Comparing Thermal Expansion Properties

Explore how quartz and glass tubes differ in thermal expansion.

Features | Quartz Glass Tubes | Borosilicate Glass Tubes |

|---|---|---|

Thermal Expansion Coefficient | 0.5 × 10⁻⁶/K | 3.3 × 10⁻⁶/K |

Material Purity | Up to 99.99% purity | Lower purity with modifiers |

Service Life | Over 10,000 cycles | 100-3,500 cycles |

Heating Rate Capability | Up to 500°C/min | 30-150°C/min |

Temperature Gradient Tolerance | Over 1000°C | 40-165°C |

Risk of Cracking | Minimal risk | High risk |

Replacement Frequency | Quarterly to annually | Monthly |

Thermal Stress Resistance | Excellent resistance | Prone to stress fractures |

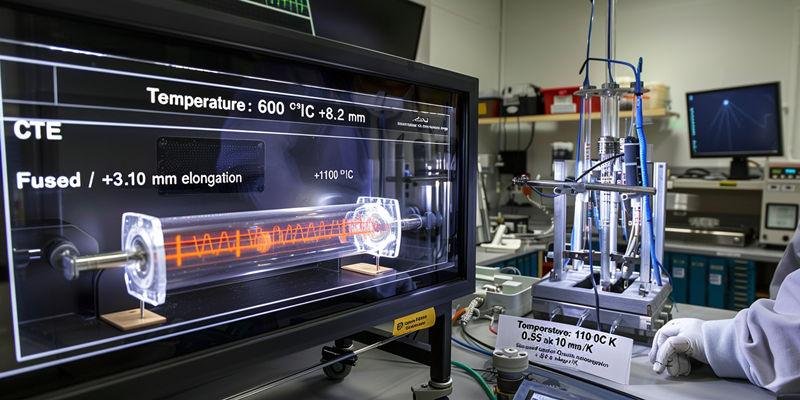

Quartz Tubes have a thermal expansion coefficient of about 0.5 × 10⁻⁶/K, which allows them to resist stress from rapid temperature changes.

Glass tubes expand much more with heat, increasing their risk of cracking during sudden temperature shifts.

Selecting Quartz Tubes for any application involving frequent or extreme temperature cycling ensures better durability and stability.

Key Takeaways

Quartz tubes have a much lower thermal expansion coefficient than glass tubes, making them more durable during rapid temperature changes.

Choosing quartz tubes for high-temperature applications reduces the risk of cracking and extends service life significantly.

Quartz glass can withstand over 10,000 thermal cycles, while glass tubes often fail after just a few hundred cycles.

Using quartz tubes minimizes maintenance costs and downtime due to their superior resistance to thermal stress and cracking.

For industries requiring rapid heating, quartz tubes allow heating rates up to 500°C/min, far exceeding the capabilities of glass tubes.

What Compositional Factors Create the 6-18× Thermal Expansion Difference Between Quartz and Glass Tubes?

The dramatic difference in thermal expansion between quartz and glass tubes comes from their unique chemical compositions. Quartz tubes use nearly pure silica, while glass tubes contain a mix of oxides and modifiers. These compositional choices directly impact how each material responds to heat and rapid temperature changes.

Pure Silica in Quartz Versus Mixed Oxides in Glass Creating Expansion Difference

Quartz tubes consist almost entirely of high-purity fused silica. This purity gives quartz a tightly bonded atomic structure, which resists expansion when heated. In contrast, glass tubes include various oxides, such as sodium oxide and boron oxide, which disrupt the silica network and increase expansion.

A comparison table highlights these differences:

Material Type | Main Components | Thermal Expansion Coefficient (×10⁻⁶/K) | Purity Level |

|---|---|---|---|

Borosilicate Glass | Sodium oxide, Boron oxide, Silicon dioxide | 3.3 ± 0.1 | Lower purity |

Quartz Glass | High-purity fused silica | 0.5 | Up to 99.99% |

The high silica content in quartz tubes results in a thermal expansion coefficient up to 18 times lower than that of glass tubes.

Network Modifier Ions Increasing Dimensional Change Under Heat

Network modifier ions in glass, such as sodium, play a key role in how the material expands. These ions break up the strong silica bonds, creating nonbridging oxygen atoms and shorter silica chains. As a result, the glass structure becomes more flexible, allowing the material to expand and contract more easily under heat.

This structural change means glass tubes experience greater dimensional shifts during rapid temperature cycling. Quartz tubes, lacking these modifiers, maintain their rigid network and resist such changes. The presence of network modifiers directly causes the higher thermal expansion seen in glass tubes.

To summarize the impact of network modifiers:

Network modifiers disrupt silica bonds, increasing expansion.

Glass tubes with modifiers expand more under heat than pure quartz tubes.

Quartz tubes’ lack of modifiers ensures superior thermal stability.

Compositional Purity Determining Thermal Cycling Capability

Compositional purity sets the limit for how well a tube survives repeated heating and cooling. High-purity quartz glass can withstand extreme temperature swings without deforming or cracking. Standard glass, with its lower purity and added modifiers, softens and cracks more easily under the same conditions.

Quartz tubes tolerate temperature changes exceeding 1000°C, while glass tubes often fail at much lower gradients. The ultra-high purity of quartz also prevents contamination and maintains shape at temperatures up to 1200°C. This makes quartz tubes the preferred choice for demanding thermal cycling applications.

A summary table shows the causal relationship:

Compositional Purity | Thermal Cycling Capability | Risk of Failure |

|---|---|---|

High (Quartz Glass) | Withstands extreme cycling, keeps shape | Minimal |

Lower (Glass Tubes) | Prone to softening, cracking | High |

How Does Low Thermal Expansion in Quartz Tubes Versus High Expansion in Glass Enable Different Rapid Heating Rates?

Rapid temperature cycling demands materials that can withstand sudden changes without failing. The thermal expansion coefficient plays a critical role in determining how quickly a tube can be heated or cooled. Quartz tubes outperform glass tubes in rapid heating applications due to their unique physical properties.

Quartz Enabling 500°C/min Heating Versus Glass Limited to 30-150°C/min

Quartz tubes allow for extremely fast heating rates, reaching up to 500°C per minute. Their low thermal expansion coefficient and high tensile strength make them ideal for processes that require rapid temperature changes. In contrast, glass tubes can only handle heating rates between 30°C and 150°C per minute, which limits their use in high-throughput environments.

Quartz tubes maintain structural integrity even when exposed to sudden temperature spikes. This capability results from their pure silica composition, which resists expansion and cracking. Glass tubes, with higher expansion rates, risk shattering or deforming under similar conditions.

The following table highlights the differences in rapid heating performance:

Property | Quartz Tubes | Glass Tubes |

|---|---|---|

Max Heating Rate | 500°C/min | 30-150°C/min |

Expansion Coefficient | 0.5 × 10⁻⁶/K | 3.3 × 10⁻⁶/K (Borosilicate) |

Robustness | 14× higher than glass | Lower |

Thermal Stress Generation at High Heating Rates

Thermal stress develops when the outer layer of a tube heats up faster than the inner layer. Quartz tubes experience minimal thermal stress because their low expansion coefficient reduces the difference in expansion between layers. Glass tubes, with much higher expansion rates, generate significant thermal stress during rapid heating, increasing the risk of cracks and failure.

The structure of quartz tubes allows them to withstand compressive and tensile stresses that occur during rapid temperature changes. Silica glass can tolerate temperatures up to 1200°C, while ordinary glass is limited to 500°C. This difference in tolerance ensures that quartz tubes remain reliable in demanding thermal cycling environments.

Key points to remember about thermal stress in rapid heating:

Quartz tubes minimize thermal stress due to low expansion.

Glass tubes are prone to cracking under high thermal stress.

Silica glass maintains integrity at higher temperatures.

Process Throughput Advantages from Rapid Heating Capability

Industries benefit from higher process throughput when using quartz tubes for rapid heating applications. The ability to heat quickly without risking tube failure allows for shorter cycle times and increased productivity. Quartz tubes also offer excellent resistance to corrosion, which further enhances their suitability for high-temperature processes.

Quartz tubes withstand repeated heating and cooling cycles, reducing downtime and maintenance costs. Their superior thermal stability ensures consistent performance, even in harsh environments. Glass tubes, on the other hand, require more frequent replacement due to their limited thermal shock resistance.

The following table summarizes the process throughput advantages:

Property | Quartz Tubes | Glass Tubes |

|---|---|---|

Thermal Stability | Withstands up to 1200°C (2192°F) | Withstands up to 500°C (932°F) |

Resistance to Cracking | Excellent under rapid changes | Prone to cracking under rapid changes |

Suitability | Ideal for high-temperature applications | Limited use in high-temperature environments |

How Does Thermal Expansion Difference Between Quartz and Glass Tubes Affect Thermal Cycling Service Life?

Thermal expansion plays a major role in determining how long tubes last when exposed to rapid temperature changes. Materials that expand less under heat can survive more cycles without damage. This section explains why quartz glass tubes offer a much longer service life than standard glass tubes in demanding environments.

Service Life Comparison: 10,000+ Cycles for Quartz Versus 100-3,500 for Glass

Service life depends on how well a tube resists cracking and breakage during repeated heating and cooling. Quartz glass tubes, with their very low thermal expansion coefficient, undergo minimal size changes when temperatures shift. This property greatly reduces thermal stress, allowing them to survive over 10,000 rapid cycles, while glass tubes often fail after only 100 to 3,500 cycles.

Glass tubes expand much more with each temperature change. This greater dimensional shift creates stress that can lead to cracks or sudden breakage, especially during fast cycling. Quartz glass tubes, on the other hand, maintain their structure and resist damage, even in extreme conditions.

The following table highlights the causal relationship between material type, expansion, and service life:

Tube Material | Thermal Expansion | Typical Service Life (Cycles) | Risk of Cracking |

|---|---|---|---|

Quartz Glass Tubes | Very Low | 10,000+ | Minimal |

Glass Tubes | High | 100–3,500 | High |

Replacement Frequency: Monthly for Glass Versus Quarterly-to-Annual for Quartz

Replacement frequency shows how often users must change tubes in high-frequency cycling applications. Quartz glass tubes can reduce replacement frequency by up to 65%, with maintenance intervals stretching from six weeks to six months. This durability means fewer interruptions and lower costs for users.

Glass tubes, in contrast, often require monthly replacement due to their higher risk of cracking and failure. Frequent tube changes increase downtime and maintenance expenses. Custom cylindrical clear quartz tubes withstand rapid cycling, reducing tube failures by as much as 80%.

To summarize the replacement frequency differences:

Quartz glass tubes last much longer between replacements.

Glass tubes need frequent changes, raising costs and downtime.

Longer intervals with quartz glass tubes improve operational efficiency.

Failure Patterns: Predictable Degradation in Quartz Versus Sudden Fracture in Glass

Failure patterns differ sharply between quartz and glass tubes. Quartz glass tubes usually show gradual, predictable wear, allowing users to plan maintenance before failure occurs. This predictability comes from their stable structure and low expansion rate.

Glass tubes, however, often fail suddenly and without warning. Their higher expansion coefficient causes stress to build up quickly, leading to unexpected fractures during rapid temperature changes. This sudden failure can disrupt processes and pose safety risks.

The table below compares failure patterns and their impact:

Tube Type | Failure Pattern | Impact on Operations |

|---|---|---|

Quartz Glass Tubes | Predictable degradation | Planned maintenance, less risk |

Glass Tubes | Sudden fracture | Unplanned downtime, higher risk |

Real-World Application Examples

Many industries rely on quartz glass tubes for their superior service life and reliability. The following table shows where these tubes excel:

Application Area | Key Advantages of Quartz Tubes |

|---|---|

Semiconductor Manufacturing | Maintains structural integrity at high temperatures (up to 1,200°C) and prevents stress fractures. |

Chemical Processing | High purity prevents contamination, crucial for chemical reactions. |

Laboratory Furnaces | Superior thermal resistance ensures reliability in rapid thermal cycling. |

These examples highlight why quartz glass tubes are the preferred choice for demanding thermal cycling environments.

How Do Temperature Differential Tolerance Differences Between Quartz and Glass Impact Rapid Cycling Survival?

Temperature differential tolerance plays a critical role in determining how well tubes survive rapid temperature cycling. Quartz glass and standard glass respond very differently to sudden temperature changes. Understanding these differences helps users make informed decisions for high-performance applications.

Temperature Gradient Tolerance: 1000°C+ for Quartz Versus 40-165°C for Glass

Quartz glass can withstand temperature gradients greater than 1000°C, while standard glass usually fails at gradients between 40°C and 165°C. This remarkable difference comes from the unique structure and purity of quartz glass, which resists expansion and stress even under extreme conditions. Glass, with its higher expansion coefficient, cannot handle such rapid changes and often cracks or shatters.

Quartz glass maintains its shape and strength during sudden heating or cooling, making it ideal for processes that demand quick temperature shifts. Glass tubes, on the other hand, show visible stress and often break when exposed to similar gradients. The superior performance of quartz glass ensures longer service life and fewer failures.

The following table highlights the causal relationship between material type, temperature gradient tolerance, and survival:

Material | Max Gradient Tolerance | Survival in Rapid Cycling |

|---|---|---|

Quartz Glass | 1000°C+ | Excellent |

Glass | 40–165°C | Poor |

Stress Generation Under Thermal Gradients During Rapid Heating

Thermal gradients create stress inside tubes during rapid heating. Quartz glass resists this stress because of its low expansion and strong atomic bonds. Glass, with its higher expansion, develops internal cracks and weak points much faster.

Quartz glass distributes heat evenly, reducing the risk of sudden failure. Glass tubes often experience uneven heating, which leads to localized stress and eventual breakage. This difference makes quartz glass the preferred choice for demanding thermal cycling environments.

To summarize the impact of stress generation, consider these key points:

Quartz glass resists internal stress during rapid heating.

Glass develops cracks and weak spots under thermal gradients.

Quartz glass ensures safer and more reliable operation.

Wall Thickness Effects Amplifying Expansion-Driven Stress

Wall thickness can amplify the effects of thermal expansion in both quartz glass and standard glass. Thicker walls in quartz glass still resist cracking because of the material’s low expansion coefficient. In contrast, thicker glass tubes become even more prone to stress buildup and sudden failure.

Quartz glass maintains structural integrity even as wall thickness increases, supporting high-pressure and high-temperature applications. Glass tubes with thick walls often fail faster because the expansion-driven stress cannot dissipate quickly. This property makes quartz glass suitable for a wide range of industrial uses.

Here is a summary table showing the relationship between wall thickness, material, and stress risk:

Wall Thickness | Quartz Glass Stress Risk | Glass Stress Risk |

|---|---|---|

Thin | Very Low | Moderate |

Thick | Low | High |

Which Composition-Based Thermal Expansion Specification Optimizes Rapid Temperature Cycling Performance?

Selecting the right tube material for rapid temperature cycling depends on understanding how composition affects thermal expansion. The specification for thermal expansion determines how well a tube can handle fast heating and cooling. This section explains how material selection, cost analysis, and certification requirements guide users toward optimal performance.

Material Selection Criteria Based on Heating Rate and Cycle Count

Engineers must consider heating rate and cycle count when choosing between quartz and borosilicate glass tubes. Quartz offers high temperature resistance and a low thermal expansion coefficient, making it suitable for rapid cycling and frequent use. Borosilicate glass tubes, with higher expansion, may not perform as well under extreme conditions.

A comparison table helps clarify the decision-making process:

Selection Criteria | Quartz | Borosilicate Glass Tubes |

|---|---|---|

Heating Rate | Up to 500°C/min | 30–150°C/min |

Cycle Count | 10,000+ | 100–3,500 |

High Temperature Resistance | Up to 1200°C | Up to 500°C |

Quartz stands out for applications requiring fast heating and many cycles.

Total Cost of Ownership Analysis for Rapid Cycling Applications

Total cost of ownership includes initial purchase price, maintenance, and replacement frequency. Quartz tubes cost more upfront, but their high temperature resistance and durability reduce long-term expenses. Fewer failures and less frequent replacements make quartz a smart investment for rapid cycling.

Users see lower maintenance costs and less downtime with quartz. Borosilicate glass tubes may need monthly replacement, increasing operational expenses. Quartz provides reliable performance and minimizes disruptions.

Key points to remember about cost analysis:

Quartz offers lower long-term costs due to durability.

High temperature resistance reduces tube failures.

Borosilicate glass tubes require frequent replacement.

Compositional Certification Requirements for Reliable Performance

Certification ensures that quartz tubes meet strict purity and performance standards. Manufacturers test quartz for high temperature resistance and low thermal expansion, guaranteeing consistent results in rapid cycling. Certified quartz supports demanding applications in laboratories and industry.

Reliable performance depends on compositional purity and verified specifications. Users should request certification documents to confirm that quartz meets required standards. Certified quartz delivers predictable results and extends service life.

A summary table highlights the importance of certification:

Requirement | Quartz | Impact |

|---|---|---|

Purity Certification | Yes | Reliable performance |

High Temperature Resistance | Yes | Extended service life |

Thermal Expansion Spec | Yes | Predictable cycling |

Certification gives users confidence in quartz for rapid temperature cycling.

Quartz tubes show much lower thermal expansion than glass tubes.

This difference allows quartz tubes to survive rapid temperature cycling with less risk of cracking or failure.

Engineers and scientists should select quartz tubes for demanding applications.

Choosing tubes with low thermal expansion ensures longer service life, fewer replacements, and safer operation.

FAQ

What makes quartz glass tube better for rapid temperature cycling than high borosilicate glass tube?

Quartz glass tube resists cracking during fast temperature changes. High borosilicate glass tube expands more, which increases stress. In semiconductor application field, quartz glass tube lasts longer and supports higher heating rates.

Quartz glass tube offers greater durability and stability in demanding environments.

How does the service life of quartz glass tube compare to high borosilicate glass tube?

Quartz glass tube survives over 10,000 cycles. High borosilicate glass tube often fails after 100 to 3,500 cycles. In laboratory application field, quartz glass tube reduces replacement frequency and maintenance costs.

Tube Type | Service Life (Cycles) | Replacement Frequency |

|---|---|---|

Quartz glass tube | 10,000+ | Quarterly-Annual |

High borosilicate glass tube | 100–3,500 | Monthly |

Which application field benefits most from quartz glass tube compared to high borosilicate glass tube?

Semiconductor manufacturing, chemical processing, and laboratory furnaces benefit most from quartz glass tube. High borosilicate glass tube suits less demanding environments. Quartz glass tube maintains purity and withstands extreme temperature gradients.

Quartz glass tube supports high throughput.

High borosilicate glass tube fits moderate cycling.

Quartz glass tube prevents contamination.

Can wall thickness affect the performance of quartz glass tube and high borosilicate glass tube?

Wall thickness amplifies stress in high borosilicate glass tube. Quartz glass tube resists cracking even with thick walls. In industrial application field, quartz glass tube maintains integrity under pressure and temperature.

Wall Thickness | Quartz glass tube Stress Risk | High borosilicate glass tube Stress Risk |

|---|---|---|

Thin | Very Low | Moderate |

Thick | Low | High |

Why do engineers prefer quartz glass tube for high-temperature application field?

Engineers select quartz glass tube for high-temperature application field because it tolerates gradients over 1000°C. High borosilicate glass tube fails at lower gradients. Quartz glass tube ensures reliable operation and longer service life.

Quartz glass tube provides predictable performance in extreme conditions.