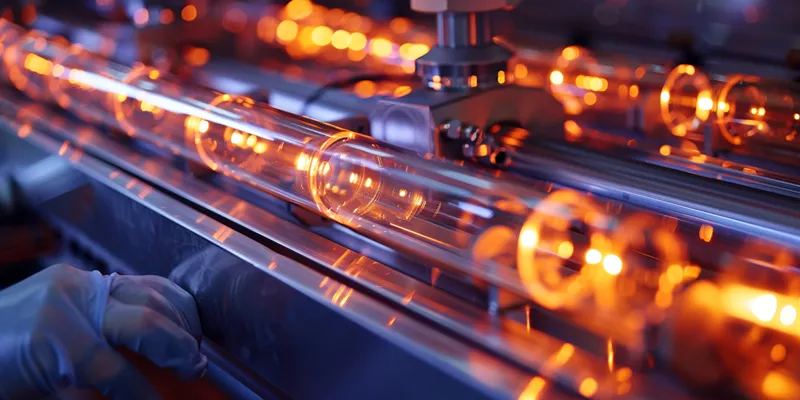

Devitrification weakens quartz tubes in CVD furnaces by making them more brittle and less resistant to sudden temperature changes. Contamination from alkali metals speeds up this process, putting both furnace reliability and product quality at risk. For these reasons, understanding quartz tube devitrification CVD furnaces becomes essential for anyone who operates or maintains high-temperature equipment.

Key Takeaways

Devitrification weakens quartz tubes, making them brittle and less reliable. Understanding this process helps maintain product quality.

Contamination from alkali metals accelerates devitrification. Operators should avoid direct contact with tubes to reduce contamination risks.

Regular cleaning and proper handling of quartz tubes extend their service life. Use gloves and follow cleaning protocols to prevent contamination.

Monitoring operational data helps predict when to replace quartz tubes. Track usage hours and temperature to avoid critical failures.

Advanced manufacturing techniques, like electric fusion, improve thermal stability and reduce devitrification risks in quartz tubes.

What Is Devitrification and Why Does It Occur in Furnace Quartz Tubes?

Quartz tube devitrification CVD furnaces present a significant challenge for operators who rely on high-temperature stability. Devitrification transforms the glassy structure of quartz into a crystalline form, which reduces performance and reliability. Understanding why this process occurs helps prevent costly failures and maintain product quality.

The Thermodynamic Driving Force Behind Amorphous-to-Crystalline Transformation

Devitrification begins when the atoms in amorphous SiO₂ rearrange into a crystalline structure.

Several thermodynamic factors drive this transformation, including silica dissolution, pH levels, supersaturation, and the presence of stable crystal nuclei. Fluctuations in alkalinity also play a major role in the process, making crystallization more likely as temperature rises above 1000°C.

This transformation causes quartz tube devitrification CVD furnaces to lose their glassy structure and optical properties.

Key Thermodynamic Drivers:

Silica dissolution and formation control

pH impact on Si–O bond cleavage

Supersaturation and crystal nuclei presence

Alkalinity fluctuations

How Nucleation Sites Form from Surface Contaminants

Surface contaminants, especially alkali metals, act as nucleation sites for cristobalite formation.

These contaminants, often from handling or environmental exposure, promote nucleation and enhance the transformation from amorphous quartz to crystalline phases. Nucleation in fused quartz starts with alkali elements and other metals, and heterogeneous nucleation proceeds more slowly in non-stoichiometric quartz.

Operators see quartz tube devitrification CVD furnaces accelerate when tubes are exposed to bare hands or water droplets.

Contaminant Source | Effect on Nucleation |

|---|---|

Alkali metals | Promote cristobalite formation |

Handling (perspiration) | Deposits alkali, lowers onset temperature |

Environmental exposure | Water collects airborne contaminants |

Quantifying Crystal Growth Rates at Different Temperature Ranges

Crystal growth rates in quartz tubes depend on temperature and contamination levels.

Above 1000°C, crystal growth shifts from negligible to significant, with rates increasing from less than 0.1 μm/year to 1-5 μm/year. Tubes with higher OH content or surface alkali contamination show 30-45% faster crystallization kinetics, according to ASTM and TOQUARTZ data.

This rapid growth explains why quartz tube devitrification CVD furnaces require strict contamination control at elevated temperatures.

Crystal Growth Rate Summary:

Below 1000°C: <0.1 μm/year

Above 1000°C: 1-5 μm/year

High OH content: 30-45% faster kinetics

Which Contamination Sources Trigger Devitrification in Tube Furnaces?

Contamination plays a major role in why quartz tubes lose their durability in high-temperature furnaces. Operators must understand the sources of these contaminants to prevent early devitrification. Identifying and controlling these triggers helps maintain stable performance and extend tube life.

Quantifying Sodium Deposition from Common Handling Practices

Bare-hand contact introduces significant sodium contamination to quartz tubes.

Skin oils and perspiration can deposit 2-8 ppm sodium, which lowers the devitrification onset temperature by up to 200°C. Even a single touch leaves enough residue to create visible fingerprint patterns that devitrify faster than untouched areas.

Operators should always use gloves and avoid direct contact to reduce this risk.

• Key summary points:

Bare hands deposit 2-8 ppm sodium

Fingerprints become devitrification hotspots

Gloves prevent most contamination

How Process Gas Purity Affects Long-Term Tube Stability

Process gas purity directly impacts the long-term stability of quartz tubes.

Impurities in process gases, such as sodium or metal compounds, accumulate on tube surfaces during operation and accelerate devitrification, especially at temperatures above 1000°C. Over time, these contaminants can diffuse into the quartz, reducing its resistance to thermal shock and increasing the rate of quartz tube devitrification CVD furnaces experience.

High-purity gases help maintain tube integrity and slow down devitrification.

Factor | Impact on Tube Stability |

|---|---|

Gas purity | Fewer impurities, slower devitrification |

Metal contaminants | Increase devitrification rate |

Hydroxyl content | Reduces performance at high temperatures |

Effective Surface Cleaning Protocols to Remove Alkali Contamination

Proper cleaning protocols remove alkali contamination and help prevent devitrification.

Alkaline washing dissolves surface residues, but operators must control the solution’s strength and cleaning time to avoid damaging the tube. After cleaning, thorough rinsing with water ensures no chemicals remain that could trigger further devitrification.

Routine cleaning and careful handling keep quartz tubes in optimal condition.

• Cleaning protocol highlights:

Use alkaline solutions for surface cleaning

Neutralize and rinse thoroughly after washing

Regular cleaning extends tube service life

What Performance Degradation Results from Cristobalite Formation?

Cristobalite formation inside quartz tubes leads to several performance issues in CVD furnaces. These changes reduce the tube’s ability to handle rapid temperature shifts, decrease transparency, and increase the risk of mechanical failure. Understanding why these degradations occur helps operators take action before costly breakdowns happen.

Measuring Thermal Shock Resistance Degradation in Crystallized Tubes

Thermal shock resistance drops sharply when cristobalite forms in quartz tubes.

Crystallized regions lose their ability to withstand sudden temperature changes, with safe temperature differentials decreasing from 1000°C/minute to 400-600°C/minute. Data from ASTM C1525 testing shows a 40-60% reduction in thermal shock resistance, which means tubes become much more likely to crack during furnace cycling.

Operators must monitor tube condition to avoid unexpected failures.

• Bulleted Summary:

Thermal shock resistance falls by up to 60%

Crystallized tubes crack more easily

Regular monitoring prevents breakdowns

How Optical Transmission Loss Affects Process Monitoring Capability

Cristobalite formation causes a dramatic loss in optical transmission.

As the crystalline layer grows thicker, visible light transmission drops from 92% in clear quartz to less than 30% when the layer exceeds 100 μm. This reduction makes it difficult for operators to visually monitor furnace processes, which can lead to missed defects or process errors.

Maintaining tube transparency is essential for effective process control.

Key Point | Impact |

|---|---|

Transmission drops below 30% | Visual monitoring impaired |

Layer thickness >100 μm | Process errors increase |

Transparency loss | Quality control suffers |

Quantifying Structural Stress from Cristobalite Phase Transitions

Cristobalite phase transitions generate significant mechanical stress in quartz tubes.

During the β→α phase change at 200-275°C, the tube experiences a 5% volumetric expansion and 2.8% linear dimension change. These stresses often exceed the 50 MPa fracture strength of fused quartz, causing cracks and structural failures, especially when the crystalline layer depth surpasses 200 μm.

Operators must replace tubes before stress-induced damage occurs.

• Bulleted Summary:

Phase transitions create high mechanical stress

Cracks form when stress exceeds quartz strength

Timely replacement avoids catastrophic failure

What Advanced Processing Methods Minimize Devitrification Risk?

Modern manufacturing and processing methods play a crucial role in reducing devitrification risk for quartz tubes in CVD furnaces. These methods focus on controlling impurities, optimizing surface treatments, and improving material stability at high temperatures. Understanding why these approaches work helps operators select the best tubes and extend furnace service life.

How OH Content Control Through Electric Fusion Improves Thermal Stability

Electric fusion lowers the hydroxyl (OH) content in quartz tubes.

Lower OH levels increase thermal stability because they reduce the risk of devitrification and allow the material to withstand higher temperatures. This process also improves ultraviolet transmission, which is important for certain applications.

Operators choose electric fusion to enhance tube performance in demanding environments.

Bulleted Summary:

Lower OH content increases resistance to devitrification

Electric fusion improves high-temperature durability

Enhanced UV transmission benefits sensitive processes

Trace Metal Reduction Technologies and Their Performance Impact

Trace metal reduction technologies remove impurities that can trigger devitrification.

Manufacturers use zone refining and multiple recrystallization cycles to lower metal content, which raises the onset temperature for devitrification and improves tube reliability. Data shows that tubes with less than 10 ppm total metallic impurities last up to 850 hours longer at 1075°C before devitrification begins.

These methods explain why high-purity quartz tubes perform better in CVD furnaces.

Key Factor | Performance Benefit |

|---|---|

Low metal content | Higher devitrification onset temp |

Zone refining | Improved tube reliability |

850+ hours longer life | Extended service in CVD furnaces |

Surface Treatment Methods That Extend High-Temperature Service Life

Surface treatments protect quartz tubes from contamination and extend their service life.

Techniques such as HF acid etching, plasma treatment, and rare earth doping create stable surfaces that resist devitrification and maintain performance during thermal cycling. These treatments also improve film adhesion and keep process chambers cleaner, resulting in less downtime.

Benefit | Description |

|---|---|

Longer MTBM | Up to 50% longer Mean Time Between Maintenance (MTBM) |

Improved Film Adhesion | More stable, uniform coatings |

Cleaner Process Chambers | Reduced downtime due to surface failure |

High Repeatability | Consistent results batch-to-batch |

Compatibility | Works with critical process surfaces |

Long-term Stability | Withstands thermal and chemical cycling |

How Should Furnace Operators Monitor and Manage Devitrification?

Furnace operators must understand why monitoring and management strategies are essential for preventing devitrification-related failures. Regular inspections and data-driven maintenance help maintain tube integrity and process reliability. Operators who follow best practices can extend tube service life and avoid costly downtime.

Visual Inspection Criteria for Different Devitrification Stages

Visual inspection remains the first line of defense against devitrification in quartz tubes.

Operators look for changes in clarity, such as the appearance of white, cloudy patches or loss of transparency, which signal the transition from amorphous to crystalline structure. Gases from sample decomposition may cause staining, making it harder to observe the tube’s condition, but installing a devitrification prevention unit allows clearer monitoring by exposing only a replaceable protection plate to harmful gases.

Early identification of these visual cues helps operators act before structural damage occurs.

• Bulleted Summary:

Loss of clarity signals devitrification onset

Staining complicates optical checks

Prevention units improve observation accuracy

Using Operational Data to Predict Tube Replacement Timing

Operational data provides a reliable method for predicting when tube replacement is necessary.

Operators track hours of use, maximum operating temperature, and frequency of thermal cycling, comparing these records to manufacturer devitrification curves and ASTM standards. Data from TOQUARTZ shows that tubes with more than 80% of their rated service life or with wall thickness reduced by over 15% should be scheduled for replacement.

This approach ensures that tubes are replaced before reaching critical failure points.

Replacement Criteria | Guideline |

|---|---|

Service life >80% used | Plan replacement soon |

Wall thickness loss >15% | Replace immediately |

Opacity reduces transmission | Monitor for further degradation |

Quartz tube devitrification CVD furnaces reduce reliability and product quality by increasing brittleness and contamination risks. Operators and managers can prevent these issues by following essential steps:

Conduct regular maintenance and inspection.

Handle quartz tubes carefully to avoid thermal shock.

Operate within rated temperature limits.

Maintain a controlled environment.

Select tube furnaces that meet process requirements.

Use inert gas before introducing reactive gases.

Regular cleaning and monthly thorough cleaning prevent contamination and extend tube service life. Advanced manufacturing techniques improve reliability and ensure consistent product quality. By adopting these protocols, operators maintain optimal furnace performance and minimize devitrification risks.

Key Aspect | Impact on Service Life |

|---|---|

Regular Cleaning | Prevents contamination and degradation |

Proper Handling | Ensures longevity |

FAQ

Why does devitrification make quartz tubes more brittle?

Devitrification changes the quartz structure from glassy to crystalline. This transformation creates boundaries that weaken the material. As a result, the tube becomes more likely to crack during thermal cycling.

Why should operators avoid touching quartz tubes with bare hands?

Bare-hand contact leaves sodium on the tube surface. Even a single touch can deposit 2-8 ppm sodium, which lowers the devitrification onset temperature by up to 200°C. Gloves help prevent this contamination.

Why does high OH content accelerate devitrification?

High OH content increases molecular mobility in quartz. This allows cristobalite crystals to grow 30-45% faster, according to ASTM data. Electric fusion reduces OH levels and slows devitrification.

Why is regular visual inspection important for quartz tubes?

Visual inspection helps operators spot early signs of devitrification, such as cloudy patches or loss of transparency. Early detection allows timely maintenance, reducing the risk of tube failure.

Why do process gas impurities affect quartz tube lifespan?

Process gas impurities, like sodium, accumulate on hot tube surfaces. Over 500-1,000 hours, these contaminants speed up devitrification and reduce tube durability. High-purity gases extend tube service life.