- Home

- /

- Types

- /

- Quartz Rod

- /

- Square Clear Fused Silica...

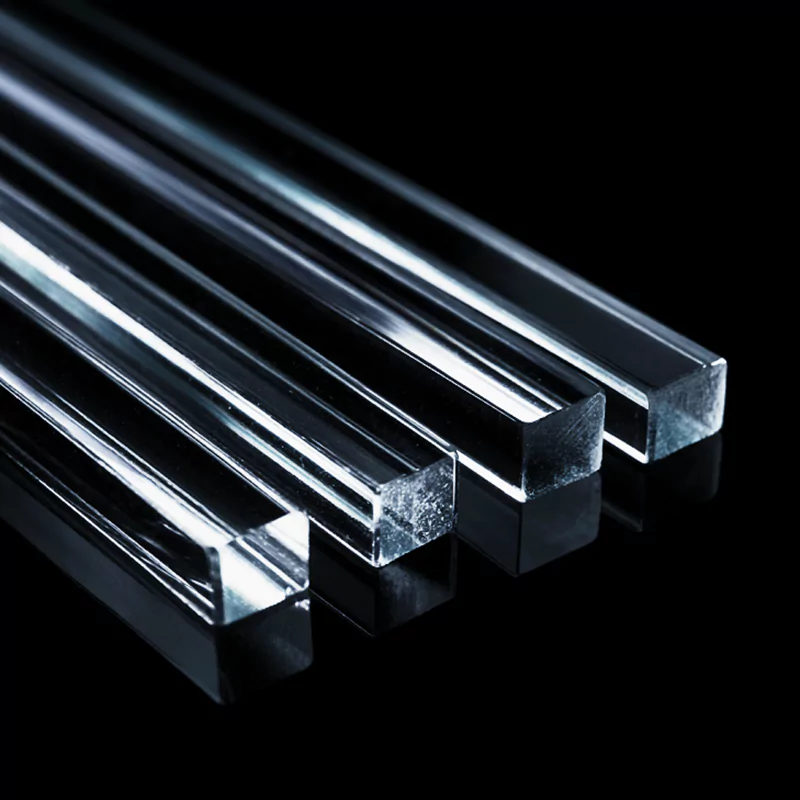

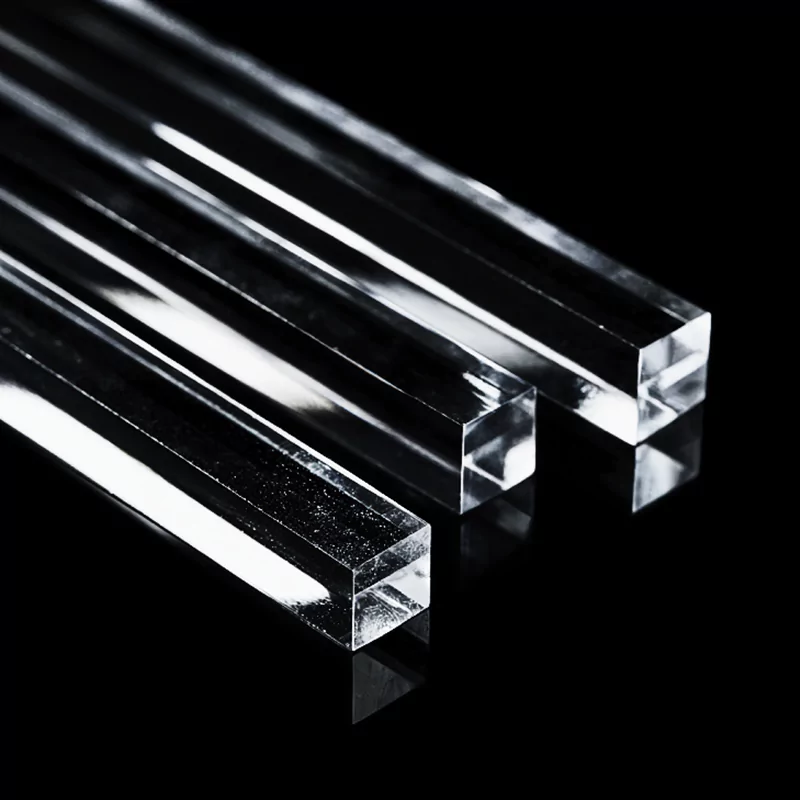

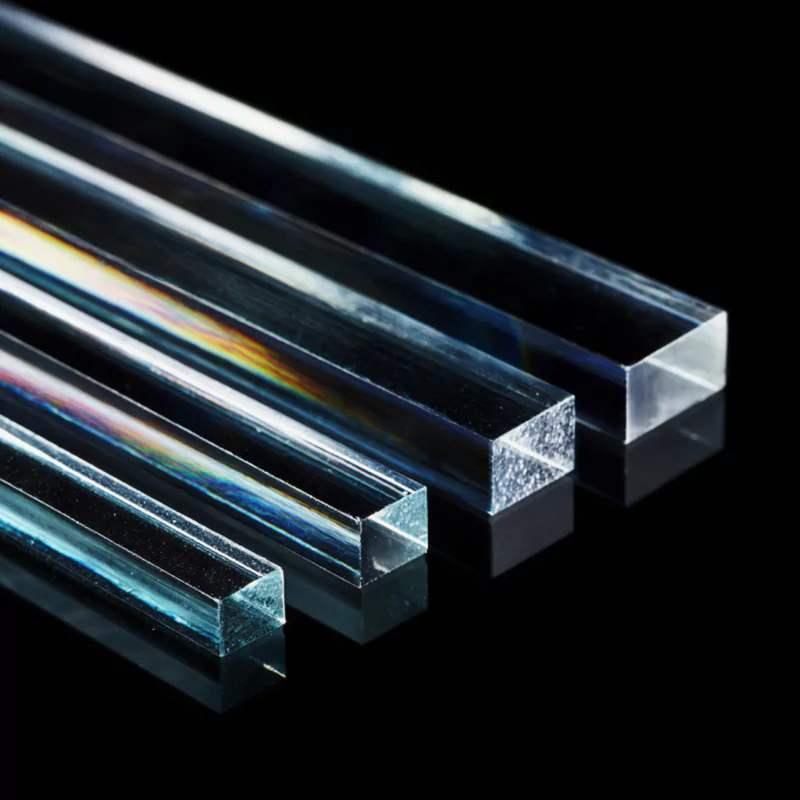

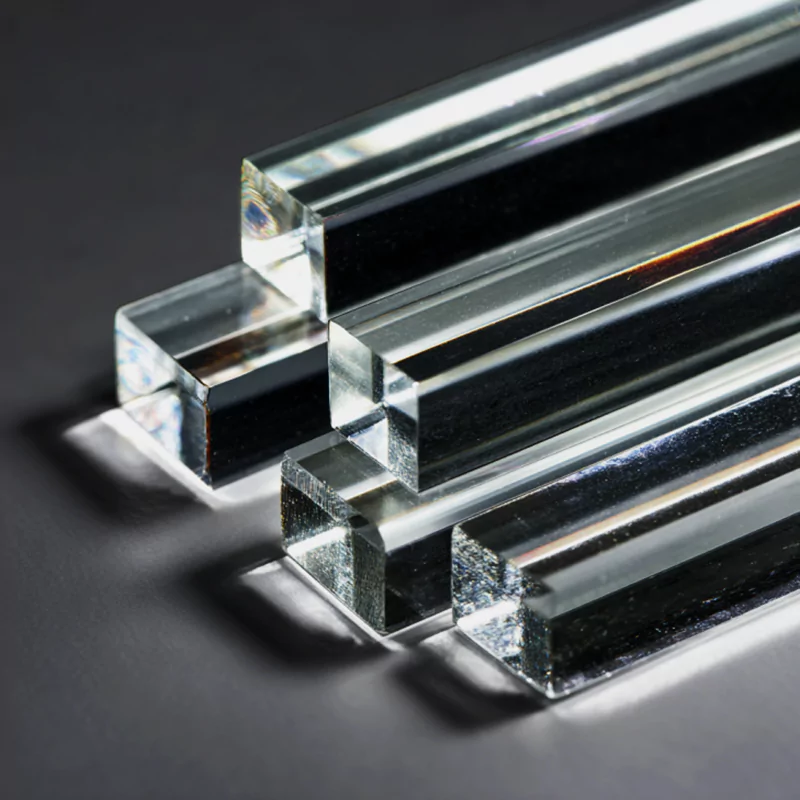

Square Clear Fused Silica Rod with High Optical Transparency for Precision Applications -TOQUARTZ®

Features of Square Clear Fused Silica Rod

Optical Properties

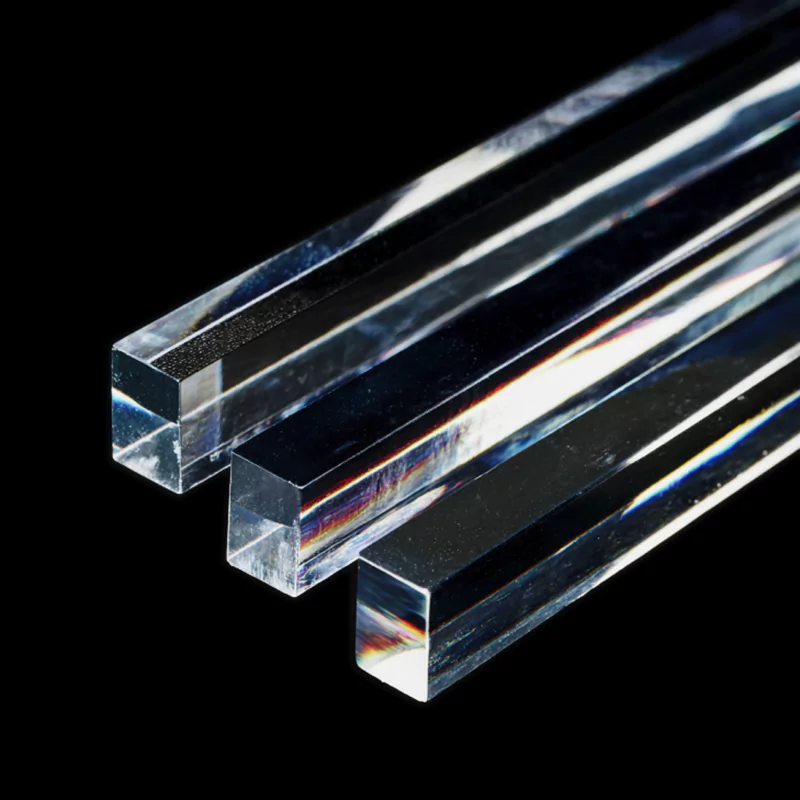

Exceptional transmission range from UV to IR (120nm-4500nm) with no absorption peaks, making these square quartz rods ideal for precision optical applications and light guidance systems.

- High UV transmission (≥85%)

- No absorption peaks across the spectrum

- Ideal for optical beam shaping and collimation

Thermal Stability

Square fused silica rods maintain dimensional stability at extreme temperatures, with a softening point of approximately 1730°C and continuous use temperature of 1100°C.

- Long-term use at 1100°C

- Short-term exposure up to 1450°C

- Low thermal expansion coefficient (5.5×10⁻⁷/°C)

Chemical Properties

TOQUARTZ® square clear fused silica rods exhibit outstanding resistance to acids, bases, molten salts, and fluorine-containing gases, making them suitable for harsh chemical environments.

- Resistant to most acids and bases

- Stable against molten salts

- Unaffected by fluorinated gases

- Temperature Resistant 1100℃+

- Wide Spectral Range 120-4500nm

- Optimal Corrosion Resistance Behaviour

Technical Specifications & Dimensions of Square Clear Fused Quartz Rod

Technical Specifications of Square Clear Fused Quartz Rod

Physical Properties

| Parameter | Value / Range | Notes |

| Density | 2.20 g/cm³ | ISO 1183 |

| Fracture Modulus | ≥ 350 MPa | ASTM C1161 |

| Thermal Conductivity | 120–160 W/m·K | At 20°C |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷ /°C | 20–1000°C |

| Softening Point | ~1730°C | ISO 7884 |

| Working Temperature (Continuous) | ≤1100°C | Long-term |

| Working Temperature (Short-term) | ≤1450°C | ≤1 hour |

| Surface Finish | Polished / Ground / Chamfered | Customizable |

| Dimensional Tolerance | ±0.1 mm (standard) | ±0.05 mm on request |

Chemical Properties

| Parameter | Value / Range | Notes |

| SiO₂ Purity | 99.00% – 99.98% | Synthetic fused silica |

| Acid Resistance | Excellent | HF excluded |

| Alkali Resistance | Excellent | NaOH, KOH |

| Fluoride Gas Resistance | Stable | Up to 1000°C |

| Moisture Absorption | None | Hydrophobic surface |

Optical Properties

| Parameter | Value / Range | Notes |

| Transmission Range | 120 nm – 4500 nm | UV to IR |

| UV Transmission (at 254 nm) | ≥ 85% | 10 mm thickness |

| Refractive Index (at 589 nm) | 1.4585 | ISO 489 |

| Absorption Peaks | None | Smooth spectrum |

| Birefringence | None | Isotropic material |

Size of of Square Clear Fused Silica Rod

| Model | Side 1 (mm) | Side 2 (mm) | Length (mm) | Purity |

| AT-QTZ-G018 | 3 | 3 | 50-1400 | 99%-99.98% |

| AT-QTZ-G019 | 3 | 5 | 50-1400 | 99%-99.98% |

| AT-QTZ-G020 | 6 | 6 | 50-1400 | 99%-99.98% |

| AT-QTZ-G021 | 6 | 4 | 50-1400 | 99%-99.98% |

| AT-QTZ-G022 | 7 | 3 | 50-1400 | 99%-99.98% |

| AT-QTZ-G023 | 7 | 7 | 50-1400 | 99%-99.98% |

| AT-QTZ-G024 | 8 | 6 | 50-1400 | 99%-99.98% |

| AT-QTZ-G025 | 8.7 | 6.3 | 50-1400 | 99%-99.98% |

| AT-QTZ-G026 | 9.5 | 9.5 | 50-1400 | 99%-99.98% |

| AT-QTZ-G027 | 10 | 10 | 50-1400 | 99%-99.98% |

| AT-QTZ-G028 | 11 | 8 | 50-1400 | 99%-99.98% |

| AT-QTZ-G029 | 13 | 10 | 50-1400 | 99%-99.98% |

| AT-QTZ-G030 | 15 | 15 | 50-1400 | 99%-99.98% |

| AT-QTZ-G031 | 16.5 | 16.5 | 50-1400 | 99%-99.98% |

| AT-QTZ-G032 | 23 | 16 | 50-1400 | 99%-99.98% |

| AT-QTZ-G033 | 25 | 25 | 50-1400 | 99%-99.98% |

| AT-QTZ-G034 | 32 | 27 | 50-1400 | 99%-99.98% |

| AT-QTZ-G035 | 36 | 30 | 50-1400 | 99%-99.98% |

| AT-QTZ-G036 | 40 | 30 | 50-1400 | 99%-99.98% |

TOQUARTZ® Square Fused Silica Rod Solutions for Critical Applications

Square Fused Silica Rod for Precision Optical Instruments

Key Advantages

-

Flat-Edge Beam Shaping

Flat square edges enable beam shaping with <0.5° angular deviation in collimation systems. -

Mounting Stability in Optical Rails

Square rods reduce rotational misalignment by 90% compared to cylindrical rods in optical mounts. -

Uniform Refractive Path

Square cross-section ensures consistent refractive index across 100% of beam path width.

TOQUARTZ® solution

A German optical metrology company required square fused silica rods for a beam collimation module with <0.5° angular deviation tolerance. Cylindrical rods caused beam drift due to rotational instability.

TOQUARTZ supplied 10×10×800mm rods with ±0.1mm tolerance and polished edges, reducing beam deviation to 0.3° and improving system alignment repeatability by 40%.

Square Fused Quartz Rod for UV/IR Light Source Applications

Key Advantages

-

Directional UV Emission Control

Square rods reduce lateral UV scatter by 35% compared to round rods in sterilization lamps. -

Flat Surface Integration

Flat sides allow direct bonding to planar reflectors with <0.05 mm adhesive gap. -

Thermal Shock Resistance

Withstands 200°C to 20°C quenching without microcrack formation (tested on 10×10×300mm rods).

TOQUARTZ® solution

A Japanese UV-C sterilization lamp manufacturer faced 18% light loss due to lateral scatter in cylindrical rod designs.

TOQUARTZ provided 7×7×600mm square fused silica rods with UV-grade polishing, reducing scatter loss to 11% and increasing sterilization efficiency by 22% in chamber tests (ISO 15883-1).

Square Clear Quartz Rod for High-Temperature Systems

Key Advantages

-

Structural Load Stability at 1200°C

Square rods maintain <0.2 mm deflection under 5 kg load at 1200°C for 4 hours. -

Anti-Rotation Mounting Geometry

Square profile prevents rotation in thermal module slots, improving assembly safety. -

Thermal Expansion Uniformity

Square rods show <0.05 mm expansion variance across 1000 mm length at 1000°C.

TOQUARTZ® solution

A US-based lab furnace OEM reported ceramic supports cracking after 3 months at 1150°C.

TOQUARTZ delivered 15×15×1000mm square fused silica rods with thermal stability up to 1450°C. After 6-month testing, rods showed no deformation or surface devitrification, reducing component replacement frequency by 70% and saving $12,000 annually in maintenance costs.

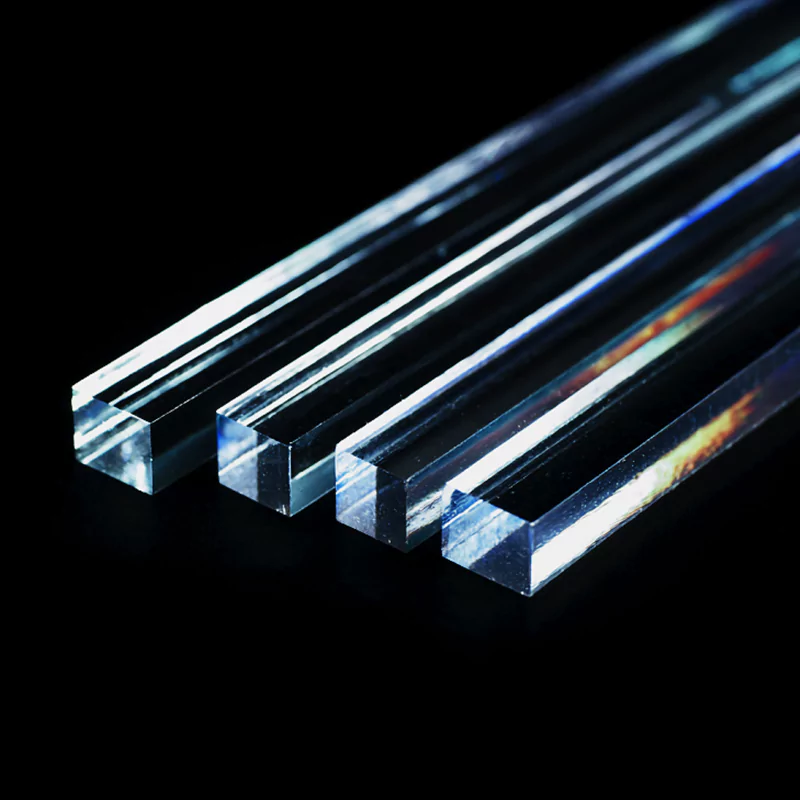

TOQUARTZ® Customization Options for Square Clear Fused Quartz Rod

Dimensional Customization

TOQUARTZ® offers custom sizing for square fused silica rods beyond our standard dimensions, including:

- Custom side lengths from 3mm to 40mm

- Non-square rectangular cross-sections

- Length cutting range of 50mm ~ 1400mm

- Tight tolerances to ±0.1mm

- Custom chamfered or rounded edges

Surface Treatment Options

Enhance the performance of your square fused silica rods with specialized surface treatments:

- Fire-polished optical finish

- Precision ground surfaces

- Acid etching for specific applications

- UV-enhanced surface treatment

- Custom roughness specifications

Engineering Support Services

TOQUARTZ® technical team provides comprehensive support for your square fused silica rod projects:

- Material selection consultation

- Design optimization assistance

- CAD drawing review and feedback

- Prototyping support

- Performance validation testing

· Our in-house engineers provide drawing assistance and feasibility review within 24 hours

· We offer rapid prototyping and short lead times (as fast as 7 days for custom rods)

· All custom square clear fused silica rods undergo 100% dimensional and visual inspection before shipment

This level of flexibility and responsiveness is rarely available from large-scale quartz manufacturers. TOQUARTZ is built to serve B2B clients who need precision, speed, and technical support—not just standard catalog parts.

Usage Guide of Square Clear Fused Silica Rod

Handling Recommendations

- Handle with clean gloves to prevent surface contamination

- Store in clean, dry conditions with protective packaging

- Avoid sudden temperature changes that may cause thermal shock

- Transport in protective containers with cushioning material

- Inspect for scratches or chips before installation

Installation Best Practices

- Clean with isopropyl alcohol or acetone before installation

- Use non-metallic supports when mounting at high temperatures

- Allow for thermal expansion in fixed mounting systems

- Avoid direct contact with metals at high temperatures

- Use vacuum-compatible adhesives for optical applications

Cutting & Machining Guidelines

- Use diamond-impregnated cutting tools for precision cuts

- Maintain constant cooling during cutting operations

- Score-and-break technique works for simple straight cuts

- Polish cut edges with cerium oxide or diamond paste

- Consult with TOQUARTZ engineers for complex machining

Maintenance & Cleaning

- Clean with ultrasonic bath for optical applications

- Remove surface contaminants with dilute HF solution (lab safety protocols required)

- Inspect periodically for devitrification in high-temperature applications

- Replace rods showing signs of mechanical stress or damage

- Document operating conditions to optimize replacement intervals

Need Custom Square Fused Silica Rods?

From prototype to production, we'll help optimize your square quartz rod design for performance and cost-efficiency.

· Submit drawings or specifications

· Request material recommendations

· Discuss manufacturing feasibility

· Get a tailored quote within 24 hours

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What are square quartz rods used for?

A: Square clear fused silica rods are primarily used in optical instruments for beam shaping and collimation, UV/IR light source applications, high-temperature structural components, laboratory equipment, and as raw material for fabricating complex quartz components. Their square cross-section provides flat mounting surfaces and precise optical paths.

Q: What are the benefits of square quartz rod compared to cylindrical rods?artz half-round rods?

A: Square fused silica rods offer several advantages over cylindrical rods: they provide flat mounting surfaces for easier fixture integration, create more defined optical boundaries for beam shaping, prevent rolling during installation, allow for more secure mounting in high-temperature applications, and offer better space utilization in compact designs.

Q: What is the light transmission range of your square fused silica rods?

A: TOQUARTZ® square clear fused silica rods feature excellent transmission across a wide spectrum from 120nm (deep UV) to 4500nm (mid-IR). The UV transmission is typically ≥85%, making them ideal for UV applications. Unlike many glass materials, these rods have no absorption peaks throughout this wavelength range, ensuring consistent optical performance.

Q: How to cut square quartz rod safely and precisely?

A: For precise cutting of square fused silica rods, we recommend using diamond-impregnated cutting tools with constant cooling to prevent thermal stress. For simple straight cuts, a score-and-break technique with a diamond scribe can be effective. After cutting, edges should be fire-polished or ground to remove any micro-cracks that could propagate during use.

Q: Are square fused silica rods electrically conductive?

A: No, standard square fused silica rods are excellent electrical insulators. They have a volume resistivity of approximately 10¹⁸ ohm-cm at room temperature, making them suitable for applications requiring electrical isolation. This insulating property is maintained even at elevated temperatures, though conductivity increases slightly as temperature rises.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.