals, or specific dimensions, these tubes can be adapted to meet those needs. This makes them a versatile solution for a wide range of industrial and laboratory applications.

The ability to customize these tubes also helps reduce operational costs. By tailoring the tubes to the specific needs of the process, engineers can ensure that the materials used are the most efficient and cost-effective for the job. This customization capability makes compact spiral opaque quartz tubes an essential tool for industries that require precise performance in high-temperature environments.

Design Features That Make Compact Spiral Opaque Quartz Tubes Ideal for High-Temperature Processes

The design of compact spiral opaque quartz tubes is optimized for high-temperature applications, with features that maximize thermal performance. Their spiral structure ensures even heat distribution, while the opaque quartz material offers added protection against UV radiation and chemical exposure. These design elements make the tubes suitable for a wide range of high-temperature processes. This section examines the key design features that contribute to their effectiveness.

The Importance of Compact Spiral Structure in High-Temperature Applications

The compact spiral structure of these quartz tubes plays a vital role in ensuring their effectiveness in high-temperature applications. This design allows for even heat distribution, which reduces thermal stress and minimizes the risk of material failure. The spiral shape enhances the overall thermal performance, making it ideal for high-precision applications that require consistent temperature control.

By ensuring that heat is evenly distributed, the compact spiral design helps prevent the formation of hot spots, which can cause thermal stress and reduce the material's lifespan. This is especially important in applications that involve rapid temperature changes, such as chemical vapor deposition (CVD) or material processing. The design helps the tubes maintain their structural integrity, even under extreme thermal conditions.

Additionally, the compact design provides space-saving benefits, making these tubes ideal for applications where space is limited. Their ability to deliver high performance while occupying minimal space enhances their versatility in a variety of industrial and laboratory settings. This makes them an excellent choice for high-temperature processes that require precise temperature management.

Enhanced Performance with Tailored Specifications

Compact spiral opaque quartz tubes can be tailored to meet the specific performance requirements of different high-temperature applications. Customization allows engineers to select the ideal size, material grade, and thermal properties needed to achieve optimal performance in various processes. This adaptability ensures that the tubes are well-suited for a wide range of industrial and laboratory uses.

By customizing the tubes, engineers can fine-tune their performance to achieve the best results for specific applications. This includes optimizing factors like heat distribution, chemical resistance, and durability. Tailored specifications help improve efficiency, reduce maintenance costs, and extend the lifespan of the equipment.

Customized compact spiral opaque quartz tubes provide a reliable solution for high-precision applications where performance is critical. Their ability to be tailored to meet the specific needs of the process ensures that they deliver consistent, long-lasting results. This makes them an indispensable tool for industries that require high-performance materials in demanding high-temperature environments.

How Customization Impacts Efficiency and Longevity

Customization plays a key role in enhancing the efficiency and longevity of compact spiral opaque quartz tubes. By tailoring the tubes to meet the specific needs of an application, engineers can optimize their performance, ensuring that the tubes are more efficient and durable in their intended use. Customization ensures that the tubes provide the highest level of performance while minimizing energy consumption and operational costs.

Tailored specifications also contribute to the longevity of the tubes by addressing the unique requirements of the application. This reduces wear and tear, extends the operational life of the tubes, and minimizes downtime due to maintenance or replacement. By selecting the right material, size, and thermal properties, engineers can ensure that the tubes remain reliable for an extended period.

In industries where cost efficiency and long-term reliability are crucial, customized compact spiral opaque quartz tubes offer a significant advantage. Their ability to perform optimally over time leads to lower maintenance and replacement costs, making them a cost-effective solution for high-temperature applications that require consistent performance.

Comparing Compact Spiral Opaque Quartz Tubes with Other High-Temperature Materials

When evaluating materials for high-temperature applications, it's essential to compare their performance metrics. Compact spiral opaque quartz tubes offer superior heat resistance, thermal shock resistance, and chemical stability compared to other materials like ceramics or glass. Their unique design further enhances their durability and efficiency. This section compares these tubes with other high-temperature materials to highlight their distinct advantages.

How Compact Spiral Opaque Quartz Tubes Compare to Glass and Ceramic Alternatives

When comparing compact spiral opaque quartz tubes to glass and ceramic alternatives, the quartz tubes consistently outperform in terms of thermal resistance and chemical stability. The superior heat resistance and durability of quartz allow it to withstand extreme temperatures and thermal shock, making it a better choice for high-temperature applications. Additionally, quartz tubes do not suffer from the brittleness that is often associated with ceramic materials.

While glass is transparent and offers some level of thermal stability, it is not as resilient to high temperatures or rapid thermal cycling as quartz. Ceramic materials, although known for their heat resistance, can be more prone to cracking and damage under thermal shock. In contrast, compact spiral opaque quartz tubes maintain their integrity even in the most demanding conditions, offering greater reliability and performance.

Another advantage of compact spiral opaque quartz tubes is their space-efficient design, which is often not achievable with glass or ceramic alternatives. The compact spiral structure allows for even heat distribution in limited spaces, making them ideal for applications where space is constrained. This unique combination of thermal performance, durability, and compactness makes quartz tubes the preferred choice over other materials in high-temperature environments.

Performance Metrics in High-Temperature Applications

In high-temperature applications, performance metrics such as heat resistance, thermal shock resistance, and chemical durability are critical for ensuring the reliability of materials. Compact spiral opaque quartz tubes exceed these requirements, offering superior performance in extreme conditions. Their ability to maintain structural integrity under thermal stress and high heat makes them a reliable choice for industrial and laboratory applications.

Compared to other materials, compact spiral opaque quartz tubes have higher heat resistance and can withstand higher temperatures over extended periods. Their thermal shock resistance is also notable, as they can endure rapid temperature changes without cracking or failing. This makes them ideal for high-heat processes that require precision and durability, such as in material testing, metal processing, and chemical reactions.

These tubes also offer enhanced chemical durability, ensuring that they remain stable even when exposed to aggressive chemicals. This combination of heat resistance, thermal shock resistance, and chemical stability makes them the top choice for industries that operate at high temperatures and require long-term performance without failure.

Key Differences in Durability and Thermal Shock Resistance

When comparing compact spiral opaque quartz tubes with other materials, the differences in durability and thermal shock resistance are clear. Quartz tubes are designed to withstand both high temperatures and rapid temperature changes, which many other materials cannot endure. This capability makes them ideal for use in industrial furnaces and laboratory equipment, where exposure to extreme conditions is common.

Unlike traditional glass or ceramic tubes, compact spiral opaque quartz tubes maintain their integrity even under thermal shock. Their ability to evenly distribute heat reduces the stress that typically leads to material failure. This ensures that the tubes remain functional over extended periods, minimizing the need for frequent replacements or repairs.

The superior durability of compact spiral opaque quartz tubes contributes to their long lifespan in high-temperature applications. Their resilience to thermal shock and wear makes them a more reliable choice for industries that rely on consistent performance, such as semiconductor manufacturing, aerospace, and high-temperature laboratories.

Conclusion

Compact spiral opaque quartz tubes offer significant advantages in high-temperature applications, combining superior thermal resistance, chemical stability, and space efficiency. These tubes are the optimal solution for industries that require reliable, durable, and customizable high-temperature materials.

Maximize your high-temperature applications with TOQUARTZ's compact spiral opaque quartz tubes. Our expert team, backed by over 20 years of manufacturing experience, offers tailored solutions to meet your exact needs. Contact us today for a consultation and get the right quartz tube for your project.

FAQ (Frequently Asked Questions)

What makes compact spiral opaque quartz tubes better for high-temperature applications compared to traditional quartz tubes?

Compact spiral opaque quartz tubes offer enhanced thermal resistance and durability, making them ideal for extreme temperature environments. Their compact design ensures efficient heat distribution and space utilization, which traditional quartz tubes lack.

How can I determine if a compact spiral opaque quartz tube is suitable for my application?

To determine suitability, consider factors like the maximum temperature the tube needs to withstand, the need for chemical resistance, and the space constraints of your equipment. A customized solution may be the best option for meeting your specific requirements.

What are the typical costs associated with compact spiral opaque quartz tubes?

Costs vary depending on the tube's specifications, size, and customization. Generally, compact spiral opaque quartz tubes offer a cost-effective solution due to their long lifespan and reduced need for frequent replacements.

How do compact spiral opaque quartz tubes compare with other high-temperature materials like ceramics or glass?

Compared to ceramics and glass, compact spiral opaque quartz tubes offer better thermal shock resistance, higher chemical stability, and better overall performance in high-temperature applications. Their compact design also offers space-saving benefits that other materials cannot match.

References:

-

Explore this link to understand CVD processes and their significance in material science. ↩