- Home

- /

- Types

- /

- Quartz Tube

- /

- Custom Multi-Channel Configurable Quartz...

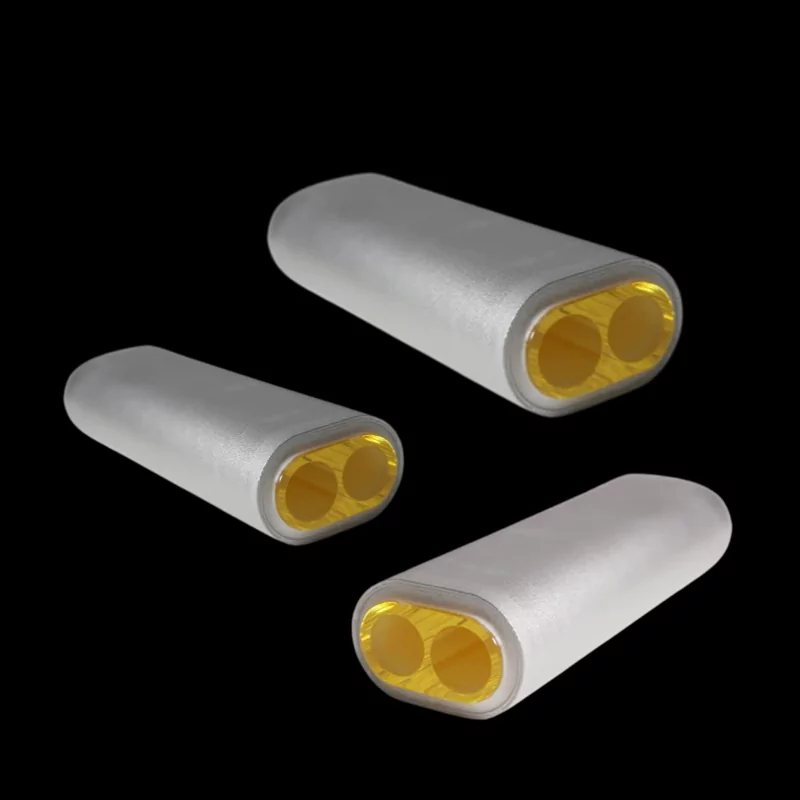

Custom Multi-Channel Configurable Quartz Laser Cavity Tube for High-Energy Devices-TOQUARTZ®

Technical Features of Quartz Laser Cavity Tube

TOQUARTZ® quartz laser cavity tubes are engineered for high-performance laser applications, combining exceptional material properties with precision manufacturing to deliver reliable operation in demanding environments.

Optical Properties

High optical transmission (>90%) across UV, visible, and IR wavelengths ensures efficient light propagation. The refractive index of 1.458 at 589.3nm provides consistent beam control and focusing capabilities for precise laser operations in medical and industrial applications.

Thermal Stability

Withstands temperatures up to 1300°C for long-term operation and 1600°C for short periods without deformation. Thermal expansion coefficient of 5.5×10⁻⁷/°C ensures dimensional stability during thermal cycling, critical for maintaining optical alignment in laser systems.

- Surface Roughness of Ra ≤0.2μm

- Corrosion Rates as low as 1.4×10⁻⁸ g/cm² in 98% H₂SO₄

- Customizable Dimensions

Technical Specifications of Quartz Laser Cavity Tube

TOQUARTZ® quartz laser cavity tubes are manufactured to rigorous standards, ensuring consistent performance in demanding industrial and medical laser applications.

Physical & Mechanical Properties

| Property | Value | Property | Value |

| Density | 2.203 g/cm3 | Compressive Strength | 1100 MPa |

| Bending Strength | 67 MPa | Tensile Strength | 48.3 MPa |

| Poisson’s Ratio | 0.14 ~ 0.17 | Young’s Modulus | 72000 MPa |

| Rigidity Modulus | 31000 MPa | Mohs Hardness | 5.5 ~ 6.5 |

Thermal Properties

| Property | Value | Property | Value |

| Deformation Point | 1280°C | Softening Point | 1680°C |

| Annealing Point | 1210°C | Specific Heat (20~350°C) | 670 J/kg.°C |

| Thermal Conductivity (20°C) | 1.4 W/m.°C | Coefficient of Thermal Expansion | 5.5×10⁻⁷ cm/cm.°C |

| Hot Work Temperature | 1700~2000°C | Short-time Use Temperature | 1300°C |

| Long-time Use Temperature | 1100°C |

Electrical & Optical Properties

| Property | Value | Property | Value |

| Resistivity | 7×10⁷ Ω.cm | Dielectric Strength | 250~400 Kv/cm |

| Dielectric Constant | 3.7~3.9 | Dielectric Absorption Coefficient | <4×10⁴ |

| Dielectric Loss Coefficient | <1×10⁴ | Refractive Index | 1.458 |

Chemical Resistance

| Solution | Treatment Condition | Corrosion Capacity |

| H₂O | 95°C, 45 Hours | 1~2×10⁻⁷ g/cm² |

| 98% H₂SO₄ | 20°C, 2 Hours | 1.4×10⁻⁸ g/cm² |

| 60% HNO₃ | 20°C, 2 Hours | 5.0×10⁻⁸ g/cm² |

| 36% HCl | 20°C, 2 Hours | 15×10⁻⁸ g/cm² |

| 5% NaOH | 100°C, 10 Hours | 1.35×10⁻³ g/cm² |

| 1% KOH | 98°C, 2 Hours | 68×10⁻⁶ g/cm² |

TOQUARTZ® Solving Critical Challenges with Quartz Laser Cavity Tube

Quartz Laser Cavity Tubes for Industrial Cutting & Welding Systems

Key Advantages

-

Micron-Level Dimensional Stability

Maintains optical alignment within ±10μm under 1000°C continuous operation. -

Dual-Channel Thermal Isolation Design

Supports internal cooling flow separation with ≤0.2mm wall tolerance between channels. -

Low Thermal Expansion Geometry

5.5×10⁻⁷/°C expansion coefficient ensures cavity shape retention during 24/7 laser output.

TOQUARTZ® solution

A German laser cutting system integrator reported beam drift due to cavity deformation at 1100°C. TOQUARTZ® delivered dual-channel elliptical quartz tubes with ±0.1mm wall thickness tolerance and verified thermal expansion control. Post-integration, beam deviation dropped by 87%, and system uptime improved by 22% over 3 months.

Quartz Glass Laser Cavity Tubes for Medical & Aesthetic Devices

Key Advantages

-

Wavelength-Calibrated UV-IR Transmission

92% transmission at 2940nm and 1064nm for dermatology and ophthalmology lasers. -

Low-OH Synthetic Quartz Composition

<10 ppm OH content ensures minimal absorption and stable energy output in IPL systems. -

Beam Uniformity in Elliptical Cavities

Elliptical cross-section deviation <±0.05mm ensures consistent beam profile across 100+ units.

TOQUARTZ® solution

A Korean IPL device manufacturer faced inconsistent energy delivery due to variable beam profiles in cavity tubes. TOQUARTZ® supplied elliptical quartz tubes with <±0.05mm cross-section deviation and certified OH content <10 ppm. The client reported a 35% improvement in treatment uniformity and reduced calibration frequency by 50%.

Fused Silica Laser Cavity Tubes for Research & Scientific Instruments

Key Advantages

-

Custom Optical Path Length Control

Supports cavity lengths from 50mm to 1200mm with ±0.1mm axial tolerance for spectroscopy. -

Low Fluorescence Synthetic Quartz

<0.05% fluorescence under 254nm UV ensures signal purity in Raman and LIBS systems. -

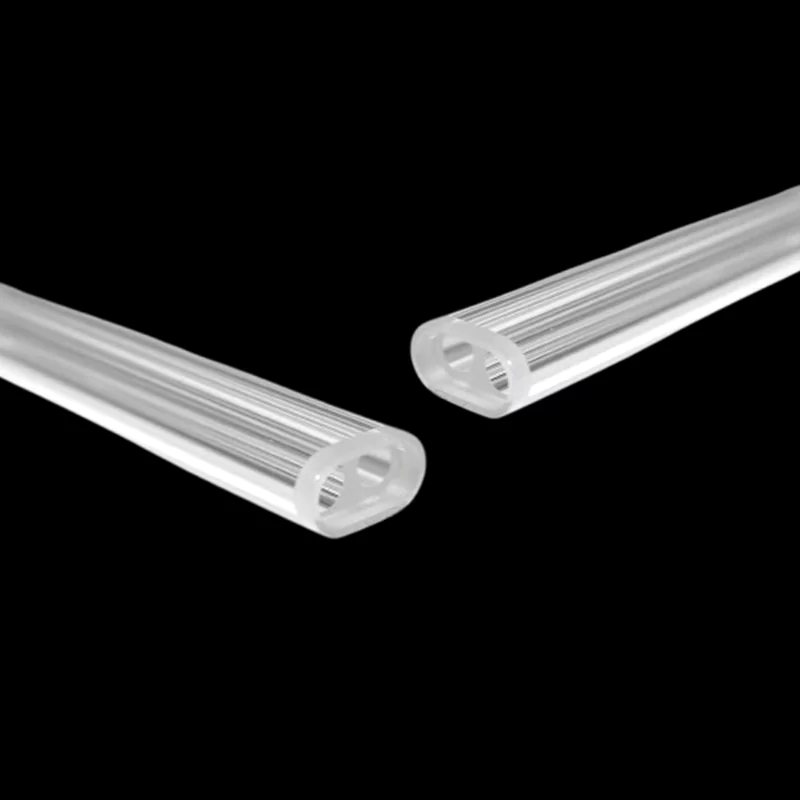

Precision Multi-Channel Fabrication

Enables 3+ channel integration with inter-channel spacing accuracy of ±0.1mm for beam splitting.

TOQUARTZ® solution

A Canadian spectroscopy lab required a dual-channel quartz cavity with 800mm optical path and <0.1mm tolerance. TOQUARTZ® delivered within 3.5 weeks, achieving <0.08mm deviation and <0.05% fluorescence under UV. The lab reported a 28% increase in signal-to-noise ratio and completed calibration 2 weeks ahead of schedule.

TOQUARTZ® Custom Quartz Laser Cavity Tube Services

Available Customization Options

-

Cross-Section Profiles:

Round, oval, elliptical, rectangular, or custom geometries -

Channel Configuration:

Single, double, triple, or multi-channel designs -

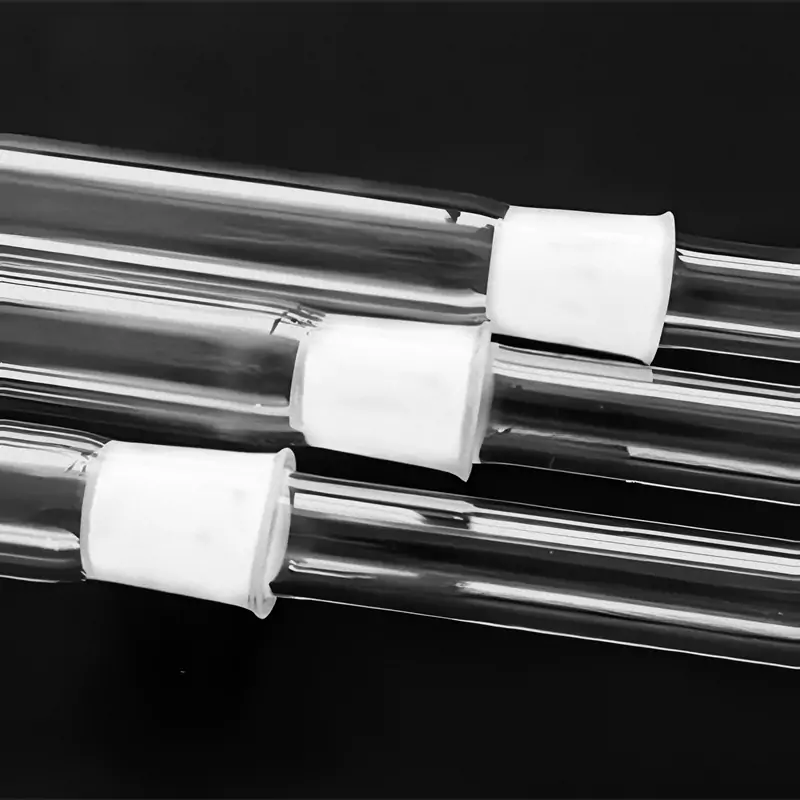

End Configurations:

Flared, flanged, ground ends, or special sealing surfaces -

Surface Treatments:

Fire polished, ground, etched, or specially coated -

Dimensional Specifications:

Custom diameters, lengths, wall thicknesses, and tolerances

Custom Design Process

-

Requirement Analysis

Our technical team works with you to understand your application needs, operating conditions, and performance requirements. -

Design & Drawing Review

We create detailed technical drawings for your approval or work directly from your provided specifications. Our engineers can suggest optimizations for manufacturability. -

Prototyping

For new designs, we offer rapid prototype production for validation testing before committing to full production runs. -

Production

Full-scale production with comprehensive quality control at each stage, including dimensional verification, visual inspection, and material testing. -

Quality Certification & Delivery

Each shipment includes quality documentation, material certifications, and inspection reports. Expedited shipping options available for urgent requirements.

Usage Guidelines for Quartz Laser Cavity Tube

Proper handling, installation, and maintenance of quartz laser cavity tubes ensures optimal performance and extends operational lifespan in your laser systems.

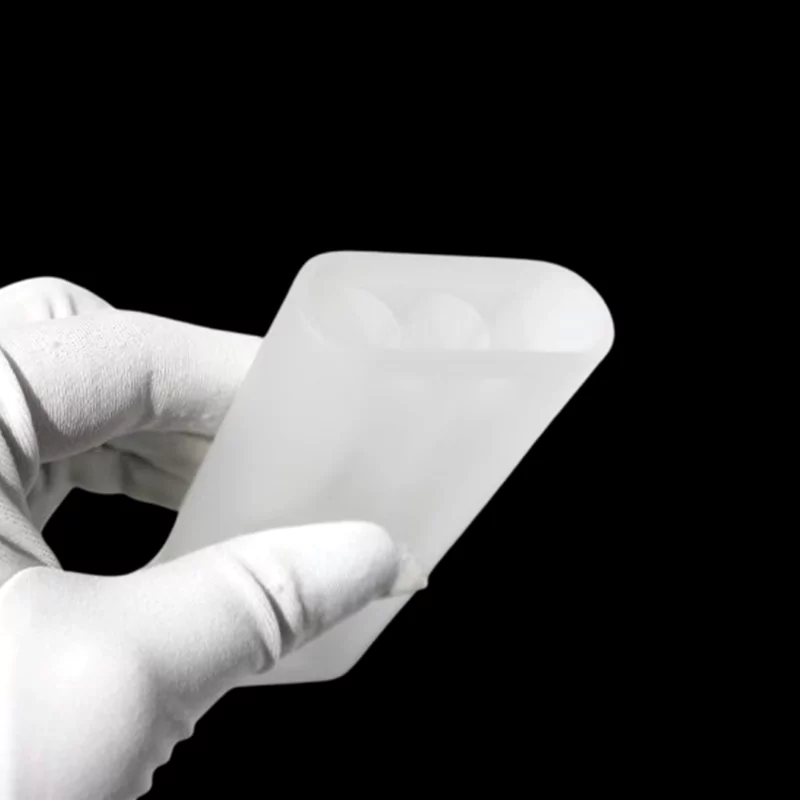

Handling & Storage

- Handle with powder-free nitrile gloves to prevent contamination

- Store in original packaging in a clean, dry environment

- Avoid mechanical stress, impact, or abrasion

- Use foam-lined cases for transportation

Installation & Operation

- Use silicone or Viton O-rings for sealing (not EPDM)

- Apply minimal clamping pressure (torque specs in manual)

- Heat/cool gradually (max 10°C/min temperature gradient)

- Ensure cooling flow is established before power-up

Cleaning & Maintenance

- Clean with isopropyl alcohol (99%) or acetone

- Use lint-free microfiber cloth for wiping

- Avoid abrasive materials and harsh chemicals

- Inspect for deposits/contamination every 500 hours

Need Custom Quartz Laser Cavity Tubes?

with rapid prototyping and full production capabilities.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: Why is quartz used in laser tubes?

A: Quartz is the preferred material for laser cavity tubes due to its exceptional thermal stability (withstanding temperatures up to 1300°C), high optical clarity (>90% transmission across key wavelengths), excellent chemical resistance, and dimensional stability. These properties ensure consistent laser beam quality and long service life even under intense operating conditions.

Q: How does a quartz laser cavity tube work?

A: A quartz laser cavity tube forms the optical cavity that contains the lasing medium. The quartz tube channels and directs the light energy, maintaining proper beam alignment while protecting the internal components. The tube’s precise dimensions and optical properties ensure that the light waves oscillate in phase, amplifying the laser beam through stimulated emission between the reflective mirrors at each end.

Q: What is the lifespan of a quartz laser tube?

A: High-quality quartz laser cavity tubes typically have an operational lifespan of 5,000-10,000 hours under normal operating conditions. Factors affecting longevity include operating temperature, power levels, cooling efficiency, and maintenance practices. With proper care and installation, TOQUARTZ laser tubes can exceed typical industry lifespan expectations by 20-30%.

Q: Can quartz laser tubes be used for all laser types?

A: TOQUARTZ® Quartz laser tubes are ideal for many laser types including CO₂, Nd:YAG, fiber, and excimer lasers. They’re particularly well-suited for applications requiring high thermal stability, UV transmission, or chemical resistance. For specialized applications like ultra-high-power lasers (>10kW) or certain wavelengths, specialized materials might be recommended.

Q: What are multi-channel quartz laser tubes used for?

A: Multi-channel quartz laser tubes serve several functions in laser systems: they can house multiple beam paths, provide cooling channels for thermal management, incorporate gas flow paths for excimer or CO₂ lasers, or create separate compartments for different optical components. This integrated design improves system efficiency and reduces complexity.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.