- Home

- /

- Types

- /

- Quartz Tube

- /

- Capillary Quartz Tubes for...

Capillary Quartz Tubes for Precision Lab & Optical Use -TOQUARTZ®

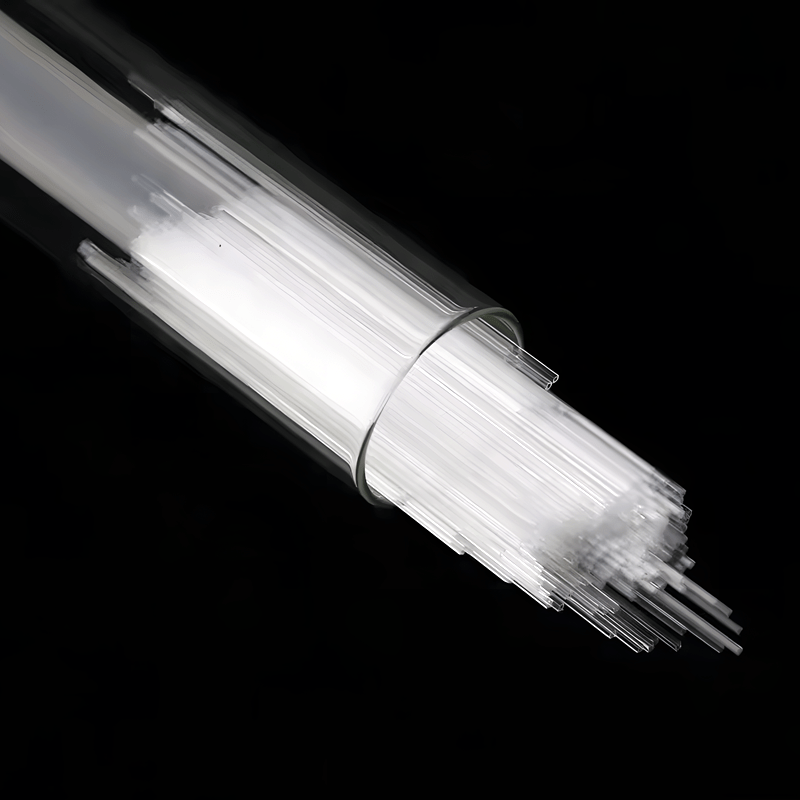

TOQUARTZ® capillary quartz tubes, with >99.98% purity, deliver exceptional dimensional accuracy, excellent UV and IR transparency, and extreme resistance to chemicals and thermal shock, making them ideal for lab analysis, optical fiber systems, chromatography (GC/HPLC), and cleanroom applications.

Features of Capillary Quartz Tubes

TOQUARTZ® capillary quartz tubes are engineered for high-performance environments requiring optical clarity, chemical durability, and reliable electrical insulation, ensuring stable results in analytical, optical, and microfluidic applications under extreme conditions.

Excellent Optical Transparency

- Transmits >90% UV-visible light from 200–1100nm

- Suitable for spectroscopy and fiber optic applications

- Exceptionally low light absorption in microchannel systems

High Chemical Resistance

- Inert to acids, solvents and reactive gases like HF

- Maintains performance in alkaline-exposed lab conditions

- Stable in prolonged plasma or chlorinated environments

Reliable Electrical Insulation

- Dielectric strength exceeds 40kV/mm under dry conditions

- Ideal for high-voltage circuits & ionized experiment setups

- Prevents unwanted current leakage in analytical chambers

- High Optical Transparency

- Superior Chemical Resistance

- Reliable Electrical Insulation

Dimension of Capillary Quartz Tubes

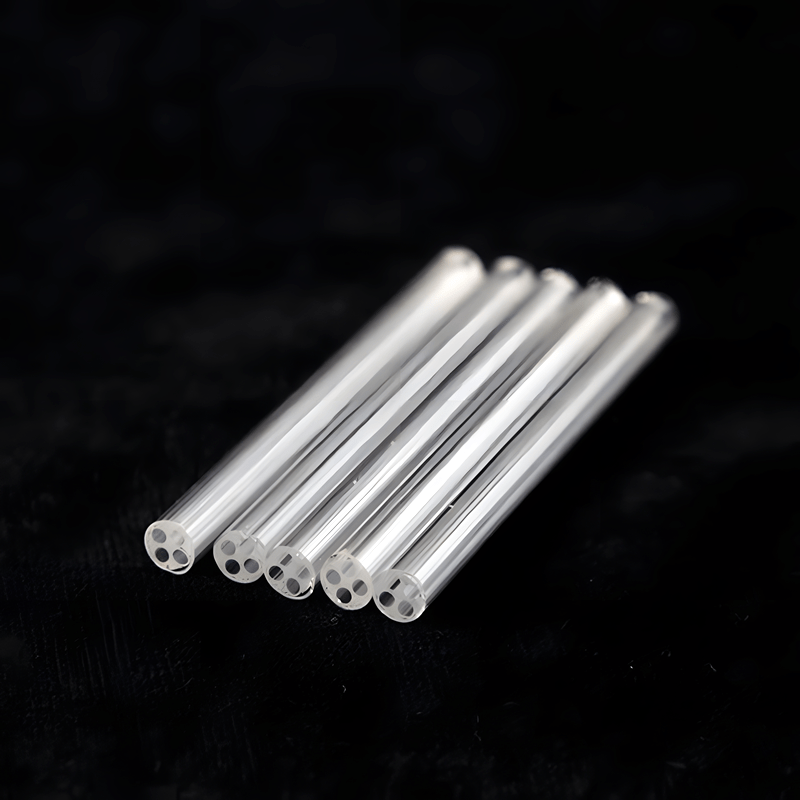

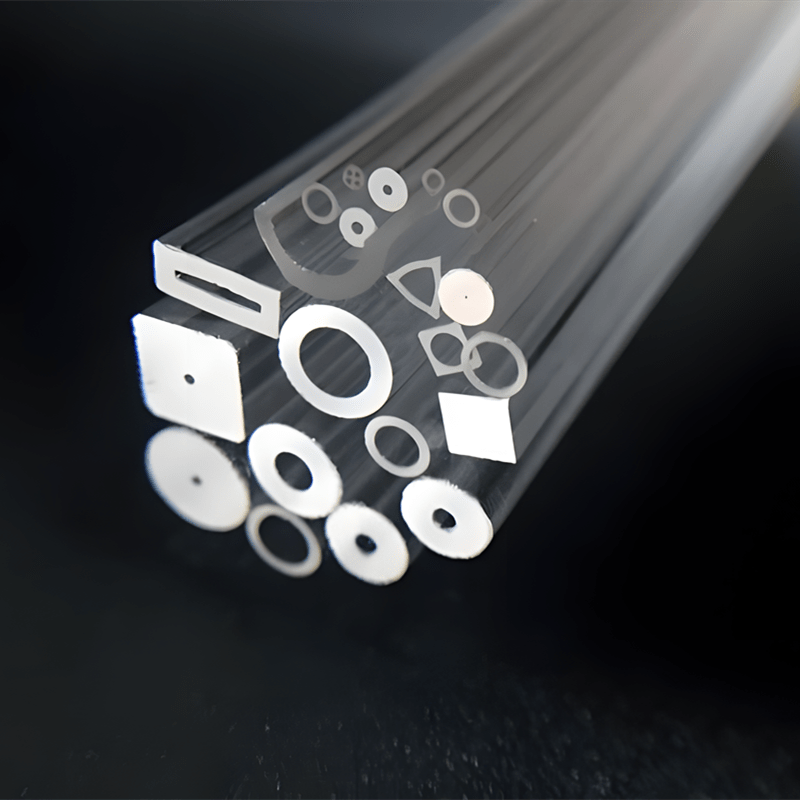

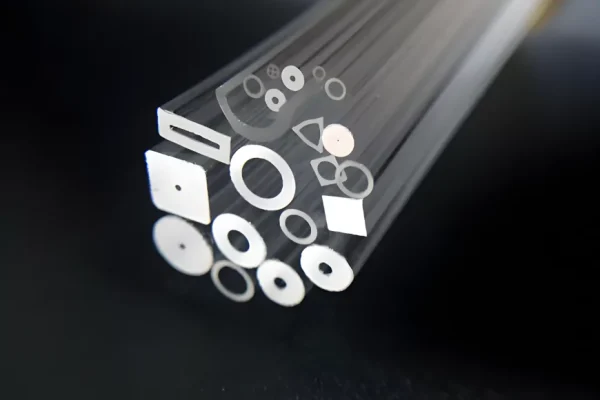

The capillary quartz tubes offer length flexibility from 10–2000 mm and versatile bore configurations including:

multi-bore designs (double/quad/hexagonal/septuple/octuple, twin-row triple), elliptical, rectangular, square, triangular, D-shaped, and eccentric geometries.

| Model | OD (mm) | ID (mm) | Length (mm) | SiO₂ (%) |

| AT-SY-MXG001 | 1 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG002 | 1.35 | 0.05 | 10-2000 | 99.98 |

| AT-SY-MXG003 | 1.35 | 0.3 | 10-2000 | 99.98 |

| AT-SY-MXG004 | 1.35 | 0.38 | 10-2000 | 99.98 |

| AT-SY-MXG005 | 1.35 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG006 | 1.35 | 1 | 10-2000 | 99.98 |

| AT-SY-MXG007 | 1.4 | 0.8 | 10-2000 | 99.98 |

| AT-SY-MXG008 | 1.7 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG009 | 2 | 0.05 | 10-2000 | 99.98 |

| AT-SY-MXG010 | 2 | 0.3 | 10-2000 | 99.98 |

| AT-SY-MXG011 | 2 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG012 | 2 | 0.1 | 10-2000 | 99.98 |

| AT-SY-MXG013 | 2 | 1 | 10-2000 | 99.98 |

| AT-SY-MXG014 | 2.5 | 0.55 | 10-2000 | 99.98 |

| AT-SY-MXG015 | 2.9 | 0.1 | 10-2000 | 99.98 |

| AT-SY-MXG016 | 2.9 | 0.2 | 10-2000 | 99.98 |

| AT-SY-MXG017 | 2.9 | 0.3 | 10-2000 | 99.98 |

| AT-SY-MXG018 | 2.9 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG019 | 2.9 | 0.6 | 10-2000 | 99.98 |

| AT-SY-MXG020 | 3 | 1 | 10-2000 | 99.98 |

| AT-SY-MXG021 | 3 | 2 | 10-2000 | 99.98 |

| AT-SY-MXG022 | 3.2 | 0.45 | 10-2000 | 99.98 |

| AT-SY-MXG023 | 4 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG024 | 4 | 1 | 10-2000 | 99.98 |

| AT-SY-MXG025 | 4 | 2 | 10-2000 | 99.98 |

| AT-SY-MXG026 | 4 | 3 | 10-2000 | 99.98 |

| AT-SY-MXG027 | 4.75 | 0.375 | 10-2000 | 99.98 |

| AT-SY-MXG028 | 5 | 0.4 | 10-2000 | 99.98 |

| AT-SY-MXG029 | 5 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG030 | 5 | 1 | 10-2000 | 99.98 |

| AT-SY-MXG031 | 5 | 4 | 10-2000 | 99.98 |

| AT-SY-MXG032 | 6 | 0.4 | 10-2000 | 99.98 |

| AT-SY-MXG033 | 6 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG034 | 6 | 0.8 | 10-2000 | 99.98 |

| AT-SY-MXG035 | 6 | 1 | 10-2000 | 99.98 |

| AT-SY-MXG036 | 6 | 1.5 | 10-2000 | 99.98 |

| AT-SY-MXG037 | 6 | 2 | 10-2000 | 99.98 |

| AT-SY-MXG038 | 6 | 3 | 10-2000 | 99.98 |

| AT-SY-MXG039 | 6 | 4 | 10-2000 | 99.98 |

| AT-SY-MXG040 | 6 | 5 | 10-2000 | 99.98 |

| AT-SY-MXG041 | 7 | 0.38 | 10-2000 | 99.98 |

| AT-SY-MXG042 | 7 | 0.5 | 10-2000 | 99.98 |

| AT-SY-MXG043 | 7 | 0.6 | 10-2000 | 99.98 |

| AT-SY-MXG044 | 8 | 1 | 10-2000 | 99.98 |

| AT-SY-MXG045 | 8 | 2.4 | 10-2000 | 99.98 |

| AT-SY-MXG046 | 10 | 1 | 10-2000 | 99.98 |

Properties of Capillary Quartz Tubes

Physical Properties:

- High mechanical strength with fracture modulus >350MPa

- Excellent thermal conductivity (120-160 W/m.K)

- Low thermal expansion coefficient (≤5.5×10⁻⁷/K)

- Superior thermal stability up to 1600°C

- Electrical insulation >40kV/mm

Optical Properties

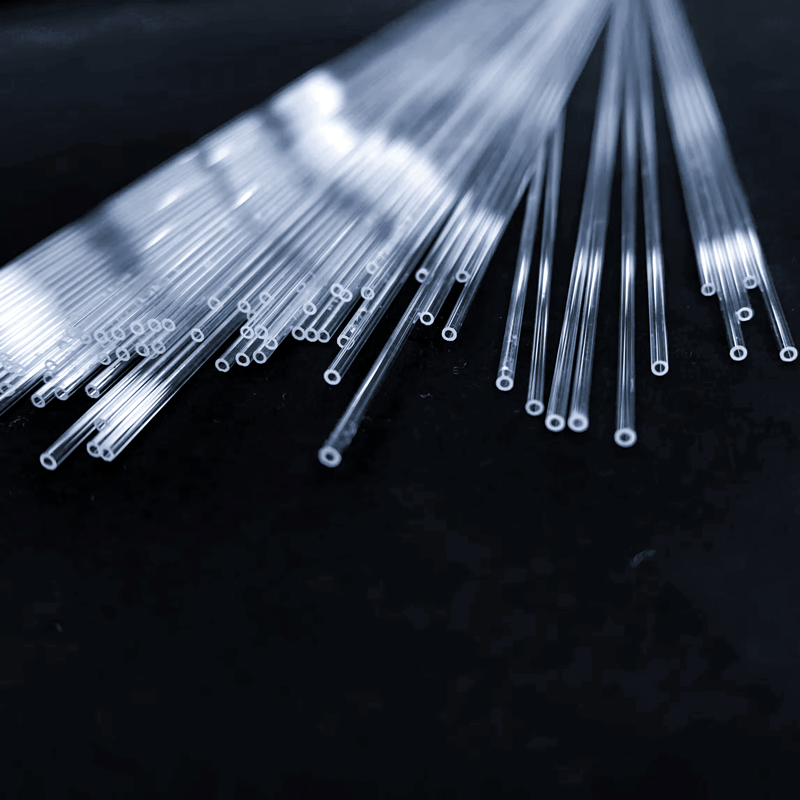

- High optical transparency (>90% in UV/visible spectrum)

- Bubble-free and crack-free surface for optimal light passage

- Consistent refractive index throughout the material

Solving Challenges in Capillary Quartz Tube Applications

Capillary Quartz Tubes for Aanalytical Instruments

Even slight ID fluctuation can lead to turbulent injection or misinterpreted pressure drops over time.

Key Advantages

- ±0.03mm ID tolerance ensures laminar flow stability

- Micro-bore precision maintains pressure-flow accuracy

- Sub-mm uniformity prevents false pressure drops compromising accuracy

TOQUARTZ® solution

Traditional fused quartz tubes often failed to stabilize flow control below ±0.1mm.

TOQUARTZ engineered a concentricity-controlled pulling & inspection protocol to deliver capillaries with precise ID parity between units, ensuring signal clarity and system repeatability.

Contaminant-Free Capillary Quartz Tubes for Photonic Devices

Internal wall quality and spectral transparency directly influence signal power, beam width, and alignment stability.

Key Advantages

- Sub-micron wall smoothness preserving beam coherence in transmission

- Precise cylindrical geometry maintaining consistent beam focus

- Controlled inner diameter optimizing light coupling efficiency

TOQUARTZ® solution

Many supply chain tubes introduced scattering due to polishing artefacts or incomplete surface treatments.

TOQUARTZ deployed proprietary cleanroom-level surface refinement and spectrum validation to guarantee minimal optical loss during signal-bearing transmission.

Capillary Quartz Tubes for Variable-Pressure Setups

In plasma-based microreactors, ionization instruments, and tunable laser cavity systems, capillary quartz tubes serve as microchamber walls subjected to high-frequency electric fields.

These fields require consistent dielectric performance, wall thickness control, and immunity from structural charging or breakdown — a challenge that disqualifies ceramic and polymer substitutes.

Key Advantages

- Uniform wall thickness preventing localized field concentration points

- Consistent dielectric constant across high-frequency operation ranges

- Predictable breakdown voltage thresholds in microreactor environments

TOQUARTZ® solution

Conventional quartz tubes lacked sufficient insulation over long microchannels in variable-pressure setups.

TOQUARTZ implemented geometry + dielectric optimization to avoid dielectric breakdown, enabling 200+ successful deployments in plasma R&D and laser-modulated chambers.

Customization Services for

TOQUARTZ® Capillary Quartz Tubes

- Custom Dimensions

- End Modifications

- Multi-Bore Options

- Design consultation to optimize capillary tubes for your application

- Material selection guidance based on your specific requirements

- Prototype development and testing support

- Precision dimensional verification using advanced measurement equipment

- Visual inspection for defects, bubbles, or inclusions

- Material composition verification for high-purity applications

- Detailed quality reports provided with each order

- Custom Design Process

Requirement Analysis

We begin by thoroughly understanding your application requirements, including dimensions, material specifications, and performance criteria.

Design & Engineering

Our engineers develop a detailed design specification, including technical drawings and material requirements.

Prototype Development

We produce sample tubes for your evaluation and testing, with rapid turnaround times for urgent projects.

Production & Quality Control

Following approval, we manufacture your custom capillary quartz tubes with rigorous quality control at every step.

Product Usage Guidelines of Capillary Quartz Tubes

Handling Precautions

Handle with care to prevent breakage

- Handle capillary tubes gently to avoid impacts or drops that could cause breakage

- Use fine-tipped tweezers or gloves when handling to prevent contamination

- Store in protective containers to prevent physical damage

- Avoid applying excessive force when connecting to fittings

Temperature Considerations

Respect thermal limits and transitions

- Do not exceed the maximum operating temperature (1600°C) to prevent softening or deformation

- Allow gradual heating and cooling to prevent thermal shock

- For high-temperature applications, ensure tubes are clean and free of contaminants

- Use fine-thread gloves when handling tubes for high-temperature applications

Chemical Compatibility

Avoid incompatible materials

- Quartz is acidic; avoid contact with alkaline substances (sodium silicate, potassium compounds) at high temperatures

- Avoid contact with asbestos or other alkaline materials that can degrade performance

- While resistant to most chemicals, prolonged exposure to hydrofluoric acid should be avoided

- Clean with appropriate solvents that won't leave residues

Cleaning & Maintenance

Proper cleaning for optimal performance

- Clean with appropriate analytical-grade solvents followed by deionized water

- For stubborn contaminants, use dilute acid solutions (except HF)

- Dry thoroughly with filtered air or nitrogen before use

- Inspect regularly for cracks or damage before critical applications

Need Help with Customization Services for Capillary Quartz Tubes?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the difference between capillary quartz tubes and regular quartz tubes?

A: Capillary quartz tubes have significantly smaller inner diameters (typically 0.1mm to 4mm) compared to regular quartz tubes. They are designed for applications requiring precise fluid control, microfluidics, or specialized optical properties. Their manufacturing process also emphasizes tighter dimensional tolerances and higher surface quality.

Q: What is the purity level of the quartz material used in TOQUARTZ® capillary tubes?

A: Our standard capillary quartz tubes are manufactured from high-purity fused silica with ≥99.98% SiO₂ content. This high purity level ensures excellent optical properties, superior chemical resistance, and reliable performance in demanding applications. For specialized applications requiring even higher purity, we can provide material up to 99.995% SiO₂.

Q: What is the maximum temperature that capillary quartz tubes can withstand?

A: TOQUARTZ® capillary quartz tubes can withstand temperatures up to 1600°C, significantly exceeding the typical industry requirement of 1100°C for continuous operation. This exceptional thermal stability makes them ideal for high-temperature analytical applications, laboratory equipment, and specialized industrial processes.

Q: Are your capillary quartz tubes resistant to chemicals?

A: Yes, TOQUARTZ® capillary quartz tubes offer exceptional chemical resistance to most acids, bases, solvents, and corrosive substances. They are inert to virtually all chemicals except hydrofluoric acid (HF) and hot phosphoric acid. This chemical stability makes them ideal for analytical chemistry, sample handling, and other applications involving aggressive chemicals.

Q: Can you produce capillary quartz tubes with special end treatments?

A: Yes, we offer various end treatments for capillary quartz tubes including fire-polished ends, flared ends, ground ends, and custom connections. These specialized end treatments facilitate integration with your equipment and ensure secure, leak-free connections. Our engineering team can work with you to develop custom end configurations for your specific application.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.