- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz IR Cuvette

- /

- Leak-Proof Infrared Quartz Fluorescence...

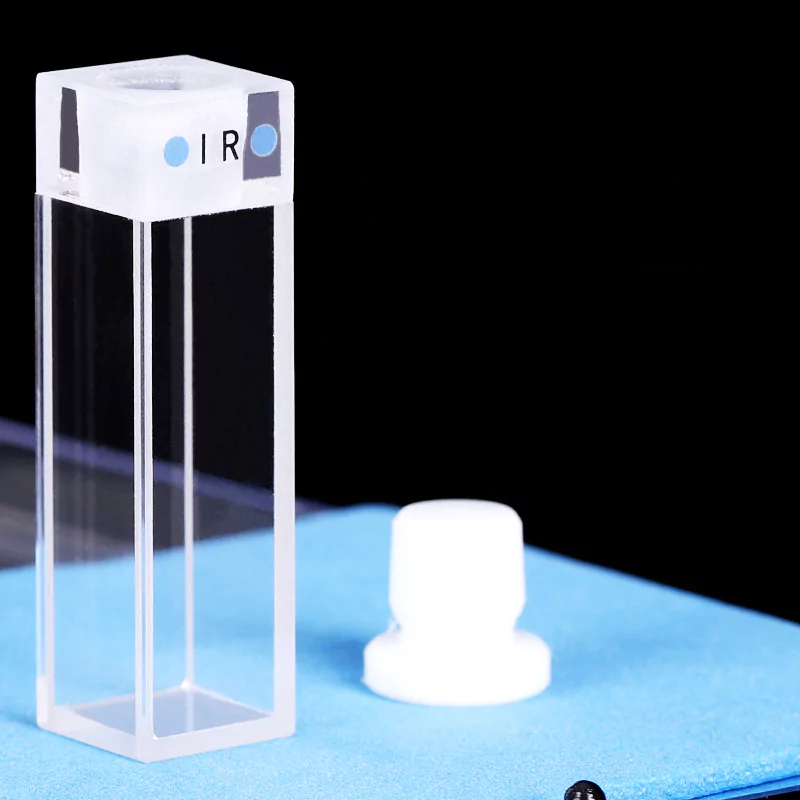

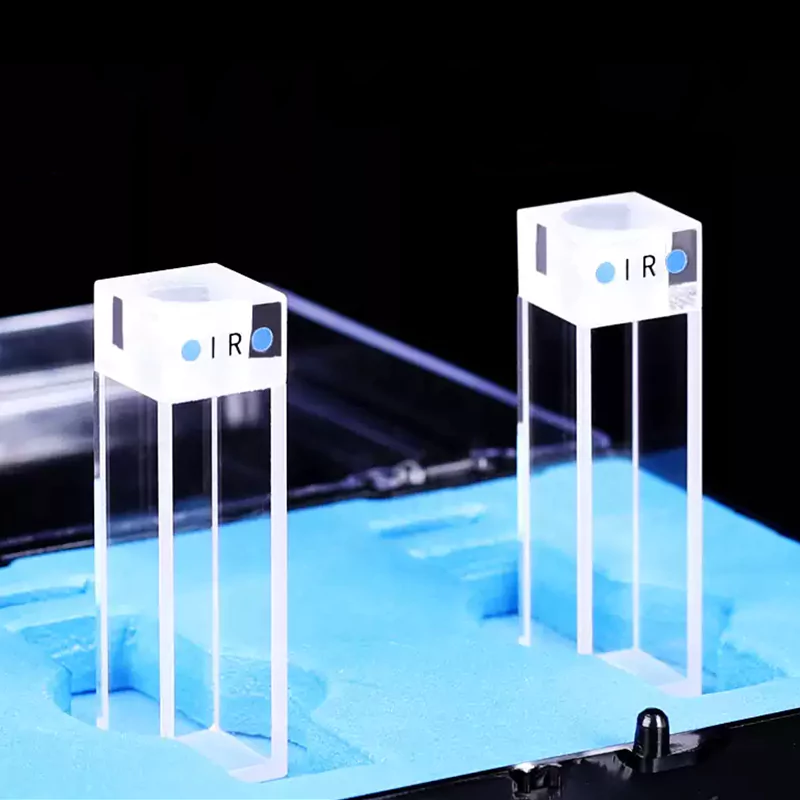

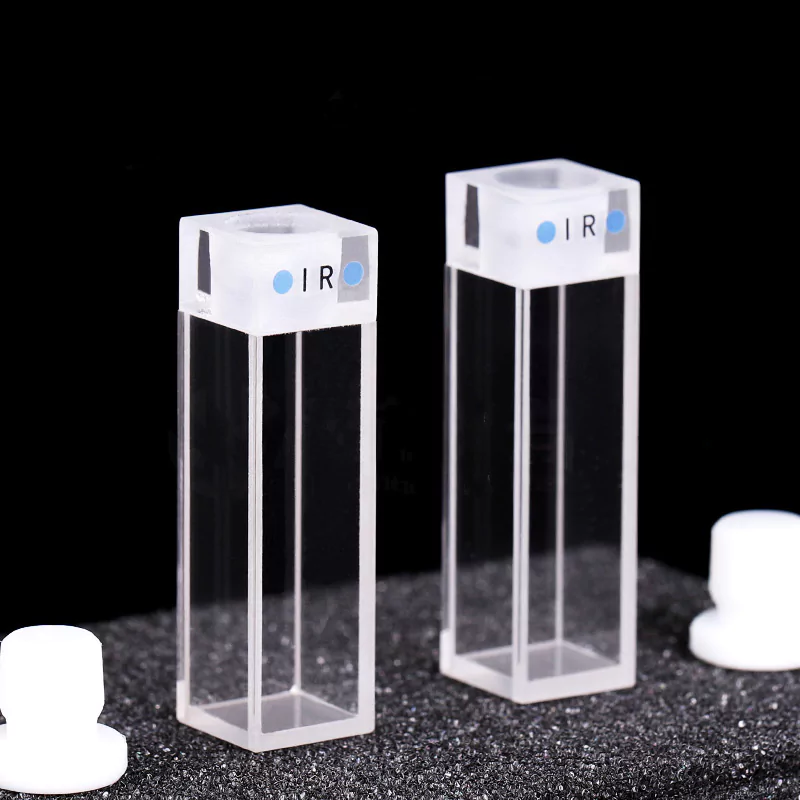

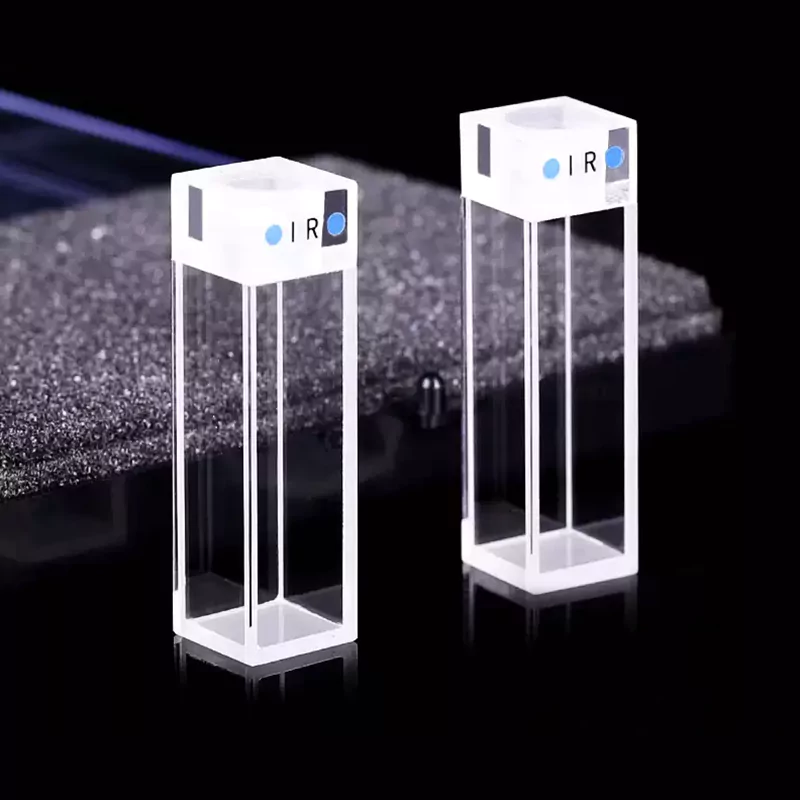

Leak-proof Infrared Quartz Fluorescence Cuvette with Stopper for Fluorescence Detection -TOQUARTZ®

Features of Infrared quartz fluorescence cuvette with stopper

TOQUARTZ® infrared quartz fluorescence cuvettes with stopper are manufactured from high-purity synthetic quartz, providing exceptional performance for spectroscopic applications. Our cuvettes combine precision manufacturing with premium materials to deliver reliable results for your analytical needs.

Precision Engineering & Design

- Precision-ground body with dimensional accuracy

- PTFE stopper for airtight sealing

- Polished optical surfaces (scratch and blemish-free)

Material Composition

- High-purity synthetic quartz (≥99.98% SiO₂)

- Premium grades up to 99.995% purity available

- Extremely low metal ion content

Optical Properties

- Exceptional transmission range (300nm-3500nm)

- No absorption peaks throughout transmission range

- Transmittance >80% (paired testing)

- Resistant to acids and alkalis(except HP)

- Temperature resistance up to 1100°C

- Low thermal expansion coefficient (5.5×10⁻⁷ /°C)

Technical Specifications & Dimensions of Infrared quartz fluorescence cuvette with stopper

Technical Specifications

| Property | Specification |

| 1. Physical Properties | |

| Density | 2.2 g/cm³ |

| Fracture Modulus | ≥350 MPa |

| Thermal Conductivity | 120-160 W/m·K |

| Thermal Expansion Coefficient | 5.5×10-7/℃ |

| Max Operating Temperature: | 1100°C |

| 2. Chemical Properties | |

| SiO₂ Content | ≥99.98% (up to 99.995%) |

| Chemical Resistance | Excellent (acids, alkalis) |

| OH Content | <30 ppm |

| Bubble/Inclusion Content | None visible |

| Water Absorption | Nil |

| 3. Optical Properties | |

| Transmission Range | 300-3500nm |

| Refractive Index (589.3nm) | 1.458 |

Size Chart

| Model | Description | Wavelength | Path Length |

Volume | Transmittance | Outline Dimension |

| AT-BSM-2004 | 3.5ml Infrared quartz fluorescence cuvette with stopper | 300nm-3500nm | 10mm | 3.5ml | >80% (Paired Testing) | 12.5×12.5x45mm |

Solving Challenges with IR Quartz Fluorescence Cuvettes with Stopper

Infrared Quartz Fluorescence Cuvette with Stopper in Organic Solvent Fluorescence Analysis

Key Advantages

-

Prevents solvent loss during 30+ min fluorescence scans

PTFE stopper maintains solvent mass within ±1.2% over 45 minutes in ethanol-based assays. -

Minimizes concentration drift in volatile organic systems

Sample concentration deviation reduced from 18% to under 2% in methanol-based fluorescence tests. -

Enables reproducible fluorescence intensity in batch testing

Fluorescence signal CV (coefficient of variation) improved from 12.5% to 1.8% across 10 replicates.

TOQUARTZ® solution

A pharmaceutical R&D lab analyzing fluorophore-tagged compounds in acetonitrile reported 15–20% signal loss due to evaporation in open cuvettes during 40-minute scans. After switching to TOQUARTZ® sealed cuvettes, signal deviation dropped to <2.1%, enabling consistent quantification across 12 batches and reducing retest rates by 35%.

Infrared Quartz Fluorescence Cuvette with Stopper for Protein Fluorescence in Biotech Labs

Key Advantages

-

Blocks oxygen ingress during kinetic fluorescence assays

O₂-sensitive FITC-tagged protein retained 96.7% signal over 60 minutes with sealed cuvette. -

Reduces photobleaching in long-duration exposure

Fluorescence decay rate decreased from 28% to 4.5% under identical light exposure conditions. -

Maintains signal stability in low-concentration protein samples

Signal-to-noise ratio improved by 3.2× in 0.1 mg/mL BSA-FITC assays using sealed cuvettes.

TOQUARTZ® solution

A biotech lab conducting 1-hour kinetic fluorescence studies on tryptophan-labeled proteins observed 30% signal degradation due to oxidation and light exposure in open cuvettes. TOQUARTZ® sealed cuvettes preserved >95% signal integrity, enabling accurate kinetic modeling and reducing experimental variability by 42%.

Infrared Quartz Fluorescence Cuvette with Stopper in Environmental Pollutant Detection via Fluorescence

Key Advantages

-

Prevents photodegradation of PAHs in UV-exposed testing

Naphthalene fluorescence intensity retained 93.5% after 20 min exposure in sealed cuvette vs. 68% in open. -

Maintains sample volume in multi-sample batch workflows

Evaporation loss reduced from 0.35 mL to <0.02 mL per cuvette over 1 hour at 25°C. -

Enables ppb-level detection with minimal background interference

Background fluorescence reduced by 87% compared to screw-cap plastic cuvettes in pesticide assays.

TOQUARTZ® solution

An environmental testing lab analyzing PAHs in river water using fluorescence spectroscopy faced 25% signal loss due to photodegradation and evaporation during batch runs. After adopting TOQUARTZ® sealed cuvettes, signal retention improved to 94% across 24 samples, enabling detection limits down to 0.3 ppb and reducing false negatives by 60%.

Customization Services for TOQUARTZ® Infrared quartz fluorescence cuvette with stopper

Dimensional Customization

- Custom path lengths

- Special outer dimensions

- Modified internal volumes

- Specialized wall thickness

- Miniaturized designs for micro-samples

Material Specification

- Ultra-high purity options (99.995% SiO₂)

- Special grade for extended UV transmission

- Enhanced IR transmission formulations

- Low fluorescence background material

- Specialized thermal resistance grades

Sealing Options

- PTFE stoppers of various sizes

- Screw-cap designs

- Ground glass stoppers

- Flow-through adaptations

- Specialized seals for extreme conditions

Custom Design Process

Requirement Consultation

Discuss your specific needs, applications & technical parameters

Technical Drawing

Engineers create detailed CAD designs for your approval

Prototype Development

Fabrication of sample units for testing and validation

Testing & Refinement

Collaborative testing and design adjustments as needed

Production

Scaled manufacturing with comprehensive quality control

Usage Guide of Infrared quartz fluorescence cuvette with stopper

Proper Handling & Operation

- Always handle cuvettes by the frosted or non-optical sides to avoid fingerprints and contamination on optical surfaces.

- Insert and remove the PTFE stopper gently to avoid damaging the cuvette or creating quartz particles.

- Ensure the cuvette is properly positioned in the spectrometer with the optical path aligned correctly.

- Allow heated samples to cool before sealing with the stopper to prevent pressure build-up.

Cleaning & Maintenance

- Clean cuvettes immediately after use to prevent sample residue from drying or adhering to surfaces.

- Use appropriate solvents for cleaning (acetone, ethanol, or mild detergent solutions), followed by thorough rinsing with deionized water.

- Dry with compressed air or nitrogen, or air dry in a dust-free environment.

- Periodically inspect PTFE stoppers for wear and replace if necessary to maintain proper sealing.

Storage Recommendations

- Store cuvettes in their original protective cases or in dedicated cuvette racks to prevent scratches and damage.

- Keep in a clean, dry environment away from chemicals, dust, and excessive humidity.

- For long-term storage, consider using desiccant packets to prevent moisture accumulation.

- Avoid extreme temperature fluctuations which can induce stress in the quartz material.

Need Technical Assistance with Infrared Quartz Fluorescence Cuvettes?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: How does the PTFE stopper ensure airtight sealing without affecting fluorescence readings?

A: The PTFE stopper is chemically inert and optically opaque, preventing solvent evaporation and oxygen ingress while avoiding background fluorescence. It is precision-fitted to the cuvette neck to maintain seal integrity without interfering with the optical path.

Q: What is the maximum solvent vapor pressure the stopper can withstand without leakage?

A: TOQUARTZ® IR quartz cuvettes with PTFE stoppers are tested to maintain seal integrity for solvents with vapor pressures up to 80 kPa at 25°C, including methanol, ethanol, and acetonitrile, under standard lab conditions.

Q: Can the stopper be autoclaved or reused after exposure to aggressive solvents?

A: Yes, the PTFE stopper is autoclavable up to 121°C and resistant to most organic solvents. However, for critical fluorescence assays, we recommend replacing the stopper after 10–15 uses to avoid micro-deformation or contamination.

Q: Are there compatibility issues with automated fluorescence readers or robotic arms?

A: TOQUARTZ® cuvettes follow standard outer dimensions (e.g., 12.5×12.5mm) and are compatible with most commercial fluorescence spectrometers and autosamplers. Custom dimensions can be provided for OEM integration.

Q: What is the lowest detectable concentration achievable using quartz ir cuvette with stopper in fluorescence assays?

A: In controlled lab tests, TOQUARTZ® sealed cuvettes enabled detection of FITC-labeled proteins at concentrations as low as 0.05 µg/mL, with signal-to-noise ratios exceeding 3:1, depending on instrument sensitivity.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.