- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Air Free Quartz Cuvette...

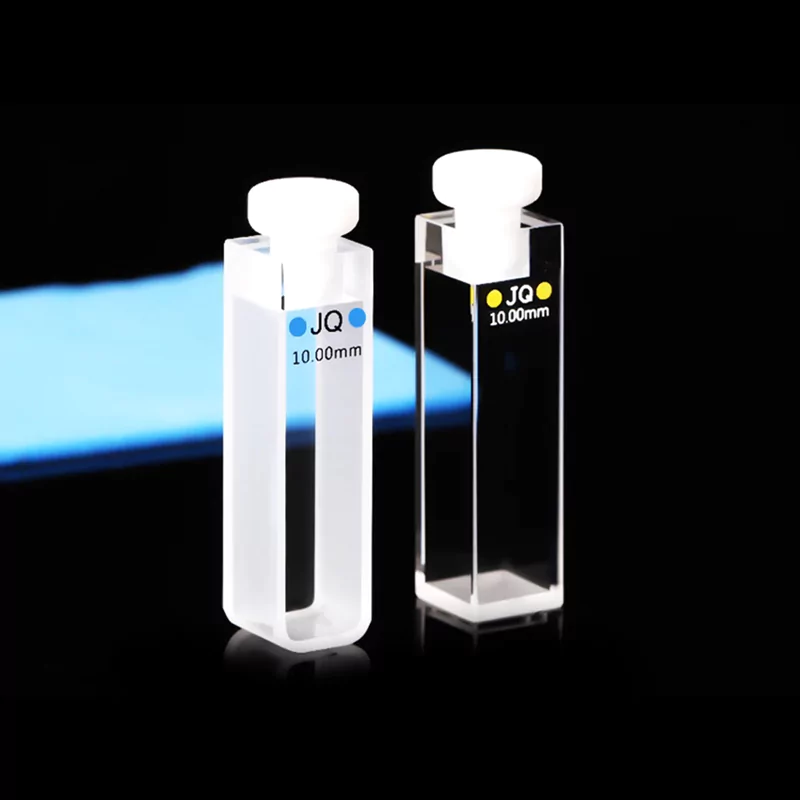

Air Free Quartz Cuvette for Laboratory Spectroscopy Applications -TOQUARTZ®

Features of Air Free Quartz Cuvette

TOQUARTZ® air free quartz cuvettes are engineered for applications requiring sealed environments during spectroscopic analysis. These specialized cuvettes provide the optimal combination of optical performance, chemical resistance, and reliable sealing capabilities.

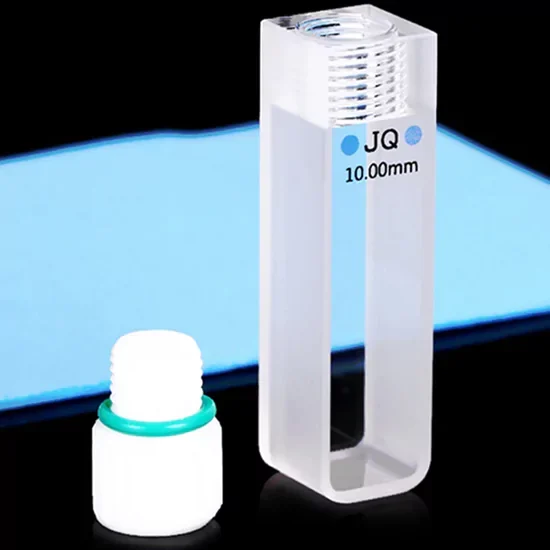

Reliable Sealing Mechanism

Vacuum quartz cuvette designs featuring precision-engineered PTFE stoppers or ground glass joints that provide gas-tight sealing. Each unit undergoes rigorous testing to ensure reliable containment of inert atmospheres.

Optical Transmission

Exceptional quartz cuvette wavelength range from 200nm to 2500nm with no absorption peaks, ideal for UV, visible, and IR spectroscopy applications. Consistent light path length ensures accurate and reproducible measurements.

Chemical Resistance

Excellent quartz cuvette solvent compatibility with stability against acids, bases, and most chemical reagents. Resistant to high temperatures up to 1100°C, making them suitable for various reaction conditions.

- Gas-Tight Sealing

- UV-IR Compatible

- High Purity Quartz

Technical Specifications & Dimensions of Vacuum Quartz Glass Cuvette

Technical Specifications of Vacuum Quartz Cuvette

| Parameter | Specification |

| Material | High-purity quartz (>99.98% SiO₂) |

| Optical Transmission Range | 200nm – 2500nm, no absorption peaks |

| Standard Path Lengths | 1mm, 2mm, 5mm, 10mm, 20mm, 50mm, 100mm |

| Dimensional Tolerance | ±0.1mm (standard), ±0.2mm (specialized designs) |

| Sealing Mechanism | PTFE stoppers, ground glass joints, or custom fittings |

| Sealing Performance | Passes water seal test and pressure testing |

| Temperature Resistance | Up to 1100°C (quartz body) |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷/K |

| Chemical Resistance | Resistant to acids, bases, organic solvents (except HF) |

| Surface Treatment | Polished, bubble-free, scratch-free optical windows |

| Quartz Cuvette Absorbance Range | 0.01 – 3.0 AU (depending on path length) |

Size of of Vacuum Quartz Cuvette

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-5001 | 3.5ml Quartz cuvette(10mm) | 3.5ml | 10mm | 12.5×12.5x45mm | 200nm-2500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-5002 | Quartz cuvette cell with screw cap for lab | 3.5ml | 10mm | 12.5×12.5x60mm | 200nm-2500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-5003 | Quartz cuvette cell with screw cap | 3.5ml | 10mm | 12.5×12.5x45mm | 200nm-2500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-5004 | Standard quartz cuvette cell with stopper without glue | 3.5ml | 10mm (4 polished sides) |

12.5×12.5x45mm | 200nm-2500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-5005 | Quartz closed cuvette airtight paired UV quartz band plug | 3.5ml | 10mm (4 polished sides) |

12.5×12.5x45mm | 200nm-2500nm |

TOQUARTZ® Solving Challenges with Vacuum Fused Quartz Cuvettes

Air Free Quartz Glass Cuvettes for Oxygen-Sensitive Spectroscopy

Key Advantages

- TOQUARTZ® Vacuum-sealed quartz cuvettes prevent oxygen ingress for over 72 hours under 1 atm pressure.

- Maintains spectral stability for oxygen-sensitive dyes in UV-Vis range (200–400nm).

- PTFE Stopper Leakage Rate < 1×10⁻⁶ mbar·L/s

- Internal O₂ concentration remains < 0.5 ppm after 48h sealed storage.

TOQUARTZ® solution

A German analytical instrument manufacturer reported 12% sample degradation during oxygen-sensitive UV-Vis analysis.

TOQUARTZ air free cuvettes reduced degradation to less than 0.5%, enabling accurate analysis of photosensitive compounds over extended periods.

Vacuum Fused Quartz Cuvettes for Inert Gas Reactions

Key Advantages

- Enables real-time reaction monitoring under N₂ or Ar with inlet/outlet flow control.

- Reaction Chamber Volume Precision ±0.05mL

- Allows temperature probe insertion without compromising gas-tight integrity.

- Pressure Stability up to 1.5 bar

- Gas Purge Efficiency > 99.9% in 3 min

TOQUARTZ® solution

A pharmaceutical R&D team required real-time UV-Vis monitoring of a nitrogen-sensitive intermediate.

TOQUARTZ® vacuum quartz cuvettes with dual gas ports enabled continuous N₂ flow and stable absorbance readings over 6 hours.

Compared to open cuvettes, signal drift was reduced by 87%, and reaction reproducibility improved by 42%.

This allowed the team to validate a new synthesis route without redesigning their spectrometer setup.

Air Free Fused Quartz Cuvettes for Microvolume Analysis

Key Advantages

- Evaporation Rate < 0.3% over 1 hour

- Optical Path Length Tolerance ±0.02mm

- Sample Recovery Rate > 98%

- Prevents fogging during temperature shifts, preserving optical clarity in low-volume assays.

- 5mm diameter neck allows direct sample injection without contamination risk.

TOQUARTZ® solution

A biomedical lab analyzing 100μL enzyme samples faced 10–15% volume loss due to evaporation in open cuvettes.

Using TOQUARTZ® vacuum quartz cuvettes with precision-sealed caps, evaporation dropped below 0.3% over 60 minutes.

This improved assay repeatability by 35% and reduced reagent waste by 40%, enabling more cost-effective screening.

The lab integrated the cuvettes into their standard protocol for all microvolume UV-Vis assays.

Customization Services for TOQUARTZ® Fused Quartz Air Free Cuvettes

Custom Design Options

Custom Path Lengths

Non-standard quartz cuvette path length options to optimize for specific sample concentrations and measurement requirements.

Specialized Sealing Mechanisms

Custom stoppers, valves, sample ports, or connection interfaces designed for compatibility with your existing equipment.

Flow-Through Modifications

Integration of inlet/outlet ports for continuous flow applications while maintaining airtight conditions.

Temperature Control Features

Modifications for integration with temperature control systems for reaction monitoring under controlled conditions.

Multi-Cell Configurations

Custom designs with multiple sealed compartments for simultaneous sample analysis or reference measurements.

TOQUARTZ® Customization Design Process

Technical Consultation

TOQUARTZ® engineers work with you to understand application requirements, specifications, and integration needs.

Design Proposal

We provide technical drawings based on your requirements, with recommendations for optimization if needed.

Prototype Development

Rapid prototyping with sample delivery within 7-14 days for testing and validation.

Refinement & Production

Based on feedback, we refine the design and proceed with production of your custom order.

Quality Control & Testing

Rigorous testing for optical performance, sealing efficiency, and dimensional accuracy before shipping.

Vacuum Fused Quartz Cuvette Cleaning Procedure

Standard Cleaning Protocol

- 1. Initial Rinse: Rinse with distilled water immediately after use to remove water-soluble substances.

- 2. Solvent Selection: For organic contaminants, use ethanol-water mixture (1:1). For inorganic residues, use dilute HCl (1:2).

- 3. Cleaning Method: Gently fill and empty the cuvette with cleaning solution 3-5 times. Never use abrasive materials or brushes.

- 4. Final Rinse: Thoroughly rinse with distilled water three times to remove all cleaning agents.

- 5. Drying: Place upside down on clean, lint-free absorbent paper. Allow to air dry completely before storage.

Special Considerations for Air Free Cuvettes

Sealing Components

Clean PTFE stoppers and ground glass joints separately with appropriate solvents. Ensure complete drying before reassembly.

Ultrasonic Cleaning

For stubborn contaminants, ultrasonic cleaning is recommended. Place the cuvette with matte surfaces facing downward in the ultrasonic bath.

Special Contaminants

For oil/grease, use petroleum ether. For dye residues like chromazurol, use dilute nitric acid (1:2).

Storage

Store cleaned and dried cuvettes in their original protective cases. Keep in a dust-free environment.

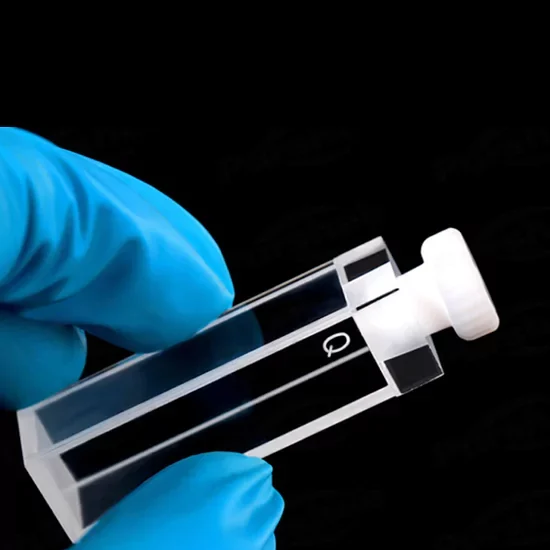

Handling

Always handle with gloves to prevent fingerprints and skin oils from contaminating optical surfaces.

· Dilute hydrochloric acid (1:2) for inorganic residues

· Specialized cuvette cleaning solution (limited exposure time: 10 minutes max)

Need Technical Consultation for Your Air Free Quartz Cuvette Requirements?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the wavelength range for your air free quartz cuvettes?

A: TOQUARTZ® air free quartz cuvettes provide excellent transmission across the 120nm to 4500nm wavelength range, making them suitable for UV, visible, and IR spectroscopy applications. The quartz material has no absorption peaks throughout this range, ensuring accurate spectral data.

Q: What is the proper quartz cuvette cleaning procedure to maintain optical performance?

A: For standard cleaning, rinse with distilled water immediately after use, then clean with an ethanol-water (1:1) mixture for organic contaminants or dilute HCl (1:2) for inorganic residues. Rinse thoroughly with distilled water three times, and air dry upside down on lint-free paper. Never use alkaline solutions, abrasives, or hydrofluoric acid, as these can damage the quartz surface.

Q: What types of sealing mechanisms are available for your air free quartz cuvettes?

A: TOQUARTZ® standard air free quartz cuvettes come with PTFE stoppers or ground glass joints that provide reliable gas-tight sealing. We also offer custom sealing options including specialized valves, septum ports for sample injection, compression fittings, and connectors compatible with standard laboratory equipment.

Q:What is the vacuum quartz cuvette solvent compatibility range?

A: TOQUARTZ® quartz cuvettes are compatible with most laboratory solvents including water, alcohols, acetone, chloroform, DMSO, acids (except HF), and bases. The high-purity quartz (99.995% SiO₂) provides excellent chemical resistance, though prolonged exposure to hydrofluoric acid or high-concentration fluoride solutions should be avoided.

Q: What is the typical quartz cuvette absorbance range for your products?

A: TOQUARTZ® vacuum quartz cuvettes support an absorbance range from 0.01 to 3.0 AU (Absorbance Units), depending on the path length selected. The high optical clarity and precision of our quartz material ensures accurate absorbance measurements across this range with minimal stray light interference.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.