Home / Types / Quartz Tube / Quartz Diffusion Furnace Tube

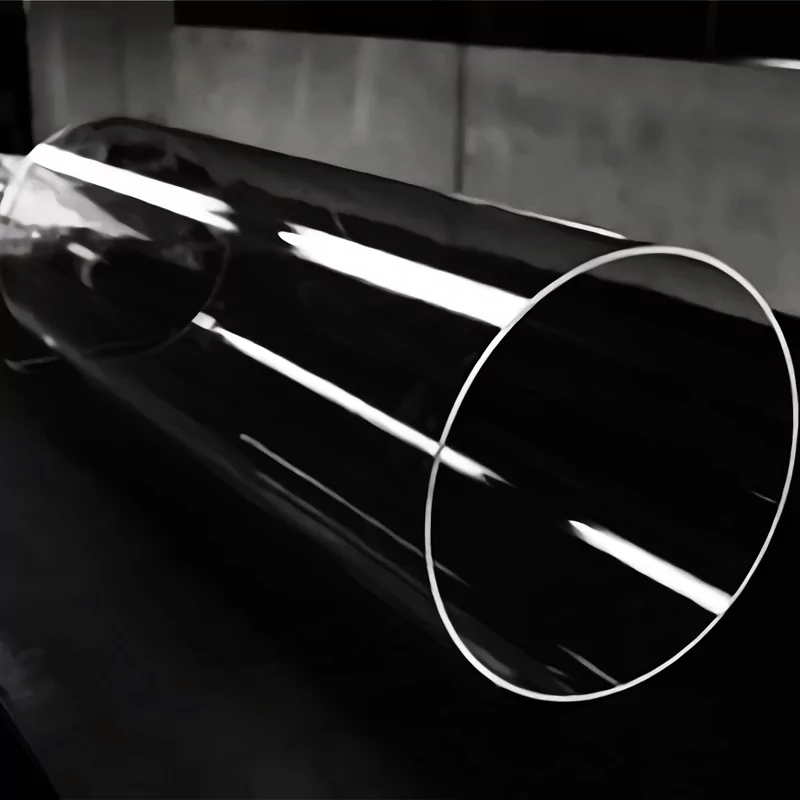

Large Diameter Customizable Quartz Diffusion Furnace Tube for Semiconductor & Solar Processing-TOQUARTZ®

Key Features of Quartz Diffusion Furnace Tube

TOQUARTZ® Quartz diffusion furnace tubes are engineered from high-purity fused silica, providing exceptional performance characteristics essential for precision thermal processing applications. These features ensure reliability in demanding semiconductor and solar cell manufacturing environments.

Thermal Stability

Withstands continuous operation at 1100°C and short-term exposure up to 1350°C with minimal deformation. Extremely low thermal expansion coefficient (5.5×10⁻⁷/°C) prevents cracking during rapid temperature changes.

Chemical Resistance

Highly resistant to acids, alkalis, molten salts, and halogen gases commonly used in semiconductor processing. Maintains structural integrity even in aggressive chemical environments at elevated temperatures.

Precision Dimensional Control

Manufactured to tight tolerances with standard precision of ±0.2mm for diameter and wall thickness. Enhanced precision of ±0.1mm available for critical applications requiring optimal sealing and gas flow characteristics.

- High Purity 99.99% SiO₂ content

- Transmission ≥93% for 1mm thickness within 280-780nm wavelength

- Electrical Resistance of 7×10⁷ Ω·cm

Specifications of Fused Quartz Diffusion Furnace Tube

TOQUARTZ® quartz diffusion furnace tubes are manufactured to precise technical specifications that ensure optimal performance in high-temperature processing environments. Each tube undergoes rigorous quality control testing to verify dimensional accuracy and material properties.

Material Property

| Property | Value |

| 1. Physical Properties | |

| Density | 2.2 g/cm3 |

| Flexture Strength | 48 MPa |

| Elastic Modulus | 72 GPa |

| Poisson’s Ratio | 0.14-0.17 |

| Compressive Strength | 1100 MPa |

| Bending Strength | 67 MPa |

| Moh’s Hardness | 5.5-6.5 |

| 2. Thermal & Optical Properties | |

| Maximum Working Temperature (long-term) | 1100°C |

| Maximum Working Temperature (short-term) | 1350°C |

| Thermal Conductivity | 1.4 W/m·K |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ /°C |

| Refractive Index | 1.4585 |

| Specific Resistance | 7×10⁷ Ω·cm |

| Transmission (280-780nm) | ≥93% (1mm thickness) |

Standard Dimensions

| Model | Outer Diameter (mm) | Inner Diameter (mm) | Wall Thickness (mm) | Length (mm) | SiO₂ Content (%) |

| AT-SY-XG001 | 55 | 50 | 2.5 | 1500-2000 | 99.99 |

| AT-SY-XG002 | 90 | 83 | 3.5 | 1500-2000 | 99.99 |

| AT-SY-XG003 | 200 | 190 | 5 | 2000-3500 | 99.99 |

| AT-SY-XG004 | 330 | 314 | 8 | 2000-3500 | 99.99 |

| AT-SY-XG005 | 430 | 410 | 10 | 2000-3500 | 99.99 |

| AT-SY-XG006 | 550 | 520 | 15 | 2000-3500 | 99.99 |

Dimensional Tolerances

| Outer Diameter (mm) | Outer Diameter (%) | Thickness (%) | Roundness (%) | Maximum Curvature (%) | End Face Flatness (mm) | End Face Perpendicularity (mm) |

| 200≤φ<250 | ±0.5 | ±10 | ±0.5 | 0.3 | ±0.1 | ±0.5 |

| φ≥250 | ±0.5 | ±10 | ±0.5 | 0.3 | ±0.1 | ±0.5 |

TOQUARTZ® Solving Challenges with Quartz Diffusion Furnace Tube

Quartz Diffusion Furnace Tubes in Semiconductor Manufacturing

Key Advantages

-

Optimized gas flow uniformity across 300mm wafer batches

Internal roundness tolerance ≤0.3% ensures consistent gas distribution during doping and oxidation. -

Dimensional stability under 1200°C continuous operation

Wall thickness deviation ≤±0.2mm prevents thermal deformation in long-cycle annealing. -

Reduced particle generation in cleanroom environments

Surface roughness Ra ≤0.8μm minimizes micro-particle shedding during high-purity processing.

TOQUARTZ® solution

A U.S. semiconductor fab reported 12% wafer yield loss due to gas flow turbulence in 300mm batch diffusion. TOQUARTZ® supplied quartz diffusion tubes with enhanced roundness and ±0.2mm wall tolerance. Post-implementation, yield loss dropped to 3%. The client standardized TOQUARTZ tubes across all four diffusion lines within 2 months.

Fused Quartz Diffusion Furnace Tubes in Solar Cell Production

Key Advantages

-

Thermal cycling durability exceeding 300+ cycles

Tubes maintain structural integrity after 300+ phosphorus/boron doping cycles at 1000°C. -

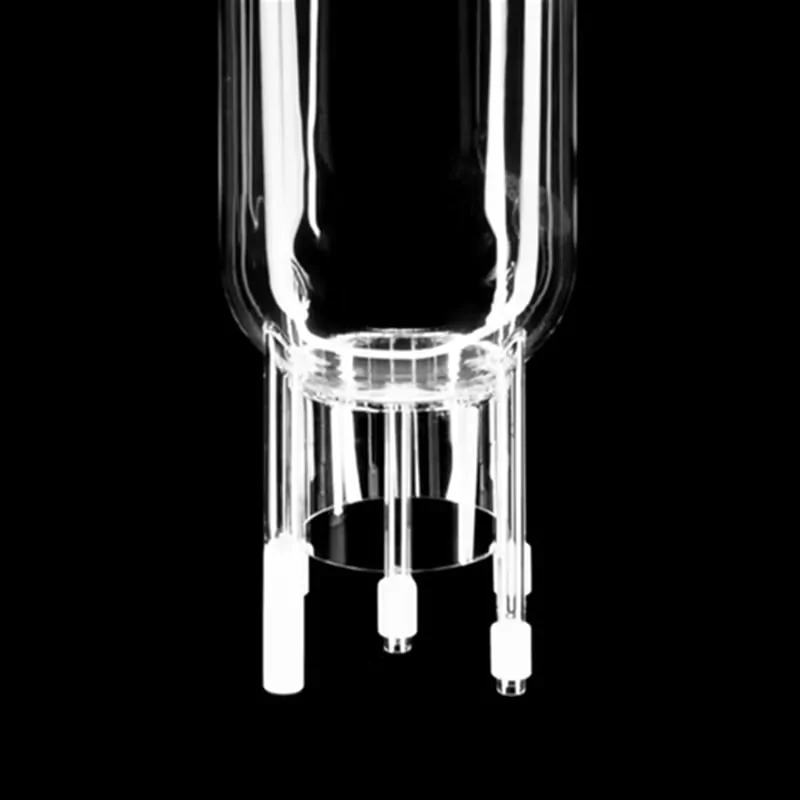

Gas-tight flange design for vacuum integrity

Custom flange sealing achieves <10⁻³ mbar leak rate, verified by helium leak testing. -

Wall thickness uniformity for stable deposition

Thickness deviation ≤±0.15mm ensures uniform silicon nitride coating during LPCVD.

TOQUARTZ® solution

A Korean solar module plant faced tube failure after 120 cycles, causing 18 hours/month downtime. TOQUARTZ® delivered reinforced quartz tubes with optimized wall distribution and flange sealing. Tube life extended to 320 cycles, reducing downtime to 4 hours/month. Client expanded order volume by 40% within one quarter.

Fused Silica Diffusion Furnace Tubes in Research Applications

Key Advantages

-

No MOQ with 3-week turnaround for custom specs

Supports single-unit orders with ID/OD tolerances tailored to ±0.1mm for lab-scale setups. -

Multi-inlet and port integration for CVD flexibility

Supports up to 4 gas inlets and 2 thermocouple ports per tube, based on user drawings. -

Rapid prototyping for experimental iterations

Prototype delivery in 18 working days enables fast validation of new thermal processes.

TOQUARTZ® solution

A European university lab required a 2-port quartz tube with 280mm OD for a novel CVD setup. Local suppliers quoted 10-week lead time with MOQ ≥5 units. TOQUARTZ® delivered a single-unit prototype in 19 days with ±0.1mm tolerance. The lab completed its grant milestone 6 weeks ahead of schedule and reordered 3 variants.

TOQUARTZ® Customization Options for Quartz Diffusion Furnace Tube

TOQUARTZ® offers extensive customization capabilities for quartz diffusion furnace tubes to meet your specific process requirements. Our engineering team works directly with you to develop solutions that optimize performance for your unique application.

End Finishing Options

- Flanged ends (standard or custom designs)

- Ground joint connections

- Fire-polished ends

- Beaded ends

- Closed/sealed ends with inlets

Structural Modifications

- Multiple gas inlets

- Thermocouple ports

- Internal baffles

- Multi-zone configurations

- Concentric tube designs

Surface Treatments

- Ground/frosted surfaces

- High-polish internal surfaces

- Opaque sections

- Graduated markings

- Specialized coatings

Customization Process

-

Requirements Analysis

We analyze your technical specifications, process parameters, and operational environment. -

Design & Engineering

Our engineers develop detailed drawings and production specifications for your approval. -

Prototype Production

We manufacture a sample for testing and validation before full production. -

Production & QC

Full production with comprehensive quality control and documentation.

Usage Guidelines for Fused Quartz Diffusion Furnace Tube

Proper handling, installation, and maintenance of quartz diffusion furnace tubes are essential for maximizing performance and operational lifetime. Following these guidelines will help prevent damage and ensure consistent results in your thermal processing applications.

Handling & Installation

- Always wear clean, powder-free gloves when handling quartz tubes to prevent contamination and fingerprints.

- Support the tube along its entire length during transport and installation to prevent mechanical stress.

- Ensure support fixtures maintain proper alignment and accommodate thermal expansion.

- Apply even torque when tightening flange connections to prevent stress concentrations.

- Use compatible sealing materials rated for your operating temperature range.

Cleaning & Maintenance

- Use dilute acid solutions (concentration below 5%) for cleaning, such as hydrofluoric acid, hydrochloric acid, or nitric acid mixtures.

- Strictly control acid cleaning time to prevent excessive etching or inadequate cleaning.

- Rinse thoroughly with deionized water after acid cleaning to remove all residual acid from the surface.

- Properly treat acidic cleaning wastewater to meet environmental regulations before disposal.

- Inspect regularly for deposits, discoloration, or microcracks that may indicate maintenance needs.

Temperature Control Guidelines

- For tubes ≤200mm diameter: maximum 5°C/min up to 1100°C

- For tubes >200mm diameter: maximum 3°C/min up to 1100°C

- Above 1100°C: reduce rate to 2°C/min maximum

- From operating temperature to 800°C: maximum 3°C/min

- From 800°C to 500°C: maximum 5°C/min

- Below 500°C: natural cooling acceptable

Need Technical Assistance?

Contact us today to discuss your project requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a quartz diffusion tube used for?

A: Quartz diffusion tubes are used in semiconductor manufacturing, solar cell production, and laboratory environments for high-temperature thermal processing applications. They provide a controlled environment for processes such as doping, annealing, oxidation, and chemical vapor deposition (CVD). Their high purity, thermal stability, and chemical resistance make them ideal for these critical applications where contamination control and precise temperature management are essential.

Q: What is the purity of quartz tubes used in semiconductor processing?

A: For semiconductor processing applications, quartz tubes with purity levels of at least 99.99% SiO₂ are typically required. TOQUARTZ diffusion tubes offer up to 99.995% SiO₂ purity with metal impurities controlled to parts-per-billion levels. This high purity is essential for preventing contamination in semiconductor wafer processing, where even trace impurities can compromise device performance. For less critical applications such as solar cell manufacturing or general laboratory use, tubes with 99.99% purity are often sufficient.

Q: What is the temperature limit for quartz diffusion tubes?

A: TOQUARTZ® diffusion tubes can withstand continuous operation at temperatures up to 1100°C and short-term exposure up to 1350°C. The practical temperature limit depends on several factors including tube dimensions, wall thickness, support configuration, and heating/cooling rates. Larger diameter tubes may require lower maximum temperatures to prevent sagging or deformation. For applications requiring operation above 1200°C, we recommend consulting with our engineering team to optimize tube design and material selection. All tubes should be heated and cooled at controlled rates (typically 3-5°C/min) to prevent thermal shock and extend operational life.

Q: What are the maximum dimensions available for quartz diffusion tubes?

A: TOQUARTZ® can manufacture diffusion tubes with outer diameters ranging from 55mm to 550mm, with wall thicknesses from 2.5mm to 15mm. Our standard maximum length is 3500mm for large diameter tubes, but we can produce custom lengths based on specific requirements. For extremely large diameters (>550mm) or specialized configurations, please contact our engineering team for feasibility assessment. Dimensional tolerances are maintained at ±0.5% for diameter and ±10% for wall thickness, with enhanced precision available for critical applications.

Q: What are the shipping and handling requirements for large quartz tubes?

A: Large diameter quartz diffusion tubes require specialized packaging and handling procedures to prevent damage during transit. TOQUARTZ uses custom-designed wooden crates with suspension mounting and shock-absorbing materials to secure tubes during international shipping. Each tube is individually wrapped in protective foam and sealed in plastic to prevent contamination. For tubes over 2 meters in length or 300mm in diameter, we recommend specialized freight arrangements. Our logistics team coordinates all shipping details including customs documentation for international orders. Upon receipt, tubes should be inspected while still in packaging and stored horizontally on padded supports until installation.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.