Кварцевые нагревательные трубки преобразуют промышленное отопление благодаря быстрому инфракрасному излучению и высокой энергоэффективности.

Эти трубки преобразуют до 90% электрической энергии непосредственно в полезное инфракрасное тепло, достигая полной мощности всего за три секунды. Их уникальные свойства делают их идеальными для применения в сложных условиях, где важны скорость, точность и эффективность.

В данном руководстве рассматриваются принципы работы, основные области применения, эксплуатационные преимущества, технические характеристики и факторы принятия решения при выборе кварцевых нагревательных трубок в 2025 году.

Что такое кварцевые тепловые трубки и как они генерируют инфракрасное тепло?

Кварцевые нагревательные трубки - это электрические нагревательные элементы, заключенные в высокочистое кварцевое стекло. При подаче напряжения внутренняя нить накаливания испускает инфракрасное излучение, которое проходит через кварцевую оболочку с минимальными потерями.

Кварцевый материал прозрачен для инфракрасных волн, что обеспечивает эффективную передачу тепла к мишени. Такое прямое преобразование сводит к минимуму потери энергии и обеспечивает быстрый рост температуры.

Инфракрасное тепло, генерируемое кварцевыми трубками, быстро поглощается большинством материалов, что делает эти обогреватели высокоэффективными для промышленных, лабораторных и коммерческих процессов.

Основные промышленные применения кварцевых нагревательных трубок

Кварцевые нагревательные трубки используются в самых разных отраслях промышленности, где требуется точный, эффективный и быстрый нагрев.

Универсальность и производительность делают их предпочтительным выбором для пищевой промышленности, производства пластмасс, покрытий, электроники и многого другого.

Оборудование для пищевой промышленности и коммерческих кухонь

Кварцевые нагревательные трубки обеспечивают мгновенный равномерный нагрев для приготовления гриля, выпечки и тостов на коммерческих кухнях. Их быстрое реагирование сокращает время ожидания и повышает энергоэффективность.

На предприятиях пищевой промышленности кварцевые нагреватели используются для сушки, стерилизации и упаковки. Чистое, бесконтактное тепло сводит к минимуму риск загрязнения.

Операторы получают преимущества благодаря точному контролю температуры и простой интеграции в конвейерные системы. Благодаря прочной конструкции и длительному сроку службы техническое обслуживание не требует особых усилий.

Обработка пластмасс и термоформование

В производстве пластмасс, кварцевые трубки обеспечивают контролируемое инфракрасное тепло для термоформовки, сварки и гибки. Их быстрый отклик обеспечивает высокую скорость производства и стабильные результаты.

Возможность нацеливания на определенные длины волн улучшает поглощение энергии пластиковыми материалами. Это сокращает время цикла и снижает потребление энергии.

Инженеры могут регулировать плотность мощности и конфигурацию трубок в соответствии с требованиями каждого процесса. Кварцевые нагреватели совместимы с автоматизированными линиями и индивидуальной оснасткой.

Отверждение краски и нанесение покрытий

Кварцевые нагревательные трубки широко используются для отверждения красок, клеев и покрытий. Их способность мгновенно включаться ускоряет процесс сушки и отверждения, увеличивая производительность.

Равномерная инфракрасная мощность обеспечивает равномерное отверждение сложных поверхностей. Это снижает количество дефектов и повышает качество продукции.

Производители ценят экономию энергии и меньшую занимаемую площадь по сравнению с конвекционными печами. Кварцевые трубки можно устанавливать в массивы для крупномасштабных операций.

Производство полупроводников и электроники

Полупроводниковые заводы используют кварцевые нагревательные трубки в диффузионных печах, CVD-реакторах и станциях сушки пластин. Высокая чистота и быстрый нагрев предотвращают загрязнение и позволяют точно контролировать процесс.

На линиях сборки электроники используются кварцевые нагреватели для пайка припоя1, отверждение клея и предварительный нагрев компонентов. Быстрый отклик трубок обеспечивает высокоскоростное и крупносерийное производство.

Регулярное обслуживание и проверка качества обеспечивают стабильную работу и долгий срок службы. Кварцевые трубки необходимы для соблюдения строгих стандартов современного производства электроники.

Эксплуатационные преимущества и сравнительные достоинства кварцевых нагревательных трубок

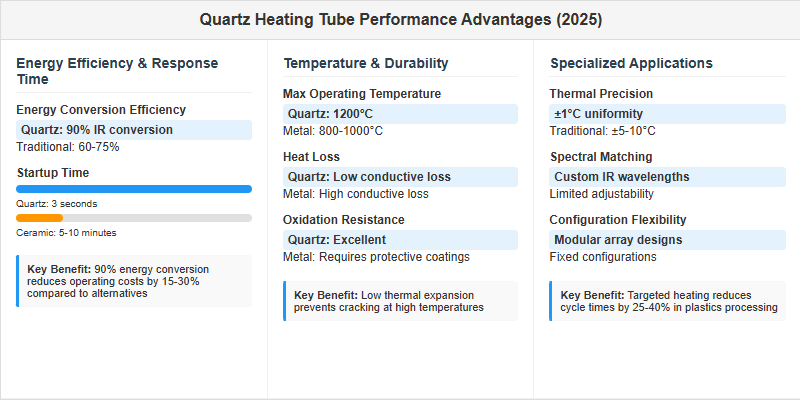

Кварцевые нагревательные трубки обеспечивают уникальное сочетание энергоэффективности, быстрого отклика и точного теплового контроля.

Они превосходят традиционные нагревательные элементы как по скорости работы, так и по общей стоимости владения.

Энергоэффективность и быстрое время реагирования

Кварцевые нагревательные трубки преобразуют до 90% входной энергии непосредственно в инфракрасное тепло. Такая высокая эффективность позволяет снизить затраты на электроэнергию и уменьшить воздействие на окружающую среду.

Функция мгновенного включения позволяет трубкам достигать полной мощности всего за три секунды. В отличие от керамических нагревателей, для достижения рабочей температуры может потребоваться 5-10 минут.

Такая быстрая реакция позволяет точно контролировать процесс и минимизировать время простоя. Инженеры могут оптимизировать производственные графики и сократить количество отходов.

Диапазон рабочих температур и долговечность

Кварцевые трубки надежно работают при температурах до 1 200°C2. Низкое тепловое расширение и высокая чистота конструкции предотвращают растрескивание и деформацию.

По сравнению с металлическими нагревательными элементами, кварцевые трубки имеют меньшую теплопроводность и сохраняют стабильную мощность в течение долгого времени. Они также менее подвержены окислению и коррозии.

Долговечность увеличивается благодаря прочной кварцевой оболочке, которая защищает нить накаливания и продлевает срок службы. Это снижает частоту технического обслуживания и затраты на замену.

Тепловая эффективность в специализированных областях применения

В специализированных областях применения, таких как обработка полупроводников или производство медицинского оборудования, кварцевые трубки обеспечивают направленное равномерное тепло. Их спектральная мощность может быть подобрана в соответствии с характеристиками поглощения конкретных материалов.

Такой селективный нагрев повышает эффективность процесса и качество продукции. Например, при переработке пластмасс правильно подобранная длина волны сокращает время цикла и энергопотребление.

Инженеры могут конфигурировать массивы кварцевых трубок для достижения точных тепловых профилей. Такая гибкость способствует инновациям в передовом производстве.

Технические характеристики, определяющие высокопроизводительные кварцевые нагревательные трубки

Понимание технических характеристик необходимо для выбора правильного кварцевая нагревательная трубка для вашего применения.

Ключевые параметры включают мощность, напряжение, плотность мощности, состав материала и стандарты качества.

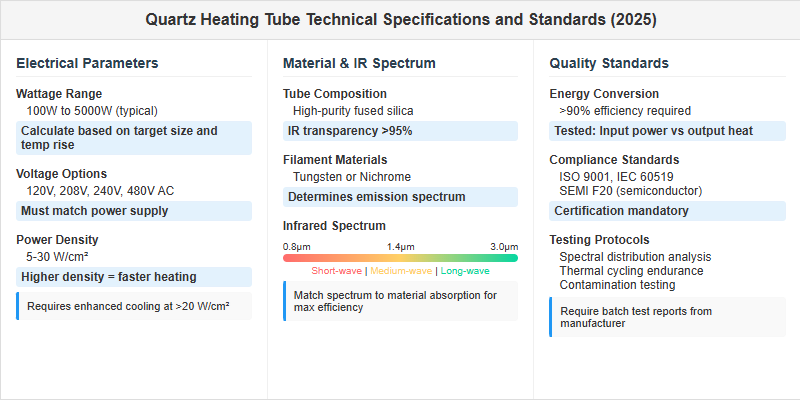

Ключевые параметры: Мощность, напряжение и плотность мощности

Мощность определяет общую теплоотдачу, а напряжение должно соответствовать источнику питания. Плотность мощности (Вт/см²) показывает, сколько тепла подается на единицу площади.

Инженеры должны рассчитать необходимую мощность, исходя из размера мишени и желаемого повышения температуры. Более высокая плотность мощности обеспечивает более быстрый нагрев, но может потребовать усиленного охлаждения или монтажа.

Выбор правильных параметров обеспечивает безопасную работу и оптимальную производительность. Всегда обращайтесь к техническим паспортам производителей и руководствам по применению.

Состав материала и спектр инфракрасного излучения

Кварцевые нагревательные трубки изготавливаются из высокочистый плавленый кварцпрозрачный для инфракрасного излучения. Материал нити накаливания (обычно вольфрам или нихром) определяет спектр излучения.

Коротковолновые кварцевые трубки излучают ИК в диапазоне 0,8-1,4 мкм, подходящем для нагрева поверхности. Средне- и длинноволновые трубки (1,4-3 мкм) проникают глубже в материалы.

Соответствие спектра излучения области применения обеспечивает максимальное поглощение энергии и эффективность процесса. Состав материала также влияет на долговечность и устойчивость к тепловому удару.

Стандарты качества для коэффициентов преобразования энергии

Согласно промышленным стандартам, кварцевые нагревательные трубки должны обеспечивать коэффициент преобразования энергии выше 90%. Тестирование включает в себя измерение входной мощности, выходного тепла и спектрального распределения.

Соответствие стандартам ISO и Стандарты МЭК3 обеспечивает стабильную работу и безопасность. Производители должны предоставить сертификаты и протоколы испытаний партии.

Перед установкой инженеры должны убедиться, что трубы соответствуют или превосходят эти стандарты. Высокие коэффициенты преобразования приводят к снижению эксплуатационных расходов и повышению экологичности.

Рекомендации по выбору правильной конфигурации кварцевой нагревательной трубки

Выбор оптимальной конфигурации кварцевой нагревательной трубки предполагает соблюдение баланса между требованиями к мощности, размерам, монтажу и интеграции.

Систематический подход обеспечивает совместимость с потребностями процесса и максимальную отдачу от инвестиций.

Расчеты плотности мощности и мощности для нужд приложений

Рассчитайте необходимую мощность, исходя из массы и удельной теплоемкости целевого материала. Учитывайте желаемое повышение температуры и время процесса.

Плотность мощности должна соответствовать условиям применения: более высокие значения для быстрого нагрева, более низкие - для мягкого. Для сложных установок используйте калькуляторы, предоставляемые производителем, или обратитесь в службу технической поддержки.

Пример из практики: Для промышленной сушильной линии может потребоваться 30 кВт общей мощности, распределенной по нескольким трубкам для равномерного покрытия. Правильный расчет позволяет избежать недостаточного или избыточного нагрева.

Размеры, монтаж и интеграция

Выберите длину и диаметр трубки в соответствии с имеющимся пространством и обеспечьте равномерное распределение тепла. Крепежная фурнитура должна учитывать тепловое расширение и обеспечивать легкую замену.

Интеграция с системами управления технологическими процессами обеспечивает точное регулирование температуры и защитные блокировки. Учитывайте воздушный поток, экранирование и доступ для обслуживания.

Правильные размеры и монтаж сокращают время установки и сводят к минимуму эксплуатационные проблемы. Инженеры должны изучить требования к интеграции на ранней стадии проектирования.

Факторы принятия решения при выборе кварцевых тепловых труб вместо альтернативных вариантов

Инженеры должны взвесить преимущества кварцевых нагревательных трубок по сравнению с другими технологиями, такими как керамические, металлические или галогенные нагреватели.

Ключевые факторы, влияющие на принятие решения, включают время отклика, энергоэффективность, стоимость и совместимость с технологическими процессами.

Сценарии, в которых кварц превосходит всех: Быстрый нагрев и точное управление

Кварцевые нагревательные трубки идеально подходят для процессов, требующих мгновенного нагрева и точного контроля температуры. Их быстрый отклик сводит к минимуму время разогрева и потери энергии.

В тех случаях, когда необходимо избежать загрязнения, химическая инертность кварца является основным преимуществом. Трубки также отлично подходят для работы в условиях частой цикличности или переменных нагрузок.

Пример: В производстве электроники кварцевые трубки обеспечивают быструю пайку припоя и отверждение клея, повышая производительность и качество продукции.

Анализ затрат и выгод: Экономия энергии и повышение производительности

Хотя кварцевые нагревательные трубки могут иметь более высокую начальную стоимость, чем некоторые альтернативы, их превосходная эффективность и долговечность снижают общую стоимость владения.

Экономия энергии за счет коэффициентов преобразования 90%+ позволяет значительно снизить счета за коммунальные услуги. Сокращение объема технического обслуживания и увеличение срока службы еще больше повышают рентабельность инвестиций.

Повышение производительности за счет ускорения технологических циклов и уменьшения количества отказов оправдывает вложения. Инженеры должны учитывать в своем анализе как прямые, так и косвенные выгоды.

Заключение

Кварцевые нагревательные трубки обеспечивают непревзойденную эффективность, скорость и надежность для современных промышленных и лабораторных нужд в области нагрева.

Выбор подходящей кварцевой нагревательной трубки - это стратегическое инженерное решение. Воспользуйтесь прямыми заводскими поставками TOQUARTZ, инженерной поддержкой и быстрой доставкой, чтобы максимизировать производительность вашего процесса - свяжитесь с нами для получения экспертной консультации и индивидуальных решений.

FAQ (часто задаваемые вопросы)

Какова типичная эффективность преобразования энергии в кварцевых нагревательных трубках?

Большинство высококачественных кварцевых нагревательных трубок обеспечивают преобразование энергии более 90%, что позволяет минимизировать отходы и снизить эксплуатационные расходы.

Как определить правильную мощность и размер для моего применения?

Рассчитайте необходимую мощность и плотность мощности, исходя из целевого материала, температуры процесса и площади нагрева. Обратитесь к руководству производителя для определения размера.

Каковы основные преимущества кварцевых нагревательных трубок перед керамическими или металлическими нагревателями?

Кварцевые трубки обеспечивают более быстрый отклик, более высокую эффективность, лучшую химическую стойкость и более точный контроль температуры, чем большинство альтернативных вариантов.

Подходят ли кварцевые нагревательные трубки для непрерывного промышленного использования?

Да, при правильном выборе и установке кварцевые нагревательные трубки обеспечивают надежную и долговременную работу в сложных промышленных условиях.

Ссылки:

-

Узнайте о процессах пайки припоя, чтобы улучшить свои знания в области сборки электроники и технологий производства.↩

-

Откройте для себя научную основу высокотемпературной надежности кварцевых трубок и узнайте, почему их предпочитают использовать в сложных промышленных и лабораторных условиях.↩

-

Узнайте, как стандарты IEC влияют на безопасность и производительность продукции и почему производителям необходимо соблюдать их для выхода на мировой рынок.↩