- Home

- /

- Types

- /

- Quartz Rod

- /

- Clear Fused Quartz Glass...

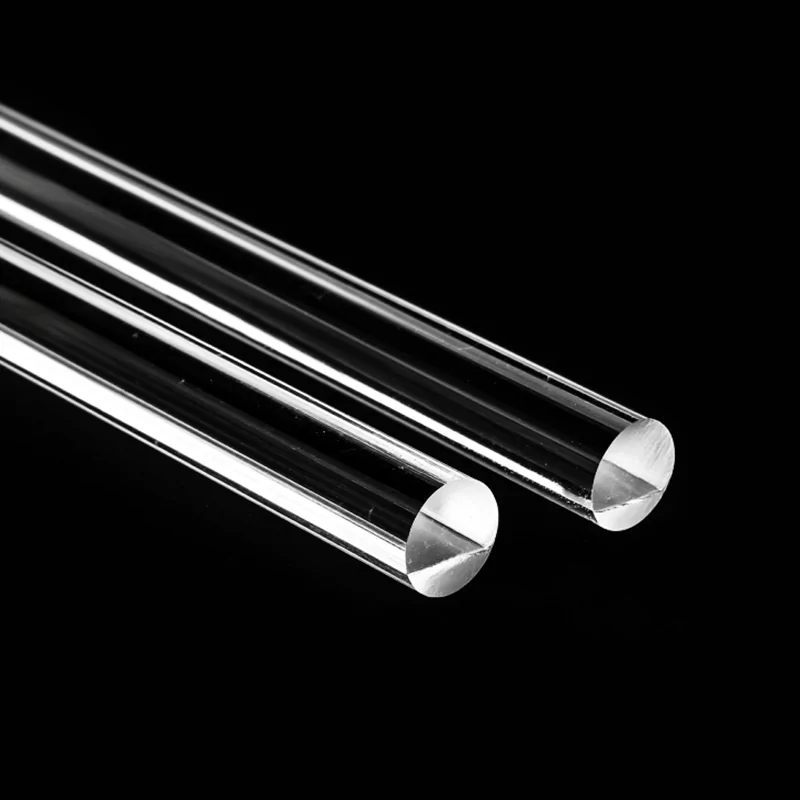

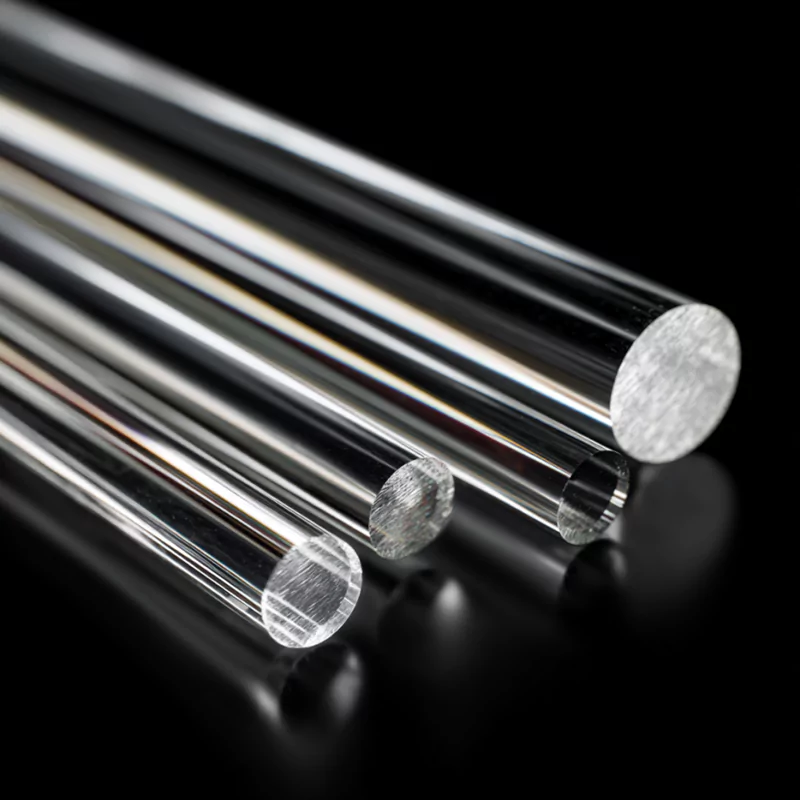

Clear Fused Quartz Glass Solid Cylinder Rod for Laboratory & Optical Applications -TOQUARTZ®

Features exceptional thermal stability up to 1450°C, superior light transmission across 120nm-4500nm spectrum, and excellent chemical resistance.

Ideal for laboratory equipment, optical instruments, and industrial heating applications.

Features of Transparent Quartz Cylinder Rod

High Temperature Resistance

Clear fused quartz cylinder rods have a softening point of approximately 1730°C, allowing sustained use at 1100°C and short-term operation up to 1450°C without deformation.

Light Transmission

Transparent quartz glass solid cylinder rods offer excellent light transmission across a wide spectral range from 120nm to 4500nm without absorption peaks, making them ideal for optical applications.

Chemical Resistance

Fused quartz cylinder rods exhibit exceptional resistance to acids, bases, and chemical reagents, making them suitable for corrosive environments and chemical laboratory applications.

Electrical Insulation

Clear quartz rods provide excellent electrical insulation properties even at high temperatures, with specific resistance of 7×10⁷ Ω·cm, making them suitable for electrical applications.

- Temperature Resistant 1100℃+

- Wide Spectral Range 120-4500nm

- Insulation with specific resistance of 7×10⁷ Ω·cm

Technical Specifications & Dimensions of Quartz Glass Cylinder Rod

Technical Specifications of Transparent Fused Quartz Rods

| Property | Value | Unit |

| Density | 2.2 | g/cm³ |

| Flexture Strength | 48 | MPa |

| Elastic Modulus | 72 | GPa |

| Poisson’s Ratio | 0.14-0.17 | – |

| Compressive Strength | 1100 | MPa |

| Bending Strength | 67 | MPa |

| Moh’s Hardness | 5.5-6.5 | – |

| Maximum Working Temperature (long-term) | 1100 | °C |

| Maximum Working Temperature (short-term) | 1350 | °C |

| Thermal Conductivity | 1.4 | W/m·K |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ | /°C |

| Specific Resistance | 7×10⁷ | Ω·cm |

Size of of Transparent Quartz Glass Solid Cylinder Rod

| Model | Diameter (mm) | Length (mm) | Purity |

| AT-QTZ-G001 | 1.8 | 30 | 99%-99.98% |

| AT-QTZ-G002 | 2 | 50 | 99%-99.98% |

| AT-QTZ-G003 | 2.5 | 200 | 99%-99.98% |

| AT-QTZ-G004 | 3 | 300 | 99%-99.98% |

| AT-QTZ-G005 | 4.5 | 150 | 99%-99.98% |

| AT-QTZ-G006 | 5 | 600 | 99%-99.98% |

| AT-QTZ-G007 | 6 | 700 | 99%-99.98% |

| AT-QTZ-G008 | 7 | 400 | 99%-99.98% |

| AT-QTZ-G009 | 8 | 635 | 99%-99.98% |

| AT-QTZ-G010 | 9 | 720 | 99%-99.98% |

| AT-QTZ-G011 | 10 | 55 | 99%-99.98% |

| AT-QTZ-G012 | 20 | 102 | 99%-99.98% |

| AT-QTZ-G013 | 30 | 50-1400 | 99%-99.98% |

| AT-QTZ-G014 | 40 | 50-1400 | 99%-99.98% |

| AT-QTZ-G015 | 50 | 50-1400 | 99%-99.98% |

| AT-QTZ-G016 | 60 | 50-1400 | 99%-99.98% |

| AT-QTZ-G017 | 1.8-350 | 20-2000 | 99%-99.98% |

TOQUARTZ® Solutions for Critical Applications with Quartz Cylinder Rod

Transparent Quartz Cylinder Rod for Laboratory Equipment

Key Advantages

-

Maintains structural integrity at 1450°C for 30 minutes without deformation

→ Proven thermal endurance in lab furnace simulations with 0.02% dimensional change at 1450°C. -

Optical transmission stability under thermal cycling from 25°C to 1100°C

→ Transmission loss <1.5% after 100 cycles, ensuring consistent spectroscopic accuracy.

TOQUARTZ® solution

A Polish laboratory furnace manufacturer reported rod deformation and cracking after repeated 1300°C cycles using borosilicate components.

TOQUARTZ® supplied 20mm × 800mm transparent quartz cylinder rods with 99.995% SiO₂ purity and thermal tolerance up to 1450°C. After 180 thermal cycles, the rods maintained full dimensional stability with zero surface crystallization, reducing component replacement frequency by 70% and improving furnace uptime.

Transparent Fused Quartz Cylinder Rod for UV Light Applications

Key Advantages

-

UV transmittance ≥85% at 254nm for 10mm thick rods

→ Verified by spectrophotometry, ideal for germicidal UV-C applications. -

Solarization resistance after 1000 hours of continuous UV exposure

→ ΔT < 2% at 254nm, ensuring long-term optical consistency in sterilization systems. -

OH content <10ppm for enhanced UV transparency and minimal absorption

→ Low hydroxyl levels reduce UV-induced color centers in high-output UV lamps.

TOQUARTZ® solution

A Japanese UV sterilization equipment manufacturer struggled with premature degradation of standard quartz components, requiring replacement every 3 months.

After switching to TOQUARTZ clear fused quartz cylinder rods, service life extended to 12+ months, reducing maintenance costs by 68% while improving sterilization performance.

Clear Quartz Glass Cylinder Rod for Optical Instrumentation

Key Advantages

-

Spectral transmission range from 120nm to 4500nm with no absorption peaks

→ Enables full-spectrum analysis in UV-VIS-NIR spectrometers and laser optics. -

Refractive index uniformity Δn < 5×10⁻⁶ across 100mm rod length

→ Ensures beam path stability in high-precision optical alignment systems. -

Dimensional deviation <±0.05mm for rods ≤20mm diameter

→ Supports tight mechanical tolerances in optical mounts and scanning assemblies.

TOQUARTZ® solution

A Korean optical instrument manufacturer struggled with inconsistent optical performance due to variations in material quality.

After implementing TOQUARTZ's clear quartz rods with controlled specification variance of ±0.1mm, they achieved a 22% improvement in instrument calibration stability and reduced optical component rejection rate from 15% to under 3%.

TOQUARTZ® Customization Options for Clear Fused Quartz Cylinder Rods

Diameter Range

from 1.8mm to 350mm, with length options from 20mm to 2000mm

Tolerance Control

up to ±0.1mm for critical applications

Material Purity Options

from 99% to 99.98% SiO₂

Surface Finish Options

fire-polished, ground, or optical-grade polished

End Processing

flat, beveled, hemispherical, or custom geometries

Optical Clarity Optimization

UV, visible, or IR transmission

· Our in-house engineers provide drawing assistance and feasibility review within 24 hours

· We offer rapid prototyping and short lead times (as fast as 7 days for custom rods)

· All custom fused quartz cylinder rods undergo 100% dimensional and visual inspection before shipment

This level of flexibility and responsiveness is rarely available from large-scale quartz manufacturers. TOQUARTZ is built to serve B2B clients who need precision, speed, and technical support—not just standard catalog parts.

Usage Guide of Transparent Quartz Glass Solid Cylinder Rod

Handling & Storage

- Handle clear quartz rods with clean gloves to prevent surface contamination and fingerprints that may affect optical performance.

- Store in clean, dry conditions with protective packaging to prevent scratches or mechanical damage.

- Avoid sudden mechanical shocks or impacts that may cause microfractures not immediately visible but potentially compromising during high-temperature applications.

Installation & Temperature Management

- When using quartz cylinder rods in high-temperature applications, implement gradual heating and cooling rates (≤5°C/min) to minimize thermal shock.

- Ensure appropriate clearance for thermal expansion when mounting in fixtures (coefficient of expansion: 5.5×10⁻⁷/°C).

- Do not exceed maximum operating temperatures: 1100°C for continuous use, 1450°C for short-term applications.

Chemical Compatibility

- While fused quartz cylinder rods resist most acids and chemicals, avoid prolonged exposure to hydrofluoric acid (HF) and hot concentrated phosphoric acid, which can etch the surface.

- At high temperatures (>1000°C), prevent contact with alkali metals, alkaline earth oxides, and metal oxides to avoid devitrification.

- For applications involving molten metals, consider protective coatings to prevent reaction with the quartz surface.

Free Technical Consultation for Quartz Glass Solid Cylinder Rod Applications

Save time and prevent costly material selection errors.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What are quartz glass solid cylinder rods used for?

A: Transparent quartz cylinder rods are primarily used in laboratory equipment, UV light systems, optical instruments, high-temperature applications, semiconductor manufacturing, and analytical instruments where high thermal stability, optical clarity, and chemical resistance are required.

Q: What is the light transmission range of clear quartz glass solid cylinder rod?

A: Transparent quartz glass solid cylinder rods offer excellent light transmission across a wide spectral range from 120nm (UV) to 4500nm (mid-IR) without absorption peaks, making them ideal for optical applications requiring consistent transmission properties.

Q: How to cut quartz glass solid cylinder rod properly?

A: Use diamond-coated cutting tools with continuous water cooling to prevent overheating. Maintain slow feed rates (≤5mm/min) and use specialized diamond slurry saws for diameters >20mm. After cutting, fire-polish or chemically polish ends to remove microcracks and optimize performance.

Q: What are the benefits of clear fused quartz cylinder rod for UV applications?

A: For UV applications, clear quartz rods offer excellent transmission in the 120-400nm range, minimal solarization (UV-induced color change), high temperature stability, and resistance to UV degradation. These properties make them ideal for UV sterilization systems, analytical instruments, and UV curing equipment.

Q: Where can I find transparent fused quartz rod suppliers with technical support?

A: TOQUARTZ provides comprehensive technical support with all quartz rod products, including engineering consultation, custom specification assistance, and application guidance. Our technical team has extensive experience in materials science and industrial applications, ensuring you receive the right product for your needs.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.