Quartz tubes for tube furnaces have strict temperature limits that protect their lifespan and reliability.

Most high-purity quartz tubes can operate continuously between 1,000°C and 1,200°C.

Short-term exposure may reach up to 1,600°C for select grades.

If temperatures rise above these levels, tubes risk structural damage or rapid devitrification. Operators must monitor temperature closely because exceeding safe limits often leads to cracks, crystal growth, and early tube failure.

Key Takeaways

Quartz tubes should operate below 1100°C for long-term use to prevent devitrification and extend lifespan.

Regular cleaning of quartz tubes helps remove contaminants that can cause early failure and maintain clarity.

Controlling thermal ramp rates during heating and cooling reduces the risk of thermal shock and cracks in quartz tubes.

Choosing high-purity quartz with low metallic impurities enhances durability and resistance to devitrification.

Monitoring for signs of devitrification, such as cloudiness, can help operators take preventive measures before tube failure.

What Temperature Limits Define Safe Operating Ranges for Furnace Quartz Tubes?

Quartz tubes for tube furnaces must operate within specific temperature ranges to maintain their strength and reliability. Industry standards, such as ASTM and ISO, set clear guidelines for safe use. Understanding these limits helps operators prevent tube damage and extend service life.

How Viscosity Changes Above 1000°C Affect Structural Integrity

Viscosity plays a key role in the performance of quartz tubes for tube furnaces at high temperatures. When the temperature rises above 1000°C, the viscosity of quartz decreases, which allows the material to flow more easily and increases the risk of devitrification. Devitrification causes the silica in the tube to crystallize into cristobalite, making the tube appear cloudy and reducing its ability to withstand rapid temperature changes.

This process does not immediately weaken the tube, but over time, it lowers the tube’s resistance to thermal shock and can lead to cracks or failure. Operators should monitor for signs of devitrification, especially in applications that require optical clarity or frequent heating cycles. Maintaining temperatures below 1000°C for continuous use helps preserve the tube’s structural integrity.

Key Points:

Viscosity drops above 1000°C, increasing devitrification risk

Devitrification leads to cristobalite formation and reduced thermal shock resistance

Regular monitoring helps prevent long-term damage

Understanding the 1200°C Maximum Temperature Rating vs. Continuous-Use Limits

Manufacturers and standards organizations set different temperature limits for short-term and continuous use. The maximum temperature for quartz tubes in tube furnaces usually ranges from 1200°C to 1400°C, depending on the quality of the quartz and the furnace design. However, continuous operation at these high temperatures is not recommended because it can cause rapid degradation or warping of the tubes.

The table below summarizes the recommended temperature limits for different use cases:

Use Type | Maximum Temperature | Notes |

|---|---|---|

Continuous-use | 1100°C | Suitable for long-term exposure in stable high-temperature environments. |

Short-term use | 1200°C | Ideal for temporary spikes in temperature without prolonged exposure. |

Vacuum conditions | 1000°C | Maximum rating decreases under vacuum due to thermal stability issues. |

Alternative | Above 1200°C | Corundum tubes recommended for higher temperature applications. |

Operators should always check the manufacturer’s guidelines and avoid exceeding the continuous-use limit to prevent early tube failure. Short-term spikes up to 1200°C may be safe, but only if the exposure is brief and the tube is allowed to cool properly.

Why 1100°C Represents the Critical Threshold for Long-Term Operations

The 1100°C mark serves as a critical threshold for long-term use of quartz tubes for tube furnaces. At or below this temperature, the tubes can maintain their structural integrity and resist devitrification for thousands of hours. Exceeding this threshold, even by a small margin, can accelerate the breakdown of the quartz and shorten the tube’s lifespan.

Data from industry standards show that continuous operation above 1100°C leads to a significant increase in devitrification and a decrease in thermal shock resistance. Operators who need to run furnaces at higher temperatures should consider alternative materials or plan for more frequent tube replacement. Staying within the recommended limits ensures reliable performance and reduces maintenance costs.

Summary of Key Points:

1100°C is the safe limit for continuous operation

Higher temperatures increase devitrification and reduce tube life

Following guidelines extends service life and reliability

Why Do Tube Furnaces Experience Premature Quartz Tube Failure?

Premature failure of quartz tubes in tube furnaces often surprises operators. Many factors can shorten tube lifespan, including contamination, rapid temperature changes, and material composition. Understanding these causes helps users prevent costly downtime and maintain safe furnace operation.

How Alkali Metal Contamination Triggers Early Devitrification

Alkali metal contamination, such as sodium or potassium, can cause quartz tubes to fail much sooner than expected. These metals settle on the tube surface during heating cycles and act as seeds for devitrification, which is the process where glassy quartz turns into crystalline cristobalite. This transformation weakens the tube and makes it more likely to crack.

Studies show that even small amounts of alkali metals can lower the devitrification onset temperature by up to 200°C. When this happens, the tube loses its ability to handle thermal shock and becomes cloudy or brittle. Operators often see white, opaque patches on the tube as an early warning sign.

Key Points:

Alkali metals accelerate devitrification

Devitrification weakens the tube and reduces lifespan

Surface cleaning helps prevent contamination

Proper cleaning and handling can greatly reduce the risk of early devitrification in quartz tubes for tube furnaces.

Quantifying Thermal Shock Stress from Rapid Temperature Changes

Rapid temperature changes create thermal shock stress in quartz tubes. When the temperature inside the furnace changes faster than 1000°C per minute, the tube can crack because different parts expand or contract at different rates. This stress often exceeds the strength of the quartz, leading to sudden failure.

The table below summarizes the relationship between temperature change rate and tube failure risk:

Temperature Change Rate (°C/min) | Failure Risk | Reason |

|---|---|---|

<100 | Low | Quartz can adjust gradually |

100–1000 | Moderate | Some stress, possible microcracks |

>1000 | High | Rapid expansion, likely fracture |

Operators can prevent thermal shock by following controlled heating and cooling protocols. Monitoring ramp rates and using gradual temperature changes help maintain tube integrity.

The Role of OH Content in Accelerating Crystallization Rates

The amount of hydroxyl (OH) groups in quartz tubes affects how quickly they crystallize at high temperatures. Tubes with more than 30 ppm OH content show a 30–45% faster rate of cristobalite growth when heated above 1050°C. This rapid crystallization makes the tubes more fragile and shortens their usable life.

Lower OH content, especially below 20 ppm, helps quartz tubes resist devitrification during frequent heating cycles. Many manufacturers recommend using tubes with low OH content for applications that require high purity and long service life.

Summary:

High OH content increases crystallization speed

Low OH content extends tube lifespan

Choose low-OH tubes for demanding applications

Selecting the right material based on OH content can make a significant difference in the performance and durability of quartz tubes.

Which Purity Specifications Prevent Contamination-Induced Degradation?

Purity standards play a vital role in the performance and longevity of quartz tubes for tube furnaces. High-purity quartz resists contamination and devitrification, which helps maintain tube strength during repeated heating cycles. Operators must understand how purity, metallic impurities, and OH content affect tube lifespan to make informed choices for demanding applications.

How Metallic Impurities Below 20 ppm Affect Long-Term Stability

Metallic impurities can significantly impact the durability of quartz tubes. When impurity levels remain below 20 ppm, the risk of devitrification and early tube failure drops sharply. This threshold ensures that the quartz maintains its amorphous structure even after many heating cycles.

Studies show that aluminum, titanium, and iron above 5 ppm each can lower the crystallization onset temperature by 80–120°C. Lower impurity levels help quartz resist chemical attack and maintain clarity, which is essential for high-temperature furnace operations. Operators who select tubes with minimal metallic content see longer service life and fewer unexpected failures.

Key Points:

Impurities below 20 ppm reduce devitrification risk

Low metallic content preserves tube strength

Consistent purity extends operational lifespan

Comparing Type I vs. Type III Quartz Performance in High-Temperature Cycles

Type I and Type III quartz differ in their manufacturing process and impurity content. Type I quartz, produced by electrical fusion, contains lower OH and metallic impurities than Type III, which uses flame fusion. This difference leads to better performance in high-temperature cycles.

Field tests reveal that Type I quartz tubes last 2.5 times longer than Type III when operated at 1100°C. Type I tubes also show 35% less devitrification after 1,000 cycles compared to Type III. These results highlight the importance of choosing the right quartz type for demanding furnace applications.

Quartz Type | OH Content (ppm) | Metallic Impurities (ppm) | Relative Tube Life | Devitrification Rate |

|---|---|---|---|---|

Type I | 8–15 | <0.5 | 2.5x longer | 35% less |

Type III | 150–200 | 1–5 | Baseline | Baseline |

Selecting Type I quartz provides clear advantages for operators who need reliable, long-term performance.

Verification Testing Protocols for Purity Specification Compliance

Manufacturers use strict protocols to verify the purity of quartz tubes. Essential documentation, such as batch-specific purity certificates, confirms impurity levels and ensures traceability. Automated inspection systems detect defects early, which improves reliability and quality.

Quality assurance teams rely on automated inspection reports, statistical process control data, and hydrofluoric acid etching tests to maintain surface integrity. These protocols help operators trust that each tube meets the required standards for high-temperature use. Consistent verification supports safe and efficient furnace operation.

Summary of Verification Protocols:

Batch-specific purity certificates document impurity levels

Automated inspections catch defects early

Surface integrity tests ensure long-term reliability

What Manufacturing Quality Standards Ensure Consistent Tube Performance?

Manufacturing quality standards play a vital role in the reliability of quartz tubes for tube furnaces. These standards help ensure that every tube meets strict requirements for purity, strength, and consistency. Operators who understand these standards can make better choices and reduce the risk of unexpected tube failure.

Critical Inspection Points in Quality Assurance Protocols

Quality assurance teams inspect quartz tubes at several key points during production. They check for purity, wall thickness, bubble content, and surface roughness to ensure each tube meets industry standards. These inspections help catch defects early and prevent weak spots that could lead to failure.

Manufacturers use advanced tools like ICP-MS for elemental analysis and ultrasonic gauges for wall thickness. They also measure surface roughness and look for bubbles using optical inspection systems. These steps ensure that only tubes meeting strict criteria move forward to final testing.

Summary of Inspection Points:

Elemental analysis confirms purity

Ultrasonic gauges check wall thickness

Optical systems detect bubbles and surface flaws

Careful inspection at each stage helps maintain high product quality.

How Batch-to-Batch Consistency Impacts Furnace Process Reliability

Batch-to-batch consistency ensures that every tube performs the same way in the furnace. When manufacturers control production tightly, operators see fewer process interruptions and more predictable results. Consistent tubes reduce the risk of thermal stress and help maintain stable furnace conditions.

Data from over 25,000 production runs show that keeping dimensional tolerance within ±0.05 mm lowers thermal stress points by 90%. This level of control means that tubes fit perfectly and resist cracking during heating cycles. Operators can trust that each batch will deliver the same high performance.

Quality Factor | Impact on Reliability |

|---|---|

Dimensional tolerance | Reduces thermal stress |

Purity consistency | Prevents devitrification |

Surface uniformity | Lowers risk of fracture |

Reliable batch quality leads to fewer failures and smoother furnace operation.

Comparing Certification Requirements for High-Temperature Applications

Certification requirements set the standard for tubes used in high-temperature environments. Leading manufacturers follow ISO 12123, ASTM E438, and ISO 9001 to guarantee quality and traceability. These certifications show that tubes have passed strict tests for purity, strength, and resistance to thermal shock.

Operators should look for certificates that list ICP-MS analysis, dimensional inspection, and thermal cycle test results. These documents prove that the tubes meet the demands of high-temperature furnace work. Choosing certified tubes helps operators avoid costly downtime and ensures safe, reliable performance.

Key Certification Takeaways:

ISO and ASTM standards confirm quality

Certificates provide proof of compliance

Certified tubes support safe furnace operation

Certification gives operators confidence in their choice of quartz tubes for tube furnaces.

How Can Furnace Operators Maximize Quartz Tube Service Life?

Operators can extend the lifespan of quartz tubes for tube furnaces by following proven maintenance and operational strategies. Careful control of heating and cooling rates, along with regular cleaning, helps prevent common failure modes. Adopting best practices ensures reliable performance and reduces the risk of unexpected downtime.

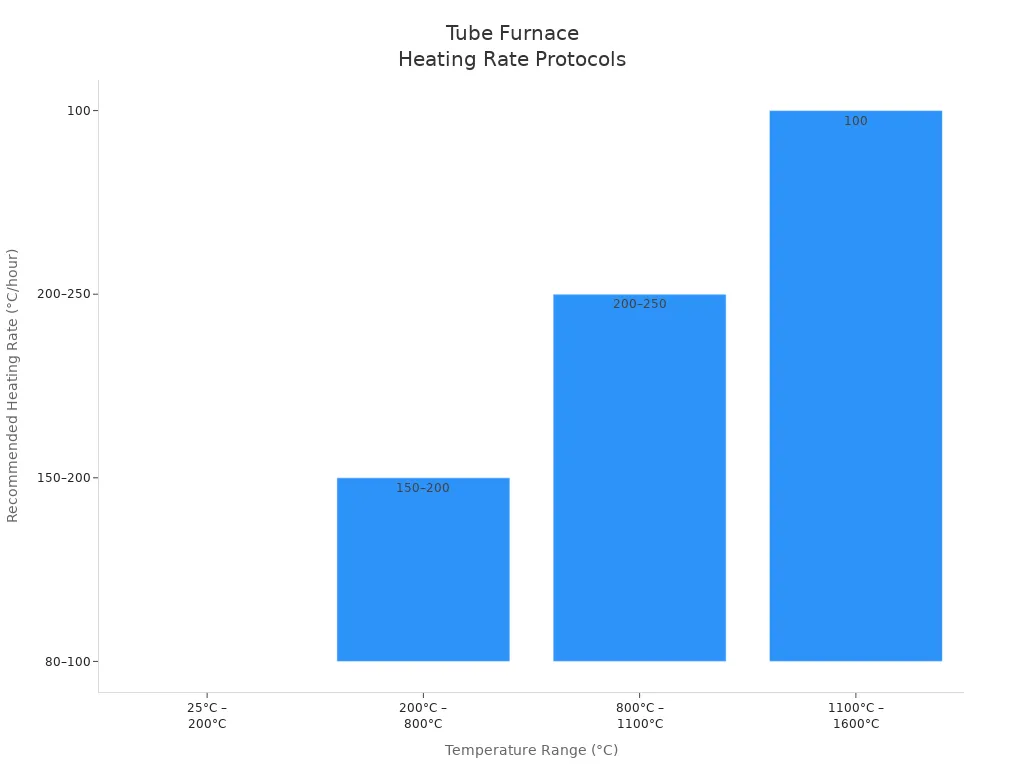

Establishing Thermal Ramp Rate Protocols for Different Temperature Ranges

Thermal ramp rate protocols play a crucial role in protecting quartz tubes from stress and damage. Operators who control the rate of temperature change reduce the risk of cracks and devitrification. Data shows that steady heating and cooling help maintain tube integrity over many cycles.

The recommended heating rates vary depending on the temperature range. The table below outlines the best practices for different operating conditions, showing how slower ramp rates at higher temperatures prevent thermal shock and extend tube life.

Temperature Range | Recommended Heating Rate |

|---|---|

25°C – 200°C | ≤ 80–100°C/hour |

200°C – 800°C | ≤ 150–200°C/hour |

800°C – 1100°C | ≤ 200–250°C/hour |

1100°C – 1600°C | ≤ 100°C/hour (with thermal buffer) |

Operators should monitor ramp rates closely and adjust protocols based on furnace requirements. Following these guidelines helps prevent premature tube failure and supports consistent high-temperature operations.

Surface Cleaning Techniques That Prevent Devitrification

Surface cleaning prevents devitrification and maintains the performance of quartz tubes. Operators use physical, chemical, and mechanical cleaning methods to remove contaminants that can trigger crystal growth. Regular cleaning keeps the tube surface clear and reduces the risk of brittleness.

A step-by-step cleaning process ensures thorough maintenance. Operators allow the tube to cool, remove debris, clean with mild acid or detergent, rinse well, and handle with gloves to avoid contamination. These actions protect the tube from alkali metals and other impurities that accelerate devitrification.

Key cleaning steps:

Allow tube to cool before cleaning

Remove debris with soft brush or vacuum

Clean exterior with mild acid, rinse thoroughly

Use mild detergent for interior, rinse until clean

Wear gloves during handling

Consistent cleaning routines help operators maintain tube clarity and strength. These techniques support longer service life and reliable furnace operation.

Quartz tubes for tube furnaces should not exceed 1,200°C for safe operation. The table below shows the temperature limits for common tube materials:

Tube Material | Maximum Temperature (°C) |

|---|---|

Quartz | 1,200 |

Alumina | 1,600 |

Graphite | >2,000 |

Maintaining purity, following quality standards, and using best practices such as balanced heating and ceramic plugs help extend tube lifespan. Operators should consider alumina tubes for applications above 1,200°C or when higher resistance is needed.

FAQ

What causes quartz tubes to fail early in tube furnaces?

Quartz tubes often fail early because of rapid temperature changes, contamination from alkali metals, or high levels of metallic impurities. These factors increase devitrification and reduce the tube’s ability to handle thermal stress.

What is the recommended maximum continuous-use temperature for quartz tubes?

Most manufacturers recommend a maximum continuous-use temperature of 1100°C for quartz tubes. Operating above this temperature increases the risk of devitrification and shortens the tube’s lifespan.

What cleaning method helps prevent devitrification in quartz tubes?

Operators should clean quartz tubes with a 7% ammonium bifluoride solution every 100 operating hours. This process removes alkali metal contamination and helps maintain the tube’s clarity and strength.

What purity level ensures long-term stability for quartz tubes?

A purity level of at least 99.98% SiO₂ with metallic impurities below 20 ppm ensures long-term stability. High purity reduces the risk of devitrification and supports reliable furnace operation.

What alternative materials can withstand higher temperatures than quartz tubes?

Alumina and graphite tubes withstand higher temperatures than quartz. Alumina handles up to 1600°C, while graphite can exceed 2000°C. Operators should choose these materials for applications above quartz’s safe limits.