- Home

- /

- Types

- /

- Quartz Tube

- /

- Ultraviolet Blocking Quartz Glass...

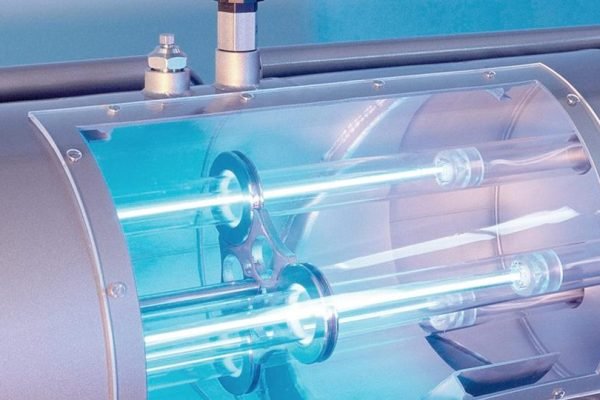

Ultraviolet Blocking Quartz Glass Tube For Optiacal & Lab Instruments -TOQUARTZ®

Ultraviolet blocking quartz tubes are manufactured by infusing cerium and other elements into pure quartz glass, effectively blocking UV radiation while maximizing visible light transmission.

These tubes offer excellent light transmission, high temperature resistance, superior corrosion resistance, and exceptional insulation properties for UV lamps, optical instruments, and laboratory equipment.

Key Features of UV Blocking Quartz Glass Tube

TOQUARTZ® ultraviolet blocking quartz glass tubes are specialized optical components designed to filter out harmful UV radiation while maintaining excellent visible light transmission.

Chemical Stability & Corrosion Resistance

- Ideal for chemically reactive lab environments

- Maintains structure with alkaline isolation precautions

- Acid resistant except hydrofluoric acid exposure

Optical Performance & UV Blocking Efficiency

- Blocks over 95% UVB and UVC radiation

- Low auto-fluorescence for optical instruments

- Maintains optical clarity under thermal load

Thermal Durability & Heat Shock Resistance

- Excellent thermal shock resilience properties

- Dimensional stability under rapid heating cycles

- Suitable for halogen and UV lamp assemblies

- Strong Chemical Stability

- High UV Blocking Efficiency

- Advanced Heat Shock Resistance

Dimension of Ultraviolet Blocking Quartz Glass Tubes

TOQUARTZ® ultraviolet blocking quartz glass tubes are available in a wide range of standard dimensions and can be customized to meet your specific requirements. All products undergo rigorous quality control to ensure dimensional accuracy and optical performance.

| Parameter | Standard Range | Custom Options |

| Length (L) | 100mm – 1000mm | Up to 2000mm available |

| Outer Diameter (OD) | 10mm – 28mm | Custom sizes available |

| Inner Diameter (ID) | 8mm – 25mm | Custom sizes available |

| Wall Thickness | 1.0mm – 3.0mm | Custom options available |

Properties of Ultraviolet Blocking Quartz Glass Tubes

Material Properties:

Chemical Composition

SiO₂ (>99.98%) with cerium oxide additives for UV blocking

Thermal Properties

Thermal expansion coefficient: 5.5×10⁻⁷/K

Electrical Properties

Excellent electrical insulation, suitable for high-voltage environments

Optical Properties:

UV Blocking

Blocks >95% of UVB/UVC radiation (wavelengths below 350nm)

Visible Light Transmission

High transparency in visible spectrum (400-700nm)

Refractive Index

1.46 at 589.3nm (sodium D line)

Solving Challenges with UV Blocking Quartz Glass Tubes

Ultraviolet Blocking Quartz Glass Tubes in UV Lighting Systems

TOQUARTZ® UV blocking quartz tubes provide precise spectral filtering for applications where certain UV wavelengths must be eliminated while allowing others to pass through.

Key Advantages

- Selective Cutoff Below 350nm UV Spectrum

- Spectral Clarity with Visible Light Transparency

- Consistent Wavelength Transmission Across Tube Surface

TOQUARTZ® solution

A German UV curing equipment manufacturer experienced inconsistent curing results due to unwanted UV wavelengths affecting their photopolymer materials.

TOQUARTZ provided custom UV blocking quartz tubes that precisely filtered out the problematic wavelengths while maintaining optimal curing efficiency, reducing their product rejection rate from 12% to under 2%.

UV Blocking Quartz Glass Tubes for Medical and Laboratory Equipment

TOQUARTZ® UV blocking quartz tubes provide reliable shielding while maintaining optical clarity for these critical applications.

Key Advantages

- High UV Attenuation Protecting Light-sensitive Sensors

- Minimal Wavelength Shift Across Tube Surface

- Ensures Chemical Analysis Integrity By Blocking UV Artifacts

TOQUARTZ® solution

A Canadian biomedical firm resolved inconsistent fluorometry results caused by UV interference by adopting TOQUARTZ's custom ultraviolet blocking quartz glass tubes with >95% UV blocking and 400-700nm visible transparency, achieving 38% higher test consistency and reduced recalibration needs.

UV Blocking Quartz Glass Tubes in Optical Instruments

TOQUARTZ® UV blocking quartz tubes provide the perfect solution for instruments that need protection from UV interference while maintaining excellent visible light transmission.

Key Advantages

- Customizable UV Cutoff Without Spectral Distortion

- Maintains Beam Uniformity and Surface Optical Flatness

- Low Auto-fluorescence to Preserve Signal Precision

TOQUARTZ® solution

A Japanese optical firm resolved UV-Vis spectrophotometer signal noise caused by UV leakage by implementing TOQUARTZ's custom 365nm UV-cutoff quartz tubes with ultra-low autofluorescence, achieving 42% baseline stability gains and ±0.2nm wavelength resolution.

Customization Services for

TOQUARTZ® Ultraviolet Blocking Quartz Glass Tubes

Customization Capabilities for Ultraviolet Blocking Quartz Glass Tubes

- End Finishing Options

- Fire polished ends for improved optical clarity

- Ground flat ends for precise optical alignment

- Custom angle cuts for specialized optical paths

- Flanged ends for secure mounting

- Surface Treatments

- Anti-reflection coatings to minimize light loss

- Hydrophobic treatments for improved cleaning

- Surface etching for better adhesion in assemblies

- Custom Dimensions

- Specialized UV Filtering

TOQUARTZ® Custom Design Process

Requirement Analysis

We begin by thoroughly understanding your application requirements, including dimensions, material specifications, and performance criteria.

Design & Engineering

Our engineers develop a detailed design specification, including technical drawings and material requirements.

Prototype Development

We produce sample tubes for your evaluation and testing, with rapid turnaround times for urgent projects.

Production & Quality Control

Following approval, we manufacture your custom ultraviolet blocking quartz glass tubes with rigorous quality control at every step.

Product Usage Guidelines of UV Blocking Quartz Glass Tube

Handling Precautions

- Use soft, lint-free gloves when handling

- Avoid direct contact with bare hands

- Store in protective packaging when not in use

Temperature Limitations

- Maximum continuous use: 1100°C

- Maximum short-term use: 1450°C

- Allow gradual heating/cooling when possible

Chemical Compatibility

- Compatible with most acids (except HF)

- Avoid alkaline materials at high temperatures

- Maintain chemical isolation in assemblies

Need Expert Guidance for Your UV Blocking Quartz Tube Requirements?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What are the main advantages of spiral quartz tubes over straight tubes?

A: Spiral quartz tubes offer several advantages: increased surface area in a compact footprint, extended UV light path for better sterilization efficiency, improved heat distribution for IR applications, and enhanced mixing capabilities for laboratory reactions. The spiral design also provides greater structural flexibility while maintaining the excellent thermal and chemical properties of quartz.

Q: What is the maximum temperature that TOQUARTZ® spiral quartz tubes can withstand?

A: Our spiral quartz tubes can withstand continuous operating temperatures up to 1100°C and short-term exposure up to 1600°C. The softening point of high-purity quartz is approximately 1730°C. However, we recommend maintaining a safety margin below these limits for prolonged use, especially for spiral configurations where stress distribution differs from straight tubes.

Q: Are TOQUARTZ® spiral quartz tubes suitable for UV-C transmission applications?

A: Yes, our high-purity spiral quartz tubes offer excellent UV-C transmission (>90% at 254nm wavelength), making them ideal for UV sterilization systems. We can provide specific transmission data for different wavelengths upon request. For UV applications, we recommend our clear fused quartz grade with minimal iron content to maximize UV transmission efficiency.

Q: Can you create spiral quartz tubes with variable pitch or diameter?

A:Yes, we can manufacture spiral quartz tubes with variable pitch or diameter changes along the length. These advanced designs can optimize flow characteristics, heat distribution, or optical properties for specific applications. Such customizations require detailed technical discussions with our engineering team to ensure manufacturability and performance.

Q: Do you offer any surface treatments for spiral quartz tubes?

A: Yes, we offer several surface treatments for spiral quartz tubes, including acid etching for improved adhesion, fire polishing for enhanced optical clarity, special coatings for specific wavelength filtering, and surface dealkalization for improved high-temperature performance. These treatments can be customized based on your application requirements.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.