Quartz tube cutting exposes workers to hazards that demand strict safety compliance at every phase. Operators must follow safety protocols quartz tube cutting operations require, including personal protective equipment, ventilation checks, equipment inspections, safe handling techniques, emergency response, and documentation. Regulatory standards such as ANSI Z49.1 for welding and cutting safety, Cal/OSHA eye and face protection rules, and ANSI Z87.1 for occupational eye protection set clear guidelines for preventing injuries. Real-world incident data shows that consistent protocols and adherence to safety guidelines reduce risks and protect workers from serious harm.

Key Takeaways

Verify local exhaust ventilation airflow before cutting. Aim for at least 300 CFM to control silica dust exposure.

Inspect personal protective equipment (PPE) before use. Ensure respirators, gloves, and eyewear are in good condition to prevent injuries.

Maintain a minimum distance of 6 inches from the blade during cutting. Use fixtures to avoid lacerations and ensure safety.

Conduct regular equipment checks, including blade condition and coolant flow. This reduces the risk of accidents and equipment failures.

Implement emergency response procedures, such as immediate irrigation for eye injuries. Quick action can prevent serious harm.

What Pre-Cutting Safety Preparations Must Be Completed Before Starting Operations?

Pre-cutting safety preparations form the foundation of a safe work environment in quartz tube cutting. These steps protect workers from hazards and ensure compliance with stone cutting safety and metal cutting safety standards. Each preparation phase addresses specific risks and sets the stage for effective safety measures throughout the operation.

Local Exhaust Ventilation Verification: Airflow Measurement and Capture Hood Positioning

Operators must verify local exhaust ventilation airflow before cutting begins. The airflow should measure at least 300 cubic feet per minute at the capture hood, positioned within 12 inches of the cutting point. This step reduces the hazards of stone cutting by controlling airborne silica dust.

Regular airflow checks prevent overexposure to respirable crystalline silica, which can exceed OSHA’s permissible limits by 16-48 times if ventilation fails. Facilities that implement this safety measure report a 78% reduction in silica overexposures. Proper ventilation supports stone cutting safety and metal cutting safety by maintaining air quality.

Standard | Requirement | Details |

|---|---|---|

OSHA | Ventilation | Exhaust systems must conform to ANSI standards, with regular inspections and maintenance. |

ACGIH | Airflow | Minimum 300 CFM at capture hood for silica control. |

Eyewash Station Testing: Flow Rate, Pressure, and Water Quality Confirmation

Eyewash stations must deliver a minimum flow rate of 0.4 gallons per minute for at least 15 minutes. Operators test the station weekly, confirming water pressure and quality. The station should be accessible within 10 seconds and have visible signage.

Immediate access to eyewash stations reduces the risk of permanent eye damage from dust or fragments. ANSI standards require tepid water and proper signage to ensure effective safety measures. Annual flow rate testing and potable water supply maintain compliance and support a safe work environment.

Key Points:

Minimum flow rate: 0.4 gpm for 15 minutes

Accessible within 10 seconds

Potable water and visible signage required

PPE Inspection Checklist: Respirator Seal Check, Eyewear Integrity, Glove Condition

Before cutting, workers inspect personal protective equipment, including ppe such as NIOSH-approved respirators, safety glasses and goggles, cut-resistant gloves, boots, and protective clothing. Each respirator must pass a user seal check, and gloves must show no tears or contamination.

Proper ppe inspection prevents direct exposure to hazards. OSHA mandates a seal check before each use, and ANSI standards require impact-rated goggles and face shields. Facilities that follow these safety measures see a 65% reduction in equipment-related injuries.

Evidence Type | Description |

|---|---|

User Seal Check Requirement | OSHA mandates a user seal check before each use of a tight-fitting respirator (Z88.2–2015). |

Glove Integrity | Cut-resistant gloves must withstand 2,200+ grams cut force (ANSI/ISEA 105 Level A4). |

Equipment Condition Assessment: Blade Runout, Coolant Flow, GFCI Function

Operators assess equipment condition by checking diamond blade runout, coolant flow, and GFCI function. The blade should have less than 0.3mm radial runout, and the coolant system must deliver 200-300ml per minute. GFCI protection prevents electrical shock during wet cutting.

Routine equipment checks reduce the risk of catastrophic failures and injuries. Facilities that verify equipment before each use report a 65% decrease in incidents. These safety measures support metal cutting safety and maintain a safe work environment.

Summary of Effective Safety Measures:

Blade runout <0.3mm

Coolant flow 200-300ml/min

GFCI protection tested before use

What Safety Protocols Must Be Followed During Active Cutting Operations?

Active cutting operations present the highest risk for injury in quartz tube processing. Safety protocols quartz tube cutting operations require must be followed at every moment to prevent accidents and ensure compliance. Operators must focus on hand positioning, coolant flow, body placement, and continuous monitoring to maintain a safe operation of cutting equipment.

Hand Positioning Rules: 6-Inch Minimum Distance and Fixture Requirements

Operators must keep their hands at least 6 inches away from the rotating blade during cutting. This rule prevents accidental contact, which can cause severe lacerations in less than a second. Operators should always use tube fixtures or push sticks instead of holding tubes by hand.

Data from industry incident reports shows that 92% of laceration injuries occurred when workers held tubes within 6 inches of the blade, even though fixtures were available. Supervisors must enforce this rule and remind workers that human reaction time is too slow to prevent injury if contact occurs. Maintaining this distance is a fundamental part of safety.

Key Points:

Minimum hand distance: 6 inches from blade

Use fixtures and push sticks

Direct hand-holding is prohibited

Rule prevents 92% of laceration injuries

Continuous Coolant Verification: Visual Flow Monitoring and Dry-Cutting Prevention

Operators must visually confirm that coolant flows at 200-300ml per minute throughout the cutting process. Coolant prevents the blade and tube from overheating and suppresses silica dust, which can spike to dangerous levels if dry cutting occurs. Operators should never allow the blade to run dry, even for a few seconds.

Facilities that monitor coolant flow every 2-3 minutes report a significant reduction in both thermal cracking and airborne silica exposure. Dry cutting for just 15 seconds can increase silica dust by 15-20 times, putting workers at immediate risk. Consistent coolant flow is essential for both safety and product quality.

Coolant Flow | Effect | Causality |

|---|---|---|

200-300ml/min | Prevents overheating, controls dust | Maintains safe operation and reduces exposure |

Dry cutting | Rapid dust spike, tube cracking | Increases injury and health risks |

Body Position Safety: 30° Offset from Blade Plane for Fragment Protection

Operators must stand at least 30 degrees to the side of the blade’s rotation plane during cutting. This position protects the face and torso from high-speed fragments if the blade fractures. Operators should never face the blade directly.

Industry data shows that standing in-line with the blade increases injury severity by 8-12 times compared to standing offset. Blade fragments can exit at speeds up to 25 meters per second, which can penetrate standard safety glasses if the operator stands directly in front. Proper body positioning greatly reduces the risk of serious injury.

Summary:

30° offset from blade plane

Reduces fragment injury severity by up to 12 times

Never face blade directly during cutting

Acoustic Monitoring: Abnormal Sound Recognition and Response Protocols

Operators must listen for abnormal sounds during cutting, such as grinding, squealing, or crackling. These sounds often signal blade binding, tube slippage, or insufficient cooling. Operators should stop the machine immediately if they detect unusual noises.

Facilities that train workers to recognize and respond to abnormal sounds detect 75% of equipment malfunctions before visual signs appear. Early detection allows for prompt corrective action, preventing injuries and equipment damage. Acoustic monitoring is a proactive safety measure that supports continuous safe operation.

Sound Detected | Possible Cause | Required Action |

|---|---|---|

Grinding (400-800 Hz) | Blade binding | Stop and inspect blade/fixture |

Squealing (4-6 kHz) | Tube slippage | Re-secure tube, check fixture |

Crackling | Insufficient cooling | Check coolant flow, pause cutting |

Operators must never reach over a moving blade or allow clutter to block emergency exits. Clear egress paths and strict adherence to these protocols ensure rapid evacuation and minimize injury risk during emergencies.

What Post-Cutting Safety Procedures Prevent Delayed Injuries?

Post-cutting safety procedures protect workers from delayed injuries and maintain a clean, hazard-free environment. These steps address risks that arise after the cutting process, such as sharp edges and airborne dust. By following a systematic approach, operators reduce the chance of accidents and ensure compliance with safety standards.

Blade Deceleration Verification: Zero-Rotation Confirmation Before Approaching

Operators must wait for the blade to stop completely before approaching the cutting area. Visual confirmation of zero rotation prevents accidental contact with a moving blade, which can cause severe lacerations. Facilities that enforce this rule report fewer injuries related to residual blade motion.

A simple pause of 15–30 seconds after power-off allows the blade to decelerate safely. Supervisors should remind workers to check for movement before reaching into the workspace. This step forms the foundation of post-cutting safety.

Action | Purpose | Result |

|---|---|---|

Wait for blade stop | Prevent contact injuries | Reduced laceration risk |

Visual confirmation | Ensure zero rotation | Increased operator safety |

Cut-Edge Handling Technique: Glove Requirements and Sharpness Awareness

Freshly cut quartz tube edges are extremely sharp and can cause deep cuts with minimal pressure. Workers must use cut-resistant gloves when handling tubes after cutting. Gloves rated A5 or higher provide the best protection for glass handling tasks.

Operators should inspect gloves for damage before each use and replace them if worn. Awareness of edge sharpness helps prevent careless handling and injuries. The following table shows recommended glove ratings for different applications:

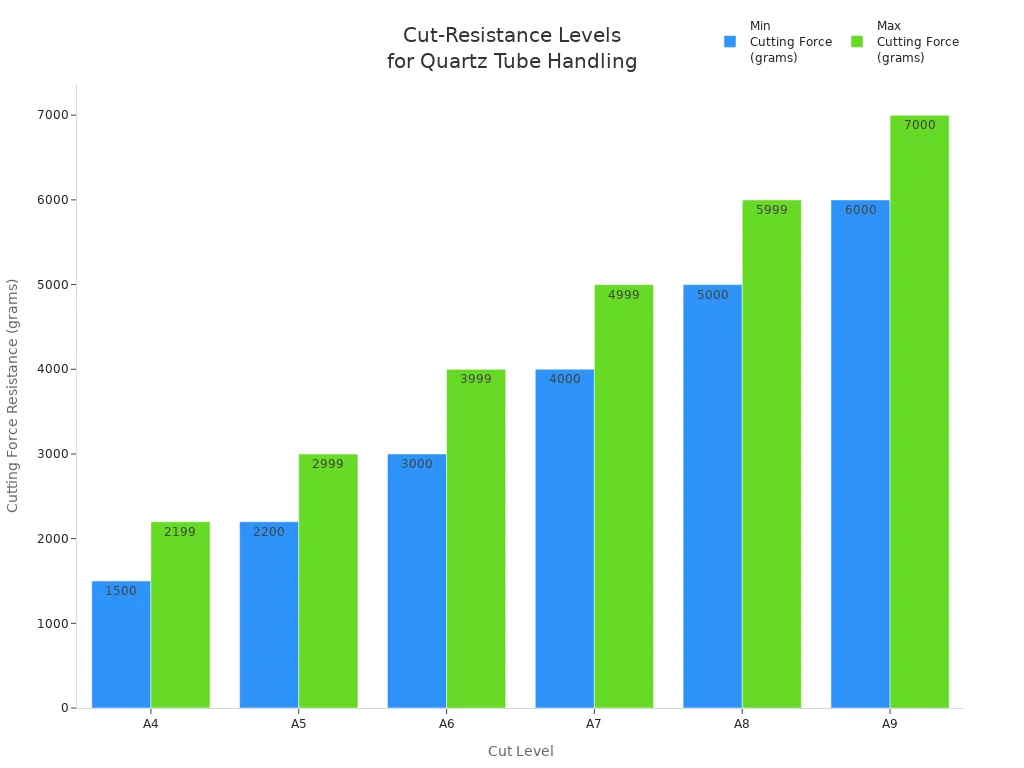

Cut Level | Cutting Force Resistance (grams) | Application |

|---|---|---|

A4 | 1,500 - 2,199 | Medium-duty assembly |

A5 | 2,200 - 2,999 | Heavy-duty assembly, glass handling |

A6 | 3,000 - 3,999 | Heavy-duty assembly |

A7 | 4,000 - 4,999 | Heavy-duty assembly |

A8 | 5,000 - 5,999 | Heavy-duty assembly |

A9 | 6,000 and above | Heavy-duty assembly, glass handling |

Key Points:

Use gloves rated A5 or higher for glass handling

Inspect gloves before each use

Fresh-cut edges can cause serious injuries

Post-Cut Inspection Protocol: 10x Magnification Defect Detection Standards

Operators must inspect cut edges under 10x magnification to detect micro-cracks and chips. Defects larger than 0.5mm increase the risk of delayed fracture and injury during handling. Tubes with visible defects should be marked and set aside for further inspection.

Quality control teams use magnifiers or microscopes to ensure edge integrity. This inspection step prevents defective tubes from entering assembly lines, reducing future accidents. Consistent inspection supports a safer workplace.

Inspection Tool | Defect Size Detected | Action Taken |

|---|---|---|

10x Magnifier | >0.5mm cracks/chips | Quarantine for review |

Visual only | Misses micro-defects | Increased injury risk |

HEPA Vacuum Cleaning: Proper Dust Removal Preventing Re-Suspension

HEPA vacuum cleaning removes dust from the work area without re-suspending particles into the air. Operators must avoid using compressed air or dry sweeping, which can create airborne dust and increase respiratory hazards. HEPA vacuums capture fine particles and reduce exposure risks.

Compressed air cleaning can dislodge dust, causing eye and skin hazards, and may even lead to air embolism or fire risk. Facilities that switch to HEPA vacuuming report lower rates of respiratory issues and improved overall safety. The table below compares cleaning methods:

Risk Type | Compressed Air | HEPA Vacuuming |

|---|---|---|

Eye and Skin Hazards | Can dislodge particles that may enter eyes or abrade skin. | Lower risk of particle dislodging. |

Air Embolism Risk | Possible if air enters bloodstream through skin or body openings. | No risk of air embolism. |

Respiratory Hazard | Forces dust particles into the air, creating airborne contaminants. | Captures dust without releasing it into the air. |

Fire/Explosion Risk | Airborne combustible dust can ignite, causing serious injuries. | Reduces risk by containing dust. |

General Safety Concerns | Horseplay and misuse can lead to serious accidents. | Generally safer with proper use. |

Summary:

Use HEPA vacuum for dust removal

Avoid compressed air and dry sweeping

HEPA vacuuming improves safety and air quality

What Emergency Response Procedures Address Injury Incidents?

Emergency response procedures play a vital role in reducing the impact of injuries during quartz tube cutting. Quick and correct actions can prevent minor accidents from becoming severe physical injuries. This section explains the essential emergency procedures for eye injuries, lacerations, respiratory distress, and the importance of annual training.

Eye Injury Response: 15-Minute Irrigation Technique and Medical Follow-Up

Immediate irrigation is the first step when dust or fragments enter the eye during cutting. Operators must use the eyewash station for at least 15 minutes, holding eyelids open and moving the eyes in all directions. Medical evaluation remains necessary even if symptoms improve after irrigation.

Prompt response removes up to 90% of contaminants and greatly reduces the risk of permanent damage. Delays longer than 10 minutes can allow particles to embed, making recovery more difficult. Facilities that enforce this emergency procedure report higher rates of full recovery after eye accidents.

Key Points:

Begin irrigation within 2 minutes

Continue for 15 minutes

Always seek medical follow-up

Laceration First Aid: Direct Pressure, Fragment Retention, Medical Evaluation Criteria

Lacerations require fast action to control bleeding and prevent complications. Operators should apply direct pressure with a clean cloth for 10-15 minutes and avoid removing any embedded glass fragments. Medical evaluation is necessary for cuts longer than 1cm or deeper than 3mm.

Recognizing injury severity and monitoring symptoms helps prevent minor wounds from becoming serious. Accurate risk assessment ensures that workers receive the right care at the right time. The following table summarizes best practices for laceration first aid and when to seek further help:

Best Practice | Description | Causality |

|---|---|---|

Initial Assessment | Observe injuries and check responsiveness | Guides care needed |

Stabilization | Apply pressure and immobilize suspected fractures | Controls bleeding, prevents harm |

Wound Management | Clean wound, bandage, monitor for infection | Reduces complications |

Respiratory Distress Protocol: Fresh Air, Emergency Services, Exposure Investigation

Respiratory distress can occur after exposure to silica dust during cutting. Operators must move the affected person to fresh air immediately and loosen tight clothing. Emergency services should be called if symptoms last more than two minutes.

Quick removal from the exposure area lowers the risk of long-term health effects. Supervisors must investigate the cause of the incident to prevent future accidents. This emergency procedure protects workers from severe respiratory injuries.

Summary of Actions:

Move to fresh air

Call emergency services if symptoms persist

Investigate exposure source

Emergency Training Requirements: Annual Hands-On Practice and Competency Verification

Annual hands-on training ensures that all workers know how to respond to emergencies. Training must include practical exercises, such as operating the eyewash station and applying first aid. Supervisors document each session to meet OSHA compliance.

Regular practice builds confidence and improves response times during real emergencies. Facilities with documented training programs report fewer injuries and better outcomes after accidents. Training records must include topics covered, trainer identity, and proof of competency.

Training Element | Requirement | Causality |

|---|---|---|

Hands-on Practice | Annual, with practical demonstrations | Ensures skill retention |

Documentation | Record topics, trainer, competency | Meets OSHA compliance |

Competency Verification | Test or demonstration required | Confirms readiness |

What Documentation and Ongoing Monitoring Ensure Sustained Safety Compliance?

Accurate documentation and ongoing monitoring form the backbone of a strong safety program. These practices help organizations identify hazards, track improvements, and maintain compliance with regulatory standards. By recording and reviewing key data, teams can prevent incidents and create a safer workplace.

Quarterly Air Sampling: NIOSH Method 7500 Protocol and Trending Analysis

Quarterly air sampling measures respirable crystalline silica levels during representative cutting operations. Safety coordinators use NIOSH Method 7500 to collect samples at breathing zone height, ensuring accurate exposure assessment. Results are compared to OSHA’s permissible exposure limit, and trends are analyzed to detect control degradation.

Facilities that monitor air quality every 90 days can identify rising exposure levels before they exceed limits. Trending analysis helps teams link exposure spikes to equipment issues or process changes. Proactive sampling supports early intervention and continuous improvement.

Sampling Frequency | Method | Key Outcome |

|---|---|---|

Quarterly | NIOSH 7500 | Detects exposure trends early |

Breathing zone | Personal sampling | Ensures accurate assessment |

Equipment Maintenance Logs: Required Entries and 30-Year Retention

Maintenance logs document all service activities for cutting equipment, including blade changes, coolant system cleaning, and ventilation filter replacements. Each entry records the date, task performed, and responsible person. OSHA requires facilities to retain these records for at least 30 years.

Consistent logging allows teams to spot patterns, such as increased incidents after delayed maintenance. Long-term records also support regulatory inspections and help verify that safety controls remain effective. Reliable documentation reduces the risk of equipment-related injuries.

Key Points:

Record all maintenance activities with dates and details

Retain logs for 30 years to meet OSHA requirements

Use logs to identify trends and prevent failures

Training Documentation Standards: Required Elements for OSHA Compliance

Training records must include the date, topics covered, trainer’s name, and proof of worker competency. Facilities document both initial and annual refresher training for all employees exposed to silica dust. Supervisors verify that workers can demonstrate required skills, not just pass written tests.

Detailed records show that employees received proper instruction and understand emergency procedures. OSHA inspectors often review these documents during audits. Well-maintained training files help organizations prove compliance and support a culture of safety.

Documentation Element | Purpose | Causality |

|---|---|---|

Training date | Tracks compliance | Ensures timely instruction |

Topics covered | Confirms content delivered | Verifies relevant knowledge |

Competency verification | Demonstrates skill mastery | Reduces risk of improper response |

Incident Investigation Process: Root Cause Analysis and Corrective Action Verification

Incident investigations follow a structured process to identify hazards and prevent recurrence. Teams define the problem, gather data, and use analytical tools like the “Five Whys” to uncover root causes. Corrective actions must be specific, measurable, achievable, relevant, and time-bound.

After implementing solutions, teams monitor outcomes to ensure effectiveness. Collecting evidence through interviews, photos, and logs strengthens the investigation. This approach drives continuous improvement and supports a safer environment.

Key Points:

Define the problem and collect accurate data

Use analytical tools to find root causes

Implement and monitor corrective actions for effectiveness

Safety protocols quartz tube cutting operations require must guide every phase, from preparation to emergency response. Teams that follow safety protocols quartz tube cutting consistently reduce injuries and avoid regulatory violations. Regular training, proactive hazard monitoring, and strict documentation help maintain safety protocols quartz tube cutting as a daily standard.

Continuous improvement in safety brings higher productivity and ensures compliance. Every worker plays a role in building a safer, more efficient workplace.

FAQ

What is the most common injury during quartz tube cutting?

Lacerations from contact with the rotating blade occur most often.

Industry data shows 92% of these injuries happen when workers hold tubes by hand.

Proper use of fixtures and gloves reduces this risk.

Key Points:

Blade contact causes most injuries

Hand-holding increases risk

Fixtures and gloves improve safety

What should workers do if silica dust exposure occurs?

Workers should leave the area and move to fresh air.

Supervisors must investigate the cause and arrange medical evaluation if symptoms last over two minutes.

Prompt action prevents long-term health effects.

Action | Purpose | Result |

|---|---|---|

Move to fresh air | Reduce exposure | Lower health risk |

Medical evaluation | Assess symptoms | Ensure proper care |

What equipment checks are required before each shift?

Operators must check ventilation airflow, blade condition, coolant flow, and GFCI function.

Each check prevents equipment failure and exposure to hazards.

Facilities that follow this protocol see a 65% drop in incidents.

Summary:

Airflow ≥300 CFM

Blade runout <0.3mm

Coolant flow 200-300ml/min

GFCI tested

What documentation supports OSHA compliance in quartz cutting?

Facilities must keep air sampling records, maintenance logs, training files, and incident reports.

Each document proves that safety protocols are followed.

OSHA requires retention of these records for at least 30 years.

Document Type | Purpose | Retention |

|---|---|---|

Air sampling | Exposure monitoring | 30 years |

Maintenance logs | Equipment safety | 30 years |

Training records | Worker competency | 30 years |

What annual training must quartz tube cutting workers complete?

Workers must practice emergency eyewash use, first aid, and equipment shutdown.

Supervisors verify skills through hands-on demonstrations.

Annual training reduces injury rates and ensures readiness.

Key Points:

Hands-on emergency drills

Supervisor skill checks

Annual refresher required