Products

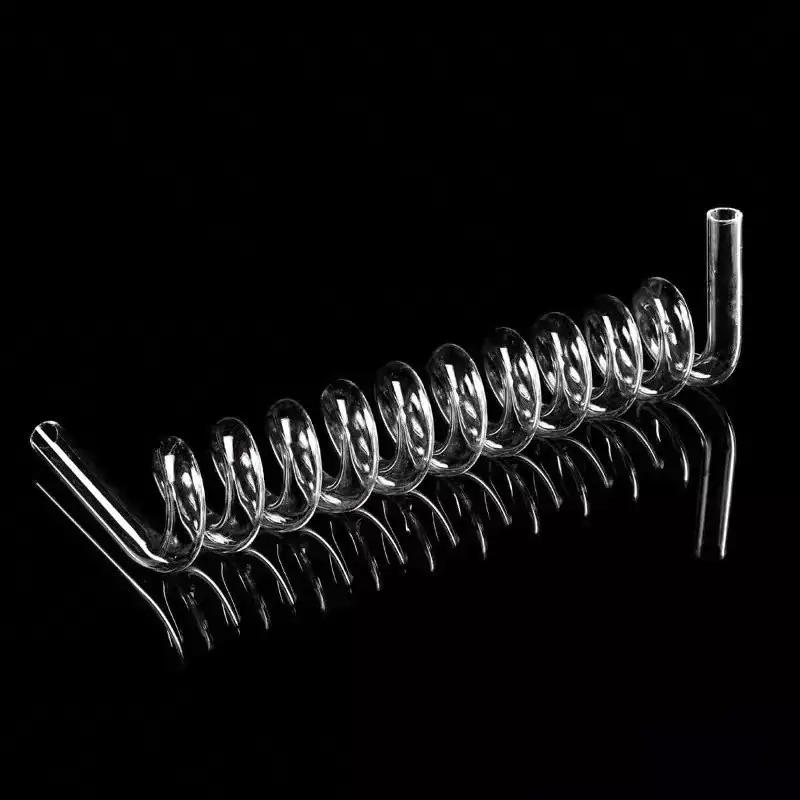

Industrial-Grade Quartz Spiral Tubes for Chemical Processing & Lab Instrumentation

Quartz spiral tubes deliver 1,450℃ thermal durability and HF-acid immunity, engineered for extreme-temperature reactor systems and ±0.1° spiral angular accuracy requirements.

Quartz Helical Tube Performance Advantages

Precision-engineered quartz spiral tubes deliver critical performance enhancements through these material properties:

- Continuous operation at 1100°C with 1450°C peak capacity

- Stable reactivity with 98% sulfuric acid at 300°C

- Negligible metal ion leaching (<0.5ppm @ 24hr/150°C)

- Oxidation resistance maintained in 10⁻⁶ Torr vacuum environments

Fused Quartz Helical Tube Functional Applications

Engineered quartz spiral tubes configurations enable precision performance across multiple industrial engineering sectors:

Process Reactor Temperature Control

- 1,200°C-rated thermal jackets for acid vapor condensation systems

- 102% H3PO4 compatibility in continuous chemical cycling operations

Fluid Monitoring Instrumentation

- ±0.025% FS accuracy in 300-bar pressure sensing modules

- Non-invasive liquid level detection via refractive index matching (Δn <0.0015)

Laboratory Measurement Systems

- Protective sheathing for 800°C molten salt electrochemical cells

- UV-Vis spectroscopy validation units with >92% transmittance @ 190nm

Fused Silica Tube Technical Specifications

Fused Silica tubing ensures ±0.1mm dimensional accuracy and 99.9% purity compliance, with fully customizable optical and thermal parameters—submit your project specs for precision-engineered solutions.

| Property | Value Range |

| Chemical Composition | Cr: 0.1%, Ge: 0.4%, Fe: 1.5%, Mg: 0.4%, Ti: 0.1%, Al: 0.8%, Na: 2.3%, Li: 0.5% |

| Spectral Transmission | >93% transmittance (350-780nm), 93.4% peak at 780nm, UV cutoff <220nm |

| Thermal Properties | Softening point: 1615–1683°C, thermal expansion: 5.5–6.7×10⁻⁷/cm·°C |

| Mechanical Strength | Compressive: >1.1×10⁹ Pa, Young’s modulus: 7.0–7.5×10¹⁰ Pa |

| Optical Performance | Refractive index: 1.456–1.460, dielectric constant: 3.75–6.0 @1MHz |

Custom Helical Fabrication Options

Custom Helical Quartz Tube Manufacturing Precision

Precision-engineered quartz spiral tubes solutions maintain custom dimensional accuracy through material-specific CNC protocols.

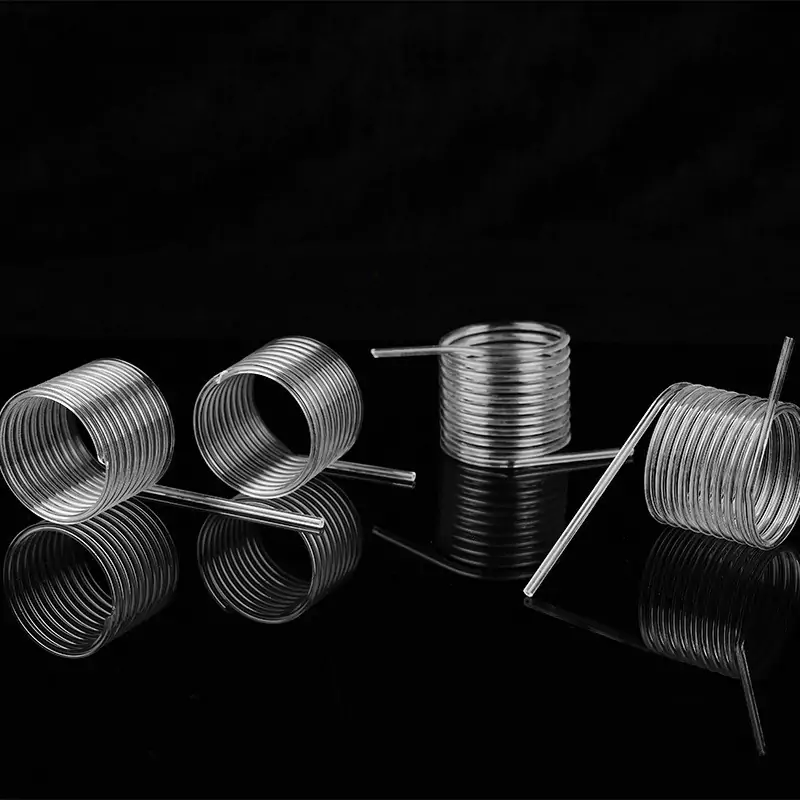

Helical Quartz Material Specification

Precision quartz spiral tubes adapt material characteristics to operational demands with JGS3 grade achieving >85% IR transmittance across 260–3500nm spectra.

JGS3 Optical Grade

- 85% Transmittance @2500nm

- Hydroxyl <5ppm

- 190–2800nm Cutoff

High-Performance Quartz Spiral Tubes: Precision Engineered for Extreme Industrial Applications

Discover how TOQUARTZ’s 1,450°C-rated quartz spiral tubes with 99.99% chemical purity solve critical thermal challenges in chemical processing and laboratory systems engineering.

Releted Products

Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio. Duis vel pulvinar dolor, at lacinia tellus.

FAQ

Vacuum compatibility validation measures?

Maintain 10⁻⁹ Torr·L/s leak rates with helium mass spec-certified sealing.

Optical performance stabilization methods?

UV-grade polishing minimizes light scattering (<0.8% @632nm wavelength).

Mitigating thermal measurement drift?

5.5×10⁻⁷/°C CTE paired with platinum traceability ensures <±0.02%/℃ drift.

What thermal cycling capabilities do helix quartz tubes offer?

Withstand 1,200℃ continuous exposure and 50+ rapid thermal shocks (ΔT>700℃) without devitrification.

Can helical angles accommodate reactor designs?

Achieve ±0.15° angular precision through CNC diamond grinding protocols.