- Startseite

- /

- Typen

- /

- Quarzflasche

- /

- Präzisions-Labor Doppelhals Rund...

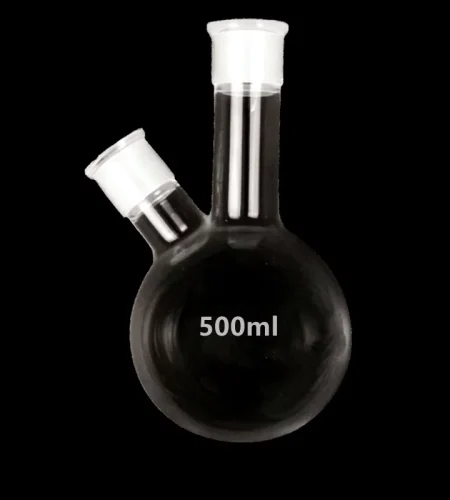

Präzisions-Labor-Doppelhals-Rundboden-Quarzglasflaschen für die chemische Synthese -TOQUARTZ®

Merkmale von Quarzkolben mit rundem Boden und doppeltem Hals

Materielle Exzellenz

-

Hohe Reinheit:

99,99% SiO₂-Gehalt, ideal für empfindliche chemische Reaktionen und Materialsynthese -

Hervorragende chemische Beständigkeit:

Widersteht Säuren, Basen, Salzlösungen und fluorierten Gasen ohne Beeinträchtigung -

Elektrische Isolierung:

Ausgezeichnete dielektrische Eigenschaften, geeignet für Hochspannungsanwendungen

Thermische Eigenschaften

-

Stabilität bei hohen Temperaturen:

Betriebstemperatur bis zu 1200°C -

Widerstandsfähigkeit gegen thermische Schocks:

Widersteht schnellen Temperaturschwankungen ohne Rissbildung -

Geringe thermische Ausdehnung:

Koeffizient von 5,5×10-⁷/°C, der die Formstabilität gewährleistet

Design Präzision

-

Standard-Schliffverbindungen:

24/29 Glasschliffe gewährleisten die Kompatibilität mit gängigen Laborgeräten -

Optimierung des Halswinkels:

Konzipiert für die effiziente Befestigung von Kondensatoren, Thermometern und Gaseinlässen

- Material: 99,99% SiO

- Temperaturbeständigkeit: Bis zu 1200°C

- Standardfugengröße: 24/29 Glasschliffe

Technische Daten und Abmessungen des Quarzglaskolbens

Technische Daten der Quarzglasflasche mit doppeltem Hals und rundem Boden

Physikalische Eigenschaften

| Eigentum | Wert |

| Dichte | 2,2 g/cm³ |

| Härte (Mohs) | 5.5-6.5 |

| Maximale Betriebstemperatur | 1200°C |

| Wärmeleitfähigkeit | 1,4 W/m-K |

| Wärmeausdehnungskoeffizient | 5.5×10-7/℃ |

Chemische Eigenschaften

| Eigentum | Wert |

| SiO-Gehalt | ≥99.99% |

| Säurebeständigkeit | Ausgezeichnet (außer HF) |

| Alkalibeständigkeit | Gut bis zu 1000°C |

| Chemische Trägheit | Inert gegenüber den meisten Chemikalien und Reagenzien |

| Verunreinigungen von Spurenelementen | <10 ppm insgesamt |

Abmessungen von Quarzglasflaschen mit rundem Boden und Doppelhals

| Modell | Fassungsvermögen (ml) | Fugengröße | Abmessungen (mm) | SiO2-Gehalt(%) |

| AT-SY-SP1012 | 100 | 24/29 | 64*105 | 99.99 |

| AT-SY-SP1013 | 250 | 24/29 | 85*140 | 99.99 |

| AT-SY-SP1014 | 500 | 24/29 | 105*163 | 99.99 |

| AT-SY-SP1015 | 1000 | 24/29 | 131*200 | 99.99 |

| AT-SY-SP1016 | 2000 | 24/29 | 131*200 | 99.99 |

TOQUARTZ® löst Laborherausforderungen mit Doppelhals-Quarzkolben

Doppelhals-Quarzkolben für chemische Hochtemperatursynthesen

Die wichtigsten Vorteile

-

Thermische Stabilität bis zu 1200°C

TOQUARTZ®-Quarzkolben behalten ihre strukturelle Integrität bei Temperaturen, bei denen herkömmliche Glaswaren erweichen oder sich verformen, und ermöglichen so Reaktionen, die eine extreme Erhitzung erfordern. -

Hervorragende Erhaltung der chemischen Reinheit

Die 99,99% SiO₂-Zusammensetzung verhindert die Kontamination empfindlicher Reaktionen und gewährleistet die Zuverlässigkeit und Reproduzierbarkeit der Ergebnisse.

TOQUARTZ®-Lösung

Ein Materialforschungsteam an einer deutschen Universität berichtete, dass bei der Synthese von Metalloxidkatalysatoren bei 900 °C mit herkömmlichen Glasgeräten immer wieder Fehler auftraten, wobei die Gefäße innerhalb von 20 Minuten nach Erreichen der Temperatur versagten.

TOQUARTZ® Doppelhals-Quarzkolben boten eine zuverlässige Lösung, die den gesamten 4-stündigen Reaktionszyklus ohne Degradation oder Verunreinigung überstand und so eine erfolgreiche Katalysatorentwicklung für ihr Projekt im Bereich der erneuerbaren Energien ermöglichte.

Doppelhalsige Quarzglaskolben für präzise Destillationsverfahren

Die wichtigsten Vorteile

-

Verbesserte Wärmeleitfähigkeit

Die gleichmäßigen thermischen Eigenschaften von Quarzglas sorgen für eine gleichmäßige Wärmeverteilung und verhindern heiße Stellen, die empfindliche Verbindungen beschädigen können. -

Präzise Zwei-Hals-Konfiguration

Die optimierten Halswinkel und Normschliffe ermöglichen eine sichere Befestigung von Thermometern und Kondensatoren mit minimalem Totraum.

TOQUARTZ®-Lösung

Ein japanischer Hersteller von Spezialchemikalien hatte bei der Destillation hitzeempfindlicher pharmazeutischer Zwischenprodukte mit Unstimmigkeiten bei der Produktreinheit zu kämpfen.

Nach der Umstellung auf TOQUARTZ-Doppelhals-Destillationskolben aus Quarzglas meldeten sie eine Verringerung der Produktkontamination um 94% und eine Verbesserung der Ausbeute um 15% aufgrund der besseren Temperaturkontrolle und der Beseitigung von Verunreinigungen aus Glas, was zu Einsparungen von etwa $15.000 pro Produktionscharge führte.

Doppelhals-Quarzglasflaschen für Reaktionen unter kontrollierter Atmosphäre

Die wichtigsten Vorteile

-

Vakuum- und Druckstabilität

TOQUARTZ®-Quarzkolben bleiben auch unter Vakuumbedingungen und mäßigem Überdruck intakt und ermöglichen Experimente in kontrollierter Atmosphäre. -

Präzisionsgeschliffene Glasfugen

Die Schliffverbindungen 24/29 bieten gasdichte Dichtungen, wenn sie mit geeigneten Fetten oder O-Ringen verwendet werden, und verhindern so eine Verunreinigung der Atmosphäre.

TOQUARTZ®-Lösung

Ein Forschungsteam eines US-Labors, das an sauerstoffempfindlichen metallorganischen Gerüsten arbeitet, berichtete über wiederholte Versuchsausfälle aufgrund von Luftverlusten bei erhöhten Temperaturen unter Verwendung von Standardglasgeräten.

Nach dem Einsatz von TOQUARTZ-Doppelhals-Quarzkolben in der Schlenk-Linie wurden während des gesamten 850°C-Syntheseprozesses konstante Sauerstoffwerte von unter 0,5 ppm erreicht, was die erfolgreiche Entwicklung neuartiger Wasserstoffspeichermaterialien mit 30% höherer Kapazität als zuvor ermöglichte.

TOQUARTZ® Quarzglas-Kolben Anpassungsdienste

Dimensionale Anpassung

- Kundenspezifische Kolbenkapazitäten (250ml bis 5000ml)

- Spezialisierte Nackenwinkel (0-90°)

- Individuelle Halslängen und -durchmesser

- Optimierung der Wandstärke (1,5-4mm)

- Kundenspezifische Schliffgrößen (10/19 bis 45/50)

Funktionale Erweiterungen

- Integration von Probenahmestellen

- Kundenspezifische Seitenarme oder Förderrohre

- Spezialisierte interne Leitbleche

- Abgestufte Volumenmarkierungen

Prozess-Unterstützung

- Unterstützung beim technischen Zeichnen

- Entwicklung von Prototypen

- Prüfung und Validierung von Proben

- Materielle Zertifikate

- Pakete mit technischer Dokumentation

Anpassungsprozess

Anforderungsanalyse

- TOQUARTZ®-Ingenieure bewerten Ihre Anwendungsanforderungen für Doppelhals-Quarzkolben mit rundem Boden, einschließlich der Größe der Mündung, des Halswinkels und der thermischen Anforderungen.

Entwurf & Genehmigung

- Wir stellen Ihnen technische Zeichnungen des kundenspezifischen Quarz-Rundkolbens zur Verfügung, um sicherzustellen, dass alle Spezifikationen mit Ihrer Laboreinrichtung übereinstimmen.

Entwicklung von Prototypen

- Auf der Grundlage der genehmigten Zeichnungen wird ein Muster-Doppelhalskolben aus Quarzglas hergestellt, so dass Sie Passform, Funktion und Materialkompatibilität überprüfen können.

Produktion & Lieferung

- Nach der Bestätigung beginnen wir mit der Serienproduktion Ihrer kundenspezifischen Quarzglasflaschen mit strenger Qualitätskontrolle und weltweiter Versandunterstützung.

Verwendungsrichtlinien für Quarzglasflaschen mit rundem Boden und doppeltem Hals

Die richtige Handhabung, Reinigung und Wartung von Quarzglas-Doppelhalskolben ist für die Maximierung ihrer Leistung und Lebensdauer unerlässlich. Befolgen Sie diese Richtlinien, um optimale Ergebnisse zu erzielen und die Integrität Ihrer Quarzglasgeräte zu erhalten.

Handhabung und Einrichtung

-

Sichere Unterstützung:

Verwenden Sie für Rundkolben immer geeignete Klammern und Stützen, damit das Gewicht gleichmäßig verteilt wird. -

Vorsichtsmaßnahmen beim Erhitzen:

Erhöhen Sie die Temperatur schrittweise (maximal 100 °C/Minute), um einen Temperaturschock zu vermeiden. Verwenden Sie für eine gleichmäßige Erwärmung eher Heizhauben als eine direkte Flamme. -

Integrität der Verbindung:

Stellen Sie sicher, dass die Schliffverbindungen mit einem geeigneten Fett für Hochtemperaturanwendungen oder mit PTFE-Manschetten für chemische Kompatibilität ordnungsgemäß abgedichtet sind. -

Vorsichtsmaßnahmen bei der Kühlung:

Lassen Sie den Kolben auf natürliche Weise auf unter 200°C abkühlen, bevor Sie ihn weiter bearbeiten oder abkühlen. Vermeiden Sie schnelle Temperaturschwankungen, die thermischen Stress verursachen könnten.

Reinigungsverfahren

-

Erste Spülung:

Mit einem geeigneten, mit den Reaktionsrückständen verträglichen Lösungsmittel spülen, solange der Kolben noch warm ist (aber unter 100 °C). -

Reinigungslösungen:

Für die meisten Rückstände verwenden Sie je nach Art der Verschmutzung Königswasser, Piranha-Lösung oder Chromsäure. Für die Standardreinigung ist eine Laborreinigungslösung, gefolgt von deionisiertem Wasser, ausreichend. -

Vermeiden Sie Scheuermittel:

Verwenden Sie keine Scheuermittel oder Bürsten, die die Quarzoberfläche zerkratzen könnten. Weichen Sie hartnäckige Rückstände in einem geeigneten Lösungsmittel ein, anstatt zu schrubben. -

Letzte Spülung:

Gründlich mit entionisiertem Wasser abspülen und anschließend mit Aceton oder Methanol trocknen.

Trocknung und Lagerung

-

Lufttrocknung:

An der Luft in einer staubfreien Umgebung oder in einem sauberen Trockenschrank bei 110-120°C trocknen lassen. -

Vakuumtrocknung:

Bei kritischen Anwendungen an die Vakuumleitung anschließen und leicht erwärmen (60-80°C), um jegliche Feuchtigkeit zu entfernen. -

Speicherumgebung:

In sauberen, staubfreien Schränken lagern, die nicht durch Stöße beschädigt werden können. Weiche Polsterung zwischen den Gefäßen verwenden. -

Schutz der Gelenke:

Decken Sie Schliffverbindungen mit geeigneten Kappen oder Aluminiumfolie ab, um Staubansammlungen und mögliche Schäden zu vermeiden.

Sicherheitsvorkehrungen

-

Druckbegrenzungen:

Nicht für Hochdruckanwendungen verwenden. Die empfohlene maximale Druckdifferenz beträgt 1 Atmosphäre. -

Inspektion vor Gebrauch:

Prüfen Sie vor dem Erhitzen oder Anlegen eines Vakuums immer auf Risse, Abplatzungen oder Spannungsspuren. -

Temperaturgradienten:

Vermeiden Sie extreme Temperaturunterschiede an der Kolbenwand, die zu thermischer Belastung und Versagen führen können. -

Anforderungen an die PSA:

Tragen Sie bei der Handhabung immer eine geeignete persönliche Schutzausrüstung, einschließlich hitzebeständiger Handschuhe, wenn Sie mit erhitzten Flaschen arbeiten.

Benötigen Sie technische Unterstützung für Ihr Projekt eines Doppelhalsquarzkolbens?

und anwendungsspezifische Empfehlungen für Ihre Laboranforderungen.

Warum eine Partnerschaft mit TOQUARTZ

Vorteil der direkten Fabrik

Als direkter Hersteller können wir die zahlreichen Zwischenstufen ausschalten.

Technische Kompetenz

Das technische Team begleitet die Kunden von der Materialauswahl bis zur Designoptimierung und setzt die Spezifikationen in Ergebnisse um.

Flexible Fertigung

Bearbeitung von Standard- und kundenspezifischen Aufträgen mit Hilfe von Kleinserien und Prototyping, um dringende Fristen einzuhalten.

Qualität

Versicherung

3-Stufen-Validierung vor dem Versand:

1. Maßhaltigkeit,

2. Materialreinheit ,

3. Leistungsschwellen

Globale Lieferkette

Zuverlässige globale Logistik zu den industriellen Zentren (Priorität DE/US/JP/KR) mit nachvollziehbaren Meilensteinen.

Wiederverwertete Produkte

Als spezialisierter Hersteller mit direkten Fertigungsmöglichkeiten bietet TOQUARTZ sowohl Standard- als auch kundenspezifische Quarzlösungen mit technischer Unterstützung während des gesamten Spezifikations- und Implementierungsprozesses.

FAQ

F: Wofür wird ein Doppelhalskolben mit rundem Boden verwendet?

A: Quarzkolben mit rundem Boden und doppeltem Hals werden in erster Linie für chemische Reaktionen bei hohen Temperaturen, Destillationsprozesse und Synthese unter kontrollierter Atmosphäre verwendet. Der zweite Hals ermöglicht die Einführung von Reagenzien, Inertgas oder Überwachungsgeräten (wie Thermometern), während der Haupthals an Kondensatoren oder andere Geräte angeschlossen wird.

F: Was ist die Höchsttemperatur für Quarzglasflaschen?

A: TOQUARTZ® Doppelhalskolben aus Quarzglas können Temperaturen von bis zu 1200°C standhalten, was deutlich höher ist als bei Borosilikatglas (das normalerweise bei 820°C erweicht). Bei längerem Gebrauch empfehlen wir jedoch, unter 1100°C zu arbeiten, um die strukturelle Integrität zu erhalten und die Lebensdauer des Kolbens zu verlängern.

F: Wie reinigt man einen Doppelhalsquarzkolben?

A: Für die Routinereinigung mit geeigneten Lösungsmitteln abspülen, solange sie noch warm sind (aber unter 100 °C). Für eine gründliche Reinigung verwenden Sie Laborreinigungslösungen, gefolgt von deionisiertem Wasser. Bei hartnäckigen Rückständen können je nach Art der Verschmutzung Königswasser, Piranha-Lösung oder Chromsäure verwendet werden. Vermeiden Sie stets Scheuermittel oder Bürsten, die die Quarzoberfläche zerkratzen könnten, und spülen Sie abschließend gründlich mit entionisiertem Wasser nach.

F: Wie trocknet man einen Doppelhals-Rundkolben?

A: Für die Standardtrocknung nach der Reinigung mit Aceton oder Methanol abspülen und an der Luft in einer staubfreien Umgebung trocknen lassen. Für analytische Anwendungen, die vollständige Trockenheit erfordern, verwenden Sie einen sauberen Laborofen bei 110-120°C. Bei kritischen Anwendungen schließen Sie die Proben an eine Vakuumleitung an und erhitzen sie vorsichtig (60-80°C), um die gesamte Feuchtigkeit zu entfernen. Für erfahrene Anwender kann auch die Flammentrocknung unter Vakuum verwendet werden.

F: Welche Sicherheitsvorkehrungen sind bei Doppelhalskolben mit rundem Boden zu treffen?

A: Zu den wichtigsten Sicherheitsvorkehrungen gehören: Kolben immer ordnungsgemäß mit Klammern befestigen; schnelle Temperaturschwankungen vermeiden, die zu thermischen Spannungen führen können; vor jedem Gebrauch auf Risse untersuchen; geeignete Heizgeräte wie Heizhauben und keine direkte Flamme verwenden; beim Erhitzen des Inhalts nie vollständig verschließen; und geeignete PSA tragen, einschließlich Schutzbrille und hitzebeständige Handschuhe.

Wenden Sie sich für technische Beratung und Preisgestaltung an unser Ingenieurteam. Wir helfen Ihnen bei der Auswahl der optimalen Spezifikationen für Ihre Anwendungsanforderungen.