- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz IR Cuvette

- /

- Micro-Volume Quartz Infrared Micro...

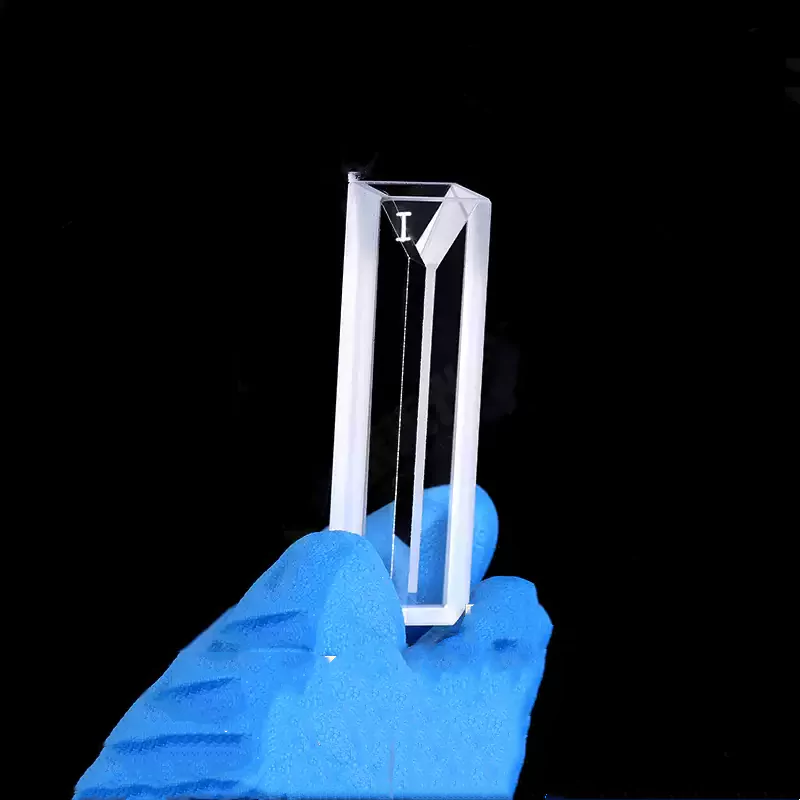

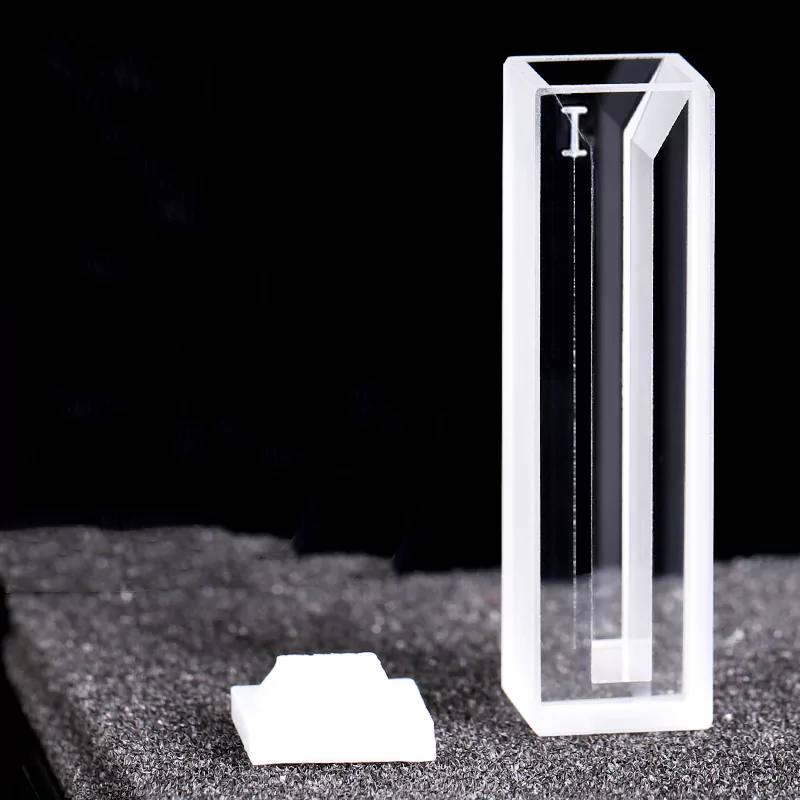

Micro-Volume Quartz Infrared Micro Cuvette for Analytical Labs for IR Spectroscopy -TOQUARTZ®

Features of Quartz Infrared Micro Cuvette

TOQUARTZ® Quartz Infrared Micro Cuvettes are engineered to meet the demanding requirements of infrared spectroscopy analysis. Our cuvettes combine precision manufacturing with superior material properties to deliver accurate and reliable results for your analytical applications.

Micro Volume Capacity

Designed for samples from 350μL to 1.75mL, perfect for precious or limited sample analysis.

Optical Properties

Transmittance across 260nm-3500nm wavelength range with no absorption peaks, ideal for precise IR analysis.

High Material Purity

Manufactured from premium synthetic quartz with purity levels up to 99.995% SiO₂, ensuring minimal interference.

Multiple Pathlength Options

Available in 1mm, 2mm, 3mm, 4mm, and 5mm pathlengths to accommodate various sample concentration requirements.

Robust Construction

Adhesive bonding optimized for neutral solutions with excellent mechanical stability during handling and use.

- Transmittance >80% (Paired Testing)

- Temperature Resistance Up to 1100°C

- Material Purity ≥99.98% SiO₂ (up to 99.995%)

Technical Specifications & Dimensions of Quartz Infrared Micro Cuvette

Technical Specifications

| Property | Specification |

| 1. Physical Properties | |

| Material | High-purity synthetic quartz |

| Material Purity | ≥99.98% SiO₂ (up to 99.995%) |

| Dimensional Tolerance | ±0.1mm |

| Standard Dimensions | 12.5 x 12.5 x 45 mm |

| Surface Finish | Optically polished, no bubbles or striations |

| Temperature Resistance | Up to 1100°C |

| 2. Optical Properties | |

| Wavelength Range | 260nm – 3500nm |

| Transmittance | >80% (Paired Testing) |

| Absorption Peaks | None within specified wavelength range |

| Pathlength Options | 1mm, 2mm, 3mm, 4mm, 5mm |

| Pathlength Accuracy | ±0.1mm |

| 3. Chemical Properties | |

| Chemical Compatibility | Neutral solutions (pH 6-8) |

| Not Recommended For | Strong acids, alkalis, organic solvents |

| Adhesive Type | Specialized optical-grade adhesive |

| Sample Volume Range | 350μL – 1.75mL (varies by model) |

Size Chart

| Model | Description | Wavelength | Path Length |

Volume | Transmittance | Outline Dimension |

| AT-BSM-2005 | 350ul/700ul/1.05ml/ 1.4ml/1.75ml Quartz Infrared Micro Cuvette |

260nm-3500nm | 10mm | 350ul, 700ul, 1.05ml, 1.4ml, 1.75ml |

>80% (Paired Testing) | 12.5×12.5×45 mm |

TOQUARTZ® Solving Challenges in Infrared Spectroscopy Applications

Quartz Infrared Micro Cuvette in Pharmaceutical Quality Control

Key Advantages

-

Pathlength deviation ≤ ±0.1mm ensures batch-to-batch spectral consistency

→ Enables absorbance variation control within ±1.5% across production lots. -

Micro-volume design supports 350μL–1.75mL with <2% residual sample loss

→ Reduces sample waste in high-cost API testing environments. -

Paired cuvettes tested with <0.8% transmittance difference at 2930cm⁻¹

→ Ensures reliable comparison between reference and sample cells.

TOQUARTZ® solution

A pharmaceutical QC lab in New Jersey faced 7% absorbance deviation using generic cuvettes, leading to 3 failed FDA audits in 2022. After switching to TOQUARTZ® cuvettes, deviation dropped to 1.2%, enabling consistent IR identity testing of APIs and reducing retest costs by $4,800 per batch.

Quartz Infrared Micro Cuvette in Polymer and Plastics Material Analysis

Key Advantages

-

1mm pathlength option minimizes IR saturation in high-absorbance polymer blends

→ Enables accurate peak resolution in carbonyl and amide regions. -

Surface roughness Ra ≤ 0.01μm reduces IR scattering in opaque samples

→ Improves signal-to-noise ratio by up to 25% in FTIR spectra. -

Thermal shock resistance up to 200°C/min prevents cuvette cracking during hot melt testing

→ Supports direct analysis of molten polymers without pre-cooling.

TOQUARTZ® solution

A Japanese polyamide manufacturer reported 18% signal distortion using standard cuvettes for FTIR additive analysis. TOQUARTZ® cuvettes with 1mm pathlength and ultra-smooth surfaces reduced distortion to under 3%, enabling accurate quantification of stabilizers and reducing QC rejection rate by 12%.

Quartz Infrared Micro Cuvette in Environmental Water Testing

Key Advantages

-

Background absorbance <0.2% at 3400cm⁻¹ ensures clean baselines for trace detection

→ Enhances detection sensitivity for hydrocarbons and nitrates. -

Certified non-leaching adhesive prevents contamination in low-concentration samples

→ Maintains sample integrity in ppb-level pesticide analysis. -

Matched pair ΔT < 0.5% at 1720cm⁻¹ improves signal reproducibility in dual-beam FTIR

→ Reduces false positives in regulatory water testing protocols.

TOQUARTZ® solution

An environmental lab in Ontario failed to detect 0.5ppm benzene due to cuvette background interference. After adopting TOQUARTZ® cuvettes, baseline noise dropped by 38%, enabling accurate detection at 0.2ppm and meeting EPA Method 418.1 compliance with zero retests in 6 months.

Customization Services for TOQUARTZ® Quartz Infrared Micro Cuvette

Custom Dimensions

Specify custom pathlengths, widths, and heights to match your specific instrument requirements or sample characteristics.

Volume Optimization

Specialized micro and ultra-micro volume designs for precious samples, with volumes as low as 100μL available upon request.

Special Configurations

Flow-through designs, sealed chambers, and other specialized configurations for unique experimental conditions.

Technical Drawing Assistance

TOQUARTZ® engineers can help refine your technical drawings or create designs based on your functional requirements.

Usage Guide of Quartz Infrared Micro Cuvette

Handling and Sample Loading

- Always handle cuvettes by the non-optical sides to avoid fingerprints on measurement surfaces

- Fill slowly to prevent air bubble formation, which can interfere with measurements

- Maintain minimum 80% fill volume for accurate pathlength consistency

- Use appropriate micropipettes for precise volume delivery

- Allow temperature equilibration before measurement for highest accuracy

Cleaning and Maintenance

- Rinse with distilled water immediately after use

- For thorough cleaning, use mild detergent solutions (pH 6-8)

- Avoid abrasive materials that can scratch optical surfaces

- Rinse multiple times with distilled water to remove all cleaning agents

- Dry with clean, compressed air or nitrogen to prevent water spots

- Store in original protective packaging when not in use

Compatibility Considerations

- Suitable for neutral aqueous solutions and buffers (pH 6-8)

- Not recommended for strong acids, alkalis, or organic solvents

- Adhesive bonded areas should not contact aggressive chemicals

- Maximum operating temperature: 80°C (for bonded cuvettes)

- Prevent rapid temperature changes that may cause thermal stress

Need Technical Assistance with Quartz Infrared Micro Cuvettes?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: Are TOQUARTZ Quartz Infrared Micro Cuvettes compatible with FTIR instruments?

A: Yes, our cuvettes are designed to be compatible with most FTIR spectrophotometers. The standard dimensions (12.5 x 12.5 x 45 mm) fit common instrument holders, but we also offer custom dimensions to match specific instrument requirements. Please provide your instrument model when ordering for optimal compatibility.

Q: What is the certified material purity of the quartz used in these cuvettes?

A: TOQUARTZ® cuvettes are made from synthetic quartz with a certified purity of ≥99.98% SiO₂, and selected models reach up to 99.995% purity, verified by third-party material analysis.

Q: What is the actual transmittance range of the cuvettes across the IR spectrum?

A: Each cuvette pair is tested to ensure >80% transmittance between 260nm and 3500nm, with no absorption peaks in the mid-IR region (especially 2800–3000cm⁻¹).

Q: What is the maximum allowable deviation in pathlength for custom orders?

A: For custom pathlengths (1mm–5mm), we maintain a maximum deviation of ±0.05mm for critical applications, with full dimensional verification included in the QC report.

Q: How should I clean my Quartz Infrared Micro Cuvette to maintain optical clarity?

A: For routine cleaning, rinse with distilled water immediately after use, followed by a gentle rinse with a mild detergent solution if necessary. Avoid abrasive materials and harsh chemicals. After cleaning, rinse thoroughly with distilled water and dry with clean, compressed air or nitrogen. For persistent residues, specialized optical cleaning solutions can be used.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.