- Home

- /

- Types

- /

- Quartz Tube

- /

- UV Quartz Tube for...

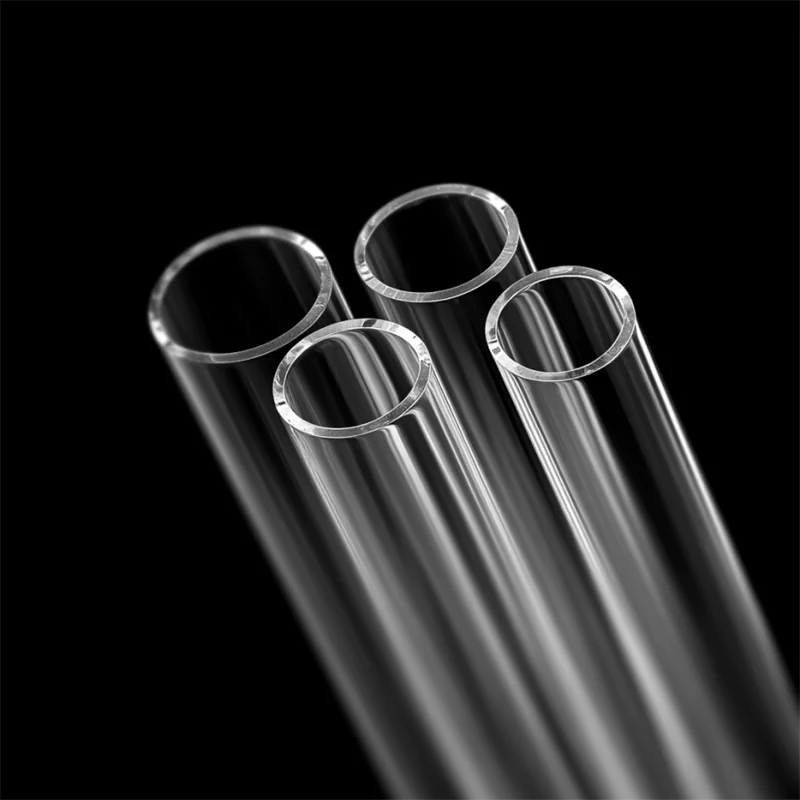

UV Quartz Tube for Sterilization & Disinfection Systems -TOQUARTZ®

UV Quartz Tubes from TOQUARTZ® are engineered with 100-200ppm titanium oxide doping to block radiation below 220nm while maintaining excellent transmittance (>70%) at the critical 253.7nm wavelength – the optimal spectrum for germicidal applications.

These specialized tubes offer superior light transmission, exceptional heat resistance, and outstanding corrosion resistance, making them ideal components for UV sterilization systems in medical, water treatment, and food processing industries.

Features of UV Quartz Tube

TOQUARTZ® UV quartz tubes are specifically engineered for applications requiring precise UV light transmission properties. The specialized composition and manufacturing process ensure optimal performance in sterilization and disinfection systems.

Heat Resistance

Withstands continuous operation at 1100°C and short-term exposure up to 1450°C with minimal thermal expansion, ensuring stability during rapid temperature changes.

Optimal UV Transmission

Excellent transmittance exceeding 70% at the critical 253.7nm wavelength, while blocking harmful radiation below 220nm, providing ideal germicidal effectiveness.

Superior Corrosion Resistance

Chemically inert to virtually all substances except hydrofluoric acid, maintaining stability even at elevated temperatures in aggressive chemical environments.

- Extreme Heat Resistance

- Optimal UV Transmission

- Strong Chemical Resistance

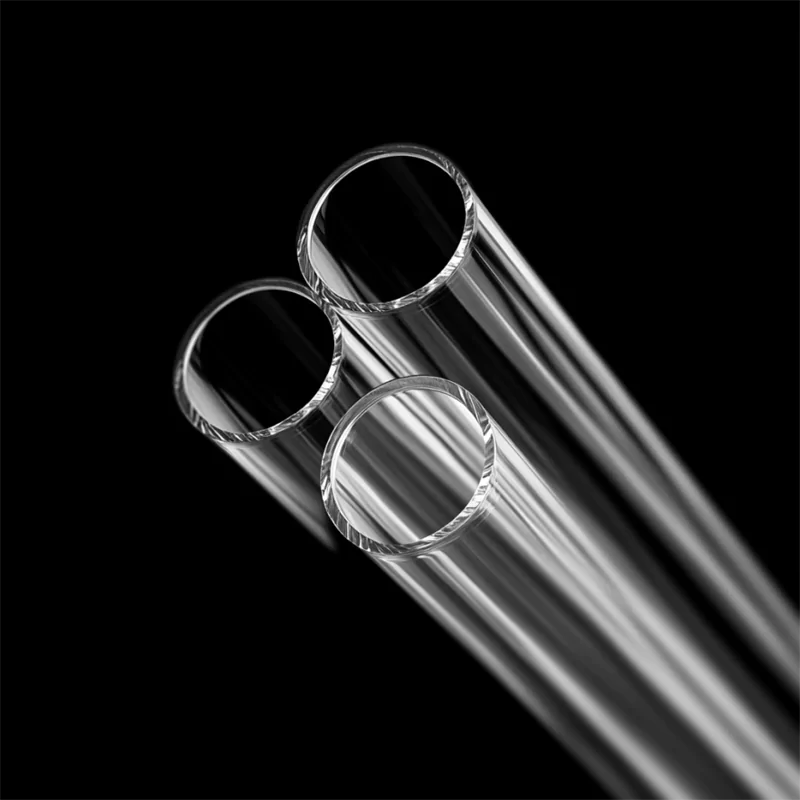

Custom Dimension of UV Quartz Tubes

TOQUARTZ® UV quartz tubes are available in standard dimensions with tight tolerances to ensure perfect fit in your sterilization systems. Custom sizes are available upon request.

| Outer Diameter (OD) | Inner Diameter (ID) | Wall Thickness | Length |

| 15mm | 13mm | 1.0mm | 100-1000mm |

| 22mm | 19mm | 1.5mm | 300-1200mm |

| 25mm | 22mm | 1.5mm | 300-1500mm |

| 32mm | 29mm | 1.5mm | 500-2000mm |

Properties of UV Quartz Tubes

| Property | Specification |

| Material Purity | ≥99.98% SiO₂(max. purity can up to 99.995%) |

| UV Transmittance (254nm) | >70% |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷ /°C |

| Maximum Operating Temperature | 1100°C (continuous) 1450°C (short-term) |

| Surface Finish | Fire Polished / Custom |

Solving Critical Challenges with UV Quartz Tubes

UV Quartz Tube for Water Treatment Systems

Key Advantages

- Stable UVC Transmittance Over 9,000 Hours

- Anti-Fouling Tube Wall Technology Applied

- Ozone-Free Transmission Window Design

TOQUARTZ® solution

A Polish water treatment facility experienced an 18% maintenance cost reduction after switching to TOQUARTZ UV tubes with our proprietary surface treatment that minimizes scaling while maintaining optimal UV transmittance throughout the 9000+ hour operational lifespan.

UV Quartz Tube for Medical Sterilization Equipment

Many suppliers claim high purity but deliver inconsistent performance, compromising sterilization efficacy.

Key Advantages

- Bio-Grade Non-O₃ Emission Spectrum Purity

- Diagnostic-Tier Internal Wall Smoothness (< 4nm Ra)

- Laminated Joint-Free Cylinder for Leak-Free Sterile Closure

TOQUARTZ® solution

A German medical equipment manufacturer reported that after switching to TOQUARTZ UV tubes, their sterilization efficacy improved by 15% while reducing rejected components from 18% to under 3%, thanks to our consistent ±0.15mm dimensional tolerance and verified UV transmittance properties.

UV Quartz Tube for UV Lamp Manufacturing

Supply chain disruptions and long lead times often cause production delays and quality inconsistencies.

Key Advantages

- High-Consistency UV Grade Cylinder Precision (<±0.1mm Roundness Tolerance)

- UV-Specific Spectrum Uniformity Certification (200~280nm)

- Zero-Fluorescence Raw Quartz for UV Purity Assurance

TOQUARTZ® solution

A German UV lamp manufacturer faced recurring delays due to inconsistent quartz tube wall thickness and 6-week lead times from their previous supplier, leading to production bottlenecks.

After switching to TOQUARTZ, they benefited from guaranteed ±0.1mm tolerances and a 10-day lead time for 5,000-piece batches, reducing rejected units by 22% and restoring on-time delivery for OEM contracts.

Customization Services for TOQUARTZ® UV Quartz Tube

- Custom Dimensions

- Surface Treatments

- End Finishing Options

- Custom Design Process

Requirement Analysis

We begin by thoroughly understanding your application requirements, including dimensions, material specifications, and performance criteria.

Design & Engineering

Our engineers develop a detailed design specification, including technical drawings and material requirements.

Prototype Development

We produce sample tubes for your evaluation and testing, with rapid turnaround times for urgent projects.

Production & Quality Control

Following approval, we manufacture your custom UV quartz tubes with rigorous quality control at every step.

Product Usage Guidelines of UV Quartz Tube

Handling & Installation

- Handle with care to avoid impacts or drops that could cause microscopic cracks or breakage.

- For high-temperature applications, clean thoroughly and wear lint-free gloves during installation to prevent contamination.

- Use appropriate O-rings and mounting hardware designed for UV applications to prevent leaks and ensure proper alignment.

Operation & Maintenance

- Never exceed the maximum operating temperature (1100°C continuous, 1450°C short-term) to prevent softening and deformation.

- Avoid contact with alkaline substances (sodium/potassium compounds, water glass, asbestos) at high temperatures, as these will significantly degrade performance.

- Regularly clean with appropriate non-abrasive solutions to maintain optimal UV transmittance and prevent scaling in water applications.

Need Engineering Support?

Contact our engineers today for a free consultation on your UV quartz tube requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the UV transmittance level of your quartz tubes at 253.7nm?

A: TOQUARTZ® UV quartz tubes offer transmittance of ≥70% at 253.7nm, which is ideal for germicidal and sterilization applications. We also provide full-spectral transmittance reports upon request for engineering validation.

Q: Are your UV quartz tubes suitable for both low-pressure mercury lamps and LED UV systems?

A: Absolutely. TOQUARTZ® quartz tubes are compatible with both low/medium-pressure mercury vapor lamps and LED UV modules, with tailored UV transmission characteristics and end-finishing options.

Q: Do your UV tubes generate ozone? Can you provide ozone-free variants?

A: TOQUARTZ offer ozone-free UV quartz tubes designed to block wavelengths below 220nm, preventing ozone formation. This is critical for enclosed environments, medical equipment, and drinking water disinfection systems.

Q: What’s the maximum continuous operating temperature TOQUARTZ® UV quartz tubes can endure?

A: Our UV quartz tubes can operate continuously at up to 1100°C and withstand short-term exposure up to 1450°C, making them safe for high-output UV lamps with thermal cycling environments.

Q: Do TOQUARTZ UV quartz tubes support use in pressurized water sterilization systems?

A: Yes. Our tubes are designed for use in high-flow water sterilization reactors and can be produced with vacuum-fit tolerances to integrate seamlessly with stainless steel chambers and UV lamp sleeves, ensuring leak-free installation.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.