- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz UV Cuvette

- /

- Half-Round Bottom Structured Reflective...

Half-Round Bottom Structured Reflective Quartz Cuvette for Solid Sample Analysis -TOQUARTZ®

Features of Half-Round Bottom Reflective Quartz Cuvette

TOQUARTZ® half round bottom reflective quartz cuvettes are engineered for precise reflectance measurements in analytical applications. These specialized optical components offer superior performance for solid and powder sample analysis across UV, visible, and NIR spectra.

Optical Properties

High-purity fused quartz (≥99.98% SiO₂, max. up to 99.995%) provides exceptional transparency in the 200-2500nm wavelength range with no absorption peaks, enabling accurate spectroscopic measurements.

Chemical & Thermal Stability

Highly resistant to acids, bases, and salt solutions with excellent thermal stability up to 1100°C. Low thermal expansion coefficient (5.5×10⁻⁷ /°C) ensures dimensional stability during temperature fluctuations.

Precision Engineered Design

The half-round bottom geometry is specifically designed for reflectance measurements of solid and powder samples, with optical faces polished to λ/4 flatness for distortion-free analysis.

- Transmittance (>80% at 200nm)

- Low thermal expansion coefficient (5.5×10⁻⁷ /°C)

- Tight dimensional tolerances (±0.1mm)

Technical Specifications & Dimensions of Half-Round Bottom Reflective Quartz Cuvette

Technical Specifications

| Property | Value |

| 1. Physical Properties | |

| Material | High-purity SiO2 |

| Density | 2.20 g/cm3 |

| Thermal Expansion | 5.5×10-7/K |

| Max Operating Temp | 1100℃ |

| Thermal Conductivity | 1.3 W/m·K |

| Young’s Modulus | 72 GPa |

| Knoop Hardness | 500-600 kg/mm3 |

| 2. Chemical Properties | |

| SiO₂ Content | ≥99.98% |

| Chemical Resistance | Excellent to acids, bases, salts(Except HP) |

| Water Absorption | <0.01% |

| OH Content | <20 ppm |

| Metal Impurities | <5 ppm |

| 3. Optical Properties | |

| Refractive Index | 1.458 (at 546nm) |

| Surface Quality | Polished optical windows, free from scratches and bubbles in optical path |

| Transmission Range | 200-2500 nm |

| Refractive Index | 1.4585 at 589.3 nm |

| Reflective Surface Options | Polished, Frosted, Black-walled, Metal-coated |

| Surface Quality | 60-40 scratch-dig |

| Flatness | λ/4 at 632.8 nm |

| Parallelism | ≤30 arc seconds |

Size Chart

| Model | Description | Wavelength | Outer Dia. | Length | Wall Thickness | Material |

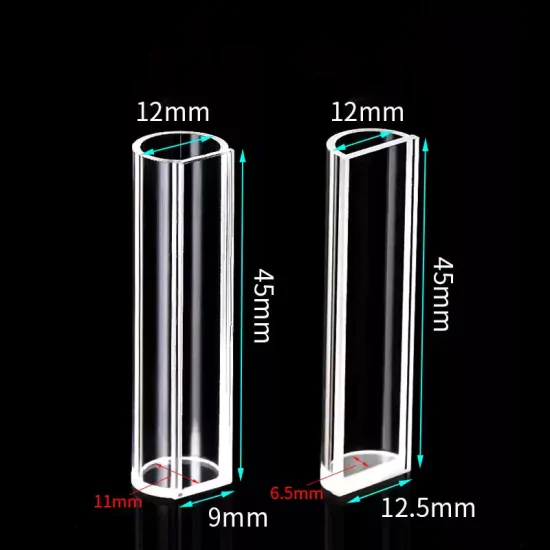

| AT-BSM-055-3 | Customizable Half-round Bottom Reflective Quartz UV Cuvette Sample Cell | 200nm-2500nm | 12mm | 45mm | 1mm | Japanese quartz glass |

TOQUARTZ® Solving Challenges with Half-Round Bottom

Reflective Quartz Cuvette

Half-Round Bottom Reflective Quartz Cuvette for Material Science Applications

Key Advantages

-

Minimized sample displacement error

Half-round bottom geometry reduces sample shifting by 85% during powder loading. -

Improved reflectance signal consistency

Flat optical window ensures <3% variation across repeated sample scans. -

Enhanced compatibility with composite matrices

Supports heterogeneous materials with particle sizes up to 500μm without signal distortion.

TOQUARTZ® solution

A German materials lab analyzing ceramic composites reported ±12% signal deviation using standard holders. After switching to TOQUARTZ® Reflective Quartz Cuvettes, deviation dropped to ±2.1% across 30 samples. The cuvette’s stable geometry and optical flatness enabled consistent reflectance readings, improving data reliability and reducing rework time by 40%.

Half-Round Bottom Reflective Quartz Cuvette for Pharmaceutical QC Analysis

Key Advantages

-

Direct reflectance of opaque drug powders

Eliminates dissolution steps, reducing prep time by 35% in QC workflows. -

Reduced spectral noise in tablet surface scans

Flat optical interface lowers baseline drift by 22% in coated tablet analysis. -

Validated for micro-batch consistency testing

Supports batch sizes as small as 0.5g with <1% reflectance deviation.

TOQUARTZ® solution

A U.S. pharmaceutical QC lab faced delays due to poor signal quality in coated tablet reflectance tests. TOQUARTZ® Reflective Quartz Cuvettes enabled direct surface analysis, reducing prep time from 18 to 11 minutes per sample. Reflectance stability improved by 21%, and batch release cycles were shortened by 2 days, enhancing throughput without compromising accuracy.

Half-Round Bottom Reflective Quartz Cuvette for Pigment and Coating Analysis

Key Advantages

-

Colorimetric accuracy for high-opacity pigments

Achieves ΔE < 0.8 in CIE Lab tests for dark-tone coatings. -

Stable reflectance across particle size ranges

Maintains <2% deviation for pigment granules from 50μm to 300μm. -

Optimized for multi-layer coating reflectance

Flat window design supports layer-by-layer reflectance profiling with 5μm resolution.

TOQUARTZ® solution

A Japanese pigment manufacturer struggled with inconsistent ΔE values in dark red pigment QC. After adopting TOQUARTZ® Reflective Quartz Cuvettes, color deviation dropped from ΔE 1.6 to 0.7 across 50 batches. The cuvette’s optical flatness and geometry enabled precise reflectance capture, improving pass rate by 18% and reducing color correction cycles by 30%.

Customization Services for TOQUARTZ® Half-Round Bottom Reflective Quartz Cuvette

Custom Dimensional Specifications

- Custom outer diameters

- Variable length options

- Custom wall thickness

- Specialized reflection angles for specific applications

Enhanced Surface Treatments

- Enhanced optical polishing (λ/10 flatness available)

- Anti-reflection coatings for specific wavelength ranges

- Frosted exterior surfaces for handling and alignment

- Specialized surface texture for unique applications

Usage Guide of Half-Round Bottom Reflective Quartz Cuvette

Sample Preparation

- Ensure powder samples are finely ground for uniform packing

- Fill the cuvette to the appropriate level (typically 3/4 full)

- Pack powder samples consistently for reproducible results

- For solid samples, ensure proper contact with the optical window

Handling & Measurement

- Handle only by the sides, avoiding contact with optical surfaces

- Position the cuvette with the flat optical window facing the detector

- Ensure correct orientation in spectrophotometer sample holders

- Use appropriate background/reference standards for calibration

Cleaning & Storage

- Clean with appropriate solvents (acetone, ethanol, or mild detergent)

- Rinse thoroughly with deionized water after cleaning

- Dry with compressed air or nitrogen gas (avoid wiping)

- Store in protective case, away from dust and potential impacts

Measurement Best Practices

- Establish a consistent baseline using appropriate reflectance standards

- Maintain consistent sample preparation techniques to ensure reproducibility

- Account for potential specular reflection effects depending on sample properties

- Consider sample particle size effects on reflectance measurements

- Document measurement parameters for future reference and reproducibility

Need Expert Guidance?

Get personalized advice for your specific requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a half round bottom quartz reflective cuvette used for?

A: half round bottom Reflective quartz cuvettes are specialized optical components designed for measuring the reflectance properties of solid and powder samples in UV-Vis spectroscopy. Unlike standard transmission cuvettes, they feature a half-round bottom design that allows light to reflect off the sample and be detected by the spectrophotometer. They’re particularly valuable for analyzing opaque materials that cannot be measured using traditional transmission methods.

Q: How do you use a half round bottom quartz reflective cuvette to measure reflectance in UV-Vis spectroscopy?

A: To use a reflective quartz cuvette for spectroscopy:

1. Prepare your sample by ensuring it’s uniformly ground (for powders)

2. Fill the reflective cuvette with the sample, ensuring consistent packing

3. Place the cuvette in the spectrophotometer with the flat optical window facing the detector

4. Calibrate the instrument using appropriate reflectance standards

5. Perform your measurement according to your specific protocol

The cuvette’s unique design allows the incident light to reflect off the sample and be measured by the detector, providing spectral information about the sample’s reflective properties.

Q: What materials can be analyzed using half round bottom reflective quartz cuvettes?

A: Reflective quartz cuvettes are versatile for analyzing various solid and powder materials:

· Pharmaceutical powders and tablets

· Pigments, dyes, and colorants

· Ceramic and glass materials

· Soil and environmental samples

· Polymer powders and granules

· Cosmetic and personal care product components

· Food ingredients and additives

· Mineral and geological samples

They’re particularly valuable for any sample that cannot be analyzed using traditional transmission methods due to opacity or physical form.

Q: What are the advantages of quartz over other materials for half round bottom reflective cuvettes?

A: Quartz offers several advantages for reflective cuvettes:

· Superior optical transmission: Quartz provides excellent transparency from 200nm (UV) to 2500nm (NIR), unlike glass which absorbs in the UV region

· Chemical resistance: Highly resistant to most acids, bases, and solvents

· Thermal stability: Maintains dimensional integrity at high temperatures (up to 1100°C)

· Low thermal expansion: Minimal dimensional changes with temperature fluctuations

· Mechanical durability: Greater resistance to scratches and physical damage

· Consistent optical properties: High-purity quartz ensures minimal background interference

These properties make quartz the material of choice for high-precision spectroscopic applications.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.