- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz UV Cuvette

- /

- Optically Matched UV Quartz...

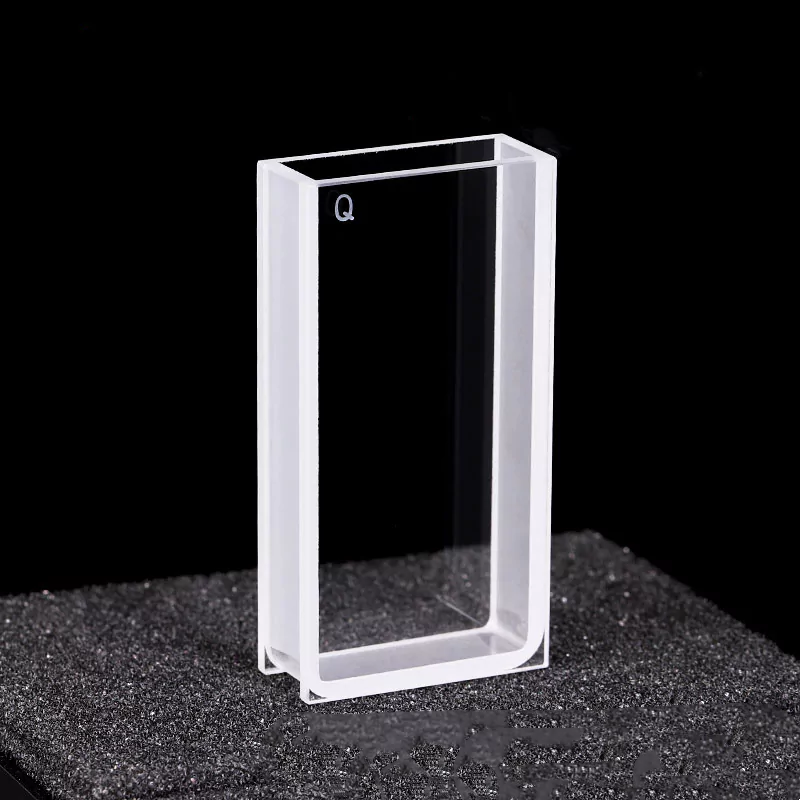

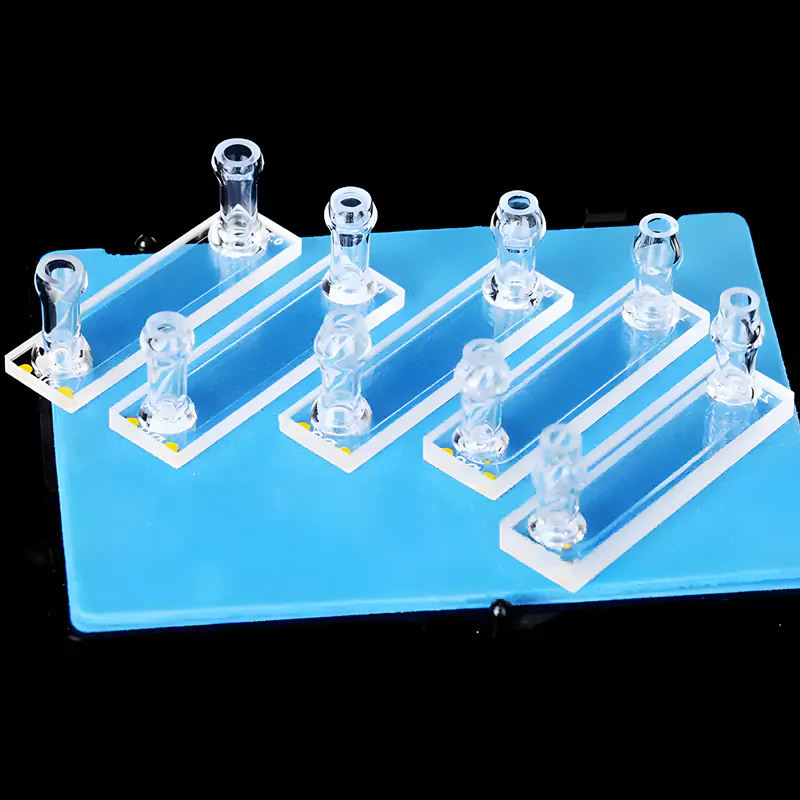

Optically Matched UV Quartz Cuvette for Colorimetric Analysis in Spectrophotometry -TOQUARTZ®

Features of UV Quartz Cuvette for Colorimetric Analysis

TOQUARTZ® UV Quartz Cuvettes are engineered from high-purity fused quartz, providing superior optical performance for precise colorimetric analysis. Each cuvette delivers exceptional chemical resistance, thermal stability, and optical transparency in both UV and visible light ranges.

Material Properties

- High Purity: ≥99.98% SiO₂ composition for reliable analytical results

- Chemical Resistance: Stable against acids, bases, organic solvents and salt solutions

- Thermal Stability: Operational up to 1100°C with low thermal expansion coefficient (5.5×10⁻⁷/°C)

- Mechanical Strength: High fracture modulus of 350MPa+ for durability

Optical Properties

- UV Transparency: Excellent transmission from 200nm to 2500nm wavelength range

- No Absorption Peaks: Clean spectral profile throughout UV-Vis range

- Surface Quality: Polished to optical grade with no bubbles or scratches

- Path Length Precision: Manufactured to ±0.1mm tolerance for accurate measurements

- SiO₂ content max. up to 99.995%

- Customizable design for specific requirements

- Tight dimensional tolerances (±0.1mm)

Technical Specifications & Dimensions of UV Quartz Cuvette for Colorimetric Analysis

Technical Specifications

| Property | Specification | Test Method |

| Material | Fused Quartz (≥99.98% SiO₂, max. up to 99.995%) | XRF Analysis |

| Chemical Resistance | Resistant to acids, bases, salts | Immersion Testing |

| Thermal Expansion | 5.5×10⁻⁷/°C | Dilatometry |

| Max Operating Temp. | 1100°C | Thermal Resistance Test |

| Wavelength Range | 200nm – 2500nm | Spectrophotometry |

| UV Transmission (200nm) | ≥80% | UV-Vis Spectrophotometry |

| Surface Quality | Optical grade, no bubbles/scratches | Visual Inspection |

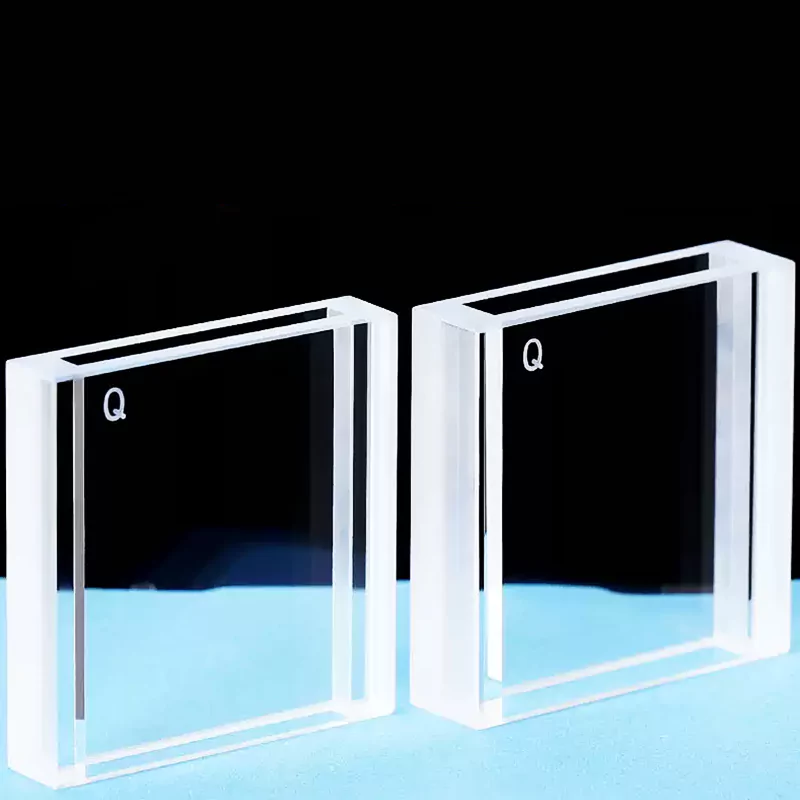

| Paired Matching | >80% transmission matching | Comparative Spectrophotometry |

Size Chart

| Model | Description | Wavelength | Volume | Path Length | Thermostability | OD.xHeight |

| AT-BSM-038 | UV Quartz Cuvette for Colorimetric Analysis | 200nm-2500nm | 16ml | 10mm | >80% (Paired Testing) | 32x14x62.5mm |

TOQUARTZ® Solutions for Precision Colorimetric Analysis Challenges with

UV Quartz Cuvette

UV Quartz Cuvette for Cosmetic Color Consistency Testing

Key Advantages

-

Solvent-resistant surface integrity

No surface degradation after 72h immersion in ethanol-based emulsions at 25°C. -

UV-visible clarity for pigment emulsions

Maintains ≥85% transmission at 280nm in titanium dioxide and iron oxide suspensions. -

Batch-to-batch ΔE stability

Paired cuvettes ensure ΔE variation <0.5 in foundation color matching tests.

TOQUARTZ® solution

A Korean cosmetics OEM faced 17% batch rejection due to ΔE drift >1.2 using glass cuvettes. After switching to TOQUARTZ UV Quartz Cuvettes, ΔE deviation dropped to <0.4 across 10 batches. The cuvettes maintained optical clarity after 50+ cleaning cycles with ethanol and surfactant blends. This reduced color rework costs by 22% and improved first-pass QC approval rate to 96%.

UV Quartz Cuvette for Beverage Color Grading in Quality Control

Key Advantages

-

Stable absorbance in 280–400nm range

<±0.002 AU baseline drift in anthocyanin-rich juice samples over 30 minutes. -

Acid fogging resistance

No surface etching after 48h exposure to citric acid (pH 3.2) at 40°C. -

Low pigment adsorption rate

<0.5% absorbance deviation after 10 repeated tests with tannin-rich tea infusions.

TOQUARTZ® solution

A German beverage QC lab reported inconsistent color grading in berry juice due to cuvette fogging. TOQUARTZ UV Quartz Cuvettes maintained baseline stability within ±0.0015 AU at 320nm. After 60 test cycles with pH 3.0 samples, no visible surface haze or absorbance shift was observed. This improved grading reproducibility by 28% and reduced false rejection of compliant batches.

UV Quartz Cuvette for Ink and Dye Color Matching in Industrial Formulation

Key Advantages

-

Solvent compatibility with dye carriers

No structural change after 24h immersion in 99.5% DMF and DMSO at 60°C. -

Path length uniformity for ΔE control

Paired cuvettes maintain ±0.05mm path length tolerance, ensuring ΔE<0.3 in cyan ink tests. -

Low spectral noise in 220–600nm

<0.001 AU absorbance fluctuation across 5 repeated scans of azo dye solutions.

TOQUARTZ® solution

A Japanese inkjet ink producer experienced ΔE mismatch >0.6 due to cuvette path length variation. TOQUARTZ supplied matched-pair UV Quartz Cuvettes with certified ±0.05mm tolerance. In 100 production runs, color deviation was controlled within ΔE<0.3, meeting ISO 12647-2 standards. This reduced reformulation frequency by 35% and improved color matching efficiency by 21%.

Customization Services for TOQUARTZ® UV Quartz Cuvette for

Colorimetric Analysis

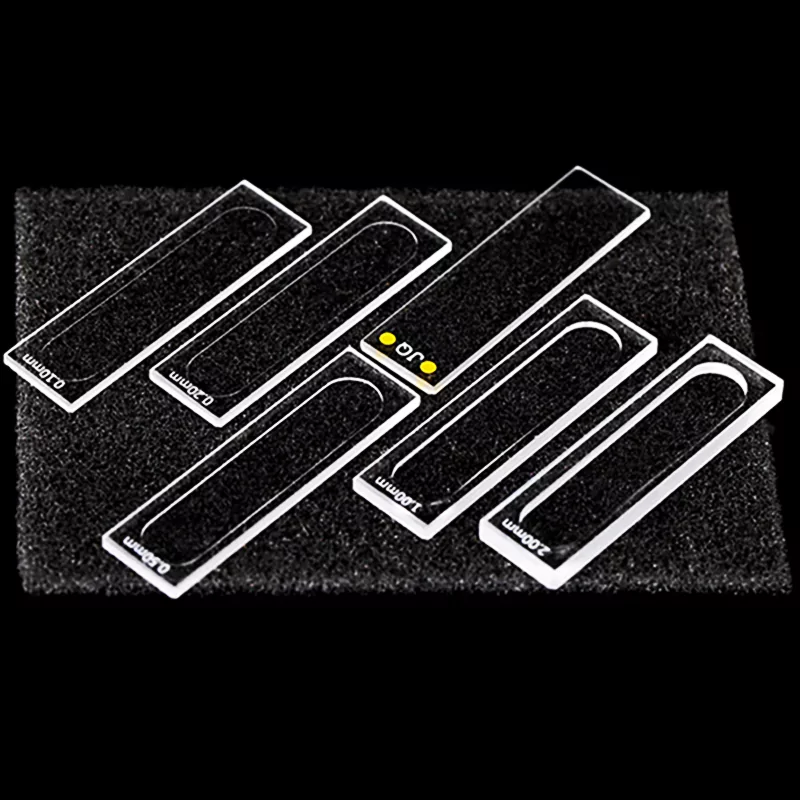

Custom Dimensions

- Non-standard path lengths

- Custom internal volumes for small sample analysis

- Specialized external dimensions for proprietary instruments

- Precision machining to ±0.1mm tolerance

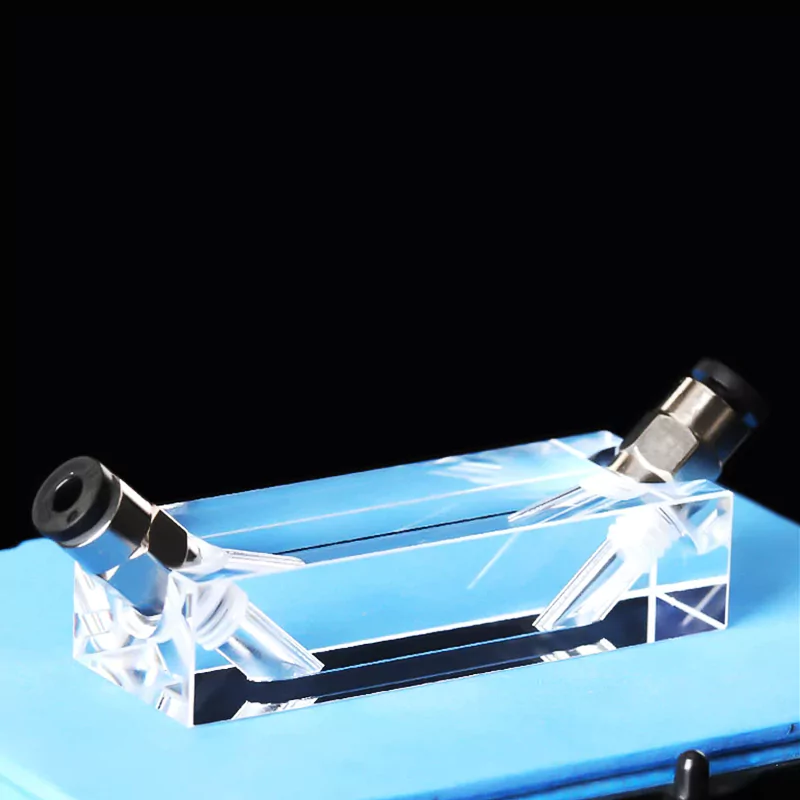

Specialized Features

- Integrated flow systems for continuous monitoring

- Custom lid/cap designs for volatile samples

- Black wall options for fluorescence applications

- Micro-volume designs for precious samples

Production Support

- Engineer collaboration for design optimization

- Technical drawing assistance

- Rapid prototyping and sample production

- Small batch orders

Usage Guide of UV Quartz Cuvette for Colorimetric Analysis

Proper Handling and Cleaning

- Always handle with care: Use gloves or finger cots to avoid fingerprints and contamination on optical surfaces.

- Initial cleaning: Rinse with distilled water, followed by laboratory-grade acetone or methanol, then rinse again with distilled water.

- For organic residues: Use mild detergent solution followed by thorough rinsing with distilled water.

- For stubborn contaminants: Soak in 1:1 mixture of concentrated HCl and methanol for 30 minutes, then rinse thoroughly (wear appropriate protection).

- Drying: Air dry in a dust-free environment or use filtered compressed air. Never wipe optical surfaces with paper towels or cloth.

Storage and Maintenance

- Storage conditions: Store clean, dry cuvettes in original packaging or dedicated cuvette holders in a dust-free environment.

- Temperature considerations: Avoid rapid temperature changes that could cause thermal stress and cracking.

- Regular inspection: Periodically check for scratches, chips, or internal residue under good lighting.

- Performance verification: Periodically test transmission properties with standard solutions to ensure consistent performance.

- Avoid mechanical stress: Never force cuvettes into holders or apply uneven pressure during handling.

Best Practices for Accurate Measurements

- Orientation consistency: Mark cuvettes and always use the same orientation in the instrument to ensure reproducibility.

- Temperature equilibration: Allow samples to reach the same temperature as the instrument before measurement.

- Bubbles elimination: Gently tap the cuvette to remove air bubbles that can interfere with light path.

- Sample filling: Fill to appropriate level, typically 2/3 to 3/4 of the cuvette height, avoiding the meniscus in the optical path.

- Handle optical faces only: Touch only the frosted or non-optical sides of the cuvette during handling.

Need Technical Assistance with UV Quartz Cuvette Specifications?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: Why use quartz cuvettes for colorimetric analysis?

A: Quartz cuvettes are preferred for colorimetric analysis because they:

· Transmit light across both UV and visible spectra (200-2500nm)

· Have no absorption peaks that could interfere with measurements

· Offer excellent chemical resistance to most solvents and reagents

· Provide superior durability and temperature stability

· Maintain consistent optical properties over time

· Can be manufactured to precise dimensional tolerances

These properties ensure accurate, reproducible measurements essential for quantitative colorimetric analysis across various applications.

Q: How to clean a quartz cuvette for accurate color measurement?

A: Proper cleaning is essential for accurate measurements. Follow these steps:

1. Immediately rinse with distilled water after use to prevent sample drying

2. For most samples, rinse with an appropriate solvent (often acetone or methanol)

3. Follow with multiple rinses of distilled/deionized water

4. For persistent residues, soak in 1:1 HCl:methanol solution (with proper safety precautions)

5. Rinse thoroughly with distilled water

6. Allow to air dry in a dust-free environment or use filtered air

7. Never wipe optical surfaces with cloth, tissues, or paper towels

8. Store in a clean, dust-free container

Always handle cuvettes by the frosted or non-optical sides to prevent fingerprints on measurement surfaces.

Q: How does TOQUARTZ® UV Quartz Cuvette ensure optical matching between cuvette pairs for ΔE-sensitive colorimetric analysis?

A: TOQUARTZ® UV Quartz Cuvette performs paired transmission testing at 280nm and 420nm to ensure optical path consistency. Each cuvette pair is matched within ±0.002 AU absorbance difference, which supports ΔE<0.5 reproducibility in high-precision color grading applications such as cosmetics and ink formulation.

Q: Can TOQUARTZ UV Quartz Cuvettes be used with emulsified or oil-based cosmetic samples without affecting transmission accuracy?

A: Yes. TOQUARTZ UV Quartz Cuvettes are tested for compatibility with oil-in-water and water-in-oil emulsions. The fused quartz surface resists adsorption of lipophilic compounds, maintaining ≥85% transmission at 280nm after 50 cleaning cycles with ethanol and surfactant-based cleansers.

Q: What is the minimum detectable absorbance variation TOQUARTZ cuvettes can support in beverage color grading?

A: TOQUARTZ® UV Quartz Cuvettes exhibit baseline drift of less than ±0.0015 AU in the 280–400nm range, enabling detection of subtle pigment concentration changes (e.g., 0.2–0.5 ppm anthocyanin variation) in juice and tea products. This level of stability is critical for automated grading systems.

Q: How does TOQUARTZ handle solvent compatibility for dye and pigment testing in industrial applications?

A: TOQUARTZ® UV Quartz Cuvettes are validated for use with aggressive solvents such as DMF, DMSO, ethanol, and acetone. No microcracking, fogging, or absorbance shift was observed after 24h immersion at 60°C. This ensures accurate colorimetric readings in ink and textile dye formulation.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.