Engineers and technical buyers face new challenges in 2025 when selecting quartz tubes for advanced applications.

Quartz tubes are essential for high-temperature, high-purity, and optical-critical processes in modern industry. Their unique properties enable reliable performance in semiconductor, laboratory, furnace, and optoelectronic systems.

This guide provides a 2025-updated, engineer-focused analysis of quartz tube uses, performance parameters, material comparisons, and specification frameworks for professional decision-making.

What Defines Quartz Tubes and Their Critical Properties?

Quartz tubes are cylindrical components made from fused silica or high-purity quartz glass. They are designed to withstand extreme temperatures, aggressive chemicals, and demanding optical requirements.

Their core properties include high thermal stability up to 1200°C, chemical inertness, and broad-spectrum optical transmission. These features make quartz tubes superior to many alternative materials in critical environments.

Engineers value quartz tubes for their low thermal expansion, minimal contamination risk, and ability to maintain dimensional precision under stress. These attributes are vital for process reliability and product quality.

1200°C High-Temperature Stability Mechanisms

Quartz tubes maintain structural integrity at temperatures up to 1200°C. Their low thermal expansion coefficient (0.5 × 10⁻⁶/K) prevents cracking during rapid heating and cooling. This stability is crucial for processes involving frequent thermal cycling.

The glass network structure of fused quartz resists deformation and softening at high temperatures. This allows for continuous operation in furnaces and reactors without loss of shape or function. Engineers should always verify the maximum continuous operating temperature for their specific application.

High-temperature stability reduces maintenance costs and downtime. It also enables precise thermal control, which is essential for semiconductor and laboratory processes.

Chemical Inertness and Contamination Control Principles

Quartz tubes are highly resistant to most acids, bases, and solvents, except hydrofluoric acid. This chemical inertness prevents unwanted reactions and contamination of sensitive products.

Ultra-high purity (≥99.995% SiO₂) ensures that quartz tubes do not leach metal ions or other impurities. This is especially important in semiconductor, pharmaceutical, and analytical applications.

Contamination control is further supported by smooth surfaces and tight dimensional tolerances. Regular cleaning and inspection help maintain purity and process integrity.

UV-IR Spectral Transmission Characteristics

Quartz tubes transmit more than 90% of ultraviolet and visible light, and maintain high transmission into the infrared range. This property is critical for optical, photonic, and analytical systems.

The absence of autofluorescence and low absorption make quartz tubes ideal for spectrometry, UV curing1, and laser delivery. Engineers can specify tubes with custom wall thickness and surface finish to optimize optical performance.

Consistent spectral transmission supports accurate measurements and efficient energy transfer. This is a key advantage over opaque or colored materials.

Industrial Applications: Where Quartz Tubes Enable Critical Processes

Quartz tubes are indispensable in a wide range of industrial settings. Their performance enables reliable operation in environments where other materials would fail.

Key sectors include semiconductor manufacturing, high-temperature furnaces, chemical reactors, and more.

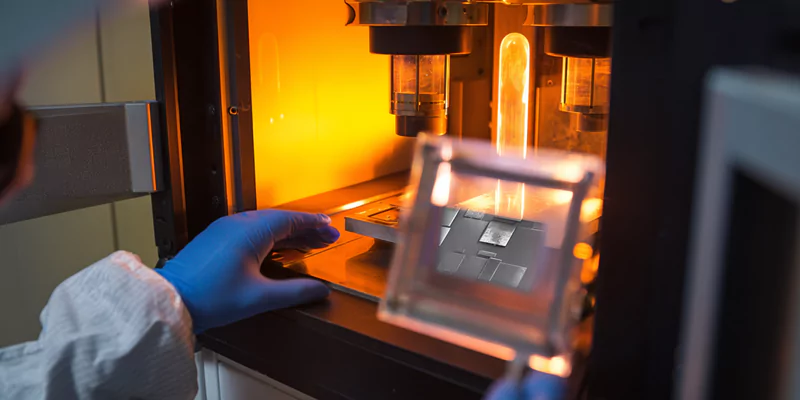

Semiconductor CVD and Etching Reaction Chambers

In semiconductor fabrication, quartz tubes are used in CVD2 reactors and etching chambers. Their purity prevents contamination of silicon wafers and thin films.

Thermal shock resistance allows for rapid temperature cycling during deposition and cleaning steps. The tubes’ transparency enables visual monitoring of processes.

Engineers rely on quartz tubes to maintain process consistency and maximize device yield. Regular inspection and replacement are recommended for optimal performance.

High-Temperature Furnace Thermal Field Protection Systems

Quartz tubes serve as protective liners and sample holders in high-temperature furnaces. They withstand repeated heating and cooling without cracking or deforming.

Their low thermal expansion ensures uniform heat distribution and minimizes stress on furnace components. This is essential for annealing, sintering, and calcination processes.

Using quartz tubes extends furnace life and reduces maintenance costs. Proper installation and handling are important to avoid accidental damage.

Chemical Reactor Corrosion-Resistant Linings

Quartz tubes are used as corrosion-resistant linings in chemical reactors. They protect against aggressive acids, bases, and solvents.

The inertness of quartz prevents unwanted side reactions and product contamination. Tubes can be custom fabricated to fit complex reactor geometries.

Routine cleaning and inspection help maintain chemical resistance. Engineers should select tubes with appropriate wall thickness for their process conditions.

Laboratory and Research: Precision Requirements Driving Quartz Tube Applications

Laboratory and research environments demand the highest levels of purity, precision, and reliability from quartz tubes.

Applications include optical analysis, sample storage, and thermal measurement.

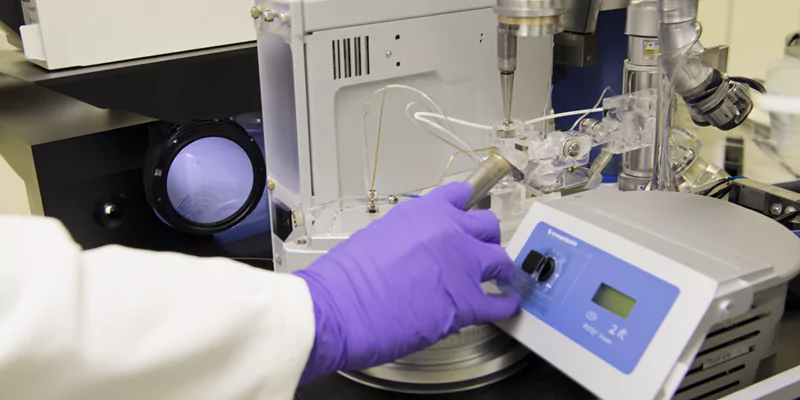

Spectrometer Optical Cavity Components

Quartz tubes are used as optical cavities3 in spectrometers and analytical instruments. Their high UV and visible transmission ensures accurate light measurements.

The material’s low autofluorescence and chemical stability prevent interference with sensitive analyses. Tubes can be manufactured to tight tolerances for precise alignment.

Regular cleaning and calibration are essential for maintaining measurement accuracy. Engineers should specify surface finish and purity based on instrument requirements.

High-Purity Sample Storage Containers

Quartz tubes provide contamination-free storage for high-purity samples. They are resistant to acids, bases, and solvents, making them suitable for a wide range of chemicals.

The smooth, non-porous surface prevents adsorption of trace elements. Tubes can be sealed or capped for secure storage.

Proper labeling and documentation support traceability in regulated environments. Always verify compatibility with stored substances.

Thermal Analysis Instrument Temperature Measurement Tubes

Quartz tubes are used as temperature measurement sleeves in thermal analysis instruments. Their stability at high temperatures ensures accurate readings.

The tubes protect sensors from direct exposure to process gases or aggressive chemicals. Dimensional precision supports consistent sensor placement.

Engineers should select tubes with appropriate length, diameter, and wall thickness for their instruments. Regular inspection prevents measurement drift.

Optoelectronic Systems: Transmitting Light from UV to IR Using Fused Silica Tube Uses

Optoelectronic systems rely on quartz tubes for efficient light transmission and protection of sensitive components.

Applications span UV sterilization, optical fiber production, and infrared heating.

Excimer Lamp UV Sterilization Systems

Quartz tubes are used as protective sleeves in excimer lamp4 UV sterilization systems. Their high UV transmission enables effective disinfection.

The tubes resist degradation from prolonged UV exposure and repeated cleaning cycles. Their chemical inertness prevents leaching of contaminants.

Engineers should specify tubes with precise wall thickness and surface finish for optimal lamp performance. Regular inspection ensures continued effectiveness.

Optical Fiber Preform Fusion Processing

In optical fiber manufacturing, quartz tubes are used to contain and process preforms during fusion and drawing. Their purity and transparency are critical for minimizing signal loss.

The tubes withstand high temperatures and maintain dimensional stability throughout the process. This supports consistent fiber diameter and optical properties.

Custom fabrication allows for integration with automated production lines. Engineers should verify compatibility with process gases and coatings.

Infrared Heater Protection Tube Applications

Quartz tubes serve as protective covers for infrared heaters in industrial and laboratory settings. Their high IR transmission ensures efficient heat delivery.

The tubes shield heating elements from contamination and mechanical damage. Their thermal stability supports long service life.

Engineers should select tubes with appropriate length, diameter, and mounting features. Proper installation and periodic cleaning maintain heater efficiency.

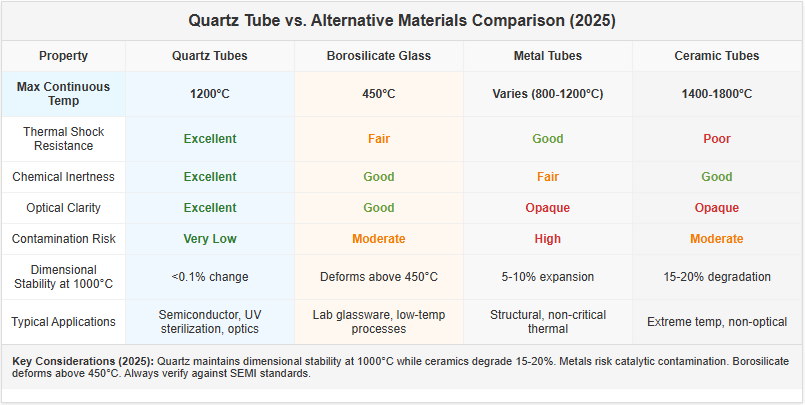

Material Selection Framework: Quartz vs. Alternative Materials for Specific Uses

Selecting the right material for high-temperature and high-purity applications requires careful comparison of quartz tubes with alternatives like borosilicate glass, metals, and ceramics.

A systematic framework helps engineers make informed decisions based on performance, risk, and cost.

Borosilicate Glass Temperature Limitations Analysis

Borosilicate glass5 tubes are limited to continuous use below 450°C. Above this temperature, they begin to soften and deform.

Their higher thermal expansion coefficient increases the risk of cracking during rapid heating and cooling. Chemical resistance is good, but not as high as quartz.

Engineers should avoid borosilicate glass in processes requiring high purity, high temperature, or rapid cycling. Quartz tubes are the preferred choice for these scenarios.

Metal Tube Catalytic Contamination Risk Assessment

Metal tubes, such as stainless steel or nickel alloys, can catalyze unwanted reactions in sensitive processes. They may also leach trace metals into products.

While metals offer high mechanical strength, they lack the chemical inertness and optical clarity of quartz. Corrosion and oxidation can further compromise performance.

For applications where contamination control is critical, quartz tubes provide a safer and more reliable solution. Always assess the risk of catalytic effects before selecting metal tubes.

Ceramic Tube Thermal Shock Failure Case Studies

Ceramic tubes, including alumina and zirconia, can withstand very high temperatures. However, they are more brittle and prone to thermal shock failure.

Case studies show that ceramics may crack or shatter when exposed to rapid temperature changes6. Their opacity also limits use in optical or photonic systems.

Quartz tubes combine high temperature resistance with superior thermal shock performance and optical transparency. This makes them a better fit for many advanced applications.

Many engineers assume standard high-temperature materials can substitute for quartz tubes in demanding applications, but this misconception leads to costly process failures. Current 2025 industry data shows quartz tubes maintain dimensional stability within 0.1% at 1000°C while ceramic alternatives can experience 15-20% degradation in purity and borosilicate glass begins deformation above 450°C. Always verify material performance against your specific process requirements and current SEMI standards to prevent contamination and equipment damage.

Technical Validation: Key Specifications for Engineers Using Quartz Glass Tube Uses

Technical validation ensures that selected quartz tubes meet all operational and regulatory requirements in 2025.

Engineers should verify thermal, chemical, and dimensional parameters against current industry standards.

Thermal Expansion Coefficients and Thermal Shock Ratings

Quartz tubes have a thermal expansion coefficient of about 0.5 × 10⁻⁶/K. This low value minimizes stress during heating and cooling cycles.

Thermal shock resistance is typically rated for ΔT values above 200°C, with some tubes exceeding 1000°C. These properties are critical for processes involving rapid temperature changes.

Always confirm ratings with the supplier and request test data for your specific application. Proper validation prevents unexpected failures.

ASTM E438 Chemical Compatibility Testing Standards

ASTM E438 provides standardized methods for testing the chemical compatibility of quartz tubes. This ensures that tubes will not degrade or leach contaminants during use.

Testing covers exposure to acids, bases, solvents, and process gases. Results help engineers select the right tube for their chemical environment.

Request recent test reports and verify compliance with ASTM and ISO standards. This supports process reliability and regulatory compliance.

SEMI F20 Wafer Manufacturing Certification Standards

SEMI F20 is the industry standard for quartz components used in wafer manufacturing. It specifies purity, dimensional tolerances, and surface finish requirements.

Compliance with SEMI F20 ensures that quartz tubes will not introduce contaminants or defects into semiconductor processes. Certification is often required by major fabs.

Engineers should request SEMI F20 certificates and audit supplier quality systems. This guarantees consistent performance and supports traceability.

Conclusion

Quartz tubes remain the gold standard for high-temperature, high-purity, and optical-critical applications in 2025. Informed selection and rigorous validation ensure safe, efficient, and reliable operation.

Choosing the right quartz tube for your 2025 application is a strategic engineering decision. Leverage TOQUARTZ’s direct factory supply, engineering support, and rapid delivery to achieve process excellence—contact us for expert consultation and custom solutions.

FAQ (Frequently Asked Questions)

What is the maximum continuous operating temperature for quartz tubes in 2025?

Most high-purity quartz tubes can operate continuously at 1,050–1,200°C, with short-term exposure up to 1,600°C.

How do I verify quartz tube quality and compliance with 2025 standards?

Request batch-specific test reports, including thermal, chemical, and dimensional data. Check for ASTM and SEMI certifications.

What factors should I consider for custom quartz tube orders in 2025?

Specify all dimensions, purity, and performance requirements. Confirm feasibility, lead time, and documentation with your supplier.

How do quartz tubes compare to borosilicate and ceramic tubes for advanced applications?

Quartz tubes offer higher purity, better thermal shock resistance, and superior optical clarity, making them preferable for demanding processes.

References:

-

Discover how UV curing technology works and why it's essential for fast, efficient industrial processes involving adhesives, coatings, and inks. ↩

-

Learn how Chemical Vapor Deposition (CVD) works and why it's crucial for producing high-quality semiconductor devices and thin films. ↩

-

Understanding optical cavities can enhance your knowledge of spectrometers and their applications in analytical instruments. ↩

-

Explore this link to understand the technology behind excimer lamp UV sterilization systems and their applications in disinfection. ↩

-

Explore this link to understand the unique properties and applications of Borosilicate glass tubes in various industries. ↩

-

Learn the science behind thermal shock in ceramics and discover how temperature changes can impact their durability and performance. ↩