- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz IR Cuvette

- /

- Broad-Spectrum Transmission Two Optical...

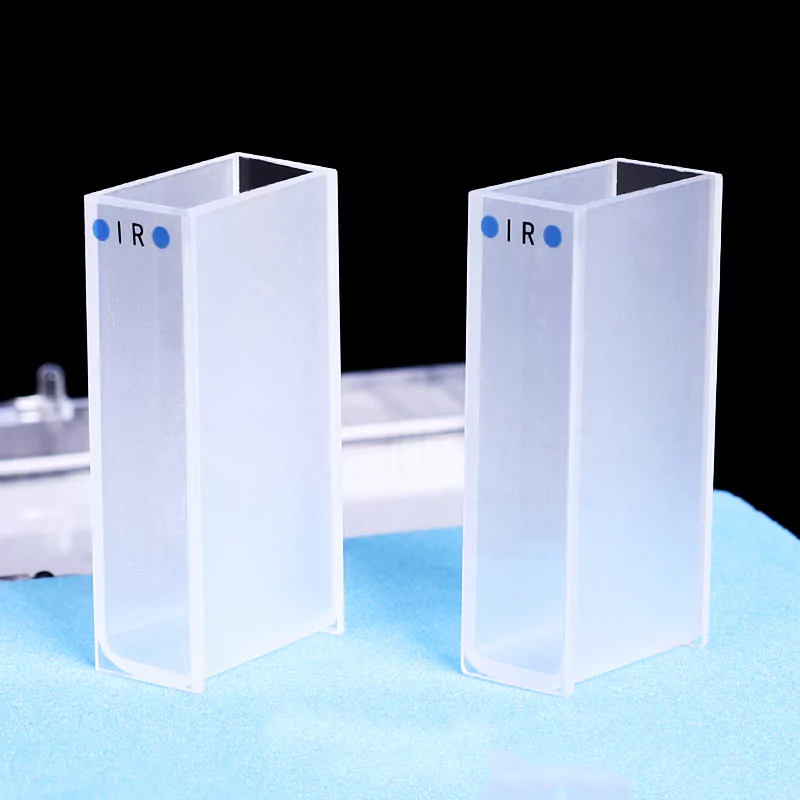

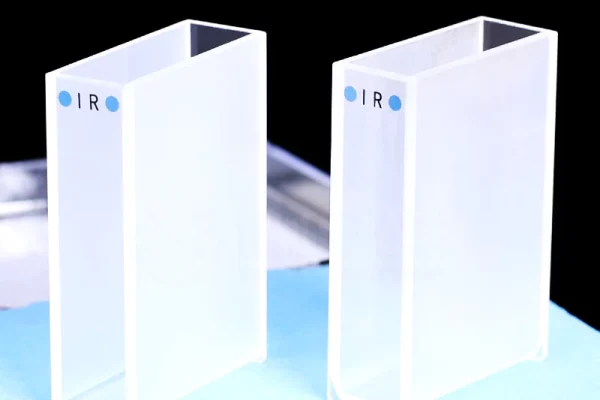

Broad-Spectrum Transmission Two Optical Windows Infrared Quartz Cuvette for Research Labs -TOQUARTZ®

Features of Two Optical Windows Infrared Quartz Cuvette

Manufactured from high-purity fused quartz (≥99.995% SiO₂), TOQUARTZ® infrared transmission cuvettes offer exceptional optical performance across the 260nm-3500nm spectral range.

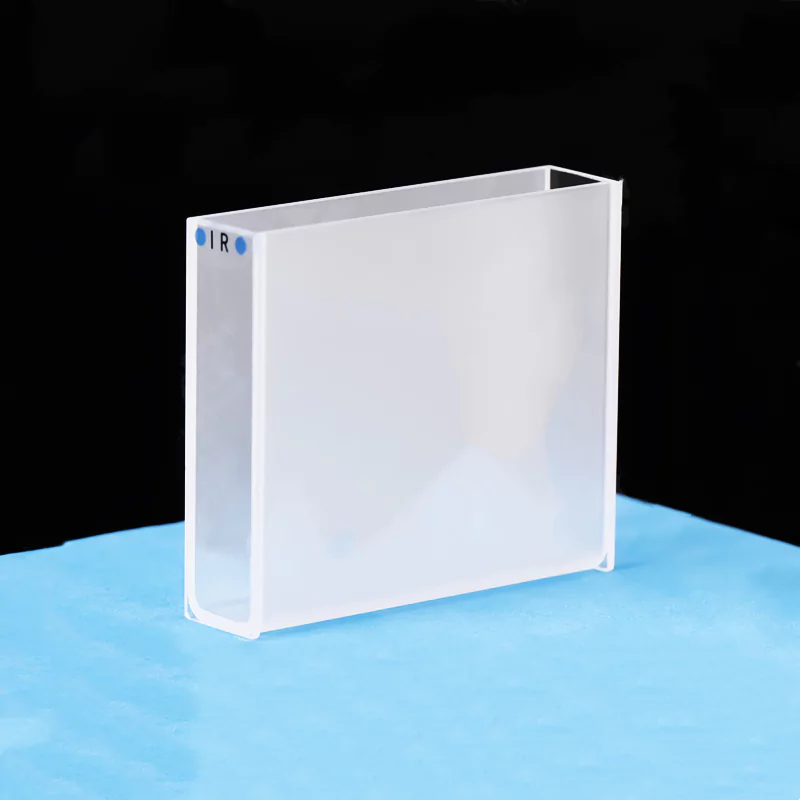

Two Optical Windows Design

Precision-engineered with two parallel optical windows for accurate and consistent sample analysis. Each window is optically polished to ensure uniform light transmission.

High IR Transmittance

Superior optical transmission in the 260nm-3500nm range, ideal for FTIR applications. TOQUARTZ® infrared cuvettes maintain >80% transmittance across the spectral range when tested in pairs.

Fused Quartz Construction

Manufactured from high-purity fused quartz (≥99.98% SiO₂, up to 99.995%), ensuring excellent chemical stability and optical performance without contaminating sensitive samples.

- Resistance to acids, alkalis, organic solvents, and corrosive chemicals

- Withstands temperatures up to 1100°C

- Thermal expansion coefficient of 5.5×10⁻⁷ /°C ensures dimensional stability

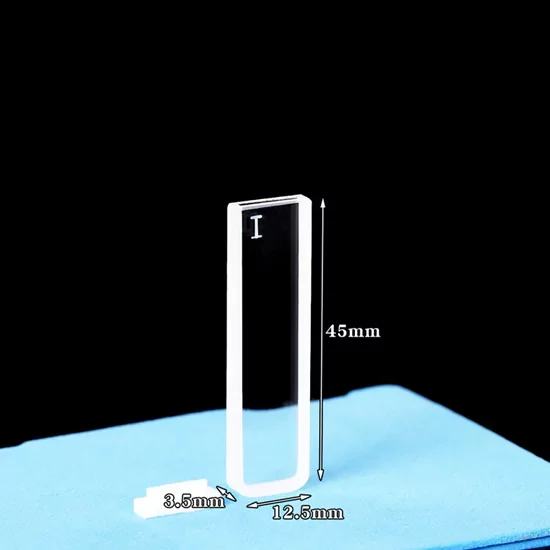

Technical Specifications & Dimensions of Two Optical Windows Infrared Quartz Cuvette

Technical Specifications

| Property | Specification | Notes |

| 1. Physical Properties | ||

| Material | High-purity fused quartz | ≥99.98% SiO₂ (up to 99.995%) |

| Path Length Range | 1mm – 50mm | Precision tolerance ±0.1mm |

| Wall Thickness | 1.25mm typical | Custom thicknesses available |

| Density | 2.2 g/cm³ | At 25°C |

| Surface Finish | Optical grade polish | Bubble and inclusion free optical windows |

| 2. Chemical Properties | ||

| Chemical Resistance | Excellent resistance to acids, alkalis, and organic solvents | Except for HF and hot phosphoric acid |

| Water Absorption | Negligible | Non-hygroscopic |

| Gas Permeability | Impermeable to gases | Suitable for vacuum applications |

| 3. Optical Properties | ||

| Transmission Range | 260nm – 3500nm | Covers UV, visible, and IR regions |

| IR Transmittance | >80% | Paired testing throughout operational range |

| Refractive Index | 1.46 at 589.3nm | At 25°C |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ /°C | 20-300°C range |

| Maximum Operating Temperature | 1100°C | Continuous use |

Size Chart

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2010 | 350μl IR quartz cuvette | 300nm-3500nm | 1mm | 350μl | >80% (Paired Testing) | 12.5×3.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2011 | 700μl IR quartz cuvette | 300nm-3500nm | 2mm | 700μl | >80% (Paired Testing) | 12.5×4.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2011-1 | 700μl Infrared quartz cuvette | 300nm-3500nm | 5mm | 700μl | >80% (Paired Testing) | 12.5×4.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2012 | 1.75ml IR quartz cuvette | 300nm-3500nm | 5mm | 1.75ml | >80% (Paired Testing) | 12.5×7.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2002 | 3.5ml IR quartz cuvette | 260nm-3500nm | 10mm | 3.5ml | >80% (Paired Testing) | 12.5×12.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2009 | 7ml IR quartz cuvette | 300nm-3500nm | 20mm | 7ml | >80% (Paired Testing) | 12.5×22.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2006 | 10.5ml IR quartz cuvette | 300nm-3500nm | 30mm | 10.5ml | >80% (Paired Testing) | 12.5×32.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2007 | 14ml IR quartz cuvette | 260nm-3500nm | 40mm | 14ml | >80% (Paired Testing) | 12.5×42.5x45mm |

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-2007-1 | 18ml IR quartz cuvette | 260nm-3500nm | 50mm | 18ml | >80% (Paired Testing) | 12.5×52.5x45mm |

TOQUARTZ® Solving Critical Challenges with Two Optical Windows Infrared Quartz Cuvettes

Two Optical Windows Infrared Quartz Cuvette for FTIR Spectroscopy

Key Advantages

-

Matched Pair Transmission Deviation ≤1.2%

Paired cuvettes are calibrated to ensure transmission deviation stays within 1.2% across 260–3500nm. -

Baseline Drift Reduction by 35%

Optical windows are polished to λ/10 flatness, minimizing baseline noise in FTIR scans by up to 35%. -

Leach-Free SiO₂ ≥99.995% Composition

No detectable leaching (<0.01 ppm) into DMSO and methanol after 72h exposure at 25°C.

TOQUARTZ® solution

A German FTIR instrument manufacturer reported baseline instability due to inconsistent cuvette transmission, causing ±0.03 absorbance unit drift. After switching to TOQUARTZ® Two Optical Windows Infrared Quartz Cuvettes with ≤1.2% matched transmission deviation and λ/10 optical polish, their baseline drift dropped by 38%, improving calibration repeatability and reducing recalibration frequency from weekly to monthly.

Two Optical Windows Infrared Quartz Cuvette for Pharmaceutical Analysis

Key Advantages

-

Solvent Compatibility Validated to 96h

Cuvettes maintain optical clarity after 96h exposure to acetonitrile, DMSO, and ethanol at 40°C. -

Evaporation Loss <0.5% in 24h

Sealed-top design with PTFE cap limits sample evaporation to <0.5% at 25°C, 50% RH. -

Spectral Noise Reduction by 28%

Surface roughness Ra ≤0.01μm reduces stray light, improving signal-to-noise ratio in trace compound detection.

TOQUARTZ® solution

A Japanese pharmaceutical R&D lab required 30mm pathlength cuvettes for low-concentration compound analysis in DMSO. Previous suppliers failed to meet evaporation control and optical clarity standards. TOQUARTZ® delivered sealed Two Optical Windows Infrared Quartz Cuvettes with <0.5% evaporation loss and Ra ≤0.01μm polish, enabling a 22% increase in detection sensitivity and reducing sample prep time by 18%.

Two Optical Windows Infrared Quartz Cuvette for Environmental Testing

Key Advantages

-

Pathlength Options from 1mm to 50mm

Supports 9 standard pathlengths with ±0.1mm tolerance, enabling accurate detection across concentration ranges. -

Impact Resistance ≥350MPa Flexural Strength

Cuvettes withstand field transport and handling with no microfracture under 10kg drop test. -

Transmission Stability ΔT <0.5% After 100 Cycles

Thermal cycling from -10°C to 80°C shows <0.5% change in IR transmission at 1000nm.

TOQUARTZ® solution

A U.S. environmental testing agency faced 18% cuvette rejection due to pathlength deviation >±0.2mm and breakage during field use. TOQUARTZ® supplied 20mm and 30mm cuvettes with ±0.1mm tolerance and 350MPa flexural strength. After 3 months of field deployment, rejection rate dropped to 1.2%, and remeasurement frequency was reduced by 40%, improving lab throughput.

Customization Services for TOQUARTZ® Two Optical Windows Infrared Quartz Cuvette

Custom Dimensions

TOQUARTZ® can manufacture Two Optical Windows Infrared Quartz Cuvettes with non-standard dimensions, including custom path lengths, heights, and widths to fit specialized instruments or sample volumes.

- Custom path lengths

- Special heights for unique instrument compatibility

- Modified wall thickness for thermal applications

Specialized Closures

We offer various closure options for Two Optical Windows Infrared Quartz Cuvettes, including custom-designed PTFE caps, screw-top systems, and specialized sealing mechanisms for volatile or sensitive samples.

- Airtight PTFE stoppers

- Screw-cap systems for secure sealing

- Flow-through designs with inlet/outlet ports

Special Surface Treatments

We can apply specialized optical coatings and surface treatments to Two Optical Windows Infrared Quartz Cuvettes to enhance performance for specific applications.

- Anti-reflection coatings for improved transmission

- Hydrophobic surface treatments

- Special polishing for enhanced optical clarity

Custom Engineering Process

Requirements Consultation

Detailed discussion of application needs and technical specifications.

Technical Design

Our engineers develop technical drawings and specifications.

Prototype Production

Initial sample manufacturing and quality testing.

Production & Delivery

Full-scale manufacturing with comprehensive QC.

Usage Guide of Two Optical Windows Infrared Quartz Cuvette

Handling Instructions

- Always handle cuvettes by the non-optical sides or top edges to avoid fingerprints on optical windows.

- Use powder-free gloves when handling cuvettes to prevent contamination.

- Avoid dropping or applying mechanical stress to prevent micro-cracks that may affect optical performance.

- Allow cuvettes to gradually acclimate to temperature changes to prevent thermal shock.

Cleaning Procedures

- Rinse with appropriate solvent immediately after use to prevent sample residue from drying.

- For stubborn residues, soak in dilute laboratory detergent solution followed by thorough rinsing.

- For optical window cleaning, use spectroscopic-grade solvents and lint-free optical wipes.

- Air dry or use oil-free compressed air to remove dust particles before storage.

Storage Recommendations

- Store in original protective case or dedicated cuvette holders to prevent dust accumulation and physical damage.

- Keep in a dry environment to prevent mineral deposits from forming on optical surfaces.

- For long-term storage, ensure cuvettes are thoroughly clean and completely dry.

Usage Tips

- Run baseline measurements before sample analysis to account for any cuvette-specific optical characteristics.

- For thermal applications, implement gradual temperature ramping to prevent thermal stress.

- Use matched pairs of cuvettes for differential measurements to minimize baseline variations.

- Maintain consistent orientation in instrument holders for reproducible measurements.

Need Expert Guidance for Your Two Optical Windows

Infrared Quartz Cuvette Project?

With direct factory pricing and no minimum order quantities, we make high-quality infrared analysis accessible.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: Can quartz cuvettes be used for infrared spectroscopy?

A: Yes, TOQUARTZ® Two Optical Windows Infrared Quartz Cuvettes are specifically designed for infrared spectroscopy applications. Our high-purity fused quartz material offers excellent transmission in the 260nm-3500nm range, making it suitable for UV, visible, and infrared spectral analysis. The precision-ground optical windows ensure accurate and consistent measurements throughout the IR spectrum.

Q: What is the typical path length of an IR quartz cuvette?

A: The typical path lengths for Two Optical Windows Infrared Quartz Cuvettes range from 1mm to 50mm. Standard path lengths include 1mm, 2mm, 5mm, 10mm, 20mm, 30mm, 40mm, and 50mm. The selection depends on your sample’s concentration and absorption characteristics. For highly absorbing samples, shorter path lengths (1-5mm) are recommended, while dilute samples benefit from longer path lengths (10-50mm) to enhance sensitivity. TOQUARTZ® also offers custom path lengths to meet specific analytical requirements.

Q: What is the difference between quartz and glass cuvettes for IR applications?

A: Quartz cuvettes offer superior infrared transmission compared to standard glass cuvettes. While glass typically absorbs infrared radiation above 2500nm, our Two Optical Windows Infrared Quartz Cuvettes transmit light up to 3500nm, allowing for a broader spectral analysis range. Quartz also provides better chemical resistance, higher temperature tolerance (up to 1100°C), and improved durability. These properties make quartz cuvettes essential for accurate infrared spectroscopy, especially when analyzing samples in aggressive solvents or at elevated temperatures.

Q: Can I use the same Two Optical Windows Infrared Quartz Cuvette for both UV and IR analysis?

A: Yes, TOQUARTZ® Two Optical Windows Infrared Quartz Cuvettes offer exceptional transparency across a wide spectrum from 260nm (UV) to 3500nm (mid-IR). This broad transmission range allows scientists to use a single cuvette for multiple spectroscopic techniques, including UV-Vis and FTIR, without changing sample containers. This multi-wavelength compatibility streamlines analytical workflows, reduces sample handling, and ensures consistent measurement conditions across different spectral regions.

Q: How do I clean an IR quartz cuvette?

A: Clean Two Optical Windows Infrared Quartz Cuvettes by first rinsing with an appropriate solvent compatible with your sample to remove residues. For thorough cleaning, use mild laboratory detergent solutions followed by multiple rinses with distilled water. For optical windows, use spectroscopic-grade solvents like acetone or methanol and lint-free optical wipes. Avoid abrasive materials that could scratch the optical surfaces. Always handle by the non-optical sides and allow to completely air dry before storage.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.