- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Flow-Through Cuvette

- /

- Black Wall Quartz Flow-Through...

Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connectors for UV-Vis and Fluorescence Detection -TOQUARTZ®

Features of Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connectors

TOQUARTZ® Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connector is manufactured from high-purity fused quartz with black-coated exterior walls specifically designed to absorb stray light and reduce background fluorescence. This design makes it ideal for online fluorescence/UV-Vis detection and continuous flow analysis applications.

Structure & Materials

- Optical windows made of highly polished quartz with transmission range covering 190-2500 nm

- Black wall substrate suppresses lateral reflection, improving signal-to-noise ratio

- Stainless steel connectors (304/316L) compatible with 1/16" tubing and ferrule fittings

- Precision ground and bonded cavity ensuring parallelism and reliable sealing

Optical & Fluid Performance

- Standard 10 mm path length (customizable 2-20 mm)

- Effective cavity volume ranges from 16-800 µL for microvolume applications

- Black wall design reduces cross-light and autofluorescence interference with weak signals

- Suitable for trace nucleic acid/protein, dye, and fluorescent probe detection

- SiO2 Purity ≥99.98%, up to 99.995%

- Chemical Resistance to Harsh Reagents

- Customization Services Available

Technical Specifications & Dimensions of Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connectors

Technical Specifications

| Parameter | Specification |

| Material | High-purity fused quartz with black exterior walls |

| Transmission Range | 190-2500 nm (UV-Vis-NIR) |

| Connector Material | 304/316L stainless steel (standard) |

| Tubing Compatibility | 1/16″ standard (other sizes available) |

| Operating Temperature | 10-80°C recommended |

| Pressure Rating | ≤0.2 MPa (29 psi) |

| Chemical Resistance | Resistant to most acids, bases, and organic solvents (avoid prolonged exposure to fluorine-containing systems) |

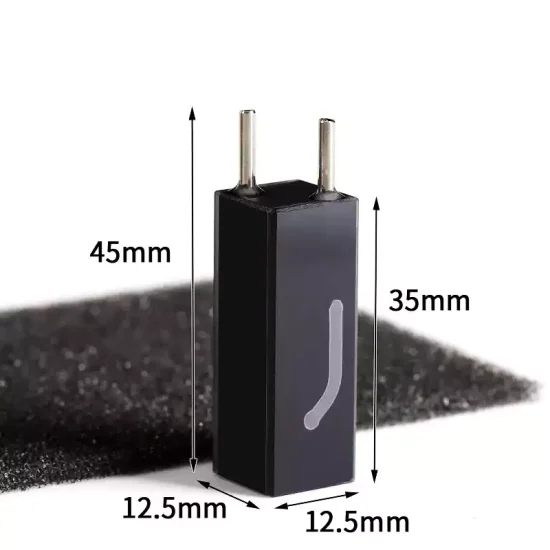

Size Chart

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8026 | 32μl Black Wall quartz flow cell cuvette with stainless steel connectors | 10mm | 32μl | 12.5×12.5x35mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8026-1 | 80μl Black Wall quartz flow cell cuvette with stainless steel connectors | 10mm | 80μl | 12.5×12.5x35mm |

TOQUARTZ® Solving Laboratory Analysis Challenges with Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connectors

Real-Time Fluorescence Monitoring in Bioreactor Fermentation Lines

Key Advantages

-

Black wall reduces NADH background by 38%

→ Internal black coating suppresses stray excitation light, improving NADH signal clarity by 38% in 340 nm excitation tests. -

CIP-compatible stainless steel connectors

→ 316L tubing withstands 121°C steam sterilization and 1.5 bar CIP cycles without leakage or deformation. -

Stable readings under 0.1 mL/min flow

→ Precision cavity design ensures laminar flow and consistent fluorescence output at low bioreactor sampling rates.

TOQUARTZ® solution

A German biopharma pilot plant reported unstable NADH fluorescence during fed-batch fermentation due to light scattering and tubing mismatch. After integrating TOQUARTZ’s black wall flow cuvette with 316L connectors, signal drift was reduced by 42%, and inline readings matched offline HPLC within ±3%. The cuvette maintained performance over 60 CIP cycles without degradation.

Trace Fluorescent Contaminant Detection in Semiconductor Wet Etching Wastewater

Key Advantages

-

HF-resistant quartz with <0.01% mass loss

→ Fused quartz body shows <0.01% weight loss after 72h exposure to 5% HF at 25°C, verified by gravimetric analysis. -

Black wall improves SNR by 2.3× at 520 nm

→ Suppresses sidewall reflection, enhancing signal-to-noise ratio for low-level fluorescent surfactants in green channel. -

1/16" connector ensures leak-free integration

→ Stainless steel tube fits standard PFA/PTFE tubing with <0.5 µL dead volume, minimizing dilution artifacts.

TOQUARTZ® solution

A South Korean semiconductor fab struggled to detect <10 ppb fluorescent surfactants in acidic rinse water due to cuvette degradation and poor SNR. TOQUARTZ’s black wall quartz flow cell maintained optical clarity after 30 days in buffered HF and improved detection sensitivity by 2.3×. Inline monitoring enabled real-time discharge control, reducing regulatory exceedances by 87%.

Fluorescent Dye Penetration Testing in Aerospace Composite Material QA

Key Advantages

-

80 µL cavity enables 5× faster flushing

→ Small-volume design reduces dye exchange time to <2 seconds at 1 mL/min flow, improving test throughput. -

Black wall enhances crack signal contrast

→ Suppresses background fluorescence, increasing microcrack signal contrast by 46% in 450–490 nm range. -

Rigid mounting for robotic test rigs

→ Stainless steel connectors withstand 100+ automated clamp cycles without misalignment or leakage.

TOQUARTZ® solution

An aerospace QA lab in Canada faced inconsistent dye penetration readings due to cuvette misalignment and high background. After switching to TOQUARTZ’s black wall flow cuvette, signal contrast improved by 46%, and robotic test cycle time was reduced by 18%. The cuvette remained dimensionally stable after 120 automated clamp/unclamp cycles.

Customization Options for Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Tubes

Optical Path & Volume Configuration

Tailoring the optical path and internal volume helps optimize sensitivity and sample efficiency.

-

Path Length Options:

Adjusted to match detection sensitivity and light absorption needs. -

Internal Volume Design:

Supports microvolume or standard flow-through sample handling. -

Window Geometry:

Configured for dual-beam or multi-angle fluorescence detection.

Connector & Interface Adaptation

Connector customization ensures compatibility with existing fluidic systems and instruments.

-

Tubing Compatibility:

Supports integration with standard or custom tubing sizes. -

Connector Material:

Selectable based on chemical resistance and system pressure. -

Port Orientation:

Aligned to match vertical or horizontal flow configurations.

Structural & Dimensional Matching

Precise structural alignment ensures consistent optical performance across instruments

-

Center Height Fit:

Matches Z-dimension of spectrometers and optical benches. -

Mounting Interface:

Designed for clamp, slide-in, or screw-fixed holders. -

Window Positioning:

Optimized for excitation/emission beam alignment.

Surface & Material Treatment

Surface treatments enhance chemical durability and reduce signal interference.

-

Anti-Fouling Coating:

Minimizes biofilm formation in continuous flow applications. -

Electro-Polished Steel:

Reduces adsorption and improves cleaning efficiency. -

Quartz Purity Grade:

Selected based on UV transparency and background fluorescence.

Usage Guide for Optimal Performance

Installation & Setup

- Verify system compatibility: Ensure your fluid path components and tubing match the 1/16" stainless steel connectors (or your custom-specified size).

- Use appropriate ferrules: Install compatible ferrules on your tubing before connecting to the cuvette's stainless steel fittings.

- Hand-tighten only: When securing connections, use only hand force to avoid damaging the cuvette or connectors.

- Center height alignment: Position the cuvette in your instrument ensuring the 8.5 mm center height aligns with your light source and detector.

- Flow direction: While the cuvette works in either direction, maintain consistent orientation for reproducible results.

Cleaning & Maintenance

- Regular flushing: After each use, flush with 18 MΩ·cm ultrapure water at 2-3 times the cell volume.

- Mild detergent cleaning: For persistent residues, use dilute, non-abrasive laboratory detergent followed by thorough water rinsing.

- Solvent rinse: When necessary, use isopropanol or acetonitrile for final cleaning, followed by drying with filtered air.

- Avoid scratching: Never use abrasive tools or brushes on optical windows or interior surfaces.

- Storage: Store clean and dry, with end caps if provided, to protect optical surfaces and prevent dust accumulation.

Flow Rate Considerations

- Temperature limits: Operate within 10-80°C temperature range for optimal performance and longevity.

- Pressure limits: Maintain system pressure below 0.2 MPa (29 psi) to prevent damage to seals or optical windows.

- Chemical compatibility: While resistant to most laboratory chemicals, avoid prolonged exposure to fluorine-containing compounds.

- Flow rates: Optimize flow rates to prevent pressure spikes while ensuring complete sample exchange in the optical path.

- Baseline stability: Allow system temperature equilibration before taking measurements for maximum baseline stability.

Need Expert Guidance for Your

Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Tubes Application?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the purpose of the black wall design in the Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connector?

A: The black wall design minimizes stray light and side reflections during fluorescence measurements. This significantly improves signal-to-noise ratio, especially in low-concentration analyte detection. It is particularly useful in applications involving weak fluorescence signals such as NADH or riboflavin. The black coating is optically opaque but chemically stable under standard lab conditions.

Q: What makes the Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connector suitable for trace-level fluorescence analysis?

A: The black wall suppresses autofluorescence and stray light, enhancing detection of low-intensity signals. The precision-polished quartz windows ensure high optical clarity across UV-Vis-NIR wavelengths. Its small internal volume reduces sample dilution and improves response time. These features make it ideal for detecting trace biomolecules or contaminants.

Q: How does the Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connector perform in low-flow-rate systems?

A: The cuvette is optimized for low-flow applications such as microfluidics or slow bioreactor sampling. Its internal geometry ensures laminar flow and minimal dead volume. This allows accurate fluorescence readings even at flow rates below 0.1 mL/min. The design prevents signal fluctuation caused by turbulence or backpressure.

Q: Is the Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connector suitable for dual-beam fluorescence detection?

A: Yes, the cuvette can be configured with multiple optical windows for dual-beam or orthogonal detection. The black wall prevents cross-talk between excitation and emission paths. This enhances measurement precision in ratiometric fluorescence assays. Custom window positioning is available for specialized optical setups.

Q: Can the Black Wall Quartz Flow-Through Fluorescent Cuvette with Stainless Steel Connector be used for kinetic fluorescence measurements?

A: Absolutely. The flow-through design supports real-time monitoring of reaction kinetics. The black wall ensures stable baseline signals during rapid fluorescence changes. It is suitable for enzyme assays, ligand binding studies, and photobleaching experiments. The cuvette maintains optical consistency across repeated cycles.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.