Comparing Quartz and Borosilicate Glass

Explore the differences between quartz tubes and borosilicate glass.

Features | Quartz Tubes | Borosilicate Glass Tubes |

|---|---|---|

Thermal Resistance | Up to 1100°C | Up to 500°C |

Chemical Purity | Over 99% pure silica | About 80% silica |

Optical Clarity | Excellent UV transmission | Limited UV transmission |

Softening Point | 1660°C | 820°C |

Dimensional Stability | High stability under heat | Moderate stability |

Thermal Expansion | Very low expansion | Low expansion |

Cost | Higher initial cost | Lower initial cost |

Applications | High-temperature and optical uses | Routine laboratory tasks |

Quartz tubes deliver superior performance in high-temperature analytical environments. Researchers often select Quartz Tubes for Analytical Applications because they offer:

Exceptional thermal stability, which supports reliable results at elevated temperatures.

Minimal catalytic effects, ensuring inert behavior in hydrothermal reactions.

Strong material properties that withstand demanding laboratory conditions.

Choosing the right material improves safety, accuracy, and reliability in sensitive analytical work.

Key Takeaways

Quartz tubes excel in high-temperature environments, withstanding temperatures above 1,000°C without deforming.

Borosilicate glass is more affordable but may not provide the same durability and purity as quartz, leading to potential contamination.

Quartz glass offers superior chemical purity, making it ideal for sensitive analytical applications where contamination must be minimized.

High UV transmission in quartz glass enhances the accuracy of optical analytical techniques, while borosilicate glass limits sensitivity in UV-based methods.

Choosing the right material based on temperature, purity, and cost can significantly impact the reliability of analytical results.

What Temperature Threshold Determines Material Selection Between Quartz and Borosilicate?

Selecting the right material for high-temperature analytical work depends on understanding the temperature limits of each option. Quartz Tubes for Analytical Applications offer distinct advantages when exposed to extreme heat. Comparing quartz and borosilicate glass helps researchers choose the safest and most reliable solution for their experiments.

Softening Point and Deformation Temperature Specifications (ASTM C598)

The softening point marks the temperature at which a material begins to lose its shape. Quartz tubes have a much higher softening point than borosilicate glass, making them suitable for more demanding environments. ASTM C598 provides standardized values that help laboratories determine which material will maintain integrity under heat.

Quartz Tubes for Analytical Applications can withstand temperatures above 1,000°C, while borosilicate glass softens at much lower temperatures. This difference means quartz tubes remain stable during high-temperature reactions, reducing the risk of deformation. Laboratories often rely on these specifications to ensure consistent results.

Material | Softening Point | Maximum Temperature |

|---|---|---|

Quartz Tubes | 1,660°C | > 1,000°C |

Borosilicate Glass | 820°C | < 820°C |

Long-Term Dimensional Stability at Elevated Temperatures

Dimensional stability ensures that tubes retain their shape and size during prolonged heating. Quartz tubes maintain their structure even after repeated exposure to high temperatures. This property is essential for analytical applications that require precise measurements and consistent sample containment.

Borosilicate glass performs well in moderate heat but may deform over time when exposed to temperatures near its softening point. Quartz Tubes for Analytical Applications provide reliable performance in environments where long-term stability is critical. Researchers benefit from reduced risk of contamination and measurement errors.

Key Points:

Quartz tubes resist deformation at high temperatures.

Borosilicate glass may lose shape with prolonged heating.

Dimensional stability supports accurate analytical results.

Thermal Expansion Coefficient Impact on Thermal Cycling Performance

The thermal expansion coefficient measures how much a material expands when heated. Fused quartz glass has a very low coefficient, which means it expands less than borosilicate glass. This property allows quartz tubes to handle rapid temperature changes without cracking or breaking.

Borosilicate glass offers good resistance to thermal shock but cannot match the performance of quartz in extreme conditions. Quartz Tubes for Analytical Applications excel in processes that involve frequent heating and cooling cycles. Laboratories choose quartz tubes to minimize the risk of failure during thermal cycling.

Property | Fused Quartz Value |

|---|---|

Thermal Expansion Coefficient |

Why Does Chemical Purity Differ Significantly Between Quartz and Borosilicate Materials?

Material purity plays a crucial role in analytical applications, especially when trace analysis demands minimal contamination. Quartz and borosilicate glass differ in their chemical composition, which affects their suitability for high-precision work. Understanding these differences helps researchers select the best option for their experiments.

Compositional Differences and Impurity Profiles

Quartz glass contains over 99% pure silica, while borosilicate glass typically has about 80% silica mixed with other oxides. This difference in composition leads to distinct impurity profiles, with quartz offering higher chemical purity. Laboratories often choose Quartz Tubes for Analytical Applications to minimize contamination and achieve reliable results.

Material | Silica Content | Chemical Purity | Thermal Resistance | Suitability for Trace Analysis |

|---|---|---|---|---|

Quartz Glass | >99% | High | Up to 1,100°C | Ideal for high-precision applications |

Borosilicate Glass | ~80% | Lower | Up to 450°C | Can contribute contaminants, less suitable for trace analysis |

Tip: Segregate labware for specific metals to avoid memory effects. Borosilicate glass can absorb metals like lead and chromium, which may interfere with sensitive measurements.

Hydrolytic Resistance Testing per ISO 720 Standards

Hydrolytic resistance measures how well a material resists leaching when exposed to water at elevated temperatures. ISO 720:2020 classifies glass based on the amount of acid needed to titrate alkali extracted from the glass at 121°C. Borosilicate glass ranks among the more resistant types, making it suitable for many laboratory uses.

Quartz glass, however, demonstrates even greater resistance due to its high purity and lack of alkali metals. This property ensures minimal leaching, which is essential for trace analysis and high-purity chemical processing. Researchers rely on these standards to select materials that maintain sample integrity.

Key Points:

Quartz glass offers superior hydrolytic resistance.

Borosilicate glass performs well but may release more alkali.

ISO 720 testing guides material selection for analytical work.

Leaching Kinetics in Different Chemical Environments

Leaching kinetics describe how quickly materials release impurities when exposed to acids, bases, or other chemicals. Quartz glass resists strong acids, including hydrofluoric acid, and maintains high chemical purity in harsh environments. Borosilicate glass resists many acids but should not be used with hydrofluoric acid or boiling phosphoric acid.

Property | Quartz Glass | Borosilicate Glass |

|---|---|---|

Chemical Purity | High chemical purity and resistance | Good resistance to a wide range of chemicals |

Resistance to Acids | Can handle strong acids like hydrofluoric acid | Resistant to strong class B acids |

Application | Ideal for high-purity chemical processing and semiconductor manufacturing | Suitable for laboratory glassware and various reactive substances |

Note: Borosilicate glass may contribute contaminants during high-temperature or aggressive chemical reactions, which can affect trace analysis results.

How Does UV Transmission Performance Affect Optical Analytical Techniques?

Optical analytical techniques rely on materials that transmit ultraviolet (UV) light efficiently. The choice between quartz and borosilicate glass affects the accuracy and sensitivity of measurements. Researchers must understand how each material performs across the UV spectrum to select the best option for their experiments.

UV Transmission Spectra Comparison (200-400 nm Range)

Quartz glass transmits UV light with high efficiency, especially in the critical 200-400 nm range. Borosilicate glass allows some UV light to pass through but blocks most deep-UV wavelengths. This difference impacts the sensitivity of analytical instruments that depend on UV detection.

Material | |

|---|---|

Quartz | up to 90% across most of the UV spectrum, including UV-C |

Borosilicate Glass | largest window among glass types, but lower than quartz |

Quartz glass maintains strong transmission at 254 nm, 300 nm, and 365 nm, while borosilicate glass drops sharply below 300 nm. Instruments using quartz tubes detect lower concentrations of analytes due to higher UV throughput.

Key Points:

Quartz glass transmits deep-UV light efficiently.

Borosilicate glass blocks most UV-C wavelengths.

High UV transmission improves analytical sensitivity.

OH Content Impact on Optical Transmission per ISO 9050

Hydroxyl (OH⁻) content in quartz glass affects its optical transmission and durability. Low OH⁻ levels, below 50 ppm, prevent devitrification and cracking during repeated heating cycles. This stability ensures that quartz tubes maintain high UV transmission over time.

Hydroxyl concentration below 50 ppm minimizes devitrification and cracking under prolonged heat cycles, ensuring predictable lifespan and lower maintenance frequency.

Uniform OH⁻ gradients, achieved through controlled atmosphere annealing, stabilize internal stress and prevent localized phase transitions. This process allows the crucible to sustain 25% longer service life before visual hazing occurs.

Samples with OH⁻ below 50 ppm show zero structural cracks after 50 cycles at 1450 °C.

Quartz Tubes for Analytical Applications deliver consistent optical performance because of their controlled OH⁻ content. Laboratories benefit from reduced maintenance and reliable results in high-temperature UV analysis.

Summary:

Low OH⁻ content preserves UV transmission and tube integrity.

ISO 9050 standards guide material selection for optical reliability.

Stable quartz tubes reduce downtime and replacement costs.

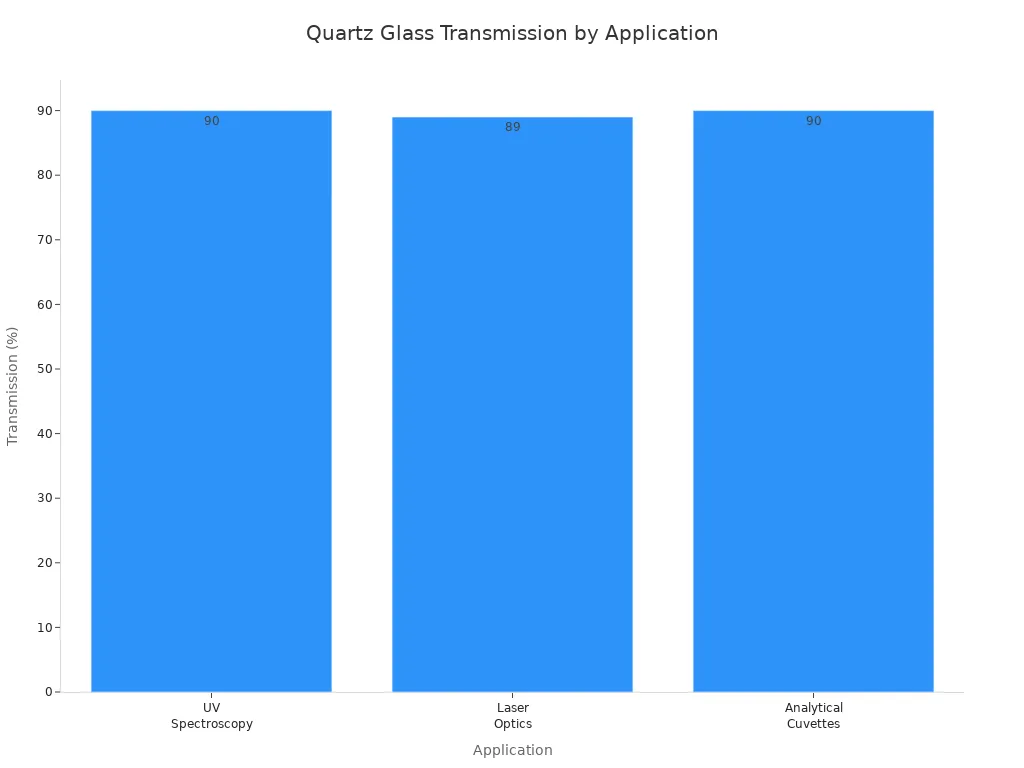

Applications Requiring Deep-UV Transparency

Many analytical techniques require materials that transmit deep-UV light. Quartz glass supports applications such as UV spectroscopy, laser optics, and analytical cuvettes. Borosilicate glass cannot match quartz in these scenarios due to its limited deep-UV transmission.

Application | Wavelength Range (nm) | Quartz Glass Transmission (%) | Key Benefits |

|---|---|---|---|

UV Spectroscopy | 200-400 | >90 | Deep UV analysis |

Laser Optics | 250-2,500 | 85-93 | Low absorption, high power |

Analytical Cuvettes | 200-800 | >90 | Precise photometric readings |

Quartz glass enables accurate measurements in fields that demand deep-UV transparency. Researchers select quartz for its superior transmission and reliability in advanced optical applications.

Bulleted Summary:

Quartz glass supports deep-UV analytical techniques.

Borosilicate glass limits sensitivity in UV-based methods.

High transmission ensures precise and reproducible results.

What Manufacturing Capabilities Distinguish High-Volume Quartz Producers from Specialty Fabricators?

Selecting the right quartz tube supplier depends on more than just material properties. Manufacturing capabilities, quality documentation, and technical support all play a role in ensuring reliable performance for analytical applications. Understanding these differences helps laboratories and engineers make informed decisions for their projects.

Production Volume and Process Control Capabilities

High-volume quartz manufacturers focus on large-scale production and strict process control. These companies use advanced quality assurance protocols to maintain consistency across thousands of tubes. Specialty fabricators, on the other hand, excel at producing custom solutions with specific engineering support.

High-volume producers often supply process tubes for semiconductor furnace systems, where purity and dimensional integrity are critical. They implement statistical process control to monitor every stage of production, reducing variability and ensuring each batch meets strict standards. Specialty fabricators provide tailored solutions for unique research needs, offering flexibility in dimensions and design.

Manufacturer Type | Production Volume | Process Control Capabilities |

|---|---|---|

High-Volume Manufacturers | Large-scale production | Stringent quality assurance protocols |

Specialty Fabricators | Customized solutions | Specific engineering support with tailored solutions |

Key Points:

High-volume producers deliver consistent quality at scale.

Specialty fabricators offer flexibility for custom projects.

Process control ensures reliability in demanding applications.

Quality Documentation Standards for Analytical-Grade Quartz

Quality documentation sets analytical-grade quartz apart from standard glassware. Leading manufacturers provide detailed records, including material certification, dimensional verification, and surface inspection reports. These documents help laboratories verify that each tube meets strict analytical requirements.

Bulleted Summary:

Material certification and dimensional reports ensure traceability.

Automated inspection reduces human error.

ASTM testing confirms analytical-grade quality.

Technical Support and Custom Fabrication Services Comparison

Technical support and custom fabrication services distinguish top suppliers in the quartz industry. High-volume manufacturers often provide standardized products with fast delivery and robust documentation. Specialty fabricators, however, offer direct engineering support and can create unique designs for specialized research.

Custom fabrication allows researchers to specify dimensions, tolerances, and surface finishes. This flexibility supports advanced applications, such as photochemistry or microfluidics, where standard tubes may not suffice. Direct access to technical experts helps resolve challenges quickly and ensures the final product meets project requirements.

Key Points:

Custom fabrication enables unique solutions for complex needs.

Engineering support improves project outcomes.

Fast delivery and documentation benefit high-volume users.

When Does Borosilicate Glass Provide Adequate Performance at Lower Cost?

Borosilicate glass tubes offer a practical solution for many analytical applications where extreme temperature or ultra-high purity is not required. Researchers often select borosilicate glass for its affordability and ease of fabrication. Understanding the cost-benefit trade-offs helps laboratories make informed decisions based on their specific needs.

Cost-Benefit Analysis Framework for Material Selection

Laboratories often compare quartz and borosilicate glass tubes using a cost-benefit analysis. Borosilicate glass tubes present a lower upfront cost, making them attractive for routine tasks and large-scale experiments. However, researchers must consider durability, contamination risk, and long-term cost impact when choosing materials.

The following table summarizes key factors in material selection:

Material | Upfront Cost | Durability | Contamination Risk | Long-term Cost Impact |

|---|---|---|---|---|

Quartz | Higher | High | Low | Reduced |

Borosilicate Glass | Lower | Moderate | Higher | Increased |

Borosilicate glass tubes suit applications with moderate temperature requirements and limited exposure to aggressive chemicals.

Key Points:

Borosilicate glass offers lower initial costs.

Long-term expenses may rise due to durability and contamination risks.

Performance Trade-offs in Different Analytical Applications

Borosilicate glass provides good machinability and moderate thermal expansion, which benefits many laboratory setups. Researchers use borosilicate glass in applications where temperature resistance up to 500°C and limited UV transmission are acceptable. The material’s lower cost supports high-volume use, but it introduces trade-offs in purity and optical performance.

The table below highlights major differences:

Feature | Borosilicate Glass | Quartz Glass |

|---|---|---|

Thermal expansion | Low | Extremely low |

Temperature resistance | Up to 500°C | Up to 1,200°C+ |

Cost | Lower | Higher |

UV/IR transmission | Limited | Excellent |

Purity | High | Ultra-high |

Machinability | Good | Challenging |

Borosilicate glass tubes may face challenges in high-pressure or trace metal analysis.

The brittleness of borosilicate glass complicates high-pressure applications.

Glass can adsorb and release metal ions, affecting trace analysis.

The hard, brittle nature makes interfacing with other materials difficult in high-pressure flow systems.

Bulleted Summary:

Borosilicate glass suits moderate temperature and routine analysis.

Researchers must weigh machinability against purity and optical needs.

Borosilicate Glass Specifications per ISO 3585 Standards

ISO 3585 outlines the key specifications for borosilicate glass, guiding its use in analytical settings. Laboratories rely on these standards to ensure consistent performance and compatibility with equipment. The specifications define thermal expansion, annealing point, softening point, and density.

Specification | Value |

|---|---|

Coefficient of Thermal Expansion (20-300°C) x10-6 K-1 | 3.3 |

Annealing Point (°C) | 565 |

Softening Point (°C) | 820 |

Density at 25°C (g/cm3) | 2.23 |

These values confirm borosilicate glass’s suitability for moderate heat and mechanical stability.

Key Points:

ISO 3585 ensures reliable performance for standard laboratory applications.

Borosilicate glass meets essential requirements for many analytical tasks.

Quartz Tubes for Analytical Applications stand out for high-temperature resistance, purity, and optical clarity. The table below highlights key differences:

Property | Quartz Glass | Borosilicate Glass |

|---|---|---|

High-Temperature Resistance | Up to 1500°C | Up to 500°C |

Chemical Purity | High | Moderate |

Optical Clarity | Excellent | Limited |

When choosing between materials, users should consider temperature range, purity needs, and budget. For expert guidance and custom solutions, suppliers like TOQUARTZ offer valuable support.

FAQ

What is the maximum operating temperature for quartz and borosilicate glass tubes?

Material | Max Operating Temp (°C) |

|---|---|

Quartz Tubes | 1100 |

Borosilicate Glass | 500 |

Quartz tubes handle much higher temperatures than borosilicate glass. This difference makes quartz the preferred choice for extreme heat applications.

How does chemical purity affect analytical results?

Quartz tubes contain over 99% pure silica. Borosilicate glass has about 80% silica and more impurities. High purity in quartz reduces contamination risk, supporting accurate trace analysis in sensitive experiments.

Which material offers better UV transmission for optical techniques?

Quartz tubes transmit up to 90% of UV light (200–400 nm).

Borosilicate glass blocks most deep-UV wavelengths.

Quartz supports UV spectroscopy and photonics, while borosilicate suits less demanding optical tasks.

Are quartz tubes more expensive than borosilicate glass tubes?

Material | Relative Cost |

|---|---|

Quartz Tubes | Higher |

Borosilicate Glass | Lower |

Quartz tubes cost more due to purity and performance. Borosilicate glass offers savings for routine laboratory work.

When should a laboratory choose borosilicate glass instead of quartz?

Laboratories select borosilicate glass for moderate temperatures, routine analysis, and budget constraints. Quartz is recommended for high-temperature, high-purity, or advanced optical applications.