- Home

- /

- Types

- /

- Custom Quartz Parts

- /

- Custom Low-Drift Quartz Hemispherical...

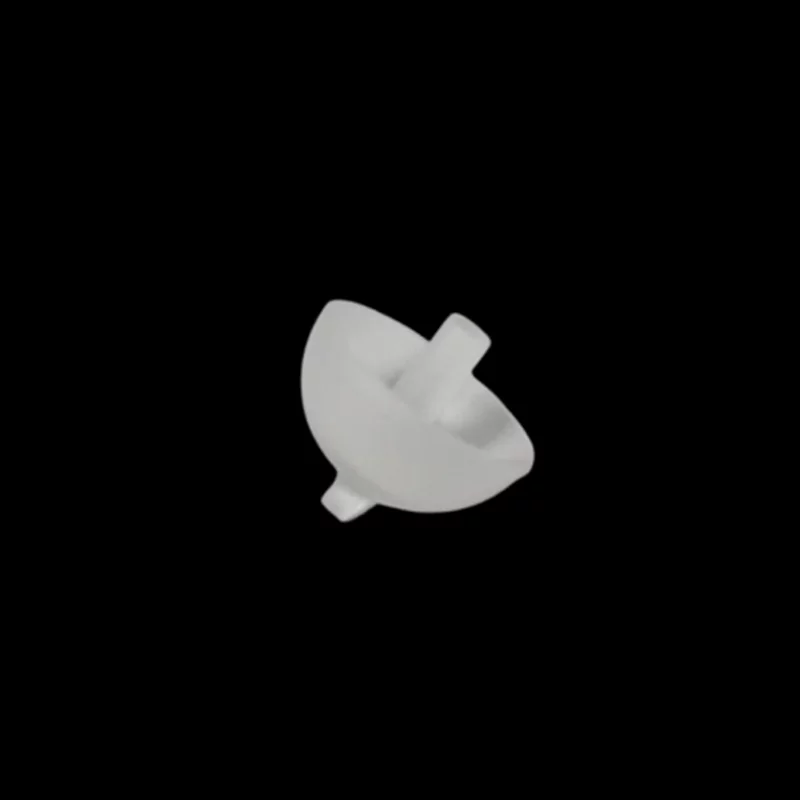

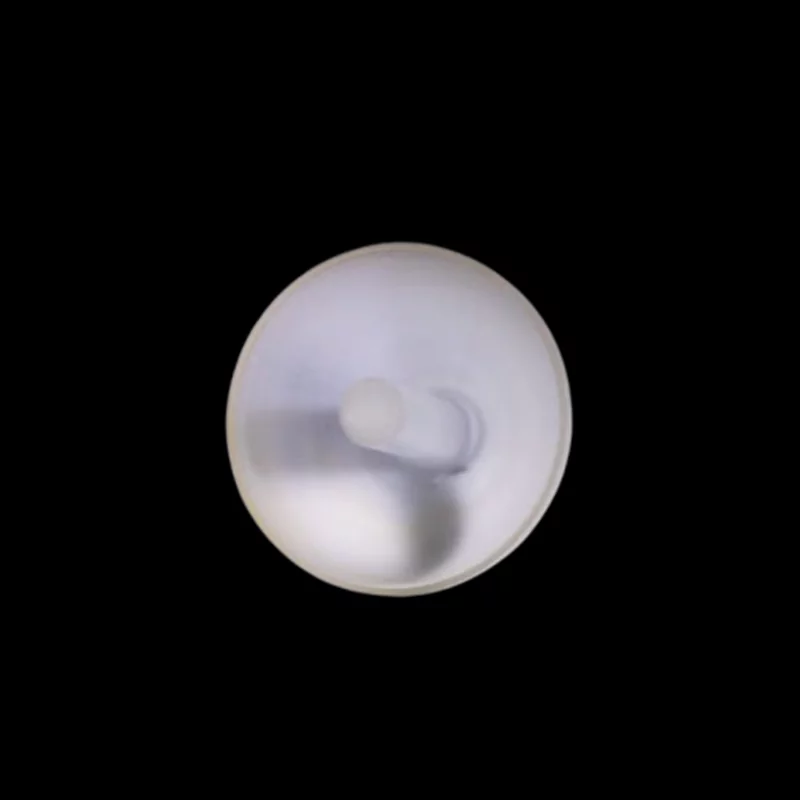

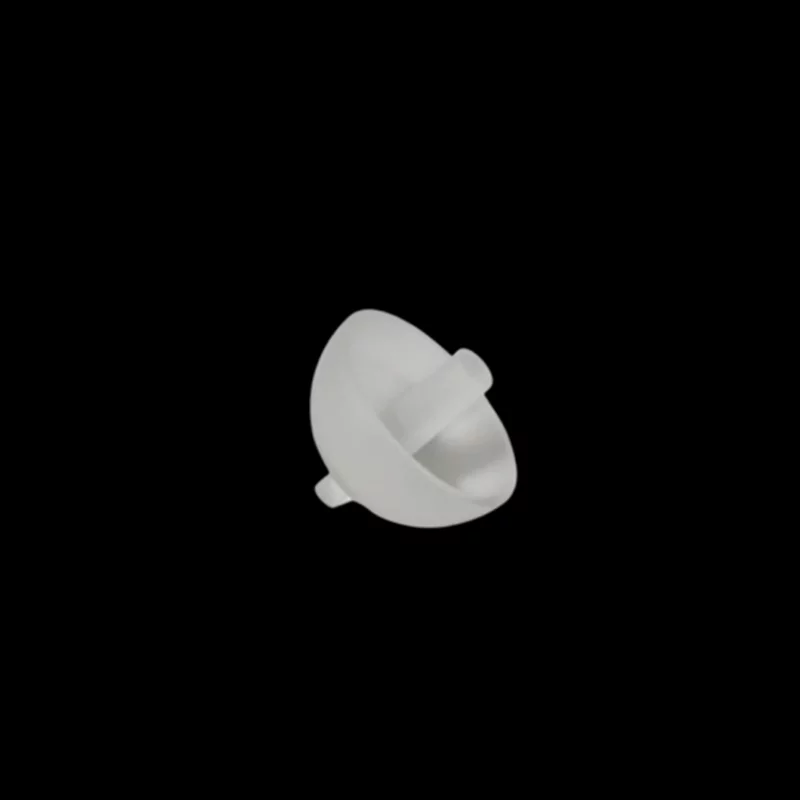

Custom Low-Drift Quartz Hemispherical Shell Resonator for Precision Sensing Applications-TOQUARTZ®

Features of Quartz Hemispherical Shell Resonator

TOQUARTZ® hemispherical shell resonators are manufactured from high-purity fused silica to meet the most demanding requirements in aerospace navigation systems and scientific instruments. Our quartz glass resonator components deliver exceptional performance in extreme environments where stability and precision are critical.

Ultra-High Precision

Manufactured with concentricity, roundness, and inner/outer sphere concentricity of less than 1μm, meeting the highest standards for gyroscopic applications.

Thermal Stability

Withstands temperatures up to 1600°C with minimal thermal expansion (coefficient of 0.5×10⁻⁶/K), ensuring dimensional stability in extreme environments.

Mechanical Resilience

High strength with fracture modulus exceeding 350MPa, combined with low density for lightweight yet durable quartz resonant cavity construction.

- Exceptional Chemical Resistance

- Composed of 99.99% SiO₂

- Customizable Dimensions

Technical Specifications of Quartz Hemispherical Shell Resonator

TOQUARTZ® quartz resonator components are manufactured to exacting standards for applications requiring exceptional precision and stability. The following specifications represent our standard offerings, with custom parameters available upon request.

Physical Properties of Quartz Hemispherical Shell Resonator

| Property | Value | Unit |

| Material | Fused Silica (SiO₂) | – |

| Purity | 99.99 | % |

| Density | 2.2 | g/cm³ |

| Fracture Modulus | ≥350 | MPa |

| Thermal Expansion Coefficient | 0.5×10⁻⁶ | /K |

| Thermal Conductivity | 120-160 | W/m·K |

| Maximum Operating Temperature | 1600 | °C |

Customized Dimensional Range of Fused Quartz Hemispherical Shell Resonator

| Model | Diameter Range | Wall Thickness Range |

| AT-SIO-XZ1001 | φ15~60mm | 0.3~1.1mm |

Manufacturing Precision of Quartz Glass Hemispherical Shell Resonator

| Parameter | Value | |

| Concentricity | <1μm | |

| Roundness | <1μm | |

| Inner/Outer Sphere Concentricity | <1μm | |

| Surface Roughness | Ra≤0.8μm | |

TOQUARTZ® Solving Critical Challenges with

Quartz Hemispherical Shell Resonators

Quartz Hemispherical Shell Resonator for Aerospace Navigation Systems

Key Advantages

-

Sub-micron concentricity for HRG stability

Maintains <1μm concentricity, reducing angular drift in HRG systems by over 85% compared to traditional gyroscopes. -

Thermal deviation under 0.002% at 1600°C

Dimensional shift remains below 0.002% across -55°C to +125°C, ensuring consistent performance in orbital temperature cycles. -

Q-factor retention >1 million in vacuum

Delivers Q-factor exceeding 1×10⁶ in vacuum environments, critical for long-duration satellite inertial navigation.

TOQUARTZ® solution

A European aerospace integrator faced 12% drift deviation in fiber optic gyroscopes during thermal cycling tests.

TOQUARTZ® supplied quartz hemispherical shell resonators with 1 million.

Post-integration, drift deviation dropped to 1.4%, enabling the client to pass ESA-grade IMU qualification.

This reduced recalibration frequency by 60%, saving over €48,000 annually in maintenance costs.

Quartz Hemispherical Shell Resonator for Precision Scientific Instruments

Key Advantages

-

Material purity ≥99.99% SiO₂ for spectral accuracy

Ensures no spectral contamination in mass spectrometry and quantum optics below 200nm wavelength. -

Dimensional repeatability within ±0.1μm

Supports consistent cavity resonance in quantum sensors with <0.05% frequency deviation across batches. -

Surface roughness Ra ≤ 0.8μm for optical resonance

Minimizes scattering loss in optical resonant cavities, improving signal-to-noise ratio by up to 22%.

TOQUARTZ® solution

A German quantum research lab required resonators with <±0.2μm tolerance for a photon entanglement experiment.

Previous suppliers failed to meet dimensional repeatability, causing 18% signal instability.

TOQUARTZ® delivered resonators with ±0.1μm tolerance and Ra ≤ 0.8μm surface finish.

The lab achieved stable resonance over 72 hours, improving measurement fidelity by 31%.

Quartz Hemispherical Shell Resonator for Industrial Measurement Systems

Key Advantages

-

Thermal expansion coefficient 0.5×10⁻⁶/K

Maintains dimensional integrity in environments with ±80°C thermal fluctuation, critical for motion control systems. -

Mechanical fatigue resistance >10⁷ cycles

Withstands over 10 million vibration cycles without structural degradation in high-frequency industrial sensors. -

Corrosion resistance in pH 1–13 environments

Operates reliably in chemically aggressive settings, including acid vapor and alkaline washdown zones.

TOQUARTZ® solution

A Japanese automation OEM reported 22% failure rate in resonators exposed to alkaline cleaning agents.

TOQUARTZ® provided quartz hemispherical shell resonators with verified pH 1–13 corrosion resistance.

After 6 months of continuous operation, failure rate dropped to 0.8%, extending sensor life by 4×.

This reduced downtime by 40 hours/month, saving the client over ¥1.2 million annually.

TOQUARTZ® Customized Quartz Hemispherical Shell Resonator Manufacturing

Custom Manufacturing Capabilities

-

Precision Dimensional Control

Concentricity, roundness, and inner/outer sphere concentricity controlled to less than 1μm for critical applications. -

Customizable Dimensions

Available in diameters from φ15mm to 60mm with wall thickness from 0.3mm to 1.1mm. Custom sizes available upon request. -

Engineering Support

Our experienced engineers provide design assistance and technical consultation throughout your project. -

Prototype Development

Rapid prototyping capabilities for design validation before committing to production volumes. -

Quality Assurance

Comprehensive inspection and testing to ensure every quartz resonator component meets your specifications.

Custom Manufacturing Process

-

Requirement-Based Customization

We follow a structured process to tailor Quartz Hemispherical Shell Resonators based on your technical drawings and performance requirements. -

Design to Specification

Each Quartz Hemispherical Shell Resonator is customized through collaborative engineering to meet exact dimensional and functional criteria. -

Validate Geometry

Our customization workflow ensures that every Quartz Hemispherical Shell Resonator aligns with your application-specific tolerances and geometry.

Usage Guidelines for Quartz Hemispherical Shell Resonators

Proper handling, installation, and maintenance of quartz glass resonator components are essential to ensure optimal performance and longevity. Follow these guidelines to maximize the effectiveness of your quartz resonant cavity solutions.

Handling Recommendations

- Always wear powder-free gloves when handling quartz resonator components to prevent contamination

- Avoid direct contact with the internal surfaces of the quartz hemispherical shell

- Use appropriate packaging and cushioning during transportation to prevent mechanical stress

- If cleaning is necessary, use only recommended solvents (isopropyl alcohol or acetone of semiconductor grade)

Installation Considerations

- Ensure mounting fixtures provide uniform support without inducing stress points

- Use appropriate low-outgassing adhesives for vacuum applications

- Apply torque specifications gradually and evenly when securing components

- Allow for thermal expansion when designing mounting interfaces

Storage Recommendations

- Store in a clean, dry environment with controlled humidity (below 40% RH)

- Maintain temperature stability between 15-25°C (59-77°F)

- Use original packaging or anti-static containers for long-term storage

- Avoid direct sunlight and UV exposure

Performance Optimization

- Allow sufficient warm-up time for thermal stabilization before critical measurements

- Isolate from mechanical vibration sources when possible

- Follow manufacturer's temperature cycle recommendations for optimal stability

- For vacuum applications, follow proper outgassing procedures

Need Technical Assistance?

We're here to help you find the right quartz glass resonator solution.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a quartz resonator used for?

A: Quartz resonators are used in precision applications requiring stable frequency control, vibration sensing, or specific resonant characteristics. In electronic applications, they control oscillator frequencies. In mechanical applications like our quartz hemispherical shell resonator, they function as the core sensing element in gyroscopes and inertial measurement devices for aerospace, navigation, and precision instruments.

Q: How does a quartz resonator work?

A: Quartz hemispherical shell resonators utilize the principle of mechanical resonance in precisely shaped structures. When excited at their natural frequency, these resonators vibrate in specific, predictable patterns. Any rotation of the resonator causes shifts in these vibration patterns due to the Coriolis effect, which can be measured to determine angular velocity and position. The extremely stable mechanical properties of high-purity quartz allow for exceptionally accurate and drift-resistant measurements.

Q: What are the applications of quartz glass resonators?

A: Quartz glass resonators are used in numerous high-precision applications including:

1) Aerospace navigation systems and inertial measurement units;

2) Hemispherical resonator gyroscopes (HRG) for satellite stabilization and aircraft navigation;

3) Scientific instruments requiring precise frequency control;

4) Seismic sensors and vibration monitoring equipment;

5) Precision timing devices;

6) Advanced optical systems and resonant cavities.

Q: What are the advantages of fused silica resonators in high-temperature environments?

A: Fused silica (high-purity quartz) resonators offer several advantages in high-temperature environments:

1) Exceptional thermal stability up to 1600°C;

2) Very low coefficient of thermal expansion (0.5×10⁻⁶/K), maintaining dimensional stability;

3) Resistance to thermal shock; 4) No phase transitions that would affect performance;

5) Maintained mechanical properties at elevated temperatures;

6) Chemical stability even at high temperatures, preventing contamination or degradation.

Q: How do I determine the right specifications for my quartz resonator application?

A: Determining the right specifications involves considering factors like operating environment, precision requirements, resonant frequency needs, and mounting constraints. TOQUARTZ’s engineering team offers complimentary consultation to help you identify the optimal dimensions, material grade, and manufacturing tolerances for your specific application. We can analyze existing designs or help develop new specifications based on your performance requirements.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.