Quartz tubes show different temperature limits depending on the operating environment. The maximum and optimal temperature ranges for quartz tube temperature different environments appear in the table below. Matching the quartz tube to the specific atmosphere and pressure ensures safe, long-lasting performance.

Environment | Maximum Continuous Temp (°C) | Short-Term Peak Temp (°C) |

|---|---|---|

Atmospheric (air/inert, 1 atm) | 1100-1200 | 1450-1600 (<30 min) |

Vacuum (<10⁻³ Torr) | 1000 | 1200-1300 (<20 min) |

Reducing (H₂ 5-15%) | 1000-1050 | 1200-1350 (<25 min) |

Oxidizing (O₂, air) | 1050-1150 | 1350-1500 (<30 min) |

Corrosive (Cl₂, HCl) | 850-950 | 1100-1250 (<15 min) |

Choosing the right quartz tube for each environment protects against early failure and maximizes service life.

Key Takeaways

Quartz tubes can operate continuously at 1100-1200°C in atmospheric pressure, ensuring long service life when proper heating practices are followed.

In vacuum environments, the maximum continuous temperature is 1000°C. Users must monitor heat transfer to prevent damage from uneven heating.

Reducing atmospheres lower the safe temperature for quartz tubes to 1000-1050°C. Thicker walls can enhance durability against chemical erosion.

Oxidizing environments allow quartz tubes to reach 1050-1150°C, but moisture can significantly reduce safe operating temperatures, so keep gases dry.

Selecting the right quartz tube requires matching temperature ratings to the specific atmosphere type to prevent early failures and maximize performance.

What Temperature Can Quartz Tubes Withstand in Atmospheric Pressure Environments?

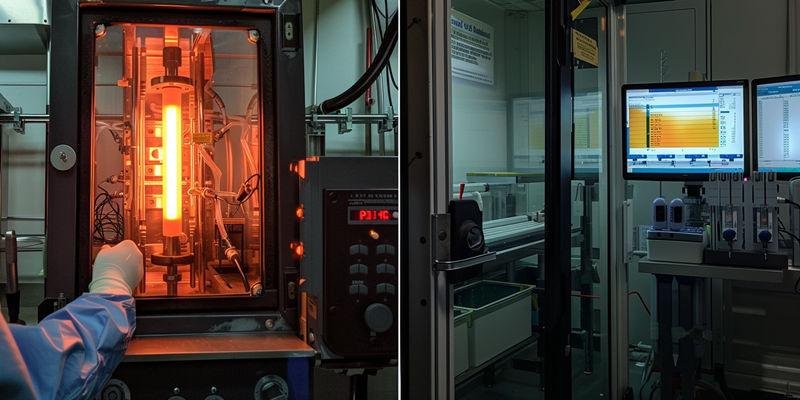

Quartz tubes perform best in atmospheric pressure environments, where they achieve their highest temperature ratings. The combination of stable pressure and effective heat transfer allows these tubes to maintain structural integrity during high-temperature applications. Understanding the temperature limits and the factors that affect service life helps users select the appropriate temperature range for their needs.

Continuous Temperature Limits: 1100-1200°C for Long-Term Operation

Quartz tubes can operate continuously at temperatures between 1100°C and 1200°C in atmospheric pressure environments. This optimal temperature range supports long-term use, often exceeding 8,000 hours, when users follow proper heating and cooling practices. The external environment temperature, gas composition, and thermal cycling frequency all influence the tube’s durability.

Key factors for long-term operation:

Maximum continuous temperature: 1200°C

Service life expectation: 8,000–10,000 hours

Influencing factors: Heating practices, gas environment, and thermal cycling

Quartz tube temperature different environments require careful attention to these factors to prevent devitrification and maintain high-temperature resistance. When users operate within the recommended temperature range and avoid rapid temperature changes, quartz tubes deliver reliable performance in high-temperature environments.

Short-Term Peak Temperature Capability: 1450-1600°C

Quartz tubes can withstand short-term peak temperatures from 1450°C to 1600°C for less than 30 minutes. These brief excursions allow for rapid thermal processing without causing permanent damage, as the material’s structure remains stable during short exposures. However, exceeding the maximum temperature tolerance for longer periods can lead to melting or rapid crystallization.

Peak Temperature | Duration | Effect |

|---|---|---|

1450–1600°C | <30 minutes | Maintains structure, no damage |

>1600°C | Any duration | Risk of melting, crystallization |

Quartz tube temperature different environments may require occasional high-temperature spikes, but users should always monitor exposure time. By respecting these short-term limits, quartz tubes continue to provide optimal performance in demanding industrial settings.

Why Atmospheric Pressure Enables Higher Temperature Ratings

Atmospheric pressure supports higher temperature ratings for quartz tubes by maintaining their shape and stability. The pressure prevents deformation and allows the material to withstand greater thermal stress compared to vacuum or other environments. This structural integrity results from the balance between the tube’s physical properties and the surrounding air pressure.

Why atmospheric pressure matters:

Structural support: Maintains tube shape at high temperatures

Maximum operating temperature: 1200°C in atmospheric conditions

Cause-effect: Atmospheric pressure reduces risk of sagging or deformation

The maximum operating temperature for quartz tubes in atmospheric pressure environments exceeds that of vacuum conditions by about 200°C. This advantage makes atmospheric pressure the preferred choice for many high-temperature applications requiring consistent performance and long service life.

What Temperature Can Quartz Tubes Withstand in Vacuum Environments?

Quartz tubes behave differently in vacuum environments compared to atmospheric conditions. The absence of air changes how heat moves through the tube and affects its structural stability. Understanding the temperature range and the factors that influence performance helps users select the right quartz tube for high-temperature applications.

Maximum Continuous Temperature: 1000°C Under Vacuum

Quartz tubes in vacuum environments reach a maximum continuous temperature of 1000°C. The lack of convective cooling means heat builds up quickly, and the tube relies on radiation and conduction to release energy. Material purity, wall thickness, and the external environment temperature all play a role in determining the maximum operating temperature.

Key points for vacuum operation:

Maximum continuous temperature: 1000°C

Material purity and wall thickness affect high-temperature resistance

External environment temperature influences tube stability

Selecting the correct quartz tube for vacuum use ensures safe operation and prevents early failure.

Heat Transfer Limitations Without Convective Cooling

Heat transfer in vacuum environments depends on radiation and conduction, not convection. The absence of air causes uneven heating, which can create hot spots and increase the risk of damage. Quartz tube temperature different environments require careful monitoring of thermal cycling to avoid cracks or deformation.

Heat Transfer Method | Effect on Tube | Cause-Effect Relationship |

|---|---|---|

Radiation | Slow, uneven cooling | Hot spots form, stress rises |

Conduction | Limited by supports | Localized heating occurs |

Managing heat flow and limiting rapid temperature changes help maintain the maximum temperature tolerance and extend tube life.

Viscous Deformation Risk Above 1000°C in Vacuum

Quartz tubes face a higher risk of viscous deformation when temperatures exceed 1000°C in vacuum conditions. The lack of pressure support allows the tube to sag or change shape, especially during thermal cycling. High-temperature resistance drops as the tube approaches its strain point, and even small increases in temperature can triple the chance of failure.

Summary of deformation risks:

Thermal cycling increases structural stress

Pressure support is critical for tube stability

Monitoring temperature and pressure helps prevent deformation and ensures reliable performance in high-temperature applications.

What Temperature Can Quartz Tubes Withstand in Reducing Atmospheres?

Quartz tubes face unique challenges in reducing atmospheres, especially when exposed to hydrogen or carbon monoxide. The temperature range for safe operation drops compared to atmospheric or inert environments, and chemical reactions can erode the tube walls over time. Selecting the right quartz tube for high-temperature applications in these conditions requires careful attention to several factors.

Temperature Derating for Hydrogen-Containing Atmospheres: 1000-1050°C

Reducing atmospheres with hydrogen lower the maximum operating temperature for quartz tubes to between 1000°C and 1050°C. This temperature derating protects the tube from accelerated chemical erosion and maintains high-temperature resistance. Engineers must consider the external environment temperature and the frequency of thermal cycling when choosing the correct tube.

Key points for hydrogen atmospheres:

Lower maximum operating temperature prevents rapid wall loss.

Frequent thermal cycling increases stress and erosion risk.

Wall thickness should increase by 30-50% for added durability.

Selecting a thicker tube and scheduling regular maintenance helps extend service life in hydrogen-rich environments.

Chemical Erosion Mechanism: SiO Formation Rates

The main chemical erosion mechanism in reducing atmospheres involves the formation of silicon monoxide (SiO) gas. Hydrogen enhances mass transfer and can directly reduce SiO₂ to SiO, which increases the rate of wall thinning. The Gibbs free energy of this reaction becomes negative at high temperatures, making the process spontaneous and more aggressive as temperature rises.

Cause | Effect | Result |

|---|---|---|

Hydrogen present | Faster SiO formation | Increased wall erosion |

High temperature | Spontaneous reaction | |

Methane formation | Enhanced mass transfer | Accelerated erosion |

Monitoring the rate of SiO formation and adjusting operating conditions can help control erosion and maintain tube integrity.

How H₂ Concentration Affects Maximum Safe Temperature

Hydrogen concentration directly impacts the maximum safe temperature for quartz tubes in reducing atmospheres. Higher H₂ levels promote faster chemical reactions, which lower the safe temperature ceiling and shorten service life. Operators must match the tube specifications to the atmosphere and adjust wall thickness to withstand increased erosion.

Atmosphere | |

|---|---|

Air | Lower than H₂ |

Inert | Higher than Air |

H₂ | Up to 1500 for CNTf |

Increasing wall thickness from 1 millimeter to 2 millimeters allows the tube to handle higher pressures and reduces sag rate by a factor of three. Regular inspection and maintenance intervals become essential in hydrogen-rich environments.

What Temperature Can Quartz Tubes Withstand in Oxidizing and Corrosive Gas Environments?

Quartz tubes face different challenges in oxidizing and corrosive gas environments. The presence of oxygen or aggressive chemicals changes the way these tubes handle heat and chemical attack. Understanding the specific temperature limits and the effects of moisture helps users select the right tube for each application.

Oxidizing Atmosphere Limits: 1050-1150°C Continuous

Oxidizing atmospheres, such as air or pure oxygen, set the continuous temperature limit for quartz tubes between 1050°C and 1150°C. Technical standards recommend a normal operating temperature of about 1050°C for continuous use, while non-continuous operation can reach up to 1250°C. Oxygen exposure speeds up surface devitrification, which lowers the safe temperature ceiling and can shorten service life.

Key points for oxidizing atmospheres:

Continuous use: 1050°C

Non-continuous use: 1250°C

Main risk: Accelerated devitrification

These limits help prevent rapid crystal growth on the tube surface, which can weaken the material over time. Operators should monitor temperature closely to avoid exceeding the recommended range.

Corrosive Gas Temperature Ceiling: 850-950°C Maximum

Corrosive gases, such as chlorine or hydrochloric acid, lower the maximum operating temperature for quartz tubes to between 850°C and 950°C. Chemical reactions with these gases attack the tube surface, causing erosion that becomes much faster as temperature rises. The presence of corrosive species means users must accept shorter service intervals and plan for regular tube replacement.

Gas Type | Maximum Operating Temperature | Cause | Effect |

|---|---|---|---|

Chlorine (Cl₂) | 900°C | Chemical attack | Wall erosion increases |

HCl | 950°C | Surface reaction | Shorter tube life |

Corrosive environments demand careful control of both temperature and gas purity to maintain tube integrity. Lowering the temperature ceiling helps slow down the rate of chemical attack.

Moisture Catalysis Effect on Temperature Tolerance

Moisture in the gas stream acts as a catalyst, reducing the safe temperature for quartz tubes even further. Water vapor speeds up chemical reactions with corrosive gases, which can double or triple the rate of wall erosion. Even small amounts of moisture can lower the safe operating temperature by 100°C to 150°C.

Summary of moisture effects:

Moisture increases erosion rate

Safe temperature drops by up to 150°C

Dry gas extends tube life

Operators should dry the process gas to a low dew point to protect the tube from rapid damage. Careful moisture control allows the tube to reach its full service life in harsh environments.

How Should You Apply These Temperature Ratings to Your Specific Operating Environment?

Selecting the right quartz tube for a specific usage environment requires careful attention to both atmosphere type and operational details. Each environment presents unique factors influencing maximum temperature, so users must match tube specifications to real-world conditions. Proper temperature control and derating ensure safe, long-lasting performance.

Matching Temperature Ratings to Your Atmosphere Type

Choosing the correct temperature rating starts with identifying the atmosphere type. Each environment—such as air, vacuum, or reducing gas—affects the tube’s thermal performance and temperature resistance. Operators must consider the thermal expansion coefficient and the risk of thermal shock resistance loss in each setting.

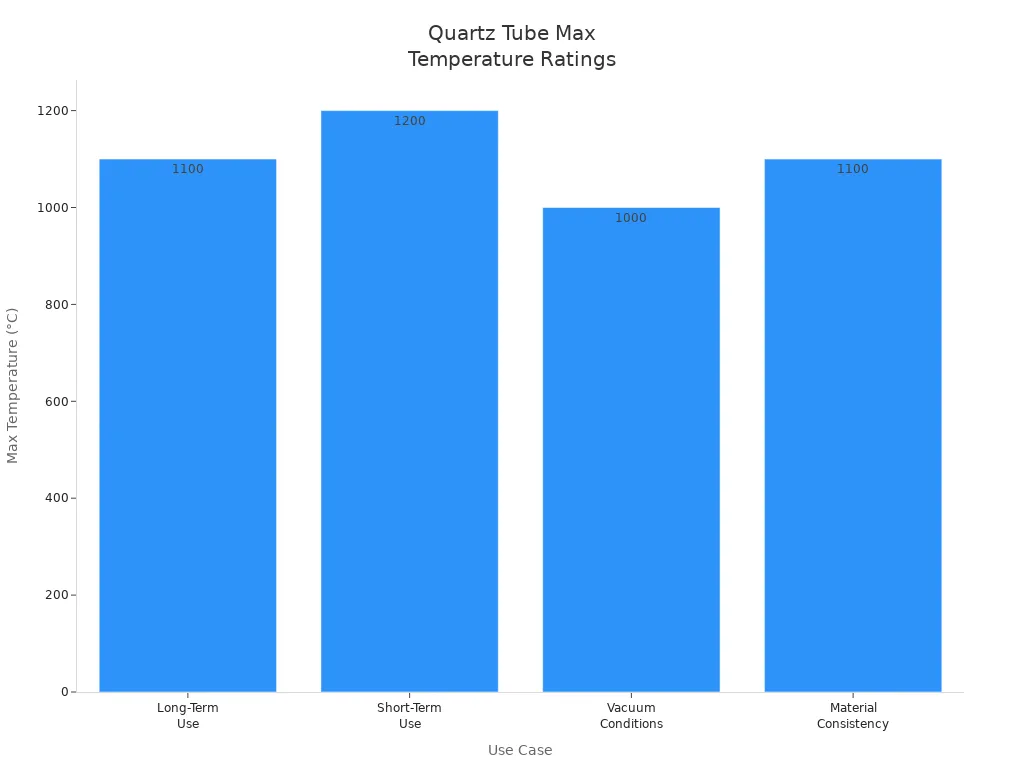

The following table summarizes how different use cases impact maximum temperature and highlights the cause-effect relationships:

Use Case | Maximum Temperature | Key Factor |

|---|---|---|

Long-Term Use | 1100°C | Consistent exposure, stable structure |

Short-Term Use | 1200°C | Brief spikes, minimal damage |

Vacuum Conditions | 1000°C | Reduced pressure, lower stability |

Higher Temp Needs | >1200°C | Corundum tubes needed |

Material Consistency | 1100°C | Same for transparent quartz |

Environmental Factors | Varies | Atmosphere changes ratings |

Matching the tube’s rating to the atmosphere type prevents early failure and maximizes service life.

Implementing Proper Temperature Derating Factors

Temperature derating means lowering the maximum operating temperature based on the actual environment. This adjustment accounts for factors like pressure, gas composition, and moisture, which can reduce high-temperature oxidation resistance and increase the risk of damage. Operators should always check for low-temperature settings when conditions change.

Key points for derating:

Lower ratings in vacuum or reducing atmospheres

Increase wall thickness for harsh environments

Monitor for rapid temperature changes

Applying proper derating factors ensures the quartz tubes maintain their structural integrity and extend their service life.

Quartz tubes show different temperature limits in each operating environment. Atmospheric pressure allows the highest continuous temperatures, while vacuum, reducing, oxidizing, and corrosive conditions require lower ratings. Proper derating and matching specifications to the application help prevent failures in a quartz tube furnace. Users should review technical data such as purity levels, dimensions, and thermal properties, since the melting point of pure quartz sets the upper boundary for safe operation. For custom solutions, manufacturers offer options for diameter, wall thickness, and surface treatment.

Regular consultation with technical experts ensures safe and efficient use.

Customization Aspect | Details |

|---|---|

Diameter | 5mm to 300mm |

Wall Thickness | Tailored for durability |

Surface Treatment | Polishing and coating |

FAQ

What is the maximum temperature quartz tubes can handle in a vacuum?

Quartz tubes reach up to 1000°C for continuous use in vacuum environments. They rely on radiation and conduction for heat transfer. Operators should avoid exceeding this limit to prevent deformation.

For vacuum use, always check the tube’s wall thickness and purity.

How does moisture affect quartz tube performance in corrosive atmospheres?

Moisture speeds up chemical reactions, lowering safe operating temperatures by 100°C to 150°C. Tubes last longer when the process gas stays dry. Regular monitoring helps maintain tube integrity.

Moisture Level | Safe Temperature | Tube Life |

|---|---|---|

Low | 950°C | Longer |

High | 800°C | Shorter |

Why do quartz tubes need thicker walls in reducing atmospheres?

Thicker walls resist chemical erosion from hydrogen and carbon monoxide. Tubes with 2.5–3.0 mm walls last 5,000+ hours at 1050°C. Increased thickness provides extra durability.

Key points for reducing atmospheres:

Wall thickness improves tube life

Higher hydrogen levels require thicker tubes

Regular inspections prevent early failure

Can quartz tubes be used for rapid thermal processing?

Quartz tubes withstand short-term peaks up to 1600°C for less than 30 minutes. They suit rapid thermal processing in high-performance industrial material applications. Operators should monitor exposure time to avoid permanent damage.

What factors determine the service life of quartz tubes?

Service life depends on temperature, atmosphere type, wall thickness, and maintenance. Tubes in atmospheric pressure last 8,000–10,000 hours at 1100°C. Regular cleaning and proper temperature control extend tube life.

Environment | Service Life (hours) | Temperature (°C) |

|---|---|---|

Atmospheric | 8,000–10,000 | 1100 |

Vacuum | 7,000–9,000 | 1000 |

Reducing | 5,000–7,000 | 1050 |