- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz UV Cuvette

- /

- Reflectance-Tailored Reflective Quartz UV...

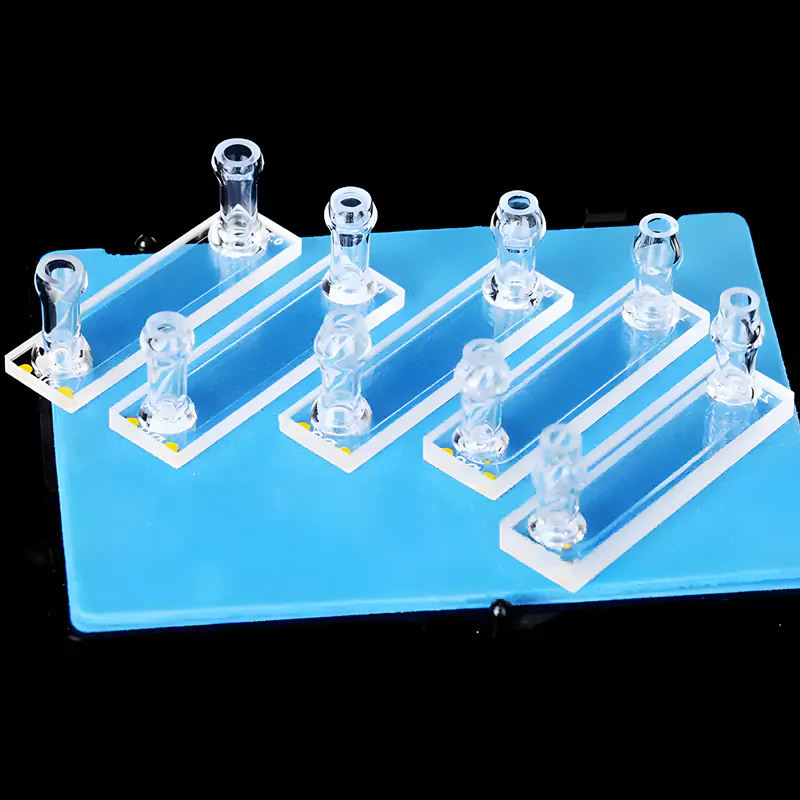

Reflectance-Tailored Reflective Quartz UV Cuvette for Analytical Instruments -TOQUARTZ®

Features of Reflective Quartz UV Cuvette

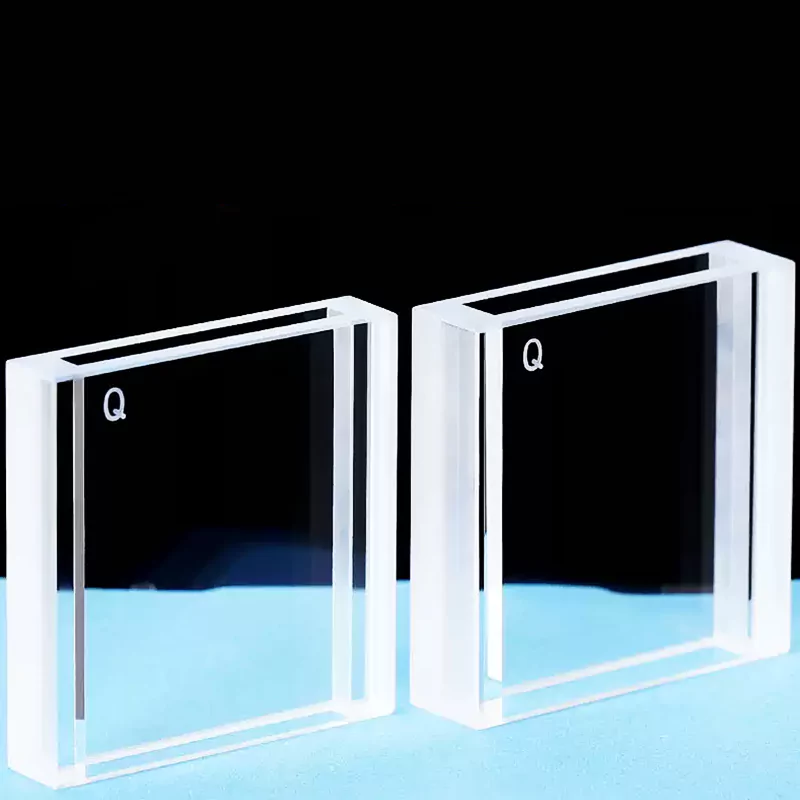

TOQUARTZ® Reflective Quartz UV Cuvettes combine precision optical design with superior material properties, delivering exceptional performance for reflectance spectroscopy and material analysis applications. Each cuvette is manufactured to exacting standards, ensuring consistent results in your most demanding analytical procedures.

Material Properties

-

Exceptional Material Purity:

Manufactured from high-purity fused quartz (≥99.995% SiO₂) ensuring minimal background interference -

Thermal Stability:

Withstands temperatures up to 1100°C with low thermal expansion coefficient (≤5.5×10⁻⁷/K) -

Chemical Resistance:

Exceptional stability against acids, bases, and most aggressive chemicals

Optical Properties

-

Optical Transparency:

Excellent transmission in the 200nm-2500nm range without absorption peaks -

Precision Optical Surfaces:

Polished to optical standards with high flatness and parallelism -

Customizable Reflective Surfaces:

Available with various reflective properties tailored to specific applications

- Customizable chamber volumes

- Various geometric configurations available

- Multiple path length options

Technical Specifications & Dimensions of Reflective Quartz UV Cuvette

Technical Specifications

| Property | Value |

| 1. Physical Properties | |

| Material | High-purity fused quartz |

| Density | 2.20 g/cm3 |

| Thermal Expansion | 5.5×10-7/K |

| Max Operating Temp | 1100℃ |

| Thermal Conductivity | 1.3 W/m·K |

| Young’s Modulus | 72 GPa |

| Knoop Hardness | 500-600 kg/mm3 |

| 2. Chemical Properties | |

| SiO₂ Content | ≥99.98% |

| Chemical Resistance | Excellent to acids, bases, salts |

| Water Absorption | <0.01% |

| OH Content | <20 ppm |

| Metal Impurities | <5 ppm |

| Gas Impermeability | Excellent |

| 3. Optical Properties | |

| Refractive Index | 1.458 (at 546nm) |

| Surface Quality | Polished optical windows, free from scratches and bubbles in optical path |

| Transmission Range | 200-2500 nm |

| Refractive Index | 1.4585 at 589.3 nm |

| Reflective Surface Options | Polished, Frosted, Black-walled, Metal-coated |

| Surface Quality | 60-40 scratch-dig |

| Flatness | λ/4 at 632.8 nm |

| Parallelism | ≤30 arc seconds |

Size Chart

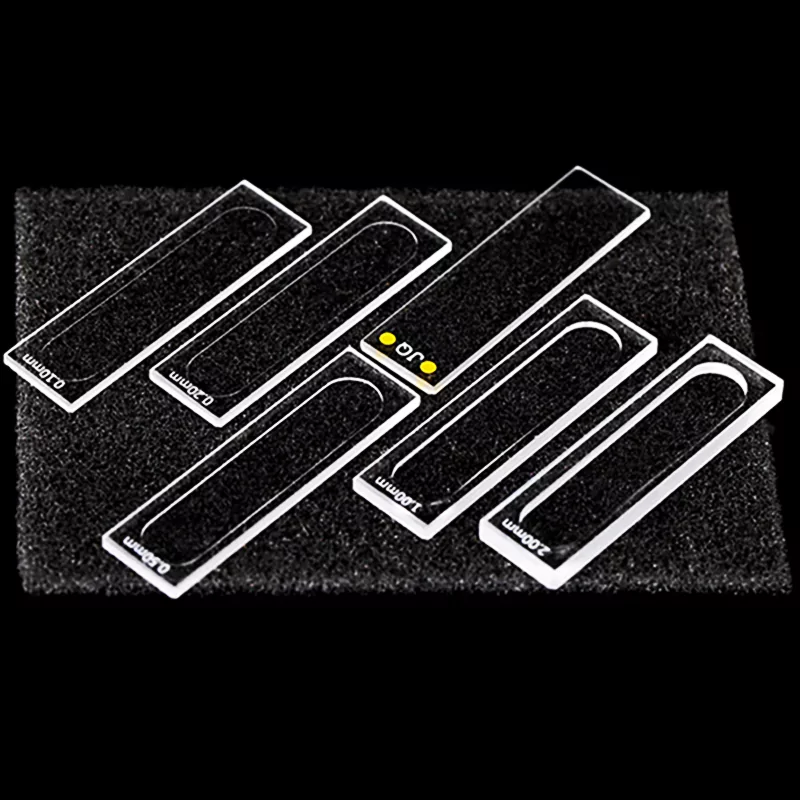

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

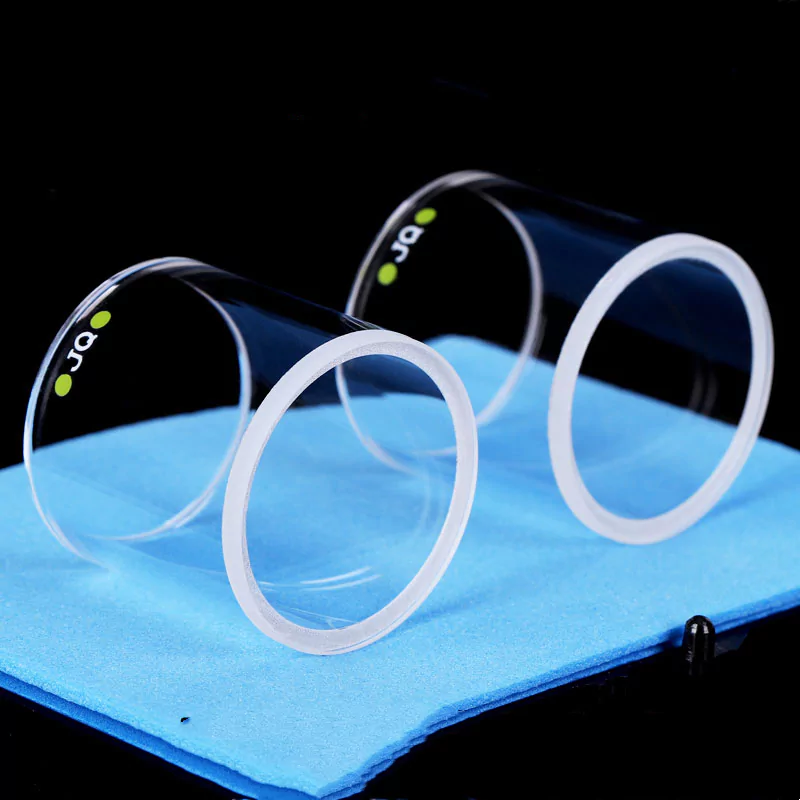

| AT-BSM-054 | 250μl Reflective Quartz UV Cuvette | 200nm-2500nm | 250μl | 1mm | 600℃ | φ7x15mm |

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

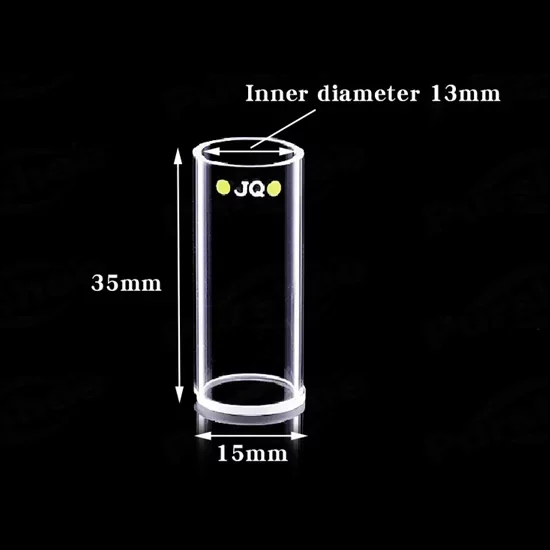

| AT-BSM-055-1 | 3ml Reflective Quartz UV Cuvette | 200nm-2500nm | 3ml | 2mm | 600℃ | φ17x35mm |

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

| AT-BSM-055 | 4.5ml Reflective Quartz UV Cuvette | 200nm-2500nm | 4.5ml | 1mm | 600℃ | φ15x35mm |

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

| AT-BSM-055-4 | 14ml Reflective Quartz UV Cuvette | 200nm-2500nm | 14ml | 2mm | 600℃ | φ30*30mm |

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

| AT-BSM-034 | 14.5ml Reflective Quartz UV Cuvette | 200nm-2500nm | 14.5ml | 1.5mm | 600℃ | φ16x100mm |

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

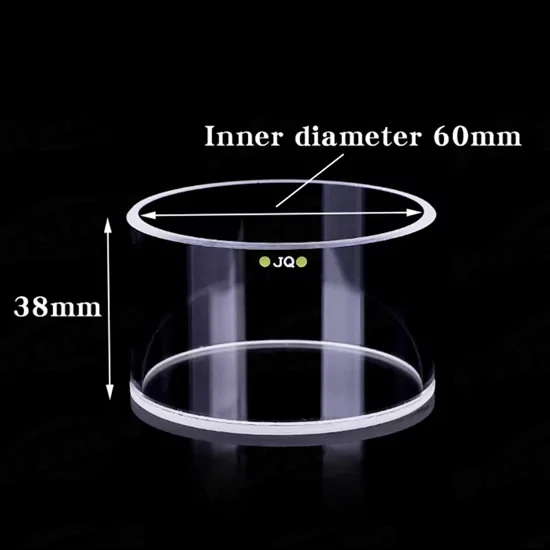

| AT-BSM-051 | 16ml Reflective Quartz UV Cuvette | 200nm-2500nm | 16ml | 2mm | 600℃ | φ29x38mm |

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

| AT-BSM-048 | 20ml Reflective Quartz UV Cuvette | 200nm-2500nm | 20ml | 2mm | 600℃ | φ44x20mm |

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

| AT-BSM-046 | 40ml Reflective Quartz UV Cuvette | 200nm-2500nm | 40ml | 1mm | 600℃ | φ35x50mm |

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

| AT-BSM-041 | 85ml Reflective Quartz UV Cuvette | 200nm-2500nm | 85ml | 2mm | 600℃ | φ64x38mm |

TOQUARTZ® Solving Challenges with Reflective Quartz UV Cuvette

Reflective Quartz UV Cuvettes for Material Science Research

Key Advantages

-

Optimized for low-angle reflectance at 8°–15° incidence

→ Enables accurate surface reflectivity analysis of thin films and coatings. -

Chamber depth tolerance within ±0.05 mm for powder compaction repeatability

→ Ensures consistent sample packing and reproducible reflectance data. -

Reflective surface flatness ≤ λ/10 at 632.8 nm

→ Minimizes signal distortion in high-resolution material characterization.

TOQUARTZ® solution

A German university materials lab required cuvettes for reflectance testing of nano-coated films with <10 nm thickness. TOQUARTZ® delivered custom reflective cuvettes with λ/10 flatness and 10×10 mm optical windows. Compared to previous suppliers, signal deviation was reduced by 38%, and measurement repeatability improved from ±4.2% to ±1.1% across 50 samples.

Reflective Quartz UV Cuvettes for Fluorescence Detection Systems

Key Advantages

-

Black-walled design reduces stray light by >92% in 250–400 nm range

→ Enhances signal-to-noise ratio in low-intensity fluorescence assays. -

Reflective inner surface coated with Al₂O₃ achieves >85% reflectivity at 365 nm

→ Maximizes excitation light return for powder fluorescence detection. -

Custom chamber geometry supports 50–200 µL micro-volume fluorescence samples

→ Enables high-sensitivity detection with minimal reagent consumption.

TOQUARTZ® solution

A Canadian biotech lab used TOQUARTZ® reflective cuvettes for fluorescence detection of rare-earth doped powders. Compared to standard cuvettes, signal intensity increased by 47%, and background noise dropped by 63%. The lab reported a 2.3× improvement in detection limit, enabling trace-level quantification in 100 µL sample volumes.

Reflective Quartz UV Cuvettes for Spectroscopy Equipment

Key Advantages

-

Dimensional tolerance of ±0.03 mm on optical window alignment

→ Ensures seamless integration into automated cuvette holders. -

Batch-to-batch optical transmission variance <1.2% across 200–800 nm

→ Guarantees calibration consistency in mass-produced instruments. -

Custom serial coding and laser marking for traceable inventory

→ Supports quality control and post-sale service traceability.

TOQUARTZ® solution

A U.S.-based spectroscopy manufacturer faced 18% assembly misfit rate due to inconsistent cuvette dimensions from previous suppliers. After switching to TOQUARTZ®, with ±0.03 mm tolerance control and batch-coded cuvettes, misfit rate dropped to <0.5%. This reduced rework costs by $8,400/month and improved instrument calibration pass rate to 99.2%.

Customization Services for TOQUARTZ® Reflective Quartz UV Cuvette

Custom Dimensions

Custom optical window sizes with precise wall thickness and chamber depth to your specifications.

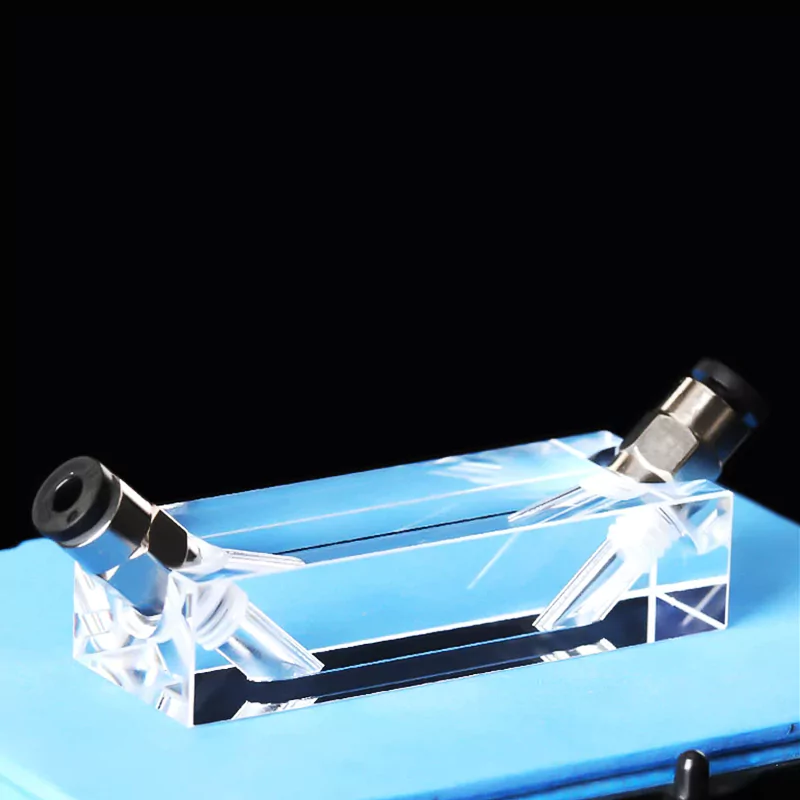

Chamber Configurations

Custom internal geometries for specialized sample types, including powder, film, or liquid analysis requirements.

Optical Path Designs

Modified light paths for unique analytical requirements, including angled windows or specialized reflection geometries.

Usage Guide of Reflective Quartz UV Cuvette

Handling and Cleaning

- Always wear powder-free gloves when handling cuvettes

- Clean using laboratory-grade solvents (ethanol, acetone)

- Use lint-free optical wipes for drying

- Avoid abrasive cleaning materials that may scratch optical surfaces

Storage Recommendations

- Store in original protective packaging when not in use

- Keep in dust-free environment

- Avoid contact with other hard surfaces

- Store at room temperature in low humidity

Sample Loading

- Follow recommended sample volume guidelines

- Ensure proper seating in spectrophotometer holder

- For powder samples, use consistent packing techniques

- Avoid overfilling which may contaminate optical surfaces

Maintenance

- Inspect regularly for scratches or damage

- Recalibrate instruments when switching between cuvette batches

- For long-term storage, apply dust caps to protect optical surfaces

- Return to manufacturer for optical resurfacing if needed

Contact our engineering team for a free consultation on your reflective quartz UV cuvette requirements

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the typical wavelength range for TOQUARTZ® reflective quartz UV cuvettes?

A: TOQUARTZ® reflective quartz UV cuvettes provide excellent optical performance across the 200-2500 nm range, covering UV, visible, and near-infrared regions, making them suitable for a wide range of spectroscopic applications.

Q: What types of samples are best analyzed with reflective quartz UV cuvettes?

A: Reflective quartz UV cuvettes are ideal for powders, solid materials, thin films, opaque liquids, and any samples where reflection properties are of interest. They’re particularly valuable for materials that cannot be analyzed using traditional transmission methods.

Q: Can reflective quartz UV cuvettes be used for both liquid and powder samples?

A: Yes, TOQUARTZ® reflective quartz UV cuvettes can be designed for both liquid and powder samples. Custom chamber configurations are available to optimize performance for specific sample types, including specialized designs for powder packing or liquid containment.

Q: How do I select the appropriate reflective surface type for my application?

A: Selection depends on your specific analytical needs. Options include polished surfaces for specular reflection, frosted surfaces for diffuse reflection, black-walled designs to minimize stray light, and metal-coated surfaces for maximum reflectivity at specific wavelengths. Our technical team can assist with selection.

Q: Can TOQUARTZ® Reflective Quartz UV Cuvettes be used for low-angle reflectance measurements in thin film analysis?

A: Yes, our cuvettes are optimized for low-angle reflectance (8°–15° incidence), making them suitable for precise surface reflectivity testing of thin films and nano-coatings.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.