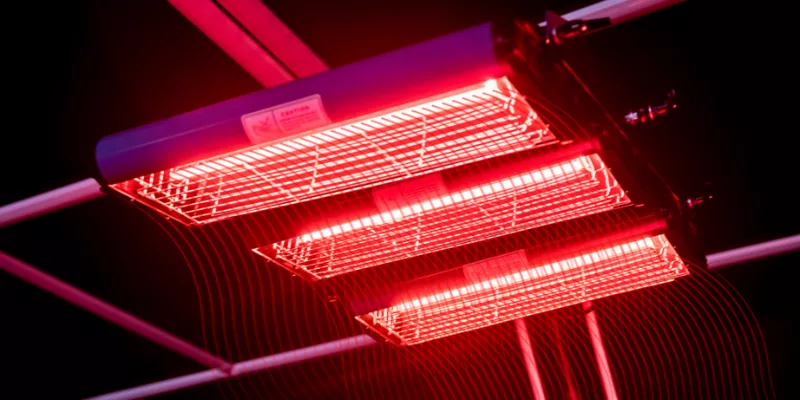

Engineers in high-temperature industries face increasing demands for materials that can withstand extreme heat without deformation or failure.

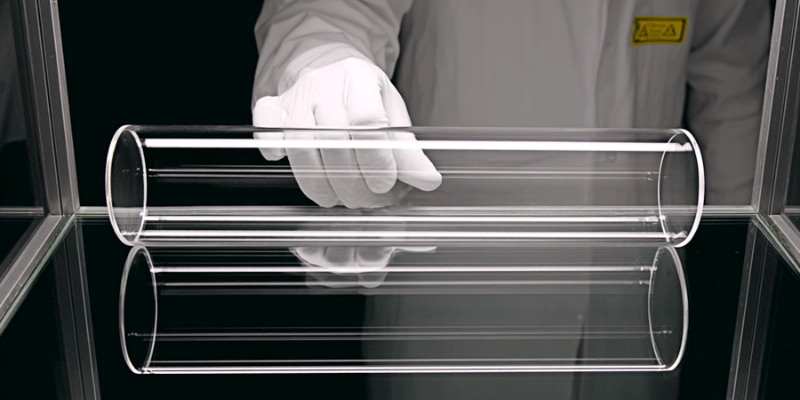

Fused quartz rods deliver exceptional dimensional stability and thermal shock resistance, making them indispensable for semiconductor furnaces, glass tanks, and other critical systems operating up to 1600°C.

This guide provides a technical roadmap for understanding, specifying, and sourcing fused quartz rods for extreme heat applications in 2025.

Fundamental Thermal Properties Enabling High-Temperature Performance

Fused quartz rods are engineered for environments where temperature, purity, and dimensional stability are paramount. Their ultra-low thermal expansion coefficient (5.5×10⁻⁷/°C) ensures minimal size change even at 1600°C.

The amorphous structure of fused quartz resists deformation and maintains integrity under rapid heating and cooling. This property is critical for processes with frequent thermal cycling.

High purity (≥99.99% SiO₂) and low hydroxyl content (<5ppm) further enhance thermal stability and prevent devitrification or stress cracking.

Amorphous Structure Stability Mechanisms

The non-crystalline, amorphous structure of fused quartz resists deformation and phase changes at high temperatures. This stability prevents warping and maintains precise dimensions even during rapid heating and cooling.

Unlike crystalline ceramics, fused quartz does not undergo grain boundary movement or microcracking under stress. This property is critical for applications requiring long-term dimensional accuracy.

Engineers can rely on fused quartz rods for processes with frequent thermal cycling and high mechanical loads.

Hydroxyl Content Thresholds (<5ppm)

Low hydroxyl (OH) content is essential for thermal stability above 1200°C. Hydroxyl groups can cause devitrification and reduce resistance to thermal shock.

Specify vacuum-fused quartz with OH content below 5ppm for the most demanding applications. Suppliers should provide batch-specific OH content data.

Maintaining low hydroxyl levels ensures long service life and consistent performance in extreme environments.

Quantifying Critical Parameters: Thermal Expansion vs Creep Resistance

Precise quantification of thermal expansion and creep resistance is essential for reliable system design. Fused quartz rods exhibit less than 0.001% dimensional change at 1600°C, far outperforming most ceramics and metals.

Thermal expansion is measured using ASTM E228-20251 protocols. Creep resistance, or the ability to resist slow deformation under load, is vital for support structures and observation ports.

ASTM E228-2025 Measurement Protocols

Thermal expansion is measured using ASTM E228-2025 protocols. Fused quartz rods typically exhibit a coefficient of 5.5×10⁻⁷/°C, ensuring minimal size change at high temperatures.

Request test data from suppliers to confirm compliance with industry standards. Accurate measurement supports process validation and regulatory requirements.

Engineers should use these values in thermal stress calculations and design models.

Creep Rate Impact on Support Structures

Creep is the slow deformation of a material under constant load at high temperature. For fused quartz rods, creep rates are extremely low, but not negligible at 1600°C.

Support structures must be designed to accommodate potential deformation over time. Use conservative safety factors and monitor rods for signs of sagging or elongation.

Proper material selection and design minimize maintenance and replacement costs.

Expert Insight:

A common mistake is neglecting creep rate in support rods. At 1600°C, a 10mm diameter rod can deform over 3mm per year if not properly specified. Always select vacuum-fused quartz with hydroxyl content below 5ppm and request ASTM E228 test data for critical applications.

Selection Criteria for Temperature-Specific Quartz Rod Grades

Selecting the right grade of fused quartz rod depends on operating temperature, purity, and application requirements. Engineers must balance performance, cost, and availability.

Clear vs Opaque Grade Performance Comparison

Clear fused quartz rods offer superior optical clarity and are preferred for applications requiring light transmission or visual inspection. Opaque grades, containing micro-bubbles, provide better thermal insulation but lower transparency.

Choose clear grades for semiconductor and optical uses, and opaque grades for insulation or non-visual applications. Both types maintain high purity and thermal stability.

Hydroxyl Content Impact on Thermal Stability

Hydroxyl (OH) content affects thermal stability and resistance to devitrification. Low-OH (<5ppm) rods are essential for continuous use above 1200°C.

High-OH rods may suffer from clouding or microcracking under prolonged heat. Always specify hydroxyl content and request supplier certification for high-temperature projects.

Diameter-Temperature Correlation Guidelines

Larger diameter rods can withstand higher loads but may be more prone to thermal gradients and stress. For 1600°C operation, select diameters and wall thicknesses based on load calculations and supplier recommendations.

Consult technical datasheets and use conservative safety factors for critical components. Custom diameters may require longer lead times.

Thermal Failure Analysis: Stress Fracture Mechanisms in Extreme Conditions

Understanding failure modes is key to preventing costly downtime and equipment damage. Thermal stress, cycling fatigue, and improper design are common causes of fracture.

Common Fracture Patterns in CVD Reactor Components

In CVD2 reactors, quartz rods may develop longitudinal cracks or star-shaped fractures at points of highest stress. These are often triggered by rapid temperature changes or uneven mounting.

Regular inspection and proper mounting can reduce the risk of catastrophic failure. Replace rods showing early signs of cracking.

Thermal Cycling Fatigue Test Data (ASTM E2227)

ASTM E2227 provides protocols for testing fatigue under repeated thermal cycling. Fused quartz rods typically withstand hundreds of cycles at ΔT=300°C/min without failure.

Test data should be reviewed for each batch, especially for mission-critical applications. Fatigue resistance is a key differentiator versus ceramics and glass.

Preventive Design Strategies

Design strategies include gradual ramping, uniform heating, and stress-relief annealing. Use support brackets that allow for expansion and minimize point loading.

Engineers should model stress distribution and validate designs with finite element analysis. Preventive maintenance and regular inspection further reduce failure risk.

Machining Protocol for High-Temperature Components: Stress Control Techniques

Precision machining and stress control are essential for producing reliable fused quartz rods.

Diamond cutting and laser machining achieve tight tolerances (±0.05mm) and smooth surfaces. Post-machining annealing at 800°C for two hours relieves internal stress.

Surface roughness should be controlled to Ra≤0.8μm per ASME B46.1 for high-purity and optical applications. Suppliers should provide inspection reports and process documentation.

Procurement Protocol: Technical Certification Requirements for Extreme Heat

Sourcing fused quartz rods for extreme heat requires rigorous supplier evaluation and documentation.

Request full material traceability, including batch numbers, raw material sources, and production records. Verify compliance with ISO 9001:2025 and relevant industry standards.

Thermal shock resistance should be tested and certified per ASTM E228 or equivalent. Reliable suppliers provide certificates and support custom requirements.

Material Traceability Documentation

Traceability ensures that each rod can be tracked from raw material to finished product. This supports quality control and regulatory compliance.

Request documentation for each batch, including purity, hydroxyl content, and test results. Transparent records build trust and facilitate troubleshooting.

Thermal Shock Resistance Test Standards

Thermal shock resistance is critical for high-temperature applications. ASTM E228 and E2227 outline standard test methods.

Suppliers should provide test data and certification for each batch. Engineers should review results and confirm suitability for their process.

ISO 9001:2025 Compliance Verification

ISO 9001:2025 certification demonstrates a supplier’s commitment to quality management. It ensures consistent production, documentation, and customer support.

Request up-to-date certificates and audit reports. Compliance supports long-term reliability and process validation.

Conclusion

Fused quartz rods deliver unmatched stability and purity for high-temperature industrial applications. Careful selection, design, and supplier validation ensure reliable performance and cost control.

Achieving precision with fused quartz rods is a strategic engineering challenge. Leverage TOQUARTZ’s direct factory supply, engineering support, and rapid delivery to ensure your system meets the highest standards—contact us for expert consultation and custom solutions.

FAQ (Frequently Asked Questions)

What is the maximum continuous operating temperature for fused quartz rods?

Fused quartz rods can operate continuously at up to 1600°C, with minimal dimensional change.

How do I prevent thermal shock failure in quartz rods?

Limit ramp rates to 300°C/min, use gradual heating and cooling, and select low-OH rods for high-temperature cycling.

What certifications should I require from a supplier for high-temperature applications?

Request ISO 9001:2025, ASTM E228/E2227 test data, and full material traceability documentation.

How does fused quartz compare to ceramics for extreme heat?

Fused quartz offers lower thermal expansion, better dimensional stability, and higher purity, while ceramics may withstand higher peak temperatures but are more brittle.

References: