- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Flow-Through Cuvette

- /

- Advanced Optical Path Quartz...

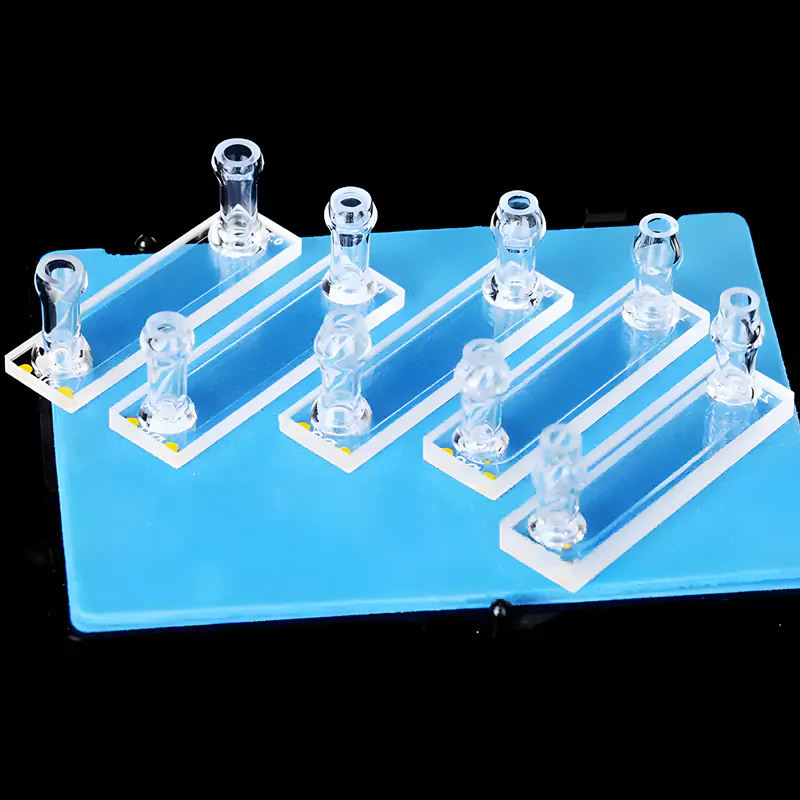

Advanced Optical Path Quartz Flow Cell with Inlet and Outlet Tubings for Spectroscopy Applications-TOQUARTZ®

Features of Quartz Flow Cell with Inlet and Outlet Tubings

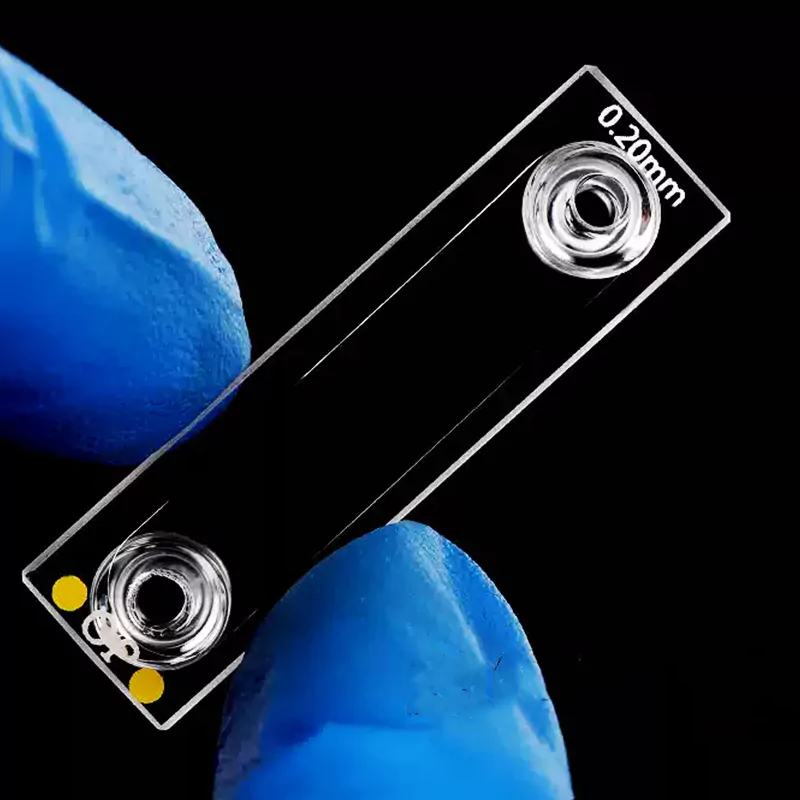

TOQUARTZ® Quartz Flow Cell with Inlet and Outlet Tubing is engineered to combine precise optical performance with reliable fluidic handling, ensuring consistent results in laboratory, industrial, and research applications. Its design integrates fused quartz tubing with high transmission range and dimensional stability, supported by measurable data.

Strong Mechanical and Thermal Stability

- Fracture strength: ≥ 350 MPa measured in three-point bending tests

- Thermal conductivity: 120–160 W/m·K for effective heat management

- Maximum service temperature: ≥ 1100 °C under continuous operation

High Optical Transmission

- Transmission range: 190–2500 nm for UV-Vis and fluorescence systems

- Absorbance deviation: ≤ 0.3% across standard path lengths

- Path length tolerance: ±0.05 mm for reproducible measurements

Chemical Resistance and Fluid Compatibility

- SiO₂ purity: 99.98–99.995% ensuring inert chemical behavior

- Stable against acids, bases, molten salts, and fluorinated gases

- Connector integrity: leak-free operation confirmed at 0.5 MPa flow pressure

- SiO2 Purity ≥99.98%, up to 99.995%

- Chemical Resistance to Harsh Reagents

- Customization Services Available

Technical Specifications & Dimensions of Quartz Flow Cell with Inlet and Outlet Tubings

Technical Specifications

| Property | Specification |

| Physical Properties | Density 2.2g/cm^3; Thermal conductivity 120–160W/m·K; Thermal expansion ≤0.55×10^-6/K; Max service temperature ≥1100°C; Softening point ~1665°C |

| Chemical Properties | SiO2 purity 99.98–99.995%; Acid/base resistance; Stable to molten salts; Resistant to fluorinated gases; Non-reactive with water vapor |

| Optical Properties | Transmission range 190–2500nm; No UV absorption peaks; Refractive index 1.46 at 589nm; Absorbance deviation ≤0.3%; Optical homogeneity >99% |

| Mechanical Properties | Fracture strength ≥350MPa; Elastic modulus 72GPa; Poisson’s ratio 0.17; Hardness 570KHN; Wear resistance suitable for high-flow rates |

| Electrical Properties | Dielectric strength 250–400 kV/cm; Volume resistivity 10^18 Ω·cm; Low dielectric loss 0.0001 at 1 MHz; Permittivity 3.8; High insulation stability |

Size Chart

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8017-1 | 30μl Quartz Flow Cell with Inlet and Outlet Tubing | 0.1mm | 30μl | 12.5*2.6*45mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8017-2 | 60μl Quartz Flow Cell with Inlet and Outlet Tubing | 0.2mm | 60μl | 12.5*2.7*45mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8017-3 | 90μl Quartz Flow Cell with Inlet and Outlet Tubing | 0.3mm | 90μl | 12.5*2.8*45mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8017 | 150μl Quartz Flow Cell with Inlet and Outlet Tubing | 0.5mm | 150μl | 12.5*3*45mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8017-4 | 300μl Quartz Flow Cell with Inlet and Outlet Tubing | 1mm | 300μl | 12.5*3.5*45mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8017-5 | 600μl Quartz Flow Cell with Inlet and Outlet Tubing | 2mm | 600μl | 12.5*4.5*45mm |

TOQUARTZ® Solving Challenges in Spectroscopic Analysis with Quartz Flow Cell with Inlet and Outlet Tubings

Quartz Flow Cell with Inlet and Outlet Tubing in UV-Vis Laboratory Analysis

Key Advantages

-

Tight Path Tolerance

— Path length controlled within ±0.1 mm ensures stable absorbance reproducibility. -

UV Transparency to 190 nm

— No absorption below 220 nm, supporting nucleic acid and protein assays. -

Leak-Free Fused Ports

— Dual-tube connectors fused at >1000 °C eliminate contamination risk from adhesives.

TOQUARTZ® solution

A European research lab reported 12% variation in absorbance values when using standard glass flow cells at 200 nm due to path drift. After switching to TOQUARTZ® Quartz Flow Cell with Inlet and Outlet Tubing, path consistency improved to within ±0.05 mm and baseline drift was eliminated. The lab achieved reproducible results across more than 500 consecutive samples, reducing retest rates and improving efficiency by 18%.

Quartz Flow Cell with Inlet and Outlet Tubing in HPLC Systems

Key Advantages

-

Low Dead Volume Design

— Internal volume as low as 30 μl reduces band broadening in HPLC peaks. -

Quartz Connector Integrity

— Withstands solvent exposure at flow pressures up to 0.5 MPa without deformation. -

Precision Optical Channe

l — Path alignment maintained within ±0.05 mm supports consistent detector response.

TOQUARTZ® solution

An HPLC manufacturer in the US reported leakage from plastic flow cells that forced instrument shutdowns twice monthly, each causing 2–3 days of lost operation. After adopting TOQUARTZ® Quartz Flow Cell with Inlet and Outlet Tubing, leak incidents dropped to zero and path stability improved detection reproducibility by 15%. The upgrade allowed their customers to extend maintenance intervals and improve instrument uptime, directly lowering operational costs.

Quartz Flow Cell with Inlet and Outlet Tubing in Industrial Monitoring

Key Advantages

-

Corrosion-Proof Quartz Body

— Stable in acidic and basic media with SiO₂ purity ≥99.98%. -

Thermal Endurance ≥1100 °C

— Maintains structural integrity under frequent heating cycles. -

Pressure-Tight Dual Ports

— Leak-free at continuous pressures up to 0.5 MPa for industrial flow conditions.

TOQUARTZ® solution

A chemical plant in Japan reported production losses of USD 25,000 during a five-day downtime caused by corroded polymer-based flow cells. After implementing TOQUARTZ® Quartz Flow Cell with Inlet and Outlet Tubing, replacements were stocked and dispatched within 24 hours. The quartz design demonstrated full resistance to solvent exposure and withstood repeated temperature cycling without leakage. This change reduced unexpected downtime events to less than once per year, significantly lowering production risk.

Customization Solutions for Your Specific Applications

Path Length Customization

Different applications demand varied optical paths for precise absorbance and fluorescence results.

-

Tolerance Control

— Path consistency aligned with required optical precision. -

Measurement Stability

— Accurate absorbance maintained across repeated cycles. -

Application Fit

— Optical path adjusted to match experimental needs.

Connector Adaptation

Fluidic systems often require specialized connectors to ensure compatibility and stability.

-

Diameter Options

— Adjusted to integrate with customer tubing systems. -

Material Choices

— Connector types selected for solvent compatibility. -

Leak Prevention

— Fused sealing avoids mechanical failures under flow.

Optical Surface Treatment

Enhanced optical surfaces improve sensitivity and consistency in demanding environments.

-

Polishing Finish

— Precision finish reduces stray light interference. -

Surface Clarity

— Optimized windows improve UV-Vis transmission levels. -

Durability Boost

— Surface treatment enhances long-term performance reliability.

Product Usage Guideline

Operating Instructions

- Connect inlet and outlet tubing securely to avoid leaks at pressures up to 0.5 MPa.

- Ensure sample flow rate is consistent with the recommended volume of 30–600 μl.

- Avoid sudden thermal shock when moving between room temperature and heated operation.

- Check optical alignment before starting UV-Vis or fluorescence measurements.

Cleaning and Maintenance

- Rinse the flow cell with deionized water immediately after each use to prevent residue buildup.

- For chemical solvents, flush with compatible neutral detergent at ≤50 °C, followed by DI water.

- Avoid abrasive brushes or tools that may scratch the fused quartz surface.

- Dry the cell using filtered air or store upright to prevent residual liquid pooling.

Storage Recommendations

- Store Quartz Flow Cell with Inlet and Outlet Tubing in a clean, dust-free container after drying.

- Maintain ambient storage temperature between 15–35 °C with stable humidity.

- Protect fused tubing connectors from physical impact by using foam-lined cases.

- Keep away from corrosive vapors to ensure long-term chemical stability.

Troubleshooting Guidelines

- If absorbance readings fluctuate, check for residue inside the optical path and repeat cleaning.

- If leakage occurs, inspect tubing connections and verify correct diameter compatibility.

- If bubbles appear during flow, degas the solvent or adjust sample loading rate.

- If transmission declines, confirm that the cell has not been exposed to thermal or chemical damage.

Quartz Flow Cell with Inlet and Outlet Tubing – Get Expert Support Today

Contact us to discuss your project requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: Why are fused dual-tube connectors important in Quartz Flow Cell with Inlet and Outlet Tubing?

A: Fused dual-tube connectors provide a seamless fluid path without adhesives or joints that could fail under pressure. They support leak-free operation up to 0.5 MPa, making them reliable for both laboratory and industrial flow systems. The design also simplifies cleaning and reduces contamination risk.

Q: How is contamination prevented in Quartz Flow Cell with Inlet and Outlet Tubing?

A: The flow cell is engineered to maintain performance under continuous service up to ≥1100 °C. This allows use in applications where thermal cycling is frequent. Its quartz body prevents deformation or cracks under rapid heating and cooling.

Q: Can the Quartz Flow Cell Counting Cuvette withstand chemical reagents used in hematology and biochemistry testing?

A: Fused connectors eliminate the need for adhesives or joints where residues often accumulate. The smooth quartz interior reduces surface retention of particles. When properly cleaned with DI water and mild detergents, contamination risks are minimal.

Q: Can Quartz Flow Cell with Inlet and Outlet Tubing integrate with HPLC systems?

A: Yes, it is commonly integrated into HPLC detectors due to its low dead volume and chemical resistance. The fused tubing connectors are compatible with silicone and PTFE lines. This ensures stable operation without leakage under typical chromatography pressures.

Q: How does Quartz Flow Cell with Inlet and Outlet Tubing reduce downtime in industrial monitoring?e Quartz Flow Cell Counting Cuvette support fluorescence detection?

A: Its corrosion-proof quartz body withstands aggressive solvents and high flow rates without degradation. Because it resists wear and leakage, replacements are less frequent. Industrial plants benefit from fewer interruptions and reduced operational costs.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.