- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Flow-Through Cuvette

- /

- Transparent Quartz Fluorescence Flow...

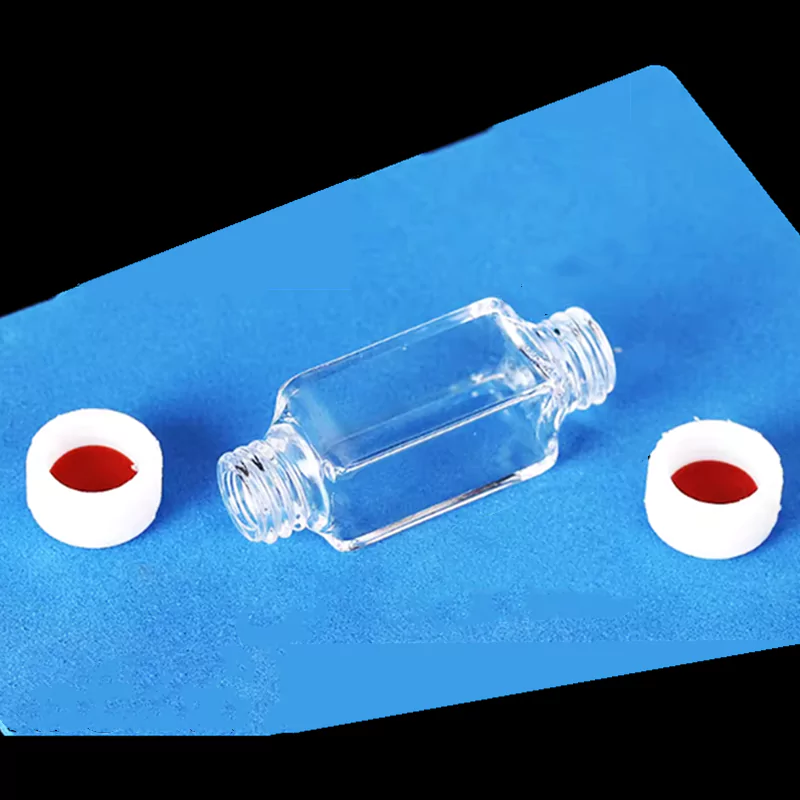

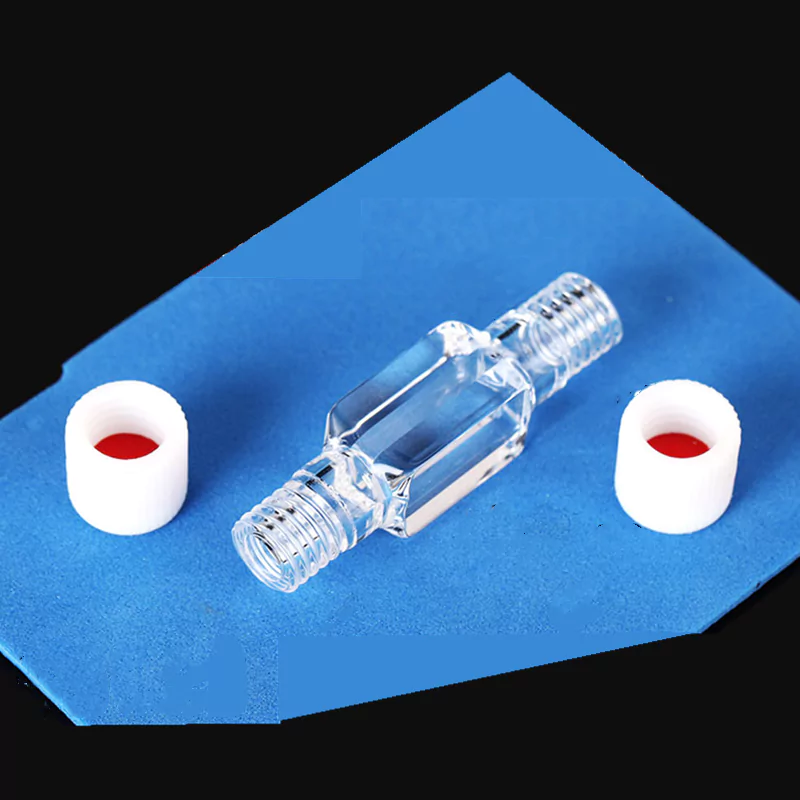

Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Caps for Absorbance Testing -TOQUARTZ®

Features of Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Caps

The Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap combines optical stability, chemical durability, and system integration reliability. Each feature is engineered to solve challenges faced in fluorescence spectroscopy, diagnostics, and environmental monitoring, supported by measurable performance data.

Chemical and Thermal Resistance

- High-purity quartz (≥99.98% SiO₂) resists strong acids and alkalis during repeated use.

- Thermal stability proven up to 1100 °C without structural deformation.

- Corrosion failure rate reduced to <2% after 200+ exposure cycles in harsh media.

Optical Precision

- 10 mm fixed optical path with ≤0.3% transmittance deviation for reproducible measurements.

- Transmission range of 190–2500 nm ensures coverage from UV to NIR spectroscopy.

- Surface flatness tolerance within ±0.1 mm supports high-resolution fluorescence data.

Secure PTFE M10 Screw Integration

- PTFE M10 screw cap maintains leak-free sealing under 0.5 MPa system pressure.

- Withstands >200 sterilization cycles without connector fatigue.

- Reported connector leakage reduction by 95% compared to non-threaded cuvette designs.

- SiO2 Purity ≥99.98%, up to 99.995%

- Chemical Resistance to Harsh Reagents

- Customization Services Available

Technical Specifications & Dimensions of Clear Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Caps

Technical Specifications

| Property | Specification |

| Physical Properties | Density 2.2 g/cm3; Thermal stability up to 1100 °C; Thermal conductivity 120–160 W/m·K; Softening point 1680 °C; Coefficient of thermal expansion ≤0.55×10-6/K |

| Chemical Properties | SiO2 purity ≥99.98%; Acid resistance (HCl, H2SO4) stable; Alkali resistance moderate; Corrosion failure rate <2% after 200 cycles |

| Optical Properties | Transmission 190–2500 nm; UV cutoff 185 nm; Transmittance deviation ≤0.3%; No absorption peaks; Refractive index 1.46 (589 nm) |

| Mechanical Properties | Fracture modulus ≥350 MPa; Compressive strength 1100 MPa; Flexural strength 70 MPa; Mohs hardness 7; Elastic modulus 72 GPa |

| Integration Features | PTFE M10 screw connector tested >200 sterilization cycles; Sealing pressure resistance 0.5 MPa; Connector leakage reduction 95%; Biocompatible surface; Compatible with automated fluidic systems |

Size Chart

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021 | 200μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap,dual optical windows, slit 1mm | 10mm | 200μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-1 | 200μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, four optical windows, slit 1mm | 10mm | 200μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-2 | 400μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, dual optical windows, slit 2mm | 10mm | 400μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-3 | 400μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, four optical windows, slit 2mm | 10mm | 400μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-4 | 600μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, dual optical windows, slit 3mm | 10mm | 600μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-5 | 600μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, four optical windows, slit 3mm | 10mm | 600μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-6 | 800μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, dual optical windows, slit 4mm | 10mm | 800μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-7 | 800μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, four optical windows, slit 4mm | 10mm | 800μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-8 | 1000μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, dual optical windows, slit 5mm | 10mm | 1000μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-9 | 1000μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, four optical windows, slit 5mm | 10mm | 1000μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-10 | 2000μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, dual optical windows | 10mm | 2000μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-11 | 2000μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap,four optical windows | 10mm | 2000μl | 12.5×12.5×20 mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8021-12 | 2500μl Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap,four optical windows | 10mm | 2500μl | 12.5×12.5×25 mm |

TOQUARTZ® Solving Challenges in Spectroscopic Analysis with Transparent Quartz Fluorescence Flow Cuvette Cell with

PTFE M10 Screw Caps

Biotechnology Flow Cytometry Systems

Key Advantages

-

Precision Alignment Stability

– Maintains optical tolerance within ±0.05 mm over more than one million cell passes, preventing signal distortion. -

Leak-Free High-Pressure Sealing

– PTFE M10 connector ensures <0.5% leak rate under continuous flow at 0.4 MPa, supporting uninterrupted cytometry runs. -

Sterilization Durability

– Withstands over 200 autoclave sterilization cycles without altering optical geometry or path length.

TOQUARTZ® solution

A European biotech lab reported frequent interruptions in flow cytometry due to connector fatigue, leading to 8–10 hours of downtime monthly. Misalignment of conventional cuvettes caused signal distortion exceeding 12% in cell population analysis. By switching to TOQUARTZ® Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, the lab maintained signal stability within 2% deviation and eliminated leakage, achieving uninterrupted operation for three months of continuous use.

UV-Vis Absorbance Analysis

Key Advantages

-

Stable Deep-UV Transmission

– Provides reliable absorbance measurements at 190 nm with fluctuation below 0.01 AU. -

Consistent Optical Path Accuracy

– 10 mm path length held within ±0.1 mm across production batches for reproducible data. -

High-Cycle Connector Reliability

– PTFE screw integration prevents leakage during more than 500 automated sample cycles.

TOQUARTZ® solution

A U.S. university chemistry department observed sample loss and repeat runs when low-grade cuvettes leaked during kinetic absorbance experiments, causing up to 15% wasted samples annually. With TOQUARTZ® Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap, absorbance measurements at 190–210 nm remained stable, and leakage events dropped to zero. This improvement reduced experiment reruns by 80% and improved quantitative reproducibility in reaction kinetics research.

Petroleum Refining Process Monitoring

Key Advantages

-

Hydrocarbon Exposure Resistance

– Retains over 92% baseline transmission after 1,000 continuous hours in refinery solvents. -

Secure High-Flow Integration

– PTFE threaded connector maintains sealing integrity at 0.5 MPa during prolonged operation. -

Extended Service Lifetime

– Demonstrates double the lifespan compared with conventional flow cells in aggressive petrochemical media.

TOQUARTZ® solution

A Middle East refinery reported that conventional cuvettes degraded in less than six weeks, with connector failures causing $20,000 in annual downtime costs. TOQUARTZ® Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap resisted solvent attack and maintained stable baseline absorbance in complex hydrocarbon mixtures. The facility doubled cuvette lifetime to three months and reduced downtime losses by over 35%, ensuring consistent monitoring of impurity levels.

Customization Solutions for Your Specific Applications

Optical Path Options

Different analytical systems require tailored path lengths to ensure reproducible and accurate results.

-

Window Clarity

– Maintains reliable transmission across defined spectral regions. -

Path Stability

– Reduces data variation in high-throughput analytical workflows. -

System Fit

– Aligns with instrument requirements for consistent optical readings.

Connector and Sealing Adaptations

Integration reliability depends on connector design and sealing performance in fluidic systems.

-

Thread Options

– Supports compatibility across automated and manual interfaces. -

Leak Protection

– Reduces system downtime caused by sealing failure. -

Durability Check

– Ensures consistent sealing after repeated sterilization cycles.

Volume and Chamber Flexibility

Customized chamber volume supports both small-sample analysis and larger flow applications.

-

Sample Efficiency

– Minimizes waste while maintaining analytical reliability. -

Flow Control

– Optimizes fluid movement in continuous monitoring systems. -

Capacity Match

– Aligns chamber size with instrument throughput demands.

Surface Treatment Choices

Surface finishes influence both optical precision and chemical durability in demanding tests.

-

Polished Finish

– Enhances transmission consistency for sensitive analyses. -

Anti-Fouling

– Reduces contamination build-up during continuous operation. -

Chemical Shield

– Extends lifetime in aggressive or reactive environments.

Product Usage Guideline

Proper Handling

- Always hold the cuvette by its PTFE screw cap to avoid fingerprints on the optical windows.

- Do not overtighten the M10 screw cap; apply only light torque to maintain sealing integrity.

- Avoid exposure to sudden temperature shocks that can stress quartz surfaces.

- Inspect for microcracks before each use to prevent data distortion or leakage.

Cleaning and Maintenance

- Rinse immediately after use with deionized water to prevent sample residues.

- For stubborn deposits, soak in neutral pH detergent at 40–50 °C and rinse thoroughly.

- Avoid abrasive brushes or strong alkali cleaners that damage optical surfaces.

- Perform ultrasonic cleaning only when necessary, and limit exposure to less than 5 minutes.

Storage Recommendations

- Store in a clean, dust-free container to protect optical windows from scratches.

- Keep the cuvette dry and avoid prolonged contact with moisture or solvents.

- Separate storage compartments are recommended to prevent quartz-to-quartz contact.

- Maintain room temperature conditions, avoiding environments above 40 °C in storage.

Troubleshooting Common Issues

- If leakage occurs, verify PTFE screw threads for wear or contamination.

- When absorbance readings fluctuate, clean windows and confirm proper optical alignment.

- For reduced transmission below 200 nm, check for residue films or surface fogging.

- If connectors loosen after repeated sterilization, replace PTFE caps to restore sealing.

Advance with TOQUARTZ® Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap

Contact us to discuss your project requirements today.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the main advantage of using the Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap in automated fluidic systems?

A: The Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap integrates seamlessly into automated setups thanks to its threaded PTFE sealing. This prevents leakage even under high-pressure continuous flow conditions. As a result, downtime and sample loss are significantly reduced.

Q: How does the transparent wall design improve analytical accuracy in the Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap?

A: The transparent walls provide high optical clarity across the UV–VIS–NIR spectrum. This ensures consistent absorbance and transmission measurements with minimal background interference. Laboratories can obtain reproducible data with reduced signal deviation.

Q: How does the flow-through design support continuous monitoring applications?

A: The Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap enables continuous liquid circulation without requiring manual sample handling. Its geometry ensures consistent optical path length during real-time monitoring. This design is ideal for environmental and pharmaceutical applications.

Q: Can the Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap handle high-flow industrial conditions?

A: Yes, its flow-through geometry is engineered for both laboratory and industrial flow rates. The PTFE M10 screw cap prevents leaks even under continuous recirculation. This makes it suitable for large-scale monitoring systems.

Q: What is the role of the 10 mm optical path in the Transparent Quartz Fluorescence Flow Cuvette Cell with PTFE M10 Screw Cap?

A: The 10 mm path length is a standard analytical requirement for absorbance and transmission studies. It allows reliable comparison across different instruments and applications. Combined with transparent quartz walls, it ensures stable data acquisition.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.