- Home

- /

- Applications

- /

- Optical Quartz Glass

- /

- Photonic-Grade Quartz Glass Dome...

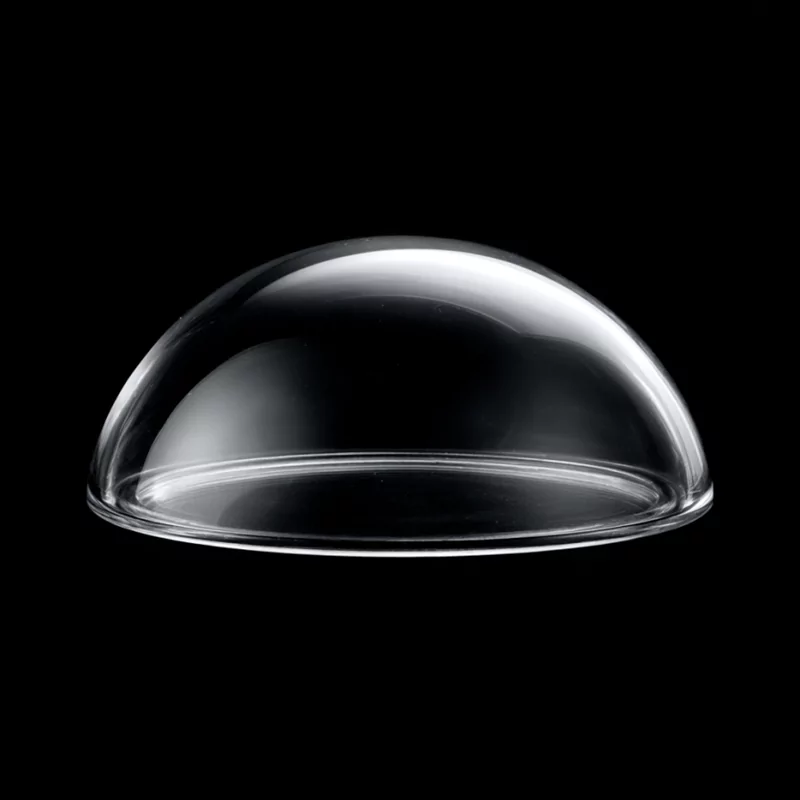

Photonic-Grade Quartz Glass Dome for Optical UV Systems-TOQUARTZ®

Key Features of Quartz Glass Dome

TOQUARTZ® Quartz Glass Domes are manufactured from high-purity fused silica, offering exceptional optical properties and thermal stability for demanding industrial applications.

High UV Transmittance

Unlike borosilicate glass, quartz glass domes offer superior transmission across the UV spectrum:

- UV-A (315-400 nm): 90-95%+

- UV-B (280-315 nm): 80-95%

- UV-C (100-280 nm): 80-90%

Thermal Performance

Designed for high-temperature applications, our quartz domes provide exceptional thermal stability:

- Operating temperature: Up to 1200°C

- Thermal expansion coefficient: ≤5.5×10⁻⁷ /°C

- Thermal shock resistance: Excellent

Precision Dimensional Control

Manufactured from high-purity fused silica for superior optical and mechanical properties:

- SiO₂ purity: ≥99.995%

- Surface quality: 60-40 scratch-dig

- Chemical resistance: Superior to acids, bases, and halides

- High Purity 99.99% SiO₂ content

- Transmission ≥93% for 1mm thickness within 280-780nm wavelength

- Electrical Resistance of 7×10⁷ Ω·cm

Technical Specifications of Fused Quartz Glass Dome

TOQUARTZ® quartz glass domes are available in standard sizes with custom options to meet your specific requirements.

| Parameter | Specification | Notes |

| Material | High-purity fused silica (SiO₂ ≥99.995%) | UV-grade or optical grade available |

| Diameter Range | 30mm – 300mm | Common sizes: 160mm, 290mm |

| Wall Thickness | 1mm – 30mm | Optimized for thermal stability |

| Dimensional Tolerance | ±0.1mm standard (±0.05mm available) | Precision grade for optical applications |

| Surface Quality | 60-40 scratch-dig standard | Higher grades available on request |

| Temperature Resistance | Up to 1200°C | Exceeds solar concentrator requirements (450°C) |

| Optional Coatings | TiO₂ photocatalytic coating, AR coating | Inner or outer surface available |

TOQUARTZ® Solving Challenges with Quartz Glass Dome

Quartz Glass Dome for UV Disinfection Systems

Key Advantages

-

UV-C Transmission ≥88% at 254nm

→ Enables effective microbial inactivation at germicidal wavelengths. -

No UV-C Cutoff Below 200nm

→ Supports full-spectrum disinfection including ozone-generating UV. -

Low Absorption Loss <5% Over 1000h

→ Maintains UV efficiency in continuous-use sterilization chambers.

TOQUARTZ® solution

A U.S.-based UV disinfection equipment manufacturer faced a 22% drop in sterilization efficiency using borosilicate domes, which blocked over 90% of UV-C light. TOQUARTZ supplied domes with verified ≥88% transmission at 254nm, restoring disinfection rates and reducing lamp overdrive costs by 18%. The client reported zero degradation after 1,200 hours of continuous operation.

Quartz Glass Dome for Solar Concentrator Systems

Key Advantages

-

Thermal Resistance ≥1200°C Continuous

→ Withstands focal point temperatures in CSP systems without deformation. -

Solar Transmittance ≥93% in 300–2500nm

→ Maximizes energy capture across full solar spectrum. -

No Optical Yellowing After 1000h Exposure

→ Maintains clarity under prolonged UV and IR radiation.

TOQUARTZ® solution

A German solar thermal integrator experienced dome warping and yellowing after 800 hours using soda-lime glass. TOQUARTZ delivered 290mm domes with certified 1200°C resistance and 93% solar transmittance. After 1,500 hours of field testing, the domes showed no optical degradation, improving system output by 14% and extending maintenance cycles by 6 months.

Quartz Glass Dome for Photocatalytic Reactors

Key Advantages

-

TiO₂-Compatible UV Transmission ≥85%

→ Ensures full activation of photocatalysts in 200–400nm range. -

Dual-Surface TiO₂ Coating Available

→ Supports both suspension and immobilized catalyst configurations. -

Coating Adhesion ≥4B (ASTM D3359)

→ Prevents delamination in high-flow wastewater environments.

TOQUARTZ® solution

A Polish wastewater treatment OEM struggled to source domes with stable TiO₂ coatings; previous suppliers had 30% coating failure rates. TOQUARTZ provided domes with dual-surface TiO₂ coatings and verified ≥85% UV transmission. After 3 months of pilot testing, pollutant degradation efficiency improved by 32%, and coating integrity remained intact under 24/7 flow conditions.

TOQUARTZ® Customization Options for Quartz Glass Dome

TOQUARTZ® engineering team works with you to design quartz glass domes that meet your exact specifications.

Custom Dimensions

Diameters from 30mm to 300mm with precision tolerances down to ±0.05mm for optical applications.

Surface Treatments

Options include TiO₂ photocatalytic coatings, anti-reflective treatments, and specialized surface finishes.

Material Grades

Select from UV-grade, optical-grade, or standard fused silica based on your application requirements.

Design Assistance

Our engineers provide technical guidance and drawing assistance to optimize your dome design.

Usage Guidelines for Fused Quartz Glass Dome

Proper handling and installation of quartz glass domes ensures optimal performance and extended service life.

Handling & Storage

- Wear powder-free gloves when handling

- Store in clean, dry environment away from chemicals

- Use original packaging for transportation

- Avoid contact with abrasive materials

- Store upright on soft, clean surfaces

Installation

- Use silicone or PTFE gaskets for sealing

- Apply even pressure during mounting

- Allow for thermal expansion in fixtures

- Use non-metallic mounting hardware when possible

- Follow heating/cooling rate guidelines

Maintenance

- Clean with isopropyl alcohol or acetone

- Avoid alkaline cleaning solutions

- Inspect regularly for microcracks

- Use optical-grade lint-free wipes

- Replace if physical damage is observed

Need engineering support for your Quartz Glass Dome project?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a quartz glass dome used for?

A: Quartz glass domes are primarily used in applications requiring high UV transmission, thermal stability, and optical clarity. Common applications include solar concentrators, UV disinfection systems, photocatalytic reactors, optical instruments, and high-temperature viewing windows. Their ability to transmit UV-C wavelengths makes them ideal for germicidal applications.

Q: Can quartz domes transmit UV-C light?

A: Yes, high-purity quartz glass domes transmit 80-90% of UV-C light (100-280 nm wavelength), making them suitable for germicidal applications. Unlike borosilicate glass which blocks virtually all UV-C, quartz glass enables efficient transmission of these shorter wavelengths critical for microbial disinfection and advanced photochemical processes.

Q: How durable are quartz domes in high-temperature environments?

A: Quartz glass domes maintain structural integrity and optical properties at temperatures up to 1200°C, far exceeding the typical requirements of solar concentrator applications (450°C). They feature low thermal expansion (≤5.5×10⁻⁷ /°C), excellent thermal shock resistance, and do not devitrify or cloud under prolonged high-temperature exposure.

Q: What coatings can be applied to quartz domes for UV applications?

A: For UV applications, TiO₂ photocatalytic coatings are commonly applied to quartz domes. These coatings enhance photocatalytic reactions for pollutant degradation in water treatment systems. We can apply TiO₂ coatings to either the inner or outer surfaces of the dome depending on your application requirements. Anti-reflective (AR) coatings are also available to minimize light loss and improve system efficiency.

Q: What dimensional tolerances are achievable for quartz optical domes?

A: Our standard manufacturing capabilities for quartz domes include dimensional tolerances of ±0.1mm. For precision optical applications, we can achieve tolerances down to ±0.05mm on diameter, thickness, and sphericity. Surface quality standards typically range from 80-50 to 60-40 scratch-dig, with higher precision available for specialized optical applications.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.