- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz UV Cuvette

- /

- UV-Transparent Malvern Quartz UV...

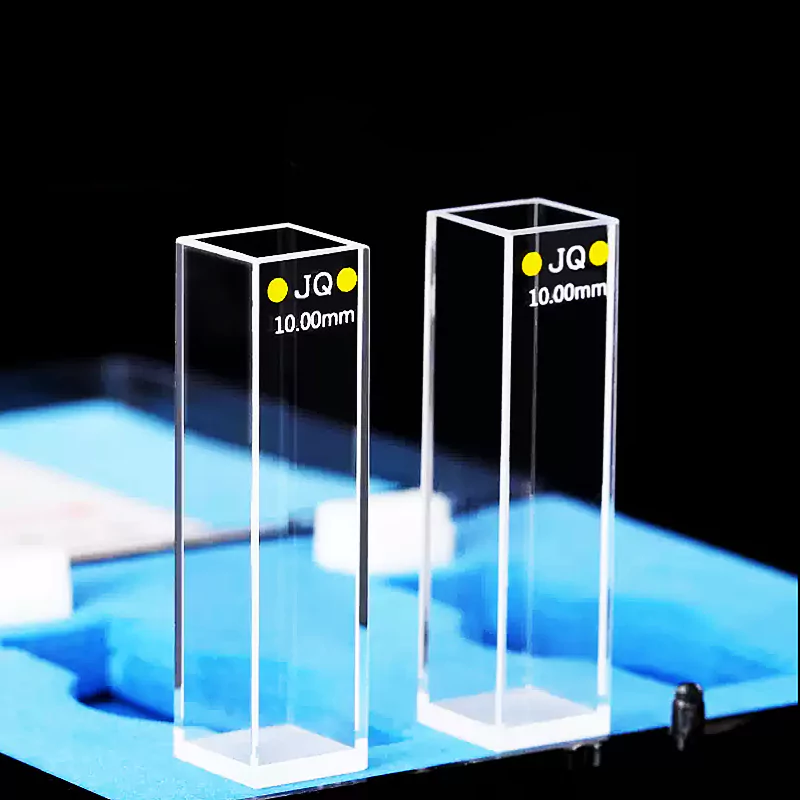

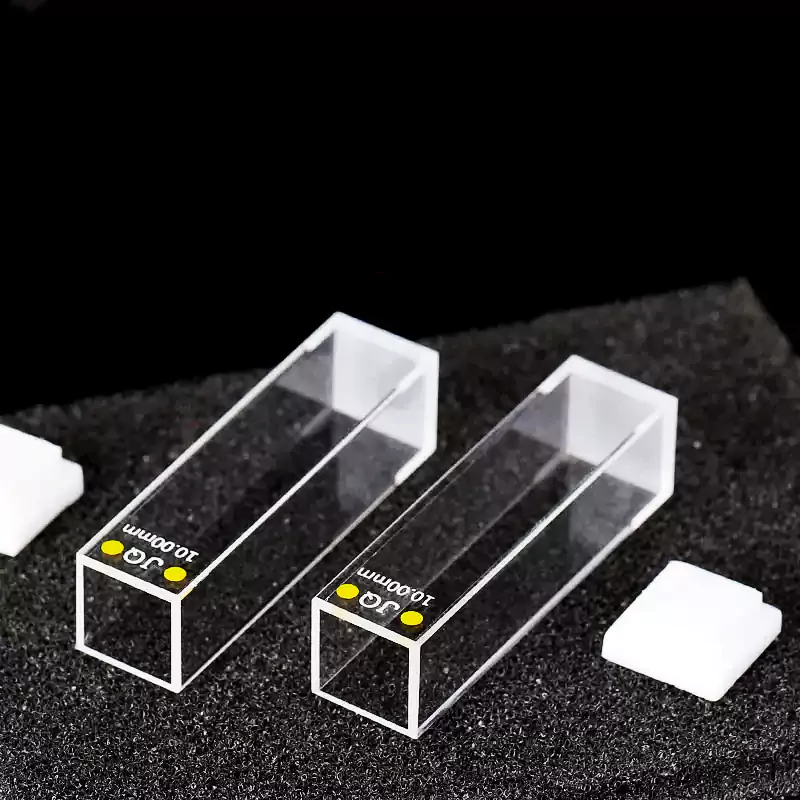

UV-Transparent Malvern Quartz UV Cuvette for UV-Vis Spectroscopy -TOQUARTZ®

Features of Malvern Quartz UV Cuvette

TOQUARTZ® Malvern Quartz UV Cuvettes are engineered for precision spectroscopy applications requiring accurate sample analysis across UV and visible light spectrums. Each cuvette is manufactured from high-purity quartz material to ensure consistent results and long service life.

Optical Transmittance

Consistently delivers >80% transmittance in paired testing, ensuring reliable spectroscopic measurements with minimal light attenuation.

Chemical Resistance

Highly resistant to acids, bases, and organic solvents, making these cuvettes ideal for a wide range of sample analysis applications with diverse chemical compositions.

Precision Dimensions

Manufactured to precise tolerances (±0.1mm) with consistent 10mm path length for accurate and reproducible spectroscopic measurements across instruments.

Thermal Stability

Excellent temperature resistance up to 1100°C with low thermal expansion coefficient (5.5×10⁻⁷ /°C), ideal for applications requiring temperature control or heated samples.

- 99.995% SiO₂ Purity

- Chemical Inertness

- Customizable Design

Technical Specifications & Dimensions of Malvern Quartz UV Cuvette

Technical Specifications

| Parameter | Specification | Notes |

| Model | AT-BSM-029 | Standard catalog item |

| Material | 99.98% SiO₂ | High-purity optical grade quartz |

| Path Length | 10mm ±0.1mm | Standard for UV-Vis applications |

| Internal Volume | 350μl | Optimal for standard analysis |

| Dimensions (Outer) | 12x12x45 mm | Compatible with standard holders |

| Wall Thickness | 1.0mm ±0.1mm | Provides structural integrity |

| Wavelength Range | 190nm-2500nm | Covers UV through NIR range |

| Transmittance | >80% (Paired Testing) | Across specified wavelength range |

| Surface Finish | Ra≤0.01μm | Optical quality polished |

| Thermal Expansion | 5.5×10⁻⁷ /°C | Low expansion for temperature stability |

| Temperature Resistance | Up to 1100°C | For high-temperature applications |

| Chemical Resistance | Excellent | Resistant to most acids, bases, solvents |

Size Chart

| Model | Description | Wavelength | Path Length | Volume | Transmittance | Outline Dimension |

| AT-BSM-029 | Transparent Malvern Quartz UV Cuvette for UV-Vis Spectroscopy | 190nm-2500nm | 10mm | 350μl | >80% (Paired Testing) | 12x12x45 mm |

TOQUARTZ® Solving Challenges with Malvern Quartz UV Cuvette

Malvern Quartz UV Cuvette for Analytical Instrument

Key Advantages

-

Optical Path Length Deviation ≤ ±0.05mm

Ensures calibration consistency across instrument batches with <0.2% absorbance deviation. -

Paired Transmittance Matching ΔT ≤ 1.5%

Each cuvette pair is tested to maintain ≤1.5% transmittance difference at 220nm and 340nm. -

Dimensional Repeatability within ±0.02mm

Enables automated holder alignment and reduces mechanical rejection rate by 95%.

TOQUARTZ® solution

A German spectrophotometer OEM reported a 12% calibration failure rate due to inconsistent cuvette path lengths from previous suppliers. After switching to TOQUARTZ® cuvettes with certified ±0.05mm path length tolerance and ≤1.5% ΔT matching, their calibration rejection rate dropped to 0.6%, improving production yield and reducing rework costs by over €9,000 per quarter.

Malvern Quartz UV Cuvette for Pharmaceutical Research

Key Advantages

-

UV Absorbance Background ≤ 0.005 AU at 220nm

Enables detection of trace APIs down to 0.1μg/mL without cuvette interference. -

Solvent Compatibility Validated for 12+ Aggressive Solvents

Maintains optical clarity after 50+ cycles in DMSO, acetonitrile, and methanol. -

Surface Roughness Ra ≤ 0.008μm

Minimizes sample residue retention and cross-contamination risk in multi-compound assays.

TOQUARTZ® solution

A US-based pharmaceutical R&D lab experienced baseline drift when analyzing low-concentration APIs in DMSO using generic quartz cuvettes. TOQUARTZ® supplied cuvettes with certified low absorbance (≤0.005 AU at 220nm) and solvent resistance. After 60 reuse cycles, no degradation was observed, and signal-to-noise ratio improved by 18%, enabling consistent quantification at 0.1μg/mL levels.

Malvern Quartz UV Cuvette for Environmental Testing

Key Advantages

-

Batch-to-Batch Transmittance Variance ≤ 1.2%

Ensures regulatory-compliant reproducibility in trace contaminant detection. -

Z-Height Tolerance within ±0.1mm

Compatible with 95% of autosampler platforms without manual adjustment. -

Certified Cleanroom Packaging (ISO Class 7)

Reduces pre-use cleaning time by 40% and eliminates particulate interference.

TOQUARTZ® solution

A Canadian water testing lab using autosamplers reported frequent misalignment and inconsistent absorbance due to cuvette height variation. TOQUARTZ® delivered cuvettes with Z-height tolerance within ±0.1mm and ISO Class 7 cleanroom packaging. This reduced autosampler errors by 92% and saved ~18 labor hours/month in pre-cleaning and alignment adjustments.

Customization Services for TOQUARTZ® Malvern Quartz UV Cuvette

Dimensional Customization

- Custom path lengths (1mm to 100mm)

- Modified outer dimensions

- Special internal volumes

- Z-height modifications

- Custom wall thickness

Optical Customization

- Specific wavelength optimization

- Black-walled options for fluorescence

- Modified optical window placement

- Anti-reflective coatings

- Special transmittance requirements

Functional Customization

- Flow-through designs

- Screw cap or PTFE stopper options

- Multi-cell configurations

- Custom markings or graduations

- Instrument-specific compatibility

TOQUARTZ® Custom Project Process

Requirements Consultation

TOQUARTZ® engineers work with you to understand your specific application requirements, constraints, and performance needs.

Design Proposal

We provide technical drawings and specifications for your review and approval, including material recommendations.

Drawing & Confirmation

We provide a detailed technical drawing of the customized Micro Quartz UV Cuvette Cell with Stopper. You will confirm dimensions, tolerances, and any special features before prototyping.

Prototype Development

For new designs, we can produce small-batch prototypes for testing and validation in your application.

Production & Quality Control

Upon approval, we proceed with production, implementing rigorous quality control measures to ensure specifications are met.

Documentation & Delivery

Products are delivered with comprehensive documentation, including quality certificates and technical specifications.

Usage Guide of Malvern Quartz UV Cuvette

Proper Handling & Cleaning

- Always handle cuvettes by the non-optical sides (frosted or ribbed sides) to prevent fingerprints on optical windows.

- Clean immediately after use with an appropriate solvent compatible with your sample, followed by ultrapure water and ethanol rinse.

- For persistent contaminants, soak in diluted laboratory detergent (2-5%) for 30 minutes, then rinse thoroughly.

- Avoid abrasive materials that can scratch optical surfaces—use only lint-free optical tissues or microfiber cloths.

- For final drying, use filtered compressed air or nitrogen, or allow to air dry in a dust-free environment.

Measurement Best Practices

- Align cuvette in the spectrometer with optical windows perpendicular to the light beam path.

- Fill to appropriate volume (typically 2/3 of height) to ensure beam passes through sample.

- Check for air bubbles by gently tapping cuvette before measurement—bubbles can interfere with readings.

- Use matched pairs of cuvettes for reference and sample measurements to minimize baseline variations.

- For temperature-sensitive applications, allow cuvette and sample to equilibrate before measurement.

Storage Recommendations

- Store clean, dry cuvettes in original protective case or dedicated cuvette storage rack.

- Maintain dust-free environment to prevent optical surface contamination.

- Avoid storage near corrosive chemicals or environments with high humidity.

- If not using for extended periods, verify cleanliness before next use.

Solvent Compatibility Guide

| TOQUARTZ® Transparent Malvern Quartz UV Cuvettes are compatible with most common laboratory solvents, including: | ||

| • Water | • DMSO | • Dilute bases |

| • Alcohols (ethanol, methanol) | • Most organic solvents | • Buffer solutions |

| • Acetone | • Dilute acids | • Hexane |

Need engineering support for your Malvern Quartz UV Cuvette requirements?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a Malvern Quartz UV Cuvette and how does it differ from standard cuvettes?

A: A Malvern Quartz UV Cuvette is a high-precision optical cell designed specifically for UV-Visible spectroscopy applications. It features standardized dimensions (typically 12x12x45mm) compatible with Malvern instruments and most standard spectrophotometers. Unlike standard glass cuvettes, quartz UV cuvettes offer superior transmittance in the UV range (down to 190nm) and greater chemical resistance, making them ideal for a wider range of analytical applications.

Q: Why use a Malvern Quartz UV Cuvette instead of glass or plastic? Cuvette with stopper?

A: Quartz cuvettes are essential when analyzing samples in the UV spectrum below 320nm, where glass absorbs light and produces inaccurate readings. They offer superior chemical resistance compared to plastic cuvettes, withstanding organic solvents that would damage or cloud plastic. Additionally, quartz provides better thermal stability, allowing analysis at higher temperatures, and delivers more consistent results over time due to its durability and resistance to scratching or chemical etching.

Q: What wavelength range can Malvern Quartz UV Cuvettes accommodate?

A: TOQUARTZ® Transparent Malvern Quartz UV Cuvettes provide excellent transmittance across the 190-2500nm wavelength range. This spans from deep UV through visible and into the near-infrared spectrum, making them versatile for various analytical applications. The material offers minimal absorption or fluorescence across this range, ensuring accurate spectroscopic measurements without interference from the cuvette material itself.

Q: Are TOQUARTZ Malvern Quartz UV Cuvettes compatible with all spectrophotometers?

A: TOQUARTZ® standard 12x12x45mm Transparent Malvern Quartz UV Cuvettes are compatible with most modern spectrophotometers from major manufacturers including Agilent, Thermo Scientific, Shimadzu, PerkinElmer, Beckman Coulter, and of course, Malvern instruments. For specialized instruments or older models with non-standard holders, we offer custom sizing options. We recommend verifying your instrument’s cuvette holder specifications before ordering if you’re uncertain about compatibility.

Q: Can you provide custom dimensions for Malvern Quartz UV Cuvettes?

A: Yes, TOQUARTZ® specializes in custom quartz cuvette manufacturing. We can produce Transparent Malvern Quartz UV Cuvettes with custom dimensions, including non-standard path lengths (1-100mm), altered external dimensions to fit specialized instruments, custom chamber volumes, and specialized optical window configurations. Our engineering team works directly with customers to design cuvettes for specific applications, providing technical drawings for approval before production. Custom orders typically require 2-3 weeks lead time, with no minimum order quantity for most customizations.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.