- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Fluorescence Cuvette

- /

- Spectral-Stable Quartz Fluorescence Reaction...

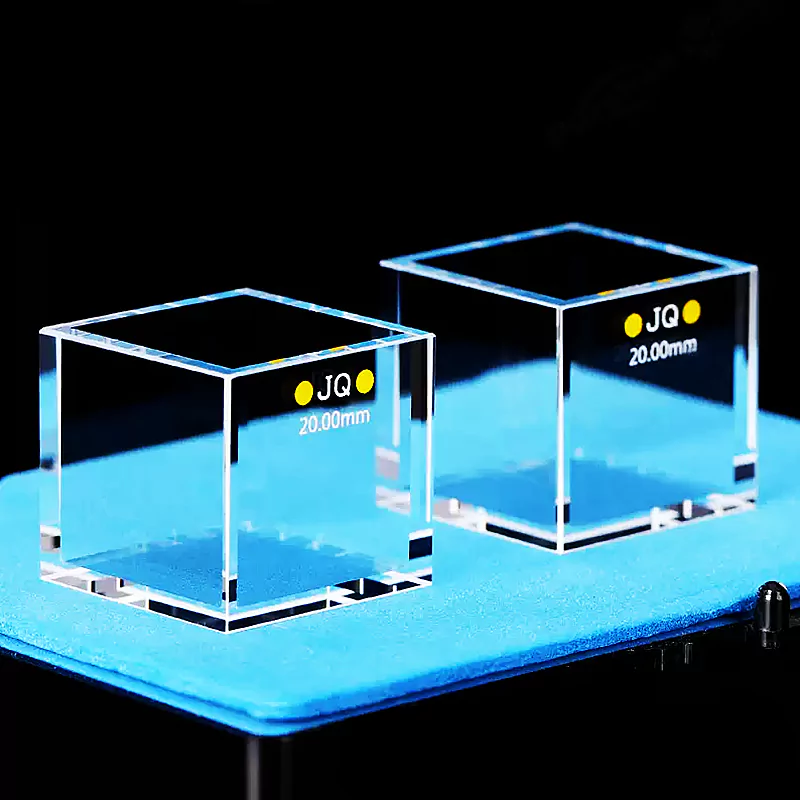

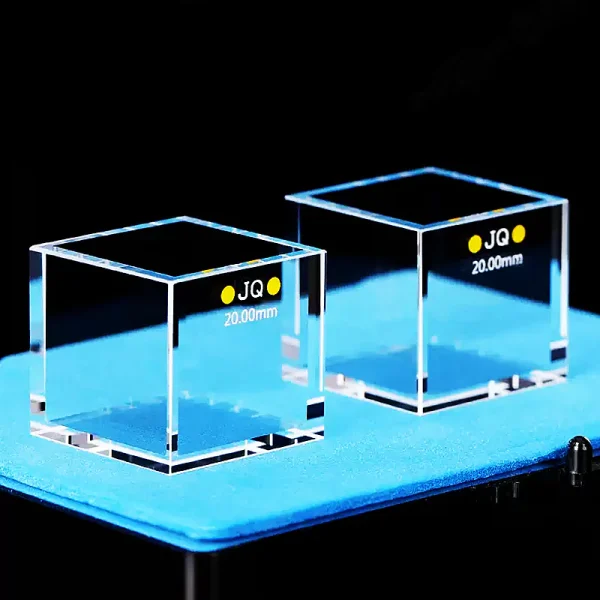

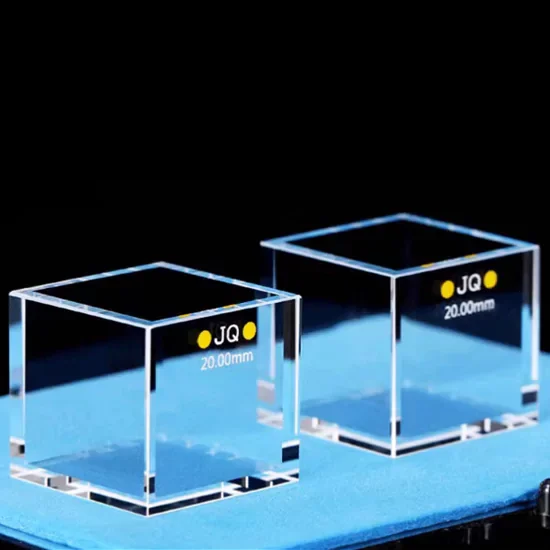

Spectral-Stable Quartz Fluorescence Reaction Cuvettes for Lab Applications -TOQUARTZ®

Features of Quartz Fluorescence Reaction Cuvettes

TOQUARTZ® quartz fluorescence reaction cuvettes combine precision manufacturing with high-purity materials to deliver superior optical performance. Each cuvette is crafted to meet the exacting requirements of spectroscopic analysis and chemical reaction monitoring.

Material Purity

Manufactured from high-purity optical quartz with SiO₂ content up to 99.995%, ensuring minimal interference in sensitive analytical applications and excellent optical clarity.

Versatile Closure Options

Available with PTFE caps for chemical resistance or quartz lids for high-temperature applications, providing flexible sealing solutions for various experimental conditions.

Optical Transmission

Wide spectral transmission range from 190nm to 2500nm covers UV, visible, and near-infrared regions without absorption peaks, ideal for comprehensive spectroscopic analysis.

Chemical Resistance

Highly resistant to acids, bases, salts, and organic solvents, making these cuvettes suitable for aggressive chemical environments and extending their service life in laboratory settings.

- SiO2 Purity ≥99.98%, up to 99.995%

- Chemical Resistance to Harsh Reagents

- Customization Services Available

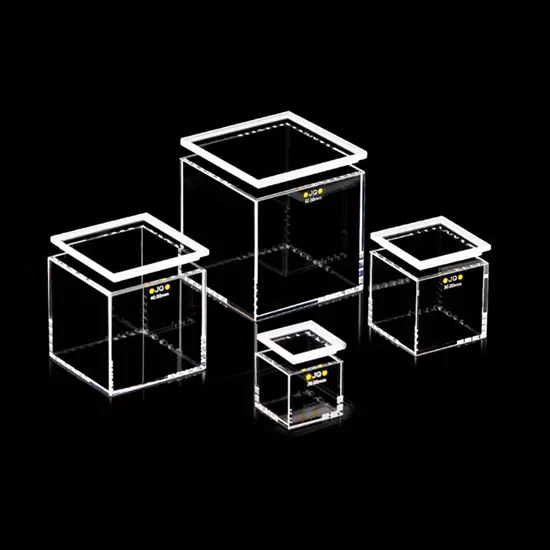

Technical Specifications & Dimensions of Quartz Fluorescence

Reaction Cuvettes

Technical Specifications

| Parameter | Specification |

| 1. Physical Properties | |

| Material | High-purity optical quartz (≥99.98%, max. up to 99.995% SiO2) |

| Surface Finish | Optical grade polishing |

| Cap Options | PTFE caps, quartz lids |

| Density | 2.2 g/cm³ |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ /°C |

| 2. Chemical Properties | |

| Acid Resistance | Excellent (except HF) |

| Alkali Resistance | Very good |

| Solvent Compatibility | Compatible with all common organic solvents |

| 3. Optical Properties | |

| Transmission Range | 200-2500nm |

| Refractive Index | 1.46 at 589.3nm |

| Transmission Rate | ≥80% (200-800nm) |

Size Chart

| Model | Description | Path Length |

Volume | Outline Dimension |

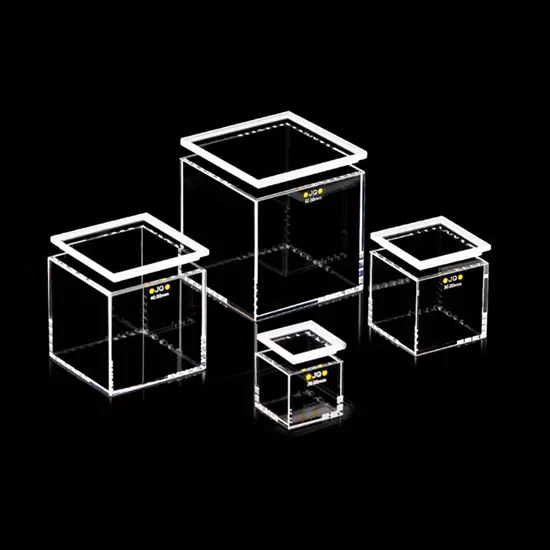

| AT-BSM-6006-4 | 20mm Quartz Fluorescence Reaction Cuvette Cell | 20mm | 800μl | 24x24x22mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-6006 | 20mm Quartz Fluorescence Reaction Cuvette | 20mm | 8000μl | 24x24x22mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-6011 | 20mm Fused Quartz Fluorescence Reaction Cuvette Cell | 20mm | 16000μl | 24x24x42mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-6006-1 | 30mm Quartz Fluorescence Reaction Cuvette | 30mm | 27000μl | 34x34x32mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-6006-2 | 40mm Quartz Fluorescence Reaction Cuvette | 40mm | 64000μl | 44x44x42mm |

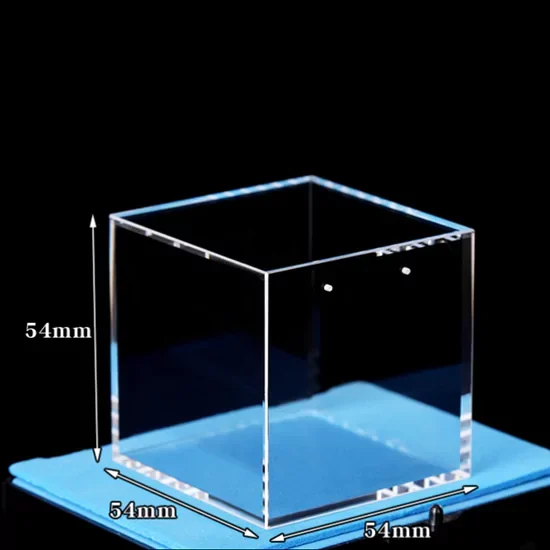

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-6006-3 | 50mm Quartz Fluorescence Reaction Cuvette | 50mm | 125000μl | 54x54x52mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-6006-5 | 50mm Quartz Fluorescence Reaction Cuvette Cell | 50mm | 125000μl | 54x54x54mm |

TOQUARTZ® Advanced Solutions for Precision Spectroscopy Applications with Quartz Fluorescence Reaction Cuvettes

Quartz Fluorescence Reaction Cuvette in Photodynamic Therapy (PDT) Drug Screening

Key Advantages

-

Oxygen-Blocking Screw Cap Design

Maintains oxygen levels below 0.5 ppm during 30-minute irradiation cycles. -

UV-Resistant Quartz Surface Stability

No surface degradation after 50+ exposures to 630nm laser at 100 mW/cm². -

pH-Neutral Optical Chamber

Internal surface pH shift <0.1 after 24h exposure to porphyrin-based photosensitizers.

TOQUARTZ® solution

A Canadian PDT research lab observed 18–22% fluorescence signal loss due to oxygen quenching and photobleaching in open-top cuvettes. After switching to TOQUARTZ® sealed quartz cuvettes, quantum yield measurements stabilized within ±2%, and photobleaching was reduced by 35% over 40-minute light exposure. This enabled accurate evaluation of 7 new photosensitizer candidates under ISO 10993-5 protocols.

Quartz Fluorescence Reaction Cuvette in Food Safety Fluorescence Detection

Key Advantages

-

Ethanol-Resistant Quartz Integrity

No surface etching after 100 cycles of 70% ethanol-based aflatoxin extraction. -

Low-Autofluorescence Baseline (<0.002 AU)

Background signal at 365nm excitation measured 0.0018 AU in blank runs. -

Sealed Cap Prevents Volatile Loss

Maintains aflatoxin B1 concentration within ±1.5% over 2-hour batch testing.

TOQUARTZ® solution

A Polish food safety lab testing aflatoxins in corn extracts reported 12% false positive rate due to cuvette autofluorescence and ethanol-induced degradation. After adopting TOQUARTZ® cuvettes, background signal dropped by 87%, and retest frequency decreased by 40%. This improved compliance with EU Regulation No. 1881/2006 for aflatoxin B1 limits (2 μg/kg).

Quartz Fluorescence Reaction Cuvette in Forensic Trace Evidence Fluorescence Analysis

Key Advantages

-

Micro-Volume Compatibility (≤200μL)

Enables trace analysis with sample volumes as low as 150μL without signal loss. -

Four-Sided Optical Clarity (≥92% at 450nm)

Ensures uniform fluorescence detection from multiple angles in fiber analysis. -

Leak-Proof Seal for Volatile Traces

Prevents evaporation of ethanol-based dye residues for up to 4 hours at 25°C.

TOQUARTZ® solution

A forensic lab in Germany analyzing dyed synthetic fibers encountered 30% signal variability due to cuvette wall scattering and sample evaporation. TOQUARTZ® cuvettes with four-sided optical polishing and screw caps improved signal-to-noise ratio by 35% and preserved sample integrity for extended analysis. This enabled successful matching of fiber evidence in a high-profile criminal investigation.

TOQUARTZ® Customization Options for Quartz Fluorescence

Reaction Cuvettes

Dimensional Customization

- Custom path lengths

- Custom internal volumes

- Specialized wall thickness

- Integrated ports or connections

Functional Enhancements

- Specialized sealing mechanisms

- Flow-through designs

- Temperature control jackets

- Reaction mixing chambers

Custom Design Process

- Requirements Assessment: Our technical team works with you to understand your specific application requirements, including dimensional, optical, and material specifications.

- Design & Engineering: We develop technical drawings and specifications for your approval, with our engineering team providing feedback on manufacturability and performance optimization.

- Prototype Development: For complex projects, we can produce prototype units for testing and validation before proceeding to full production.

- Quality Manufacturing: Production using high-purity quartz materials with precision machining and optical finishing to meet exact specifications.

- Inspection & Documentation: Comprehensive quality checks with detailed dimensional reports and material certifications upon request.

Usage and Care Guidelines

Proper Handling & Cleaning

- Wear gloves: Always handle cuvettes with powder-free gloves to prevent fingerprints and contamination that can affect optical measurements.

- Initial cleaning: For new cuvettes, rinse with ultrapure water followed by spectroscopic-grade solvent compatible with your analysis.

- Routine cleaning: Empty cuvette immediately after use and rinse with appropriate solvent. For persistent residues, use 5% Hellmanex® solution or dilute acid (except HF).

- Drying: Allow to air dry in dust-free environment or use filtered compressed nitrogen gas for rapid drying.

- Avoid: Ultrasonic cleaners, abrasive materials, and hydrofluoric acid (HF), which attacks quartz.

Storage & Maintenance

- Storage container: Store in original protective case or dedicated dust-free container with soft lining to prevent scratches.

- Environmental conditions: Store in clean, dry environment away from chemical vapors that could contaminate optical surfaces.

- Regular inspection: Periodically check for chips, cracks, or scratches using appropriate light source.

- Thermal handling: Allow cuvettes to gradually reach operating temperature; avoid rapid temperature changes that can cause thermal shock.

- Cap maintenance: Inspect PTFE or quartz caps regularly for proper sealing. Replace if damaged to ensure proper containment.

Best Practices for Optimal Performance

- Validate optical performance periodically using certified reference materials to ensure measurement accuracy.

- Standardize handling procedures among laboratory personnel to minimize variation in results.

- Use dedicated cuvettes for specific applications to prevent cross-contamination between incompatible chemicals.

- Position cuvettes consistently in instrument holders to maintain reproducible optical path alignment.

- Consider maintaining a log of cuvette usage and cleaning history for critical applications.

Need Engineering Support for Your Quartz Fluorescence Reaction Cuvette Project?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: Can the Quartz Fluorescence Reaction Cuvette be used with highly acidic or basic samples?

A: Yes, our cuvettes are chemically stable in pH 1–14 environments. The high-purity quartz resists corrosion from strong acids and bases, except hydrofluoric acid (HF), which should be strictly avoided.

Q: What is the autofluorescence level of the Quartz Fluorescence Reaction Cuvette under UV excitation?

A: The autofluorescence is <0.002 AU at 365nm excitation. This ensures minimal background interference in low-concentration fluorescence assays.

Q: How does the screw cap of the Quartz Fluorescence Reaction Cuvette improve sample integrity?

A: The precision screw cap prevents evaporation and contamination, especially for volatile solvents like ethanol or DMSO. It ensures consistent concentration during long assays.

Q: Can the Quartz Fluorescence Reaction Cuvette be used in field testing environments?

A: Yes, our cuvettes are compatible with portable fluorometers. The sealed design and chemical durability make them suitable for on-site environmental or food safety testing.

Q: How should the Quartz Fluorescence Reaction Cuvette be cleaned and stored to maintain performance?

A: Rinse with deionized water and spectroscopic-grade solvents. Avoid HF and ultrasonic cleaning. Store in a dust-free case to prevent scratches and contamination.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.