99.98% SiO₂ Quartz Glass: Chemical-Purity for Demanding Sectors

- Lab-Grade 99.98% putiry(max. can up to 99.995%) for Laboratory Instrumentation Standards

- Maintain 190-4500nm Transparency Through 1000hr UV Exposure

- Resist 1450°C Thermal Cycling in Extreme Industrial Environment

What is Quartz Glass?

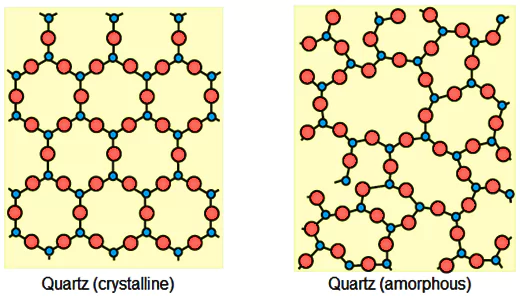

Quartz glass is an engineered material created by melting high purity silica (SiO₂ ≥99.95%) at 2000°C+, forming a non-crystalline structure with unmatched thermal stability and optical clarity.

Unlike natural quartz crystals, synthetic quartz glass lacks grain boundaries, enabling its use in precision optics and extreme industrial environments.

TOQUARTZ is an authoritative quartz glass wholesale and custom supplier in China, improving various types of quartz glass.

TOQUARTZ® Quartz Glass Products

TOQUARTZ® offers a complete range of quartz glass products, from tubes and rods to lab-grade glassware and custom-engineered components.

Properties of Quartz Glass

Optical Properties of Quartz Glass

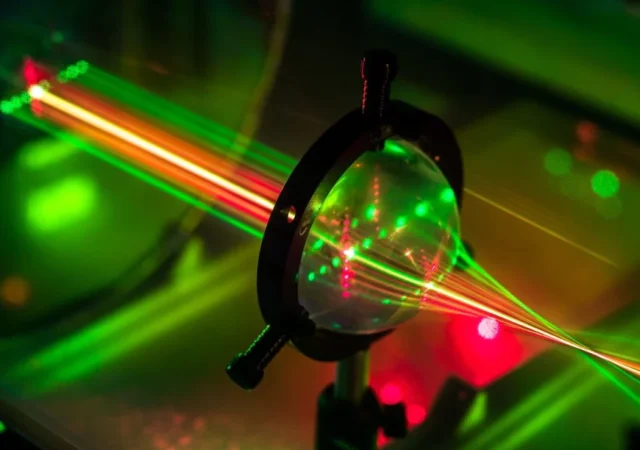

Quartz glass delivers > transmittance across UV-Vis-NIR spectra (200-2500nm), enabling precision laser optics and analytical instrumentation. Explore tailor-made solutions with <5nm/cm birefringence for mission-critical applications.

- Ultrahigh Transmittance (>92% 200-2500nm)

- Sub-nanometer Polishing (Ra ≤0.5nm)

- Low Stress Birefringence (<5nm/cm)

- Broadband UV-IR Compatibility

- Premier Thermal Stability (ΔT=1600℃)

Thermal Characteristics of Fused Quartz

Fused quartz excels in 1600°C+ thermal stability with CTE ≤5.5×10⁻⁷/K, ensuring precision in high-temperature semiconductor processing and industrial furnace applications.

- Ultralow CTE (≤5.5×10⁻⁷/K)

- High Thermal Shock Resistance (>800℃/water)

- Sustained High-Temp Stability (1600°C+)

- Minimal Creep Deformation (<0.005%/100h)

- Non-Outgassing in Vacuum (<1×10⁻⁹ Pa·m³/s)

Mechanical Features of Fused Silica

Fused silica delivers ≥250MPa compressive strength and Mohs 7 hardness, ensuring reliability in high-stress semiconductor fabrication and precision optics.

- High Compressive Strength (≥250MPa)

- Superior Surface Hardness (Mohs 7)

- Ultralow Deformation Rate (<0.003mm/℃)

- Excellent Wear Resistance (100k cycles Δ<5μm)

- Controlled Fracture Toughness (0.8 MPa·m¹/²)

Quartz Glass Applications Across Industries

TOQUARTZ fused quartz components deliver high thermal stability (1100°C continuous operation),

corrosion resistance (0.008mm/yr in 2M HCl), and UV-IR transparency to critical manufacturing sectors worldwide.

Quartz Glass for Lab Equipment Device

- Reaction Vessels for Harsh Chemistry

The quartz glassware can tolerate 48hr acid baths (HF/HCl), ensuring contamination-free catalyst testing chambers.

- High-Precision Measurement Tools

They can maintain ±0.01mm tolerances in lab spectrometers, resisting 500+ thermal cycles without deformation.

- Controlled Environment Monitoring Devices

They also enable multi-wavelength analysis (190-3500nm) for air or water quality sensors in extreme field labs.

Quartz Glass for Optical Device

- Laser & Imaging Systems Components

Ultra-low hydroxyl (<1ppm) quartz glass material is able to eliminate UV absorption, perfect for 193nm lithography lenses.

- Optical Sight Glasses Units

99.99% SiO₂ quartz glass achieve 92% UV-C (280nm) transmission for industrial sterilization viewports.

- Fiber Optics Core Materials

Quartz glass can minimize signal loss (≤0.1dB/km) in high-speed photonics networks.

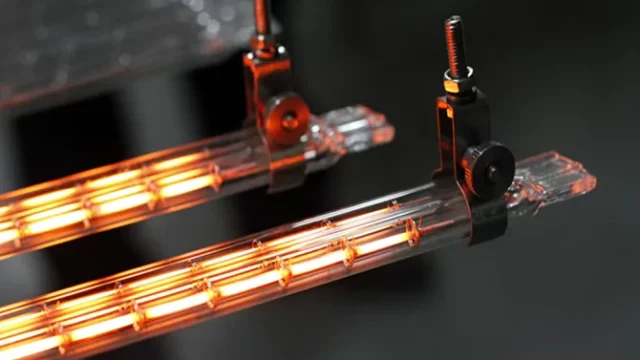

Quartz Glass Used in Extreme Condition

- Extreme Temperature Containment Tool

Quartz glass products withstand 1200°C SO₂ gas flows in metal smelting, outlasting alumina by 5x lifespan.

- Corrosive Process Engineering Device

Quartz insulation fiber maintains 98% integrity after 1000hr chlorine vapor exposure, ideal for pulp bleaching towers.

- High-Purity Metal Processing Instruments

They enable metalorganic CVD coating with ≤0.0005% impurities for aerospace alloy production.

Purity Guaranteed Quartz Glass

TOQUARTZ fused quartz meets global material safety thresholds, with 99.99% SiO₂ content and <0.5ppm metallic contaminants guaranteed through rigorous quality protocols.

Traceable Manufacturing Assurance

- ISO-Certified Production

Every lot undergoes 100% dimensional (±0.01mm) and thermal stability testing (1100°C ×48hrs) to ensure atomic-level purity.

EU-Regulatory Ready Material

- REACH-Compliant Inertness

Zero SVHCs with sub-ppm Fe/Al impurities (<0.5ppm) for chemical reactors and filtration systems in EU markets.

Eco-Safe Integration

- REACH-Compliant Inertness

Heavy metals (Pb/Cd/Hg <100 ppm) eliminated for electronics encapsulation and photonic device assembly.

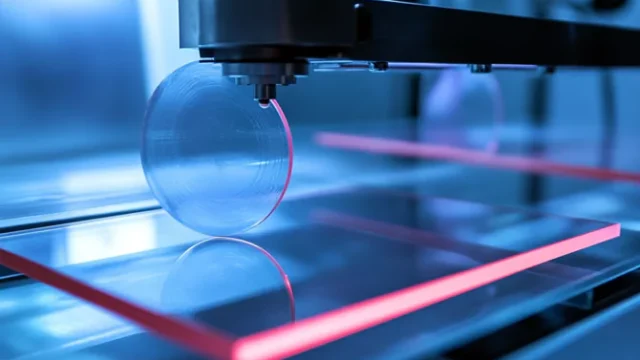

Advanced Quartz Glass Manufacturing Process

Custom Fused Quartz Glass Products Fabricating丨TOQUARTZ

- Precision Custom Services — No MOQ + Rapid Prototyping

- Cross-Industry Solutions — Optics R&D + Chemical Labs

- Innovative Manufacturing — High Accuracy + Bulk Accessibility

Scientific Manufacturing Process

The quartz glass composition relies entirely on synthetic SiO₂, where the chemical formula (SiO₂) masks a transformative process — raw silica transitions from crystalline to amorphous states through advanced fusion techniques.

Raw Material Purification

Pre-calcinate at 800°C×12hrs to eliminate 99% volatiles (H₂O, CO₂, hydrocarbons).

Arc Fusion & Phase Transition

1600-2000°C arc melting in inert gas furnaces to convert crystalline silica into amorphous structure.

Ion Exclusion Leaching

Submerge fused ingots in 18.2 MΩ·cm deionized water for 72hrs, dissolving residual Al³⁺/Na⁺ ions.

Stress-Free Solidification

Programmable gradient cooling at -15°C/min prevents micro-fractures and devitrification below 1200°C.

TOQUARTZ elevates this science further, refining SiO₂ to 99.995% purity to suppress metallic impurities below 0.5ppm, ensuring material integrity for laser optics and sensor housings.

Bespoke Manufacturing Workflow & Service

From concept sketches to production-ready quartz solutions – we turn specifications into reality.

Define Your Needs

Share your requirements through any format:

- Technical drawings (DXF/DWG/PDF)

- Sample photos with annotations

Co-Creation

Engineering team will:

- Propose material & process optimizations

- Deliver a virtual prototype for your approval

Accelerated Realization

Once confirmed:

- Dedicated production line activation

- Real-time progress updates via your preferred channel

- Strict compliance with your quality protocols

Engineering Partnership

Precision from Concept to Operation

TOQUARTZ engineers deploy 20+ years of fused quartz expertise to streamline your project lifecycle, optimizing material selection, design, and performance validation.

Material Science Consultation

Conduct application-specific purity audits (SiO₂ ≥99.98% and max. upto 99.995%, Fe ≤0.5ppm) to match quartz grades with thermal/optical demands.

Predictive Thermal Stress Modeling

Simulate thermal expansion gradients (-15°C/min to 1200°C) to preempt cracking in custom quartz reactors or viewports.

Prototype-to-Production Optimization

Refine machining tolerances to ±0.01mm via CNC grinding, ensuring airtight seals in corrosive gas handling systems.

Lifetime Performance Validation

Accelerated aging tests verify <0.01% transmittance loss over 10,000hr UV exposure for optical components.

FAQs

Q: What is quartz glass made of?

A: High-purity silica (≥99.99% SiO₂) synthesized structurally.

Q: How to make fused quartz glass?

A: High-temperature fusion of pure silica sand, vacuum-processed.

Q: How to clean quartz glass?

A: Gentle deionized water or alcohol rinses; avoid HF acid exposure.

Q: Quartz glass vs pyrex?

A: Lower thermal expansion, higher temperature resistance than Pyrex.

Q: Quartz glass vs borosilicate

A: Superior thermal stability (0.55 vs. 3×10⁻⁶/°C) and acid resistance over borosilicate.

Q: What is the melting point of quartz glass?

A: ~1700°C melting point, stable below 1200°C continuously.

Q: What is the thermal conductivity of quartz glass?

A: Thermal conductivity: 1.3–1.5 W/m·K (ambient temperature range).

Q: What is the density of quartz glass?

A: Density: ≈2.2 g/cm³, varying slightly with purity grade.

Start Your Order

TOQUARTZ streamlines access to premium fused quartz glass products – NO MOQ, guaranteed purity, and tailored support. Act now:

-

Instant Wholesale Pricing:

Submit specs online for same-day fused quartz products quotes – bulk discounts auto-calculated, no hidden fees. -

Engineer-Driven Sourcing:

Call +86-19311583352(Whatsapp) for project-specific advice on optical/lab/industrial quartz tubing. -

Priority Production Slots:

Email info@toquartz.com with “URGENT REQUEST” to secure expedited high-purity quartz glass products delivery – reserved capacity for urgent projects.