- Home

- /

- Types

- /

- Quartz Tube

- /

- Spiral Quartz Tubes for...

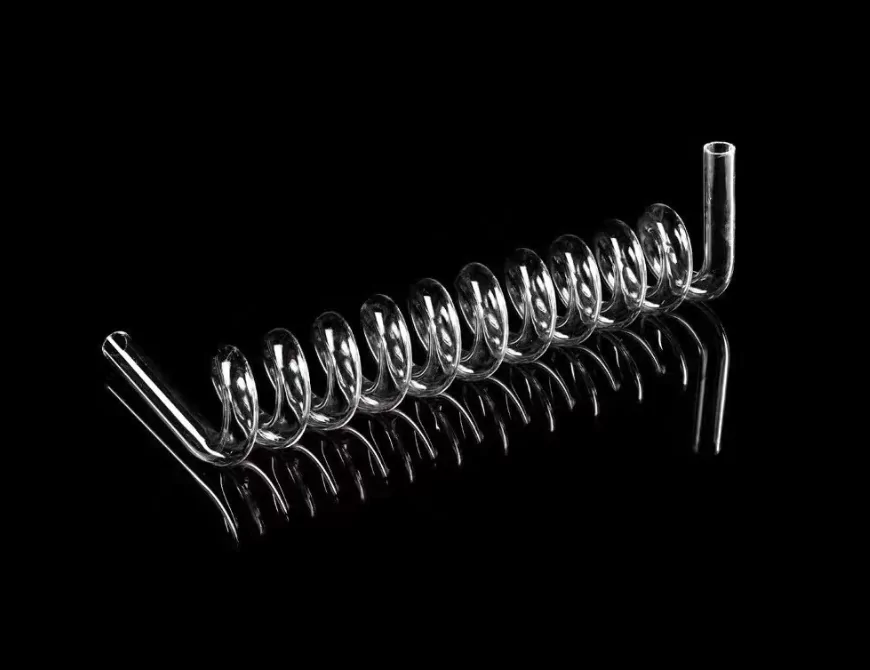

Spiral Quartz Tubes for UV Sterilization, IR Heating & Laboratory Equipment -TOQUARTZ®

High-purity spiral quartz tubes with 99.98% SiO₂ purity(max. can up to 99.995%), engineered for UV sterilization systems, IR heating applications, and laboratory equipment.

TOQUARTZ® spiral quartz tubes feature exceptional thermal stability (up to 1600°C), superior corrosion resistance, and precise dimensional control for optimal performance in demanding industrial environments.

Features of Spiral Quartz Tube

TOQUARTZ® spiral quartz tubes are designed to perform under the most demanding industrial and laboratory environments. Whether facing extreme temperatures, rapid thermal cycling, or aggressive chemical exposure, our tubes consistently deliver high performance and longevity.

Extreme Heat Resistance for Demanding Applications

- Handles sustained temperatures exceeding 1100 degrees Celsius

- Maintains physical structure under intense furnace operations

- Suitable for IR heaters, sterilizers, and photonic applications

Advanced Thermal Stability During Rapid Cycling

- Tolerates fast heating and cooling without deformation risk

- Low thermal expansion reduces mechanical strain accumulation

- Ideal for lab environments with repeated thermal shock cycles

Strong Chemical Resistance Against Acids and Solvents

- Inert against strong acids like HCl, HNO₃ and HF (dilute)

- Non-reactive with organic solvents in lab-based applications

- Stable in harsh environments like oxidizing or reducing atmospheres

- Extreme Heat Resistance

- Advanced Thermal Stability

- Strong Chemical Resistance

Customizable Dimension of Spiral Quartz Tube

TOQUARTZ® spiral quartz tubes are available in standard dimensions or can be customized according to your specific requirements. All products undergo rigorous quality control to ensure dimensional accuracy.

| Parameter | Standard Range | TOQUARTZ Capability |

| Outer Diameter (OD) | Φ10 – 40 mm | Full Range |

| Wall Thickness | 1.0 – 2.5 mm | Partially Supported |

| Spiral Pitch | 15 – 25 mm | Full Range |

| Length | 300 – 1200 mm | Full Range |

| Spiral Angle | Custom | Full Range |

Properties of Spiral Quartz Tube

Material Properties:

Material

99.98% purity quartz glass (max. can up to 99.995%)

Maximum Working Temperature

1600°C

Thermal Expansion Coefficient

5.5×10⁻⁷/°C

Thermal Conductivity

120-160 W/m·K

Chemical Resistance

Excellent resistance to acids, alkalis, molten salts, and fluoride gases

Surface Finish

Acid-washed and polished for bubble-free, scratch-free surface

Mechanical Properties:

Tensile Strength

>350 MPa

Hardness

Mohs 5.5-6.5

Electrical Properties

Excellent insulation, can be doped for specialized applications

Friction Coefficient

Extremely low, ideal for high-flow applications

Spiral Angle Tolerance

±5° maximum deviation

Solving Challenges with Spiral Quartz Tubes

Spiral Quartz Tube for UV Sterilization Systems

TOQUARTZ® spiral quartz tubes extend the UV light path, increasing disinfection efficiency in water treatment, air purification, and medical sterilization equipment.

Key Advantages

- Full 360° Radial Irradiation for Uniform Sterilization

- Optimized Flow Disruption to Minimize Shadowing

- Matching Light Geometry with Spiral UV Lamp Arrays

TOQUARTZ® solution

A US medical equipment manufacturer struggled with insufficient disinfection rates in their compact UV sterilization units, achieving only 85% pathogen elimination with straight quartz sleeves.

After implementing TOQUARTZ spiral quartz tubes, they documented a 99.2% disinfection efficiency due to the extended UV exposure path, while maintaining the same compact footprint. This improvement allowed them to meet stringent healthcare standards and expand into hospital markets.

Spiral Quartz Tube for Infrared Heating Applications

TOQUARTZ® spiral quartz tubes for IR applications provide increased heating surface area while maintaining excellent thermal stability, ideal for industrial heaters, drying systems, and thermal processing equipment.

Key Advantages

- Maximized Effective Heating Surface in Restricted Space

- Consistent Radial Heat Dispersion Without Thermal Hotspots

- Compact Modularization for Multi-Zone Heating Units

TOQUARTZ® solution

A German industrial oven manufacturer faced heat distribution inefficiencies in their compact drying systems, resulting in product quality inconsistencies and 12% rejection rates.

After integrating TOQUARTZ spiral quartz tubes, they achieved uniform temperature distribution across their heating chambers with temperature variances reduced from ±35°C to just ±8°C. The improved thermal performance and 1600°C temperature resistance allowed them to increase processing speeds by 22% while reducing energy consumption.

Spiral Quartz Tube for Laboratory Research

TOQUARTZ® spiral quartz tubes provide increased reaction surface area and excellent chemical resistance for advanced research applications.

Key Advantages

- Increased Internal Surface Area for Enhanced Reaction Kinetics

- Compact Experimental Footprint with High Experimental Throughput

- Versatile Custom Geometry to Fit Specialized Reactor Rigs

TOQUARTZ® solution

A Canadian university research team was struggling with low catalyst efficiency in their photocatalytic water purification experiments, achieving only 40% conversion rates with standard reaction vessels.

After implementing TOQUARTZ custom spiral quartz tubes with precisely calculated surface area enhancement, they documented a 175% increase in reaction efficiency due to optimized catalyst exposure and superior chemical resistance to their aggressive reagents. This breakthrough enabled their research to advance to pilot-scale testing and secure additional grant funding.

Customization Services for

TOQUARTZ® Spiral Quartz Tubes

- Drawing-Based Customization

- Prototype Development

- Special Configurations

- Drawing-Based Customization

2. Receive technical feasibility assessment within 48 hours

3. Review and approve the design proposal and quotation

4. Receive prototype for testing (if required)

5. Proceed with production after approval

Product Usage Guidelines of Capillary Quartz Tubes

Handling & Installation

Handle with Care

Handle spiral quartz tubes gently to avoid impacts or drops that could cause breakage. Use clean gloves to prevent contamination of the surface.

Temperature Control

Do not exceed the maximum operating temperature of 1600°C. Rapid temperature changes should be avoided to prevent thermal shock.

Chemical Compatibility

Avoid contact with alkaline substances (sodium/potassium compounds, water glass, asbestos) at high temperatures, as these will significantly degrade performance.

Maintenance & Storage

Cleaning

Clean with mild detergent and distilled water. For stubborn deposits, use diluted acids (avoid hydrofluoric acid). Rinse thoroughly and dry completely before reuse.

Storage

Store in a clean, dry environment. Use original packaging or cushioned containers to prevent contact with hard surfaces. Avoid stacking heavy items on top of tubes.

Inspection

Regularly inspect for cracks, chips, or discoloration. Replace damaged tubes immediately to prevent system failures or contamination.

Need Engineering Support for Your Spiral Quartz Tube Project?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What are the main advantages of spiral quartz tubes over straight tubes?

A: Spiral quartz tubes offer several advantages: increased surface area in a compact footprint, extended UV light path for better sterilization efficiency, improved heat distribution for IR applications, and enhanced mixing capabilities for laboratory reactions. The spiral design also provides greater structural flexibility while maintaining the excellent thermal and chemical properties of quartz.

Q: What is the maximum temperature that TOQUARTZ® spiral quartz tubes can withstand?

A: Our spiral quartz tubes can withstand continuous operating temperatures up to 1100°C and short-term exposure up to 1600°C. The softening point of high-purity quartz is approximately 1730°C. However, we recommend maintaining a safety margin below these limits for prolonged use, especially for spiral configurations where stress distribution differs from straight tubes.

Q: Are TOQUARTZ® spiral quartz tubes suitable for UV-C transmission applications?

A: Yes, our high-purity spiral quartz tubes offer excellent UV-C transmission (>90% at 254nm wavelength), making them ideal for UV sterilization systems. We can provide specific transmission data for different wavelengths upon request. For UV applications, we recommend our clear fused quartz grade with minimal iron content to maximize UV transmission efficiency.

Q: Can you create spiral quartz tubes with variable pitch or diameter?

A:Yes, we can manufacture spiral quartz tubes with variable pitch or diameter changes along the length. These advanced designs can optimize flow characteristics, heat distribution, or optical properties for specific applications. Such customizations require detailed technical discussions with our engineering team to ensure manufacturability and performance.

Q: Do you offer any surface treatments for spiral quartz tubes?

A: Yes, we offer several surface treatments for spiral quartz tubes, including acid etching for improved adhesion, fire polishing for enhanced optical clarity, special coatings for specific wavelength filtering, and surface dealkalization for improved high-temperature performance. These treatments can be customized based on your application requirements.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.