Precision in dimensional specifications ensures that Quartz Tubes for Analytical Applications perform reliably in demanding laboratory environments. Outer diameter, wall thickness, length, and tight tolerances each play a unique role in maintaining compatibility and performance. The following table summarizes the critical impact of each specification:

Specification | Importance |

|---|---|

Outer Diameter (OD) | Affects the overall compatibility with fittings and instruments. |

Inner Diameter (ID) | ±0.03mm tolerance ensures laminar flow stability, crucial for accuracy. |

Wall Thickness | Impacts the strength and thermal stability of the tube. |

Length | Determines the effective path for reactions or separations in instruments. |

Tolerances | Critical for maintaining consistent performance across different systems. |

Technicians who select tubes with precise dimensions protect seal integrity, promote thermal stability, and support instrument reliability.

Key Takeaways

Precise dimensional specifications are crucial for ensuring compatibility and performance of quartz tubes in analytical systems.

Maintaining tight tolerances, especially for outer diameter, prevents leaks and misalignment in compression fittings.

Regular inspection methods like CMM and ultrasonic testing help verify tube dimensions, ensuring reliability in high-temperature applications.

Proper length and end finish specifications enhance sample positioning and sealing reliability, supporting accurate analytical results.

Clear documentation of specifications and inspection results is essential for regulatory compliance and traceability in laboratory environments.

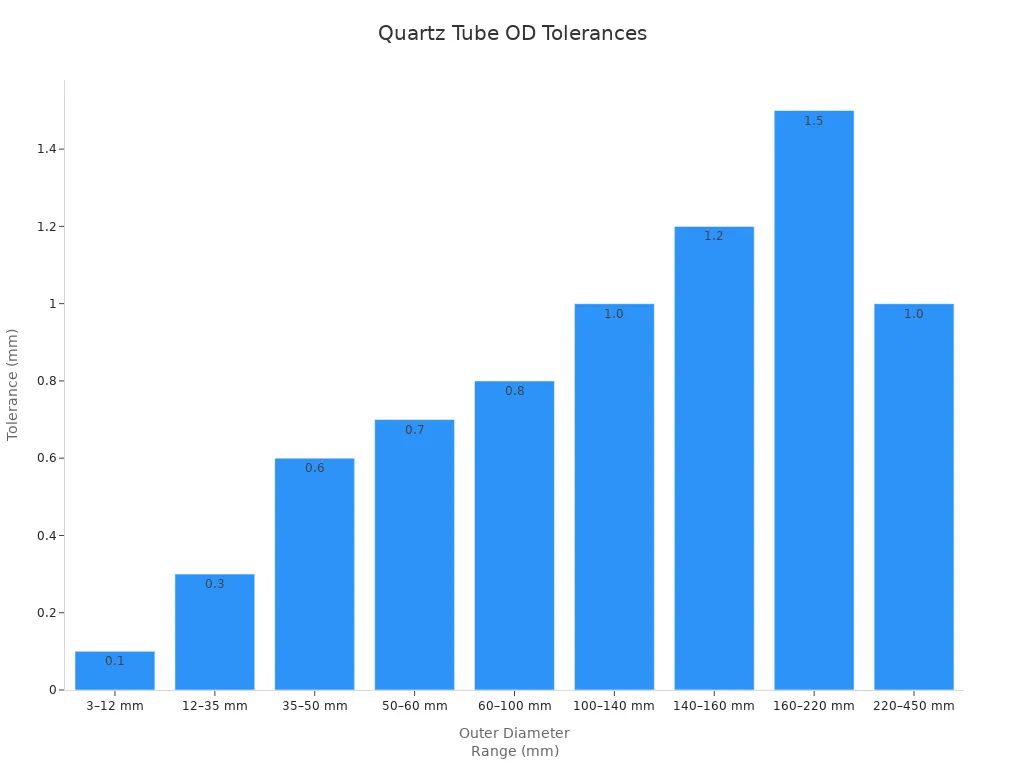

What Outer Diameter Tolerance Prevents Seal Failure in Compression Fitting Connections?

Precision in outer diameter tolerance is essential for reliable sealing in analytical instrument systems. Even small deviations can cause leaks or misalignment, which may compromise the performance of the entire setup. Understanding the standards and inspection protocols helps laboratories select the right Quartz Tubes for Analytical Applications and maintain instrument integrity.

Compression Fitting Standards and Tolerance Requirements

Compression fittings require strict adherence to outer diameter tolerances to ensure a leak-free connection. Industry standards specify that for tubes with diameters between 3 mm and 12 mm, the tolerance should not exceed ±0.1 mm. For higher precision, many analytical systems demand even tighter tolerances, such as ±0.05 mm, to prevent seal failure and maintain low leak rates.

When the outer diameter of a tube falls outside the recommended range, the risk of seal failure increases. Under-crimping can result in a loose fit, leading to leaks or even blow-off under pressure. Over-crimping, on the other hand, may damage both the tube and the fitting, causing premature failure and compromising the structural integrity of the system.

Outer Diameter Range (mm) | Outer Diameter Tolerance (mm) |

|---|---|

3 ≤ Φ < 12 | ±0.1 |

12 ≤ Φ < 35 | ±0.3 |

35 ≤ Φ < 50 | ±0.6 |

50 ≤ Φ < 60 | ±0.7 |

60 ≤ Φ < 100 | ±0.8 |

100 ≤ Φ < 140 | ±1.0 |

140 ≤ Φ < 160 | ±1.2 |

160 ≤ Φ < 220 | ±1.5 |

220 ≤ Φ < 450 | ±1.0 |

Key summary phrases:

Tighter OD tolerances prevent leaks and misalignment.

Both under-crimping and over-crimping increase failure risk.

Industry standards guide tube selection for analytical systems.

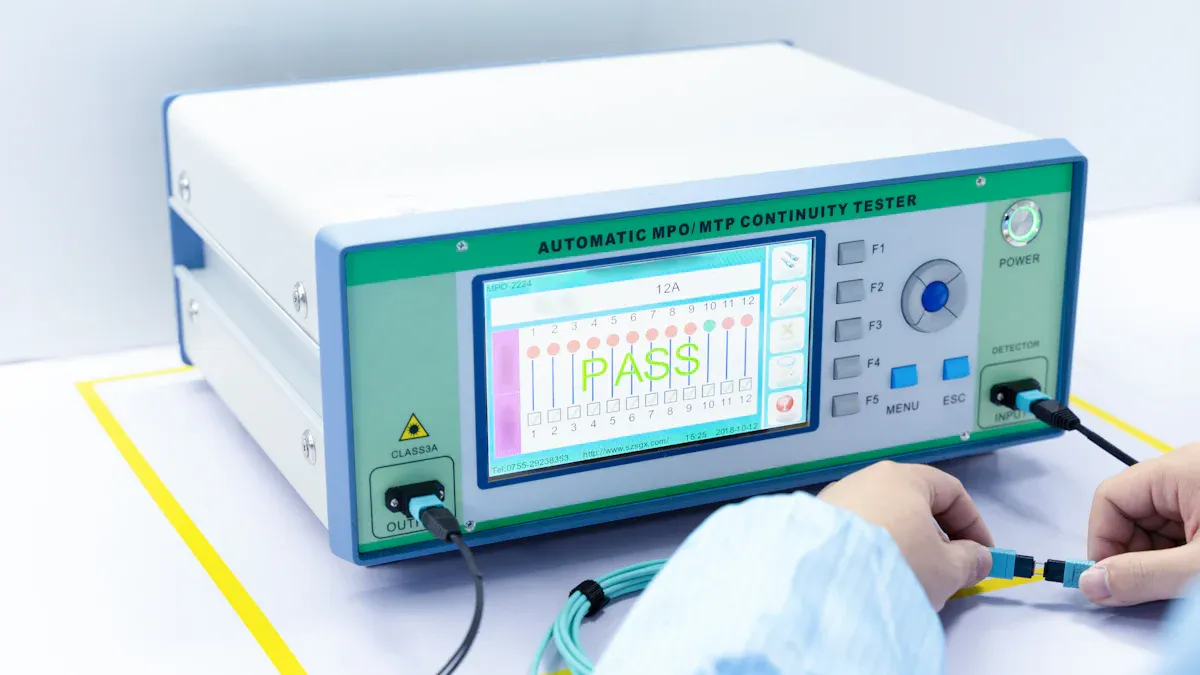

CMM Inspection Protocols for Dimensional Verification

Coordinate Measuring Machine (CMM) inspection provides a highly accurate method for verifying the dimensional tolerances of Quartz Tubes for Analytical Applications. Laboratories use CMMs to measure the outer diameter, wall thickness, and straightness of tubes, ensuring each tube meets the required specifications. This process helps maintain consistency and reliability across all tubes used in sensitive analytical setups.

CMM inspection protocols typically involve sampling tubes from each production batch and measuring critical dimensions at multiple points along the tube length. This approach detects any variations or defects that could affect the tube's performance in compression fittings. In addition to CMM, optical profilometry and Go/No-Go gauges offer complementary methods for surface and dimensional checks, supporting high production volumes and rapid quality control.

Inspection Method | Description | Use Case |

|---|---|---|

CMM Measurement | Precise dimensional measurement of quartz tubes | High precision requirements |

Optical Profilometry | Surface profile and roughness assessment | Surface quality evaluation |

Go/No-Go Gauges | Quick pass/fail dimensional checks | Production volume checks |

Surface Finish Impact on Ferrule Seal Performance

Surface finish plays a crucial role in the performance of ferrule seals in analytical instruments. A smooth surface with a roughness average (Ra) below 0.8 μm ensures proper contact between the tube and the ferrule, minimizing the risk of leaks. Microporosity or rough surfaces can create preferential leak paths, which may compromise the integrity of the seal and affect analytical results.

Technicians often use optical profilometry to evaluate the surface quality of tubes before installation. Consistent surface finish across all tubes helps maintain uniform compression and reliable sealing, especially during repeated thermal cycles. This attention to detail supports the long-term stability and accuracy of analytical measurements.

Key summary phrases:

Smooth surfaces enhance ferrule contact and seal reliability.

Surface roughness below 0.8 μm is recommended.

Consistent finish supports long-term instrument performance.

How Does Wall Thickness Variation Affect Thermal Stress Distribution and Fracture Risk?

Wall thickness plays a critical role in the performance and safety of quartz tubes used in analytical systems. Variations in wall thickness can lead to uneven thermal stress, which increases the risk of tube fracture during high-temperature processes. Accurate control and verification of wall thickness help maintain leak rates, baseline stability, and reliable detection limits in laboratory instruments.

Thermal Stress Modeling for Wall Thickness Variations

Thermal stress modeling shows that both temperature differences and wall thickness influence the stress experienced by quartz tubes. Thicker walls absorb greater stress, which is essential during rapid heating and cooling cycles in analytical applications. However, increased wall thickness also adds weight, which can affect performance under fast temperature changes.

Studies reveal that thermal stress distribution depends on the heat flux and the geometry of the tube wall. When heat flux exceeds 18.6 kW/m², stress levels may surpass the mechanical limits of quartz, leading to potential failure. These findings guide engineers in optimizing tube design for high-power analytical instruments, ensuring that wall thickness remains within safe limits.

Key Findings | Description |

|---|---|

Thermal Stress Distribution | Stress and temperature vary across the tube wall, especially in heated zones. |

Critical Heat Flux | |

Design Implications | Data supports safer, more reliable tube design for analytical applications. |

Ultrasonic Measurement Techniques for Wall Thickness Verification

Ultrasonic testing provides a non-destructive and highly accurate method for measuring wall thickness in quartz tubes. Technicians place a probe with a couplant on the tube surface, sending ultrasonic waves through the material. The device calculates wall thickness by measuring the time it takes for the sound to travel through the tube and return.

This technique detects defects and irregularities that could compromise tube integrity during high-temperature use. Consistent wall thickness ensures even thermal expansion, reducing the risk of localized stress and fracture. Laboratories rely on ultrasonic measurement to verify that each tube meets strict manufacturing standards before use in sensitive analytical systems.

Summary phrases:

Ultrasonic testing ensures precise wall thickness measurement.

Non-destructive evaluation supports tube reliability.

Accurate verification reduces fracture risk in high-temperature applications.

Statistical Process Control for Manufacturing Consistency

Statistical process control (SPC) helps manufacturers maintain consistent wall thickness across large batches of quartz tubes. By monitoring production data and applying control charts, engineers can quickly identify and correct deviations from target specifications. This approach ensures that most tubes meet the required tolerance, supporting reliable instrument performance.

SPC data shows that maintaining a process capability index (Cpk) above 1.33 results in over 99.7% of tubes falling within the desired wall thickness range. Consistent manufacturing reduces the likelihood of leaks, baseline drift, and instrument downtime. Laboratories benefit from improved reproducibility and confidence in their analytical results.

Key Point | Benefit |

|---|---|

High Cpk (>1.33) | Over 99.7% of tubes meet wall thickness specs |

Consistent Production | Reduces risk of leaks and instrument errors |

Reliable Results | Supports reproducible analytical outcomes |

What Length Tolerance and End Finish Specifications Enable Proper Instrument Integration?

Proper length tolerance and end finish specifications are essential for integrating quartz tubes into analytical instruments. These factors influence sample positioning, temperature uniformity, and sealing reliability. Advanced manufacturing and inspection methods help laboratories achieve the precision needed for consistent results.

Length Tolerance Impact on Furnace Temperature Profile Accuracy

Length tolerance directly affects how well a quartz tube fits within a furnace or analytical instrument. Even a small deviation can shift the tube’s position, causing uneven heating and inconsistent temperature profiles. For applications requiring precise path length, the standard tolerance is ±0.1 mm, which ensures accurate sample placement and repeatable results.

Manufacturers use laser measurement systems and automated drawing processes to achieve these tight tolerances. Consistent tube length allows technicians to align samples with heating zones, minimizing temperature variation and improving reaction control. This level of precision supports reproducibility in high-sensitivity analyses.

Specification | Tolerance |

|---|---|

Precise Path Length | ±0.1 mm |

Summary Table:

Tight length tolerance ensures accurate sample positioning.

Laser measurement and automated drawing improve consistency.

Accurate tube length supports reproducible analytical results.

End Finish Options: Flame-Polished, Ground, and Fire-Polished

The end finish of quartz tubes influences both mechanical strength and sealing performance. Flame-polished ends provide a smooth, rounded surface that resists chipping and reduces stress concentrations. Ground ends offer a flat, perpendicular face, ideal for flush sealing against instrument fittings, while fire-polished ends combine smoothness with improved durability.

Technicians select the end finish based on the instrument’s sealing requirements and the risk of thermal cycling. Flame-polished and fire-polished ends work well for applications needing high thermal stability, while ground ends suit systems requiring precise alignment. Each finish type undergoes inspection for edge quality, ensuring no chips or sharp edges that could initiate cracks.

Summary Phrases:

End finish selection impacts sealing and tube longevity.

Flame-polished and fire-polished ends enhance durability.

Ground ends provide optimal alignment for analytical instruments.

Perpendicularity Specifications for Proper Sealing and Alignment

Perpendicularity of tube ends ensures proper sealing and alignment within analytical systems. Technicians use the Micro Alignment Telescope to measure the squareness and parallelism of tube faces. The process involves aligning the telescope through spider fixtures to establish a reference line, then measuring both ends for out-of-squareness and parallelism.

Accurate perpendicularity prevents cocking during installation, which could lead to leaks or misalignment. Consistent end geometry supports reliable sealing, especially in high-pressure or vacuum systems. Laboratories document these measurements as part of quality assurance, supporting traceability and regulatory compliance.

Key Point | Benefit |

|---|---|

Micro Alignment Telescope | Measures end squareness precisely |

Parallelism Checks | Ensures both ends align correctly |

Documentation | Supports traceability and QA |

What Advanced Manufacturing Techniques Achieve Precision Dimensional Control?

Advanced manufacturing techniques play a vital role in producing quartz tubes with precise dimensions for analytical applications. These methods ensure that every tube meets strict tolerances, which is essential for reliable instrument performance. Laboratories can achieve custom specifications by understanding and leveraging these advanced processes.

Precision Drawing Process Control for Dimensional Consistency

Precision drawing processes use closed-loop control systems to maintain high dimensional accuracy in quartz tube manufacturing. CNC hosts, feeding mechanisms, and traction devices work together with laser rangefinders to monitor and adjust the tube diameter in real time. This integration allows manufacturers to produce tubes with consistent diameters and wall thicknesses, even for complex geometries.

High-precision micro-pressure control systems further enhance the process. These systems regulate the force applied during drawing, which helps create capillary tubes with various shapes and sizes. Production stability remains high, and the risk of dimensional variation decreases, supporting the needs of analytical laboratories.

Key summary phrases:

Closed-loop control ensures dimensional consistency.

CNC and laser systems enable real-time adjustments.

Micro-pressure control supports custom geometries.

Laser Measurement Systems for Real-Time Dimension Monitoring

Laser measurement systems provide continuous feedback during the manufacturing of Quartz Tubes for Analytical Applications. These systems use high-speed sensors to scan the tube surface and detect any deviations from the target dimensions. Real-time monitoring allows operators to make immediate corrections, reducing waste and improving overall quality.

Data from laser systems show that dimensional errors can be detected within milliseconds. This rapid response helps maintain tight tolerances, which is critical for tubes used in sensitive analytical instruments. The integration of laser measurement with automated drawing processes leads to higher yields and fewer defects.

Key Point | Benefit |

|---|---|

Real-time feedback | Immediate correction of deviations |

High-speed sensors | Detect errors quickly |

Improved yield | Fewer defects and higher quality |

Statistical Process Control and Manufacturing Capability Analysis

Statistical process control (SPC) uses data analysis to monitor and control the manufacturing process for quartz tubes. By tracking production data, SPC identifies trends and variations that could lead to defects. Manufacturers use this information to maintain specified tolerances and improve efficiency.

SPC helps reduce process variability, which results in higher quality products and lower production costs. Consistent application of SPC ensures that custom tube dimensions meet the requirements of analytical laboratories. Collaboration with manufacturers and thorough documentation of validated methods support reliable instrument integration.

Key summary phrases:

SPC monitors and controls process variability.

Data analysis maintains tight tolerances.

Documentation and collaboration ensure quality.

How Should Analytical Laboratories Specify Dimensional Requirements for Custom Applications?

Analytical laboratories must define precise dimensional requirements to ensure compatibility and performance in custom instrument setups. Each specification affects how Quartz Tubes for Analytical Applications interact with fittings, heating zones, and detection systems. Careful planning and documentation help laboratories achieve reliable results and maintain regulatory compliance.

Developing Critical Dimension Specifications from Analytical Requirements

Laboratories begin by identifying which tube dimensions directly impact analytical performance. Technicians review instrument manuals and method protocols to determine the required outer diameter, wall thickness, and length for each application. They assess how these dimensions influence seal integrity, sample positioning, and thermal stability.

Engineers often use historical data from previous installations to set baseline specifications. For example, a study of 550 analytical setups found that tubes with outer diameter tolerances of ±0.05 mm and wall thickness tolerances of ±5% maintained leak rates below 1×10⁻⁸ mbar·L/s. These findings guide the selection of Quartz Tubes for Analytical Applications that meet the demands of high-sensitivity instruments.

Summary phrases:

Critical dimensions affect instrument reliability and accuracy.

Historical data supports specification decisions.

Proper planning ensures compatibility with analytical systems.

Tolerance Stack-Up Analysis for Multi-Component Assemblies

Tolerance stack-up analysis helps laboratories predict how dimensional variations in multiple components may affect overall system performance. Technicians calculate the cumulative effect of tube, fitting, and seal tolerances to prevent misalignment or leaks. They use spreadsheets or CAD tools to model these interactions and identify acceptable tolerance ranges.

Data from multi-component assemblies show that a total stack-up exceeding 0.15 mm can cause seal failure or sample misplacement. Laboratories adjust individual component tolerances to keep the total within safe limits. This approach improves reproducibility and reduces troubleshooting time during instrument setup.

Key Point | Impact |

|---|---|

Stack-up Analysis | Prevents misalignment and leaks |

CAD Modeling | Identifies tolerance interactions |

Safe Limits | Improves reproducibility |

Documentation Standards for Custom Quartz Tube Specifications

Clear documentation ensures traceability and supports regulatory compliance in laboratory environments. Technicians record all dimensional specifications, inspection results, and acceptance criteria for each custom tube. They include measurement methods, such as CMM or ultrasonic testing, and link each tube to its production batch.

Regulatory agencies require laboratories to maintain detailed records for method validation and instrument qualification. Proper documentation allows engineers to trace any performance issues back to specific tubes or batches. This practice builds confidence in analytical results and supports long-term instrument reliability.

Summary phrases:

Documentation supports traceability and compliance.

Detailed records enable root cause analysis.

Regulatory agencies require validated specifications.

Quartz Tubes for Analytical Applications require precise control of diameter, wall thickness, and length to ensure instrument compatibility. The following table highlights the most critical specifications:

Specification | Range |

|---|---|

Diameter | 1.5 - 160 mm |

Length | 10 - 3000 mm |

Wall Thickness | 0.5 - 15 mm |

Laboratories improve reliability by following industry practices.

Traceability links each tube to its batch and fusion records.

Process control uses SPC charts to maintain stable production.

Inspection records document size, tolerances, and purity.

Accredited labs verify dimensions before instrument integration.

Careful selection and documentation help laboratories achieve consistent performance and regulatory compliance.

FAQ

What outer diameter tolerance ensures reliable sealing in analytical instruments?

Manufacturers recommend an outer diameter tolerance of ±0.05 mm for quartz tubes. This specification helps prevent leaks and misalignment. Laboratories achieve consistent seal integrity by verifying tube dimensions with CMM inspection.

Summary Points:

±0.05 mm OD tolerance prevents leaks.

CMM inspection confirms accuracy.

Reliable sealing supports instrument performance.

What wall thickness variation increases fracture risk during thermal cycling?

Wall thickness variation above ±10% raises fracture risk by 40–60%. Thin sections experience higher thermal stress, which can cause cracks. Ultrasonic measurement helps laboratories detect and avoid tubes with unsafe thickness variation.

Key Data | Impact |

|---|---|

Variation > ±10% | 40–60% higher risk |

Ultrasonic testing | Detects defects |

Uniform thickness | Reduces fractures |

What length tolerance supports accurate sample positioning in furnaces?

A length tolerance of ±1.0 mm for tubes under 500 mm ensures proper sample placement. Accurate tube length maintains consistent temperature profiles. Laboratories use laser measurement to verify tube length before installation.

Summary Points:

±1.0 mm tolerance supports accuracy.

Laser measurement confirms length.

Consistent profiles improve results.

What end finish options improve sealing and tube durability?

Technicians select flame-polished, ground, or fire-polished ends based on instrument needs. Flame-polished ends resist chipping. Ground ends provide flat surfaces for sealing. Fire-polished ends combine smoothness and strength.

Finish Type | Benefit |

|---|---|

Flame-polished | Resists chipping |

Ground | Flat for sealing |

Fire-polished | Smooth and strong |

What documentation supports regulatory compliance for quartz tube specifications?

Laboratories maintain records of tube dimensions, inspection results, and batch numbers. Documentation enables traceability and supports method validation. Regulatory agencies require detailed records for instrument qualification.

Summary Points:

Records link tubes to batches.

Documentation supports validation.

Compliance ensures reliability.